Method for directly synthesizing titanium dioxide nanoparticles on fabric fiber in situ

A fabric fiber and titanium dioxide technology, applied in plant fiber, chemical instruments and methods, fiber treatment, etc., can solve the problems of low utilization rate of sunlight, easy agglomeration and loss of photocatalysis, and achieve low preparation cost, avoid agglomeration, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the first step, take 120mL of absolute ethanol in a beaker, add 8mL of butyl titanate drop by drop while ultrasonicating, mix and prepare a butyl titanate solution, and then soak 1.6227g of pure cotton fabric into the prepared solution for 24 hours ;

[0025] In the second step, immerse the pure cotton fabric treated in the first step in 20mL of absolute ethanol, add 20mL of deionized water drop by drop while ultrasonicating, and hydrolyze for 0.5h;

[0026] In the third step, the hydrolyzed mixed solution in the second step is placed in a polytetrafluoroethylene autoclave, subjected to hydrothermal treatment at 120° C. for 8 hours, and cooled at room temperature;

[0027] In the fourth step, pour the mixed solution after the hydrothermal treatment in the third step into a beaker, ultrasonicate for 1 minute, and then wash the fabric with deionized water three times to remove the substances that are not firmly bonded to the surface, and dry;

[0028] In the fifth ste...

Embodiment 2

[0031] In the third step, the hydrothermal treatment temperature is 130° C., and the rest of the steps are the same as in Example 1.

Embodiment 3

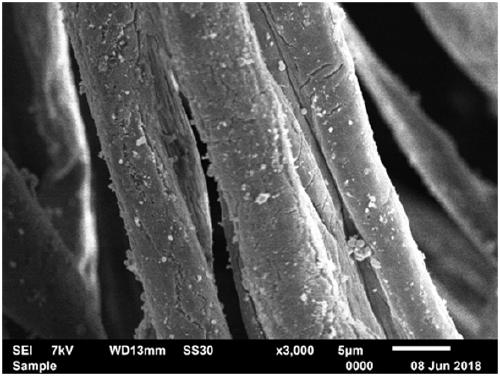

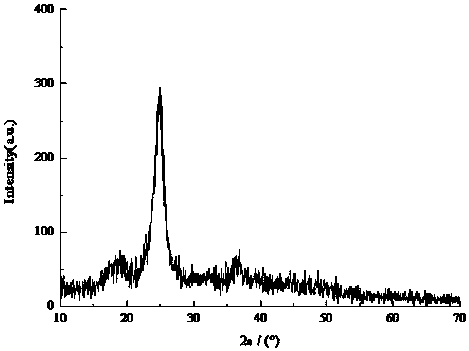

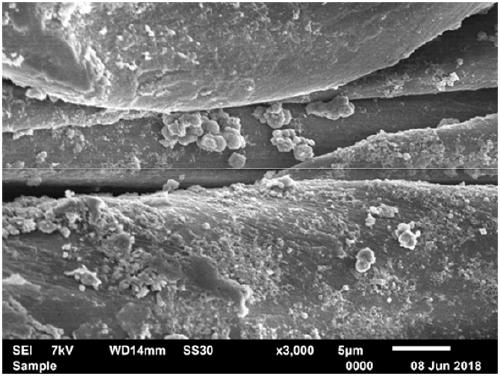

[0033] In the third step, the hydrothermal treatment temperature is 150° C., and the rest of the steps are the same as in Example 1. Its SEM image and XRD pattern are as follows image 3 , Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com