Method for preparing Ni@C or Co@C core-shell nanoparticles

A nanoparticle, core-shell technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited commercial production, high reaction temperature, long reaction time, etc., and achieve low cost , Simplify the preparation process, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of NiC core-shell nanoparticles, the steps are as follows:

[0019] 1) Add 1.5 g NiCl 2 ·6H 2 O was added to an aqueous solution of isopropanol consisting of 20 mL of water and 20 mL of isopropanol, and under continuous stirring, 0.6 g of nitrogen triacetic acid (NTA) was added and stirred at room temperature for 1 hour to obtain a mixed solution;

[0020] 2) Transfer the above mixed solution into a reaction kettle, place the reaction kettle in a blast drying oven at 180 °C for 6 hours, then lower it to room temperature, separate the product and wash it with water and ethanol three times in turn, and after vacuum drying, get Precursor Ni-NTA;

[0021] 3) The above precursor Ni-NTA was placed in a tube furnace, heated to 500 °C at a heating rate of 2 °C / min and kept for 2 hours to obtain the black product NiC core-shell nanoparticles.

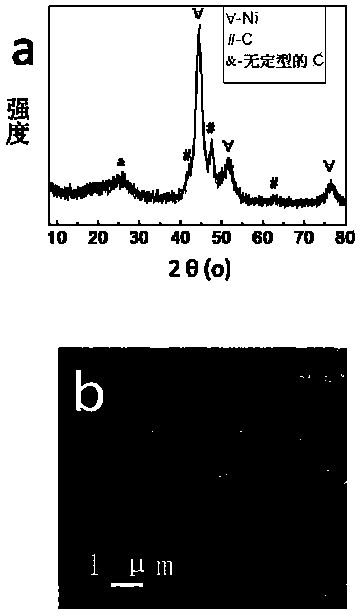

[0022] figure 1 The XRD pattern and SEM pattern of the NiC core-shell nanoparticles prepared in Example 1, in t...

Embodiment 2

[0024] A preparation method of CoC core-shell nanoparticles, the steps are as follows:

[0025] 1) 1.5 g CoCl 2 ·6H 2 O was added to an aqueous solution of isopropanol consisting of 20 mL of water and 20 mL of isopropanol, and under continuous stirring, 0.6 g of nitrogen triacetic acid (NTA) was added and stirred at room temperature for 1 hour to obtain a mixed solution;

[0026] 2) Transfer the above mixed solution into a reaction kettle, place the reaction kettle in a blast drying oven at 180 °C for 6 hours, then lower it to room temperature, separate the product and wash it with water and ethanol three times in turn, and after vacuum drying, get Precursor Co-NTA;

[0027] 3) The above precursor Co-NTA was placed in a tube furnace, heated to 500 °C at a heating rate of 2 °C / min and kept for 2 hours to obtain the black product CoC core-shell nanoparticles.

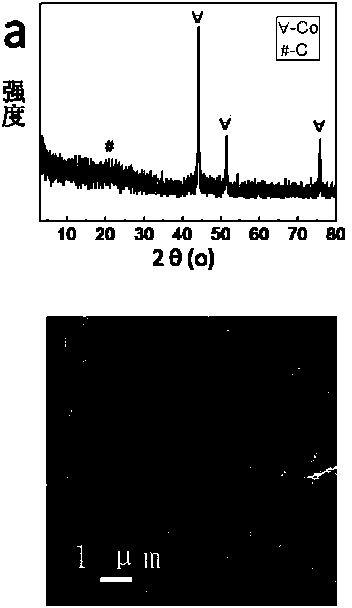

[0028] figure 2 XRD pattern and SEM pattern of the CoC core-shell nanoparticles prepared for Example 2, in the fig...

Embodiment 3

[0030] A preparation method of NiC core-shell nanoparticles, the steps are as follows:

[0031] 1) Add 1.5 g NiCl 2 ·6H 2 O was added to an aqueous solution of isopropanol consisting of 20 mL of water and 20 mL of isopropanol, and under continuous stirring, 0.6 g of nitrogen triacetic acid (NTA) was added and stirred at room temperature for 1 hour to obtain a mixed solution;

[0032] 2) Transfer the above mixed solution into a reaction kettle, place the reaction kettle in a blast drying oven at 180 °C for 6 hours, then lower it to room temperature, separate the product and wash it with water and ethanol three times in turn, and after vacuum drying, get Precursor Ni-NTA;

[0033] 3) The above precursor Ni-NTA was placed in a tube furnace, heated to 600 °C at a heating rate of 2 °C / min and kept for 2 hours to obtain the black product NiC core-shell nanoparticles.

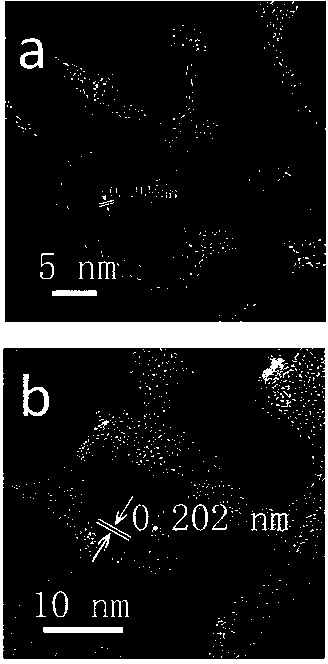

[0034] The XRD pattern, SEM pattern and TEM pattern of the prepared NiC core-shell nanoparticles are similar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com