Device for cooling an exhaust gas stream

A technology of exhaust gas flow and exhaust pipe, which is applied in the direction of exhaust devices, silencers, gas passages, etc., and can solve the problems of increasing exhaust gas back pressure of exhaust equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

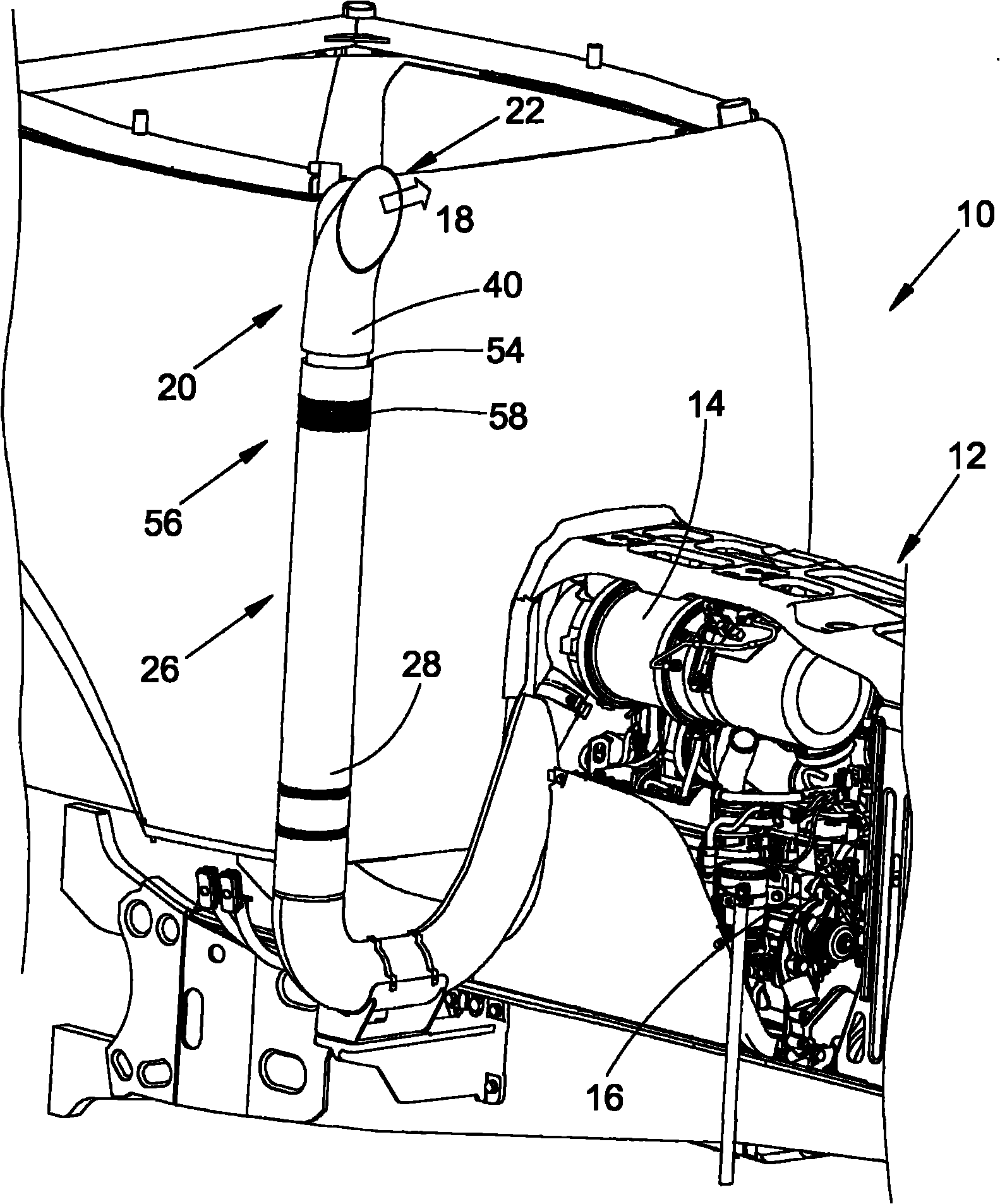

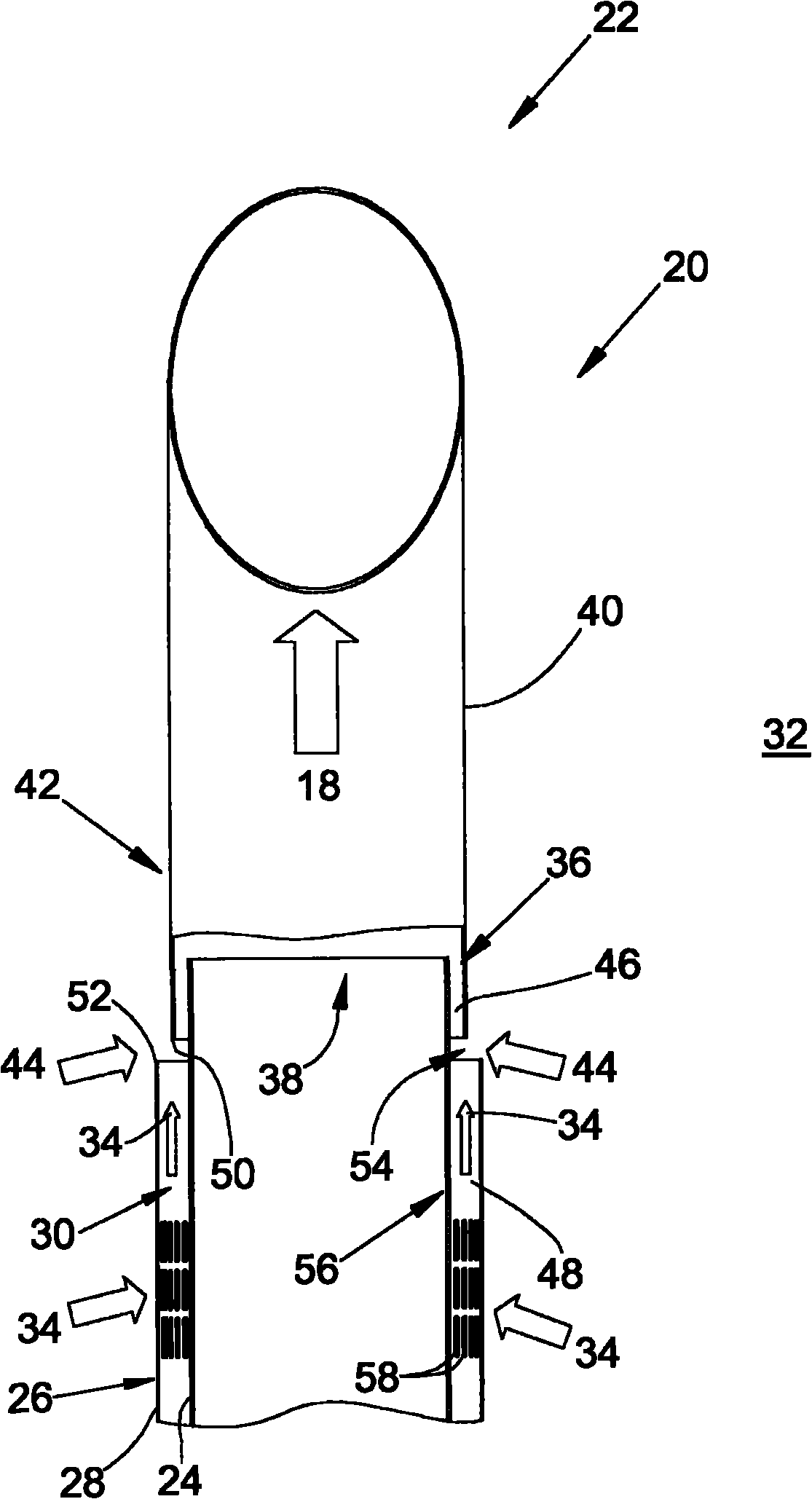

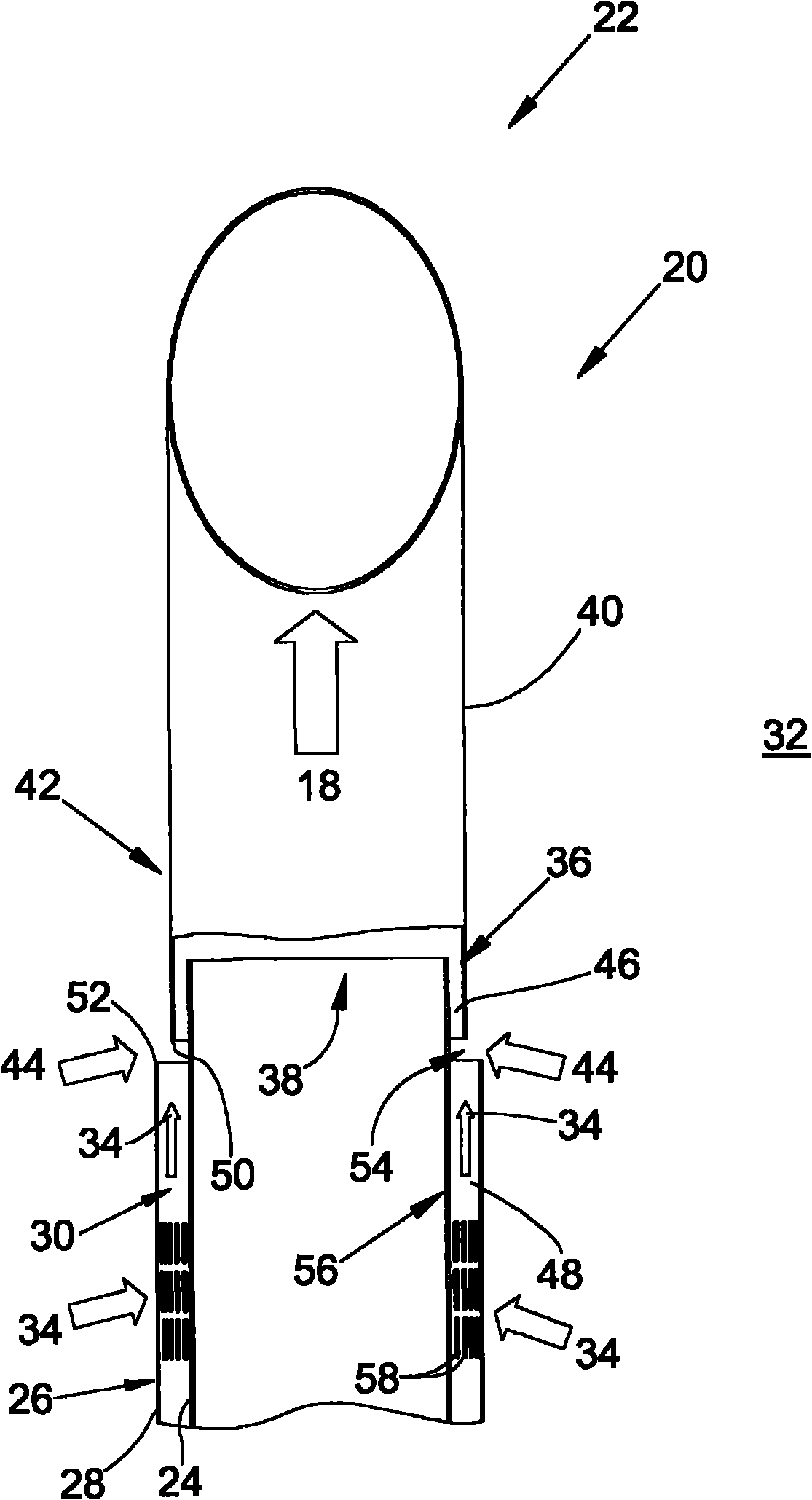

[0018] figure 1 An exemplary embodiment of the device for cooling an exhaust gas flow according to the invention is shown mounted on an agricultural vehicle, wherein figure 2 A detail view of the device according to the invention is shown in longitudinal section.

[0019] The agricultural vehicle 10 includes a soot particulate filter 14 disposed within the engine compartment 12, wherein this filter consists of a conventional wall-flow filter in which engine exhaust gas produced by the diesel engine 16 of the agricultural vehicle 10 passes through a ceramic or metal filter. Porous filter walls made of material. The soot particles contained in the engine exhaust gas are here deposited not only on the surface of the soot filter 14 but also inside its filter walls. Because the exhaust gas back pressure increases with the degree of clogging of the filter walls, in order to regenerate the soot particulate filter 14, the deposited soot particles are burned at regular intervals, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com