Metal surface nano-composite processing device with stirring head capable of synchronously feeding powder, and method

A metal surface and processing method technology, applied in the field of in-situ synthesis of nano-composite material surface layer, can solve the problems affecting the promotion and application of FSP composite material preparation technology, affecting the level of process automation, affecting the performance of composite materials, etc., to facilitate in-situ synthesis. , The effect of convenient processing and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

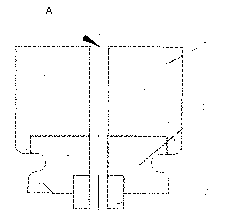

Embodiment 1

[0037] Equipment: The whole set of equipment for friction stir processing is transformed from X6140A vertical milling machine. The milling machine provides a rotating shaft and an automatic lifting table. The table provides axial pressure and drives the workpiece to move laterally. The external IGS-3(x) type precision powder feeder is connected by thread plug-in and fastened to the entrance of powder feed channel A on the side of the clamping part of the mixing head, and the powder feeder is fixed on the side of the rotary bearing platform with iron rings and bolts , The powder feeding rate is 5g / min. The clamping part is 26mm in diameter and 20mm in height; the shaft shoulder is 20mm in diameter and 24mm in height; the probe is 9mm in diameter and 3mm in length, and the outlet hole diameter of the powder feeding channel inside the mixing head is 3mm. . The material used for the mixing head is H13 hot work die steel, which is prepared by machining and heat treatment.

[0038...

Embodiment 2

[0043] Equipment: The whole set of equipment for friction stir processing is transformed from X6140A vertical milling machine. The milling machine provides a rotating shaft and an automatic lifting table. The table provides axial pressure and drives the workpiece to move laterally. The external scraper type powder feeder (model) is connected by screw plug-in and fastened to the inlet of powder feeding channel A on the side of the clamping part of the mixing head, and the powder feeder is fixed on the side of the rotary bearing table with iron rings and bolts, and the powder is fed Rate 10g / min. Integral mixing head with axial powder feeding, in which the diameter of the clamping part is 26mm, the height is 20mm; the diameter of the shaft shoulder is 20mm, the height is 24mm; the diameter of the probe is 9mm, the length is 3mm, and the outlet diameter of the powder feeding channel inside the mixing head is 3mm. The material used for the mixing head is H13 hot work die steel, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com