In-situ synthesis of Pt-supported fullerene catalyst

An in-situ synthesis and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the impact of catalyst performance, complex preparation process, and easy introduction of impurities and other problems, to achieve the effects of short preparation time, reduced Pt aggregation, and simple and easy-to-control process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

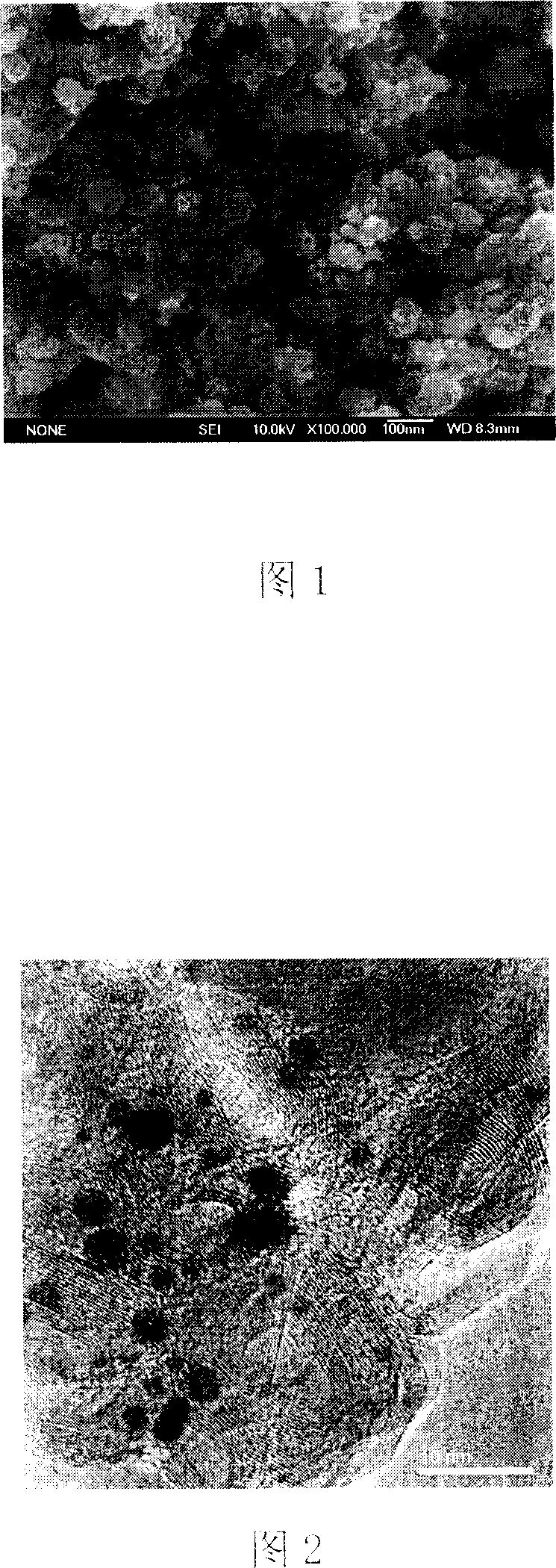

[0017] Dissolve 1 g of chloroplatinic acid in 1 L of deionized water to prepare a chloroplatinic acid solution with a concentration of 0.00193 mol / L, and add it to a heat-resistant container. Spectroscopically pure graphite rods are used as electrodes, in which the diameter of the cathode is 12mm, and the diameter of the anode is 6mm. The two electrodes are arranged along a horizontal line and immersed in a place 40mm below the liquid surface. The current and voltage are controlled at 30A and 28V respectively, and the gap between the two electrodes must be 0.8mm after arcing. The arc discharge evaporates the anode to provide a carbon source for the growth of the fullerene structure, and at the same time the metal cations in the salt solution are reduced to generate Pt metal particles, which are loaded on the surface of the fullerene structure. The discharge was stopped after 10 minutes, and the product at the bottom of the container was collected after the water was cooled, an...

Embodiment approach 2

[0019] Dissolve 1 gram of chloroplatinic acid in 2L of deionized water to prepare a chloroplatinic acid solution with a concentration of 0.000965 mol / L, and add it to a heat-resistant container. Spectroscopically pure graphite rods are used as electrodes, in which the diameter of the cathode is 12mm, and the diameter of the anode is 6mm. The two electrodes are arranged along a horizontal line and immersed in a place 40mm below the liquid surface. The current and voltage are controlled at 30A and 28V respectively, and the gap between the two electrodes must be 1mm after arcing. The arc discharge evaporates the anode to provide a carbon source for the growth of the fullerene structure, and at the same time the metal cations in the salt solution are reduced to generate Pt metal particles, which are loaded on the surface of the fullerene structure. The discharge was stopped after 10 minutes, and the product at the bottom of the container was collected after the water was cooled, a...

Embodiment approach 3

[0021] Dissolve 1 gram of chloroplatinic acid in 0.5 L of deionized water to prepare a chloroplatinic acid solution with a concentration of 0.00386 mol / L, and add it to a heat-resistant container. Spectroscopically pure graphite rods are used as electrodes, in which the diameter of the cathode is 12mm, and the diameter of the anode is 6mm. The two electrodes are arranged along a horizontal line and immersed in a place 40mm below the liquid surface. The current and voltage are controlled at 30A and 28V respectively, and the gap between the two electrodes must be 1mm after arcing. The arc discharge evaporates the anode to provide a carbon source for the growth of the fullerene structure, and at the same time the metal cations in the salt solution are reduced to generate Pt metal particles, which are loaded on the surface of the fullerene structure. The discharge was stopped after 10 minutes, and the product at the bottom of the container was collected after the water was cooled,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com