Hand operated belt sander

A portable and abrasive belt machine technology, which is applied to abrasive belt grinders, portable grinders, grinders, etc., can solve the problems of large footprint and heavy cost of the driving device, and achieve the effects of weight reduction, low structure, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

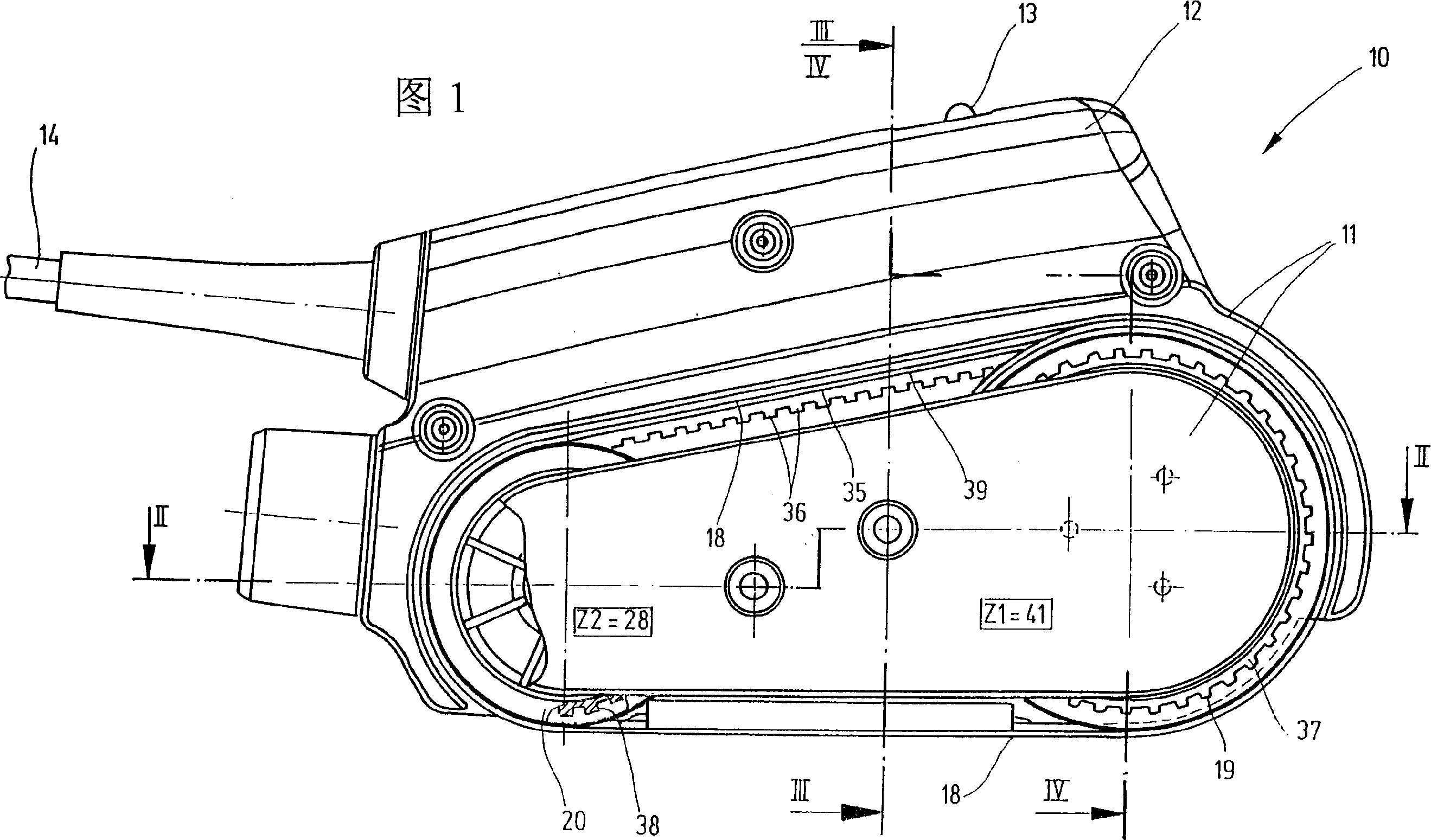

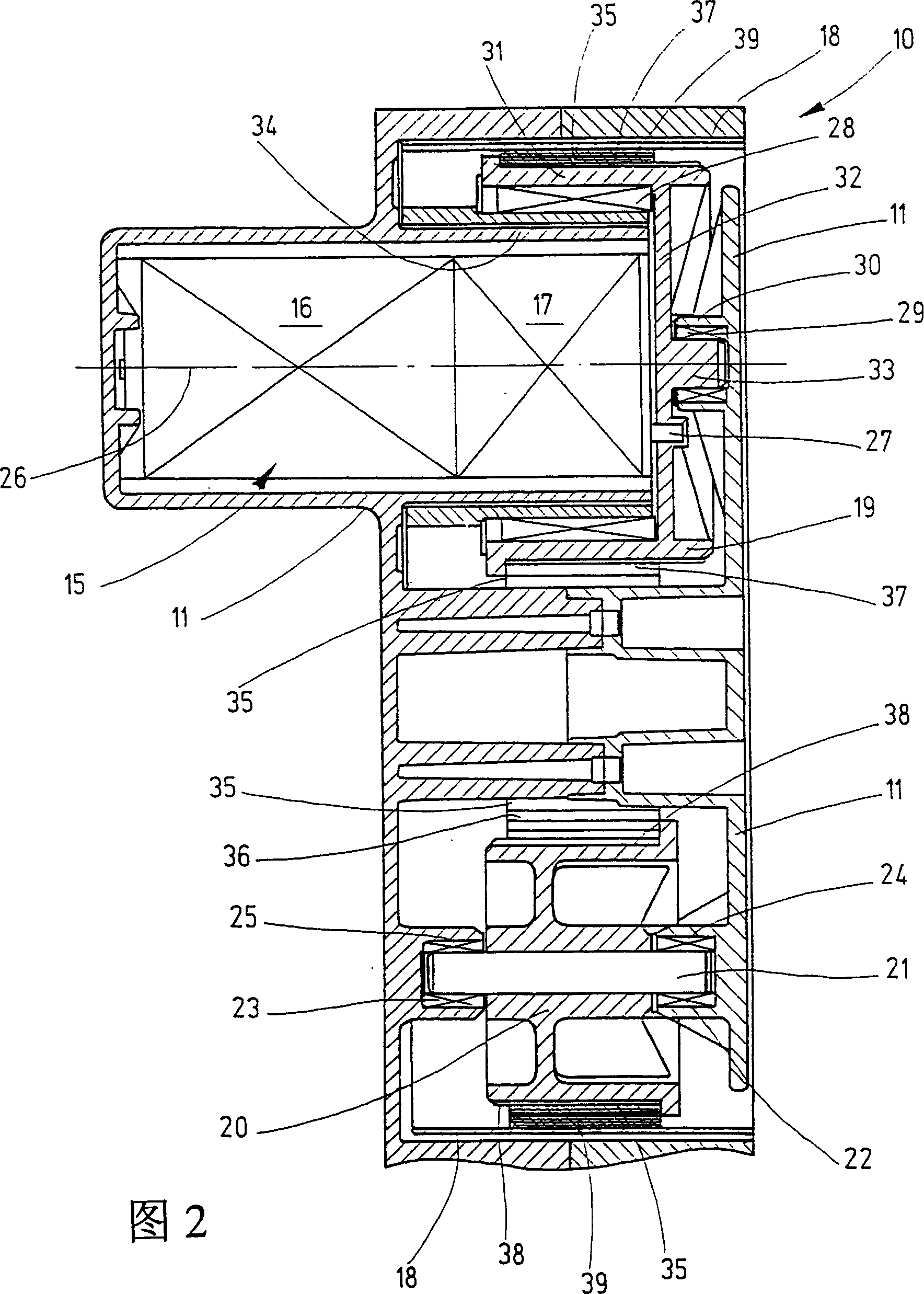

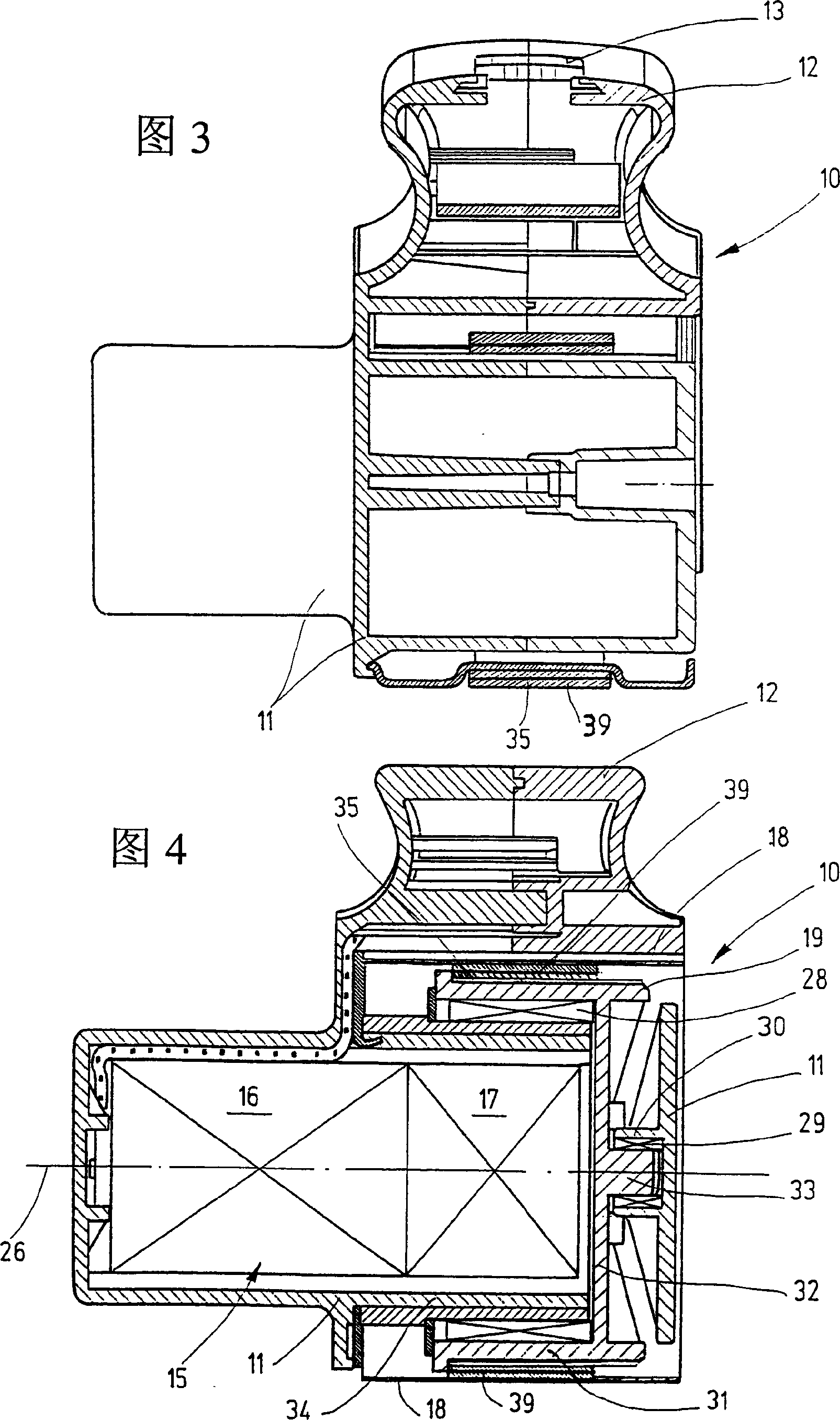

[0016] In the drawings, as an example of a portable abrasive belt grinder, a portable abrasive belt machine 10 is shown, which has a housing 11 on the upper side with a handle 12 that is, for example, substantially slat-shaped. The handle 12 contains a switch formed as a sliding switch 13 on the upper side in the right area in FIG. 1, through which the electric energy input via the wire 14 can be controlled, and the electric energy is used to drive the housing 11 uniformly marked with 15 Device power supply. The drive device 15 has an electric motor 16 with a transmission device 17 and is used to drive an abrasive belt 18, which is only shown schematically. The abrasive belt 18 can be separated from it by a rotatably driven drive roller 19 The steering roller 20 disposed at a distance in the housing 11 is rotatably guided, and can be driven by the rotational drive of the driving roller 19. The housing 11 is a multi-piece structure extending substantially in the longitudinal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com