Biomedical material and preparation method thereof

A technology of biomedical materials and products, used in electrolytic coatings, polyester coatings, anodizing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

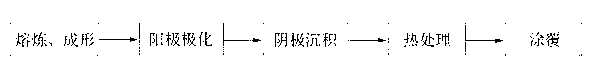

Method used

Image

Examples

Embodiment 1

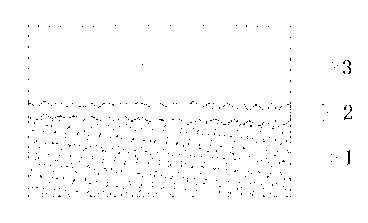

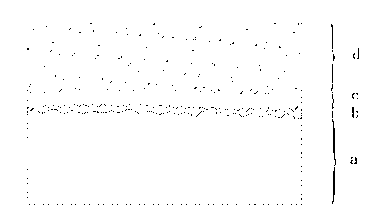

[0058] The sample of AZ91 magnesium alloy in mold casting state was taken as the research object. Using distilled water as solvent, prepare 20.0g / L sodium chloride solution as anodic polarization electrolyte. Connect the equal-area samples of the same material to the wires, then connect them to the two output ports of the sinusoidal AC power supply, and immerse them in the above-mentioned electrolyte with a temperature control of 25°C, keep the distance between the samples at 3cm, and use a constant current of 1.0mA / cm at 50Hz 2 After processing for 30 minutes, it was found that the surface of the sample was evenly distributed with finely crushed pits with the same size and depth visible to the naked eye. The washed and dried anodized sample and the stainless steel cylinder form an electrode pair, the sample is connected to the negative pole of the DC power supply, and the stainless steel cylinder is connected to the positive pole of the DC power supply, respectively immersed ...

Embodiment 2

[0062] The sample of high-purity magnesium as cast metal was taken as the research object. Except that the concentration of sodium chloride was changed to 100.0g / L, the other conditions of anodic polarization were controlled the same as in Example 1. It was found that, except that the area of a single pit increased, the density of pits and their distribution uniformity decreased, the others were the same as in the implementation example 1. Except that the concentration of magnesium chloride was changed to 0.5g / L, other conditions and results of cathodic deposition were the same as in Example 1. Except that the temperature is changed to 350°C and the time is changed to 24h, the control and results of other heat treatment conditions are the same as in Example 1. Using chloroform as a solvent, first prepare four parts of 30.0g / LPLLA solution, then add 10.0g / L magnesium hydroxide and pure magnesium powder (spherical, median particle size d 50 =47 μm), β-TCP and CPP, stirred ev...

Embodiment 3

[0064] The sample of AZ31 magnesium alloy in mold casting state was taken as the research object. Except that the concentration of sodium chloride was changed to 20.0 mg / L, other conditions of anodic polarization were controlled as in Example 1. It was found that the treatment effect was the same as in Example 1 except that the density and depth of pits were reduced. Except that the concentration of magnesium chloride was changed to 150.0g / L, other conditions and results of cathodic deposition were the same as in Example 1. Except that the temperature was changed to 550° C. and the time was changed to 1 h, the control and results of other heat treatment conditions were the same as in Example 1. Using chloroform as solvent, prepare 75.0g / LPLLA solution, marked as solution S 08 ; Take ethanol as dispersant (liquid), add 0.5g / L magnesium hydroxide (solid dispersed phase), stir well to obtain a suspension, marked as solution S 09 . Using dichloromethane as a solvent, first prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com