High-isotactic polypropylene alloy and preparation method thereof

A polypropylene, high gauge technology, applied in the field of polypropylene/polyolefin copolymer elastomer alloy materials, can solve the problems of poor low temperature mechanical properties, poor thermal creep resistance, easy aging, etc., and achieve the effect of good hydrogen adjustment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

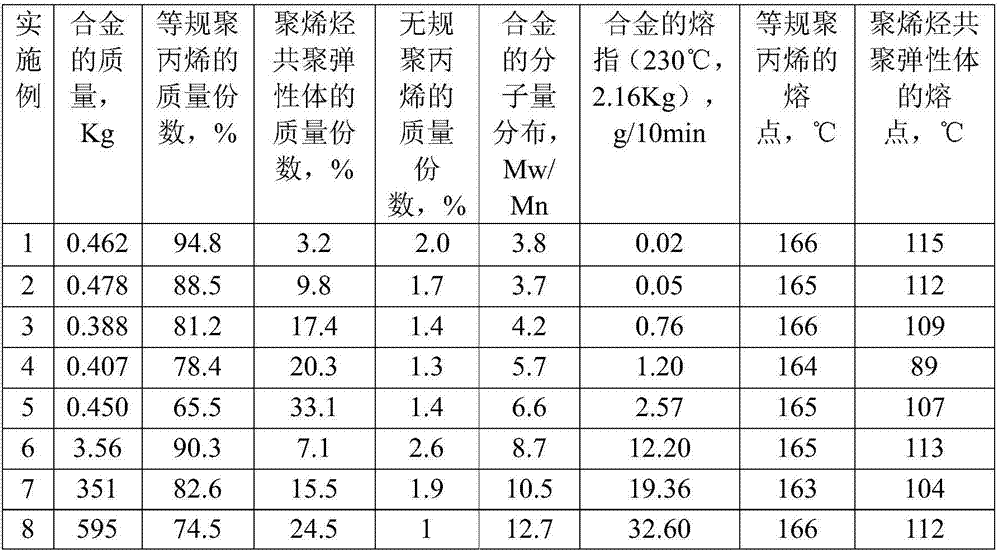

Examples

Embodiment 1

[0046] 1L fully-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced with high-purity nitrogen for several times, then metered and added liquid phase propylene 0.5Kg, triethylaluminum (Al), external electron donor diphenyl diphenyl Methoxysilane (Si) and MgCl 2 Loaded TiCl 4 Catalyst (Ti content 2.5wt%) 0.25g, wherein Al / Ti=60 (molar ratio), Al / Si=6 (molar ratio). Stir and polymerize at 30°C for 5h, then lower the temperature and empty the propylene, add 0.25Kg of butene and 0.05Kg of hexene into the reactor, react at 20°C for 1h, and obtain 462g of powdery polymer directly after the drying is terminated. The properties of the alloy are shown in Table 1.

Embodiment 2

[0048] 1L fully-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced several times with high-purity nitrogen, then metered and added triethylaluminum (Al), external electron donor cyclohexyltrimethoxysilane (Si) and MgCl 2 Loaded TiCl 4 Catalyst (Ti content: 2.5wt%) 0.25g, 0.5Kg of gas-phase propylene is fed continuously, wherein Al / Ti=80 (molar ratio), Al / Si=10 (molar ratio). Stir and polymerize at 30°C for 5h, then lower the temperature and empty the propylene, add 0.25Kg of butene and 0.05Kg of octene into the reactor, react at 30°C for 5h, and obtain 478g of powdery polymer directly after the drying is terminated. The properties of the alloy are shown in Table 1.

Embodiment 3

[0050] 1L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped out and replaced with high-purity nitrogen for several times, then metered 0.4Kg of propylene, triethylaluminum (Al), and external electron donor diphenyl dimethoxy into the reaction kettle Silane (Si) and MgCl 2 Loaded TiCl 4 Catalyst (Ti content 2.5wt%) 0.25g, wherein Al / Ti=120 (molar ratio), Al / Si=10 (molar ratio). Stir and polymerize at 50°C for 1 hour, then lower the temperature and empty the propylene, add 0.25Kg of butene and 0.08Kg of decene into the reactor, react at 40°C for 5 hours, and obtain 388g of powdery polymer directly after drying. The properties of the alloy are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com