Method for treating gaseous contamination using with ferrate

A technology of ferrate and gas pollution, applied in the field of environment, can solve the problems of unseen research and application examples of ferrate, poor stability of ferrate aqueous solution, and limitation of direct application, etc., to overcome the problem of secondary pollution and easy to promote The effect of less application and drug consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, prepare the NaOH-Na of 0.1mol / L 2 SiO 3 The solution is an electrolyte solution with a constant current of 0.8A. After electrolysis for 70 minutes, the concentration of ferrate is 215mg / L.

Embodiment 2

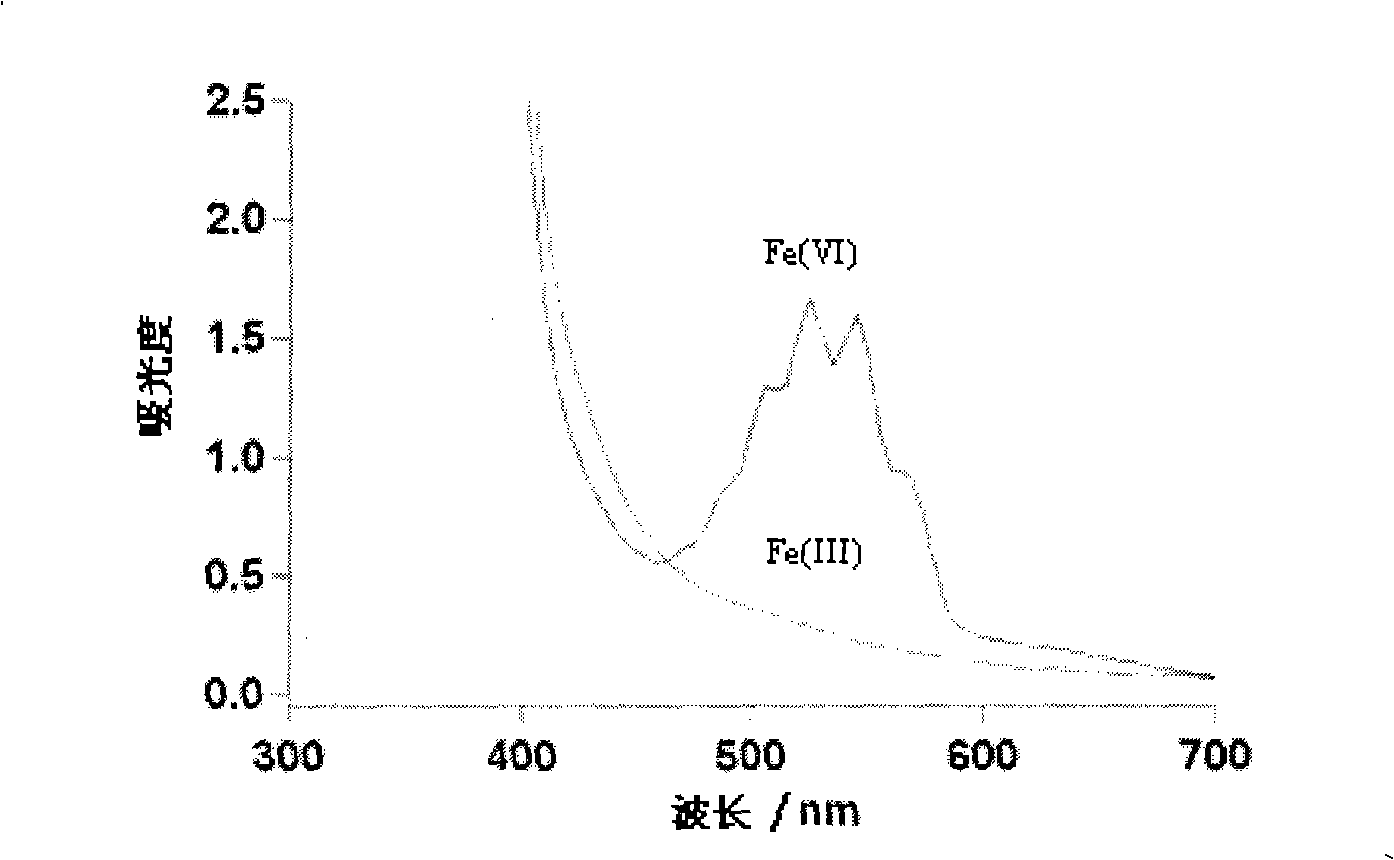

[0027] Embodiment 2, prepare the NaOH-Na of 0.1mol / L 2 SiO 3 The solution is an electrolyte, and a diaphragm-type electrolytic cell and an iron-based anode are used for electrolytic reaction. After 30 minutes of electrolysis at a constant voltage of 8V, the electrolyte is obtained and its scanning spectrum at a wavelength of 400-700nm is measured by a UV-visible spectrophotometer; Glucose was added to the sample and then scanned under the same conditions. Get the scanning spectrum of Fe(VI) and Fe(III), such as figure 1 shown.

Embodiment 3

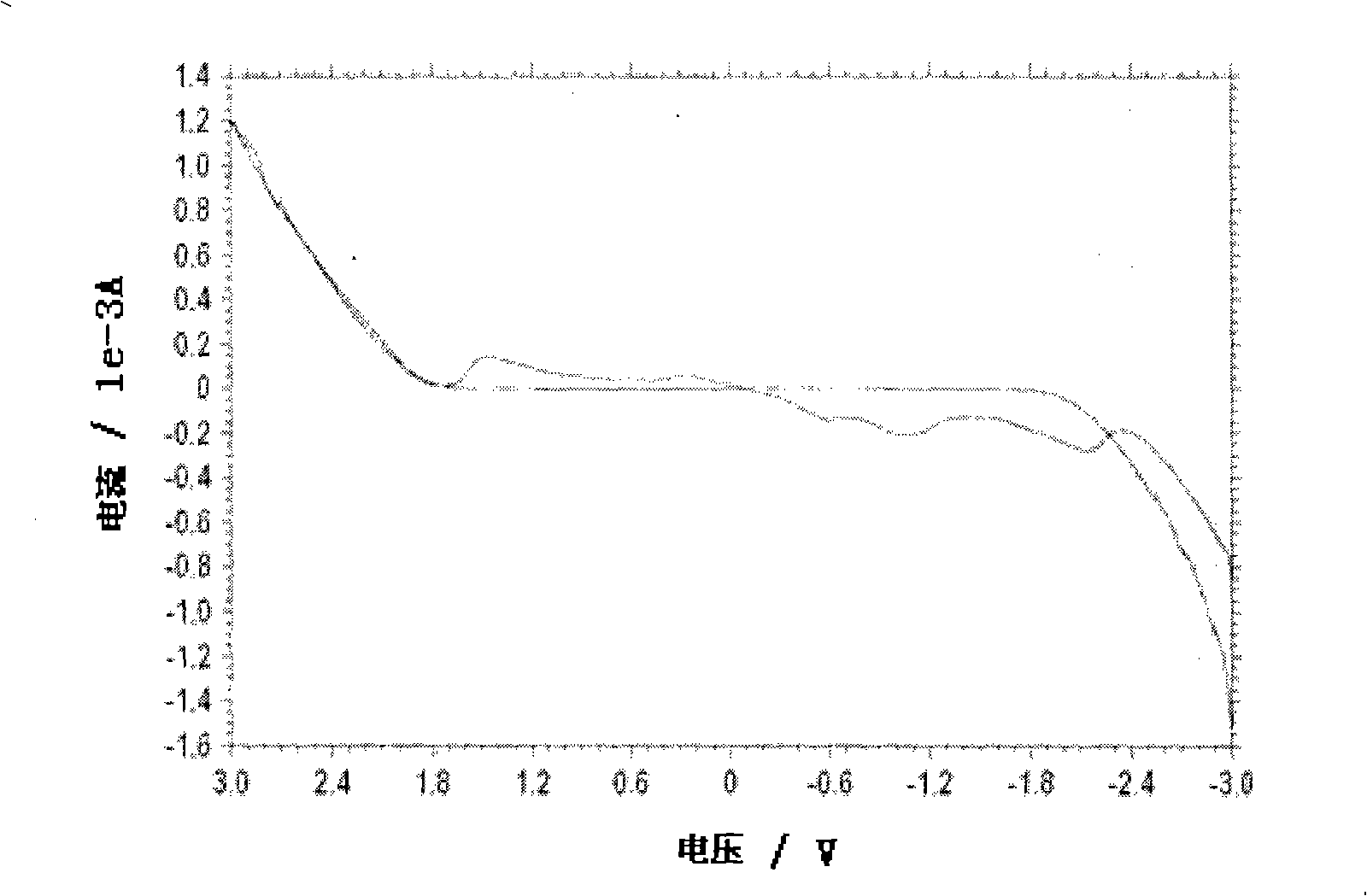

[0028] Embodiment 3, prepare the NaOH-Na of 0.1mol / L 2 SiO 3 The solution is an electrolyte, and the constant voltage is 8V. After electrolysis for 30 minutes, the electrolyte is measured by chemical cyclic voltammetry to obtain an electrochemical cyclic voltammogram, as shown in figure 2 shown. Scanning conditions: InitE(V)=-3, High E(V)=3, Low E(V)=-3, InitP / N=P, Scan Rate(V / s)=0.02, Segment=2, Smpl Interval (V)=0.02, Quiet Time(s)=2, Sensitivity(A / V)=2×10 -4 . Platinum carbon electrode, sanded electrode, polished, sodium dihydrogen phosphate (PBS) PH=7 buffer solution, add 1ml sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com