Method for preparing porous silicon-carbon composite material in situ

A carbon composite material, in-situ preparation technology, applied in nanotechnology for materials and surface science, electrical components, electrochemical generators, etc., can solve high cost, complex equipment requirements, unfavorable large-scale production and industrialization, etc. problem, to achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Add 0.2g PEI (Mw=70000) into a mixed solvent composed of 30mL ethanol and 2mL water, stir at room temperature for 1h to obtain a mixed solution;

[0054] 2. While stirring, slowly add tetraethyl orthosilicate (1.15mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (speed: 8000r / min) to obtain transparent colloid;

[0055] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0056] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

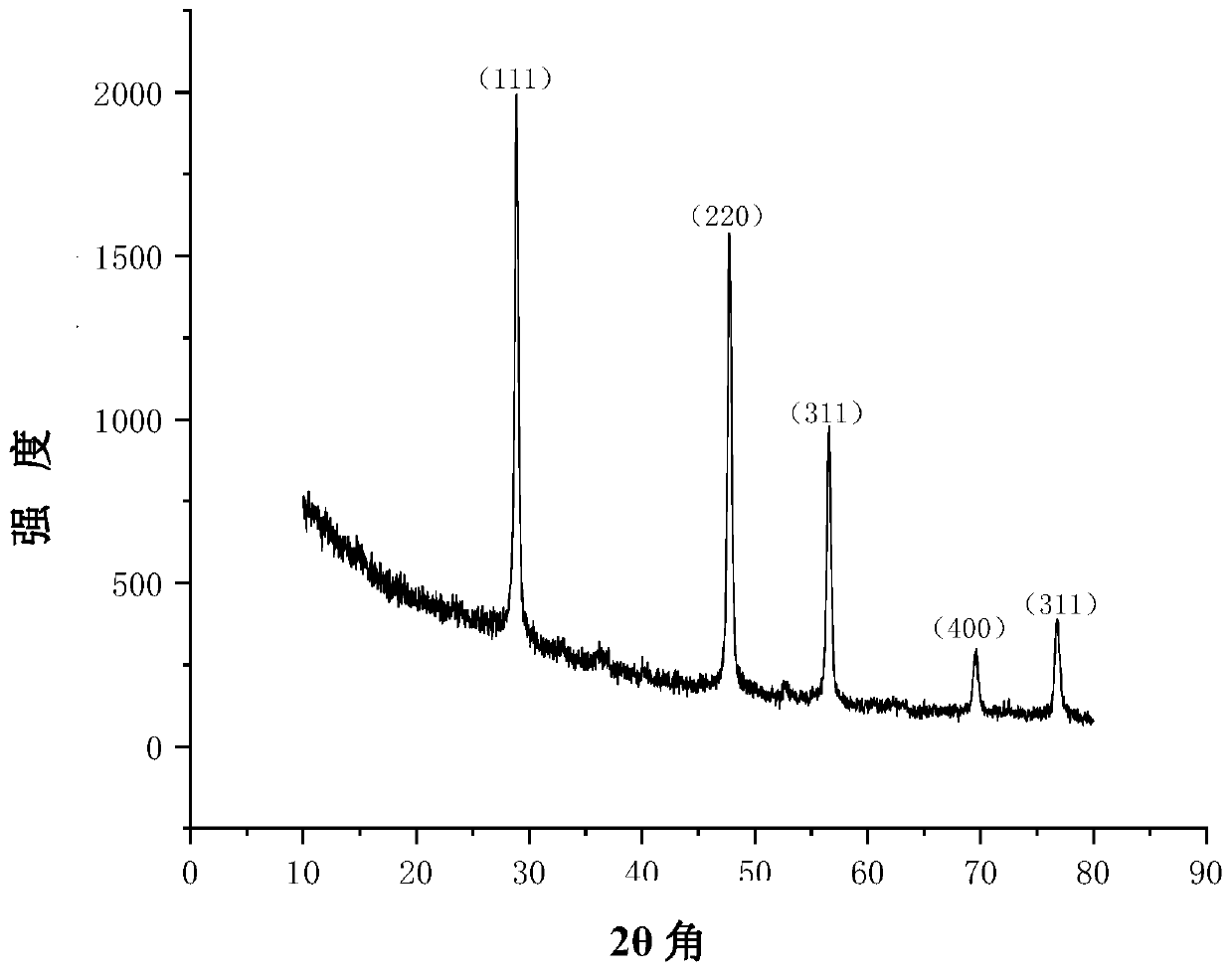

[0057] figure 1 In the XRD pattern of the product prepared in this example, an obvious peak of silicon was...

Embodiment 2

[0068] 1. Add 0.6g PEI (Mw=100000) into a mixed solvent composed of 30mL ethanol and 0.5mL water, and stir at room temperature for 1 hour to obtain a mixed solution;

[0069] 2. While stirring, slowly add tetraethyl orthosilicate (1.15mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (speed: 8000r / min) to obtain transparent colloid;

[0070] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0071] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

Embodiment 3

[0073] 1. Add 0.4g PEI (Mw=70000) into a mixed solvent composed of 30mL ethanol and 3mL water, stir at room temperature for 1h to obtain a mixed solution;

[0074] 2. While stirring, slowly add tetraethyl orthosilicate (3mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (rotating at 8000r / min) to obtain transparent colloid;

[0075] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0076] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com