Microcubic composite material with hierarchical structure, electrode sheet, sodium ion battery and preparation method thereof

A composite material and hierarchical structure technology, which is applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems that it is difficult to realize the mutual unification of sodium storage performance and production processes, and achieve simple packaging technology, long cycle life, and preparation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

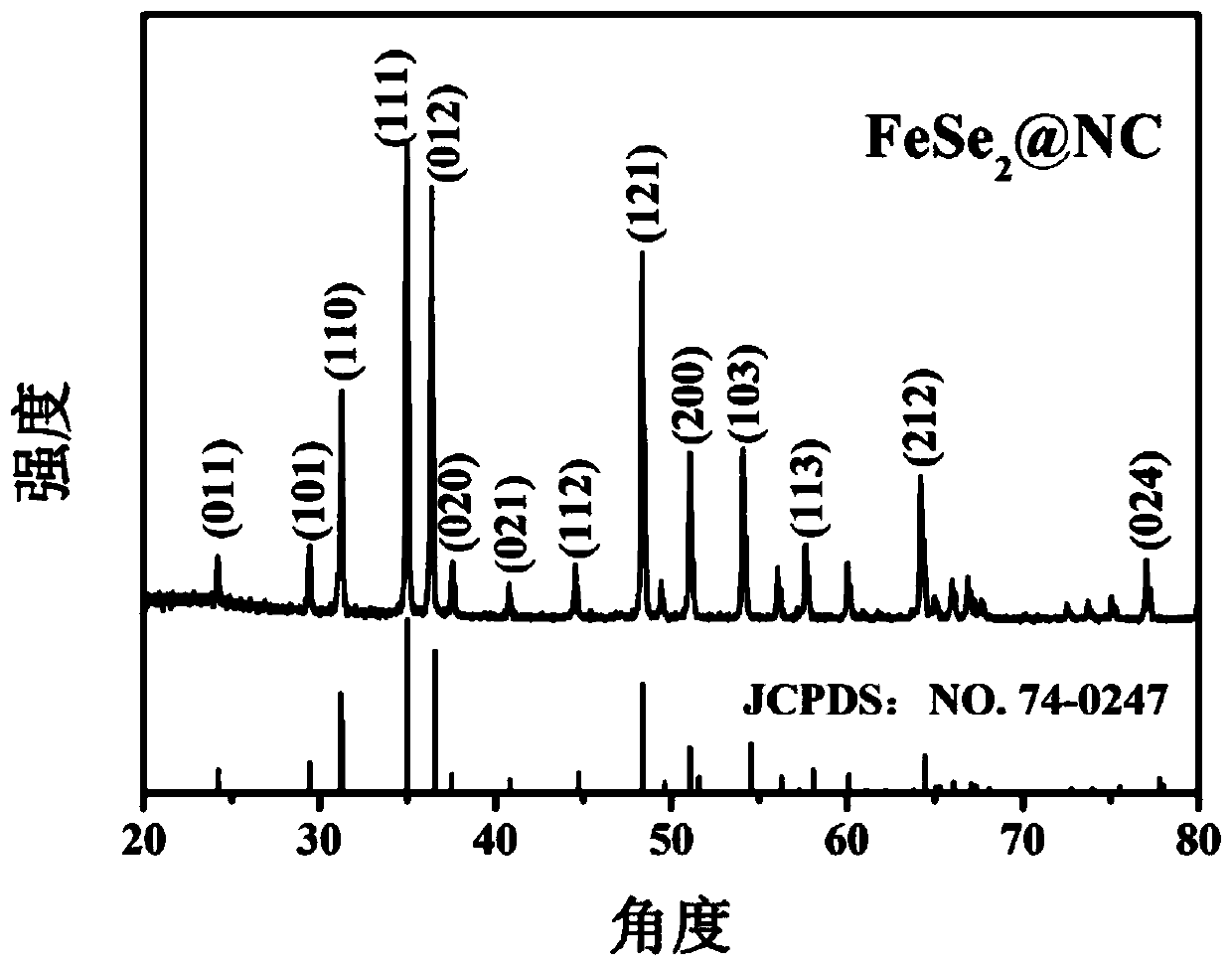

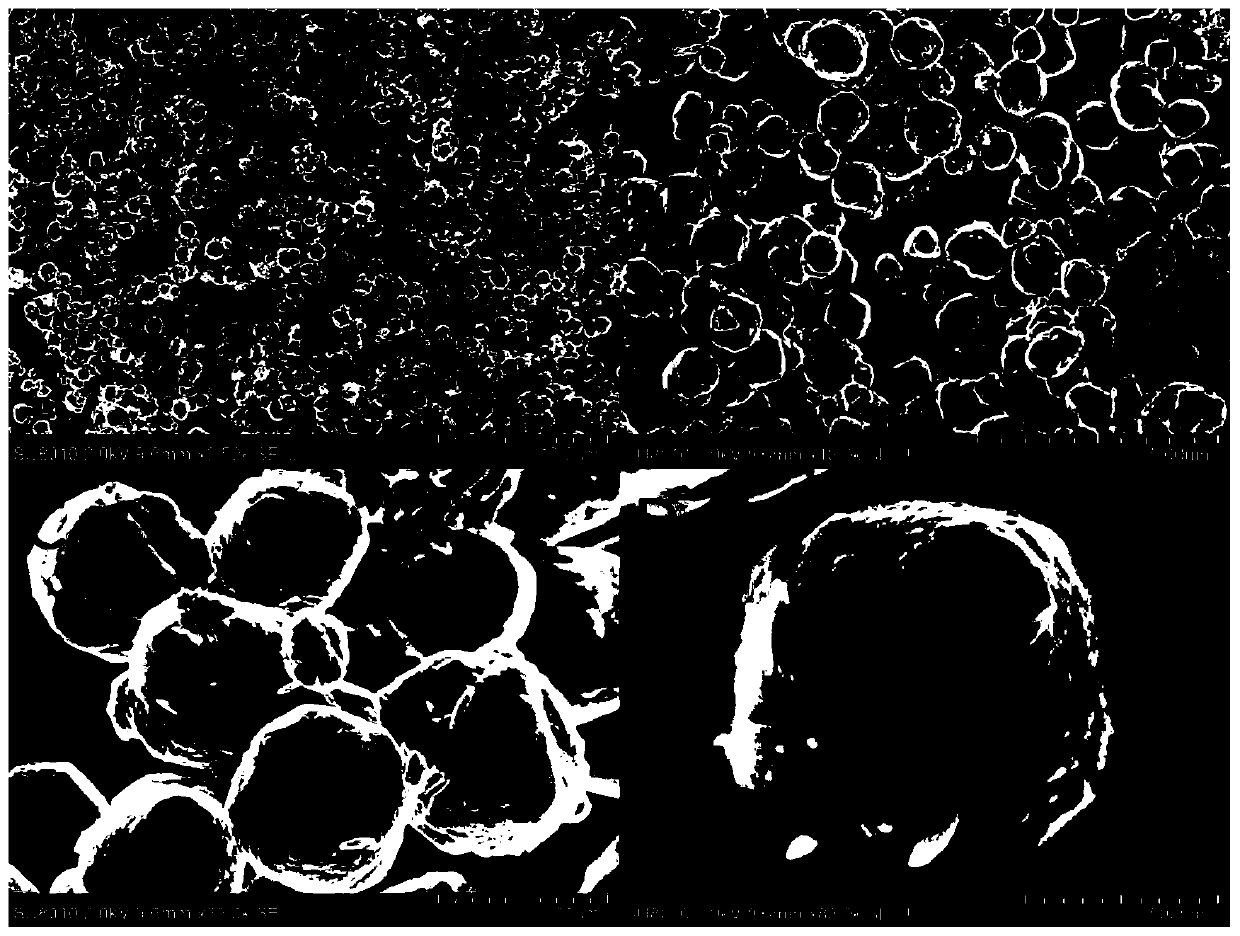

[0029] The preparation method of the precursor involved in the present invention, the preparation method of the final product, and the electrochemical performance displayed by it for the negative electrode of the sodium ion battery will be described in detail below in conjunction with the drawings and specific embodiments of the description, but the embodiment does not explain the present invention. Invention is not limited in any way.

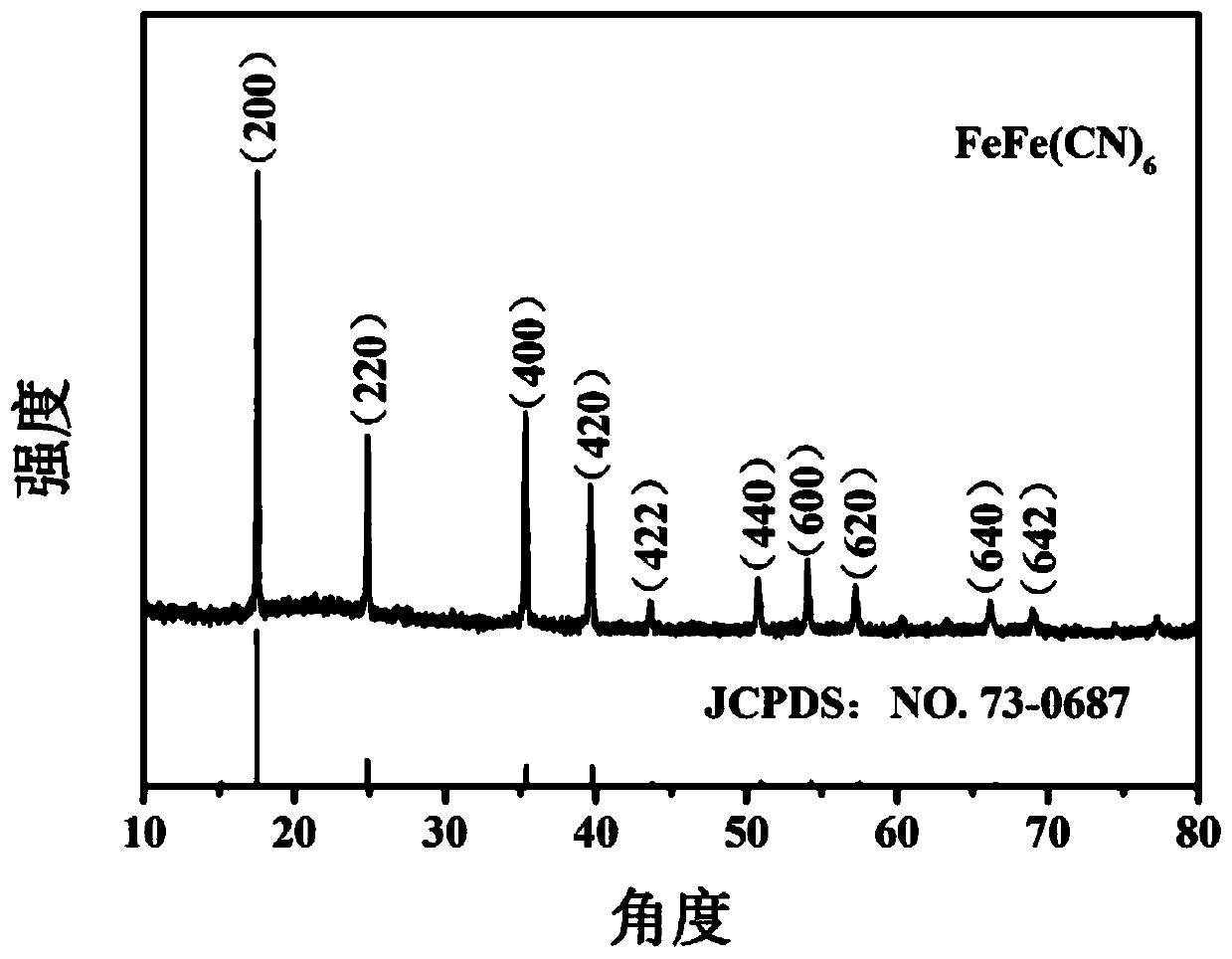

[0030] Precursor material FeFe(CN) 6 Preparation: The present invention prepares the precursor material FeFe(CN) by a heat-assisted wet chemical method 6 , the specific preparation process is as follows, firstly, take K with a mass of 1.65g 3 Fe(CN) 6 Dissolved in deionized water with a volume of 50ml to obtain solution A, FeCl with a mass of 2.70g 3 Dissolved in deionized water with a volume of 100ml to obtain solution B, then solution A was added dropwise to solution B to obtain a mixed solution, the mixed solution was kept at 80°C for 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com