Clutch drive with radially nested seals, (double) clutch with clutch drive and drive train

A sealing device and active device technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of harsh noise, high noise radiation, system leaks, etc., achieve small volume absorption, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

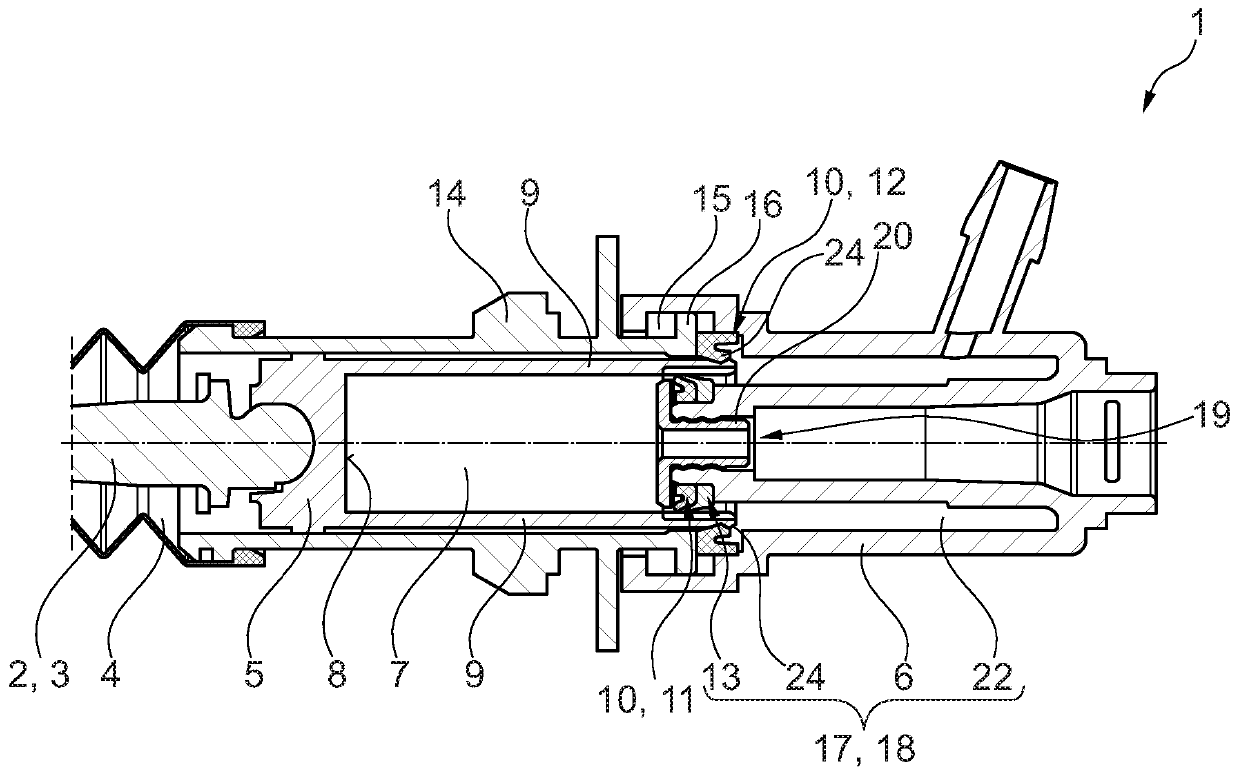

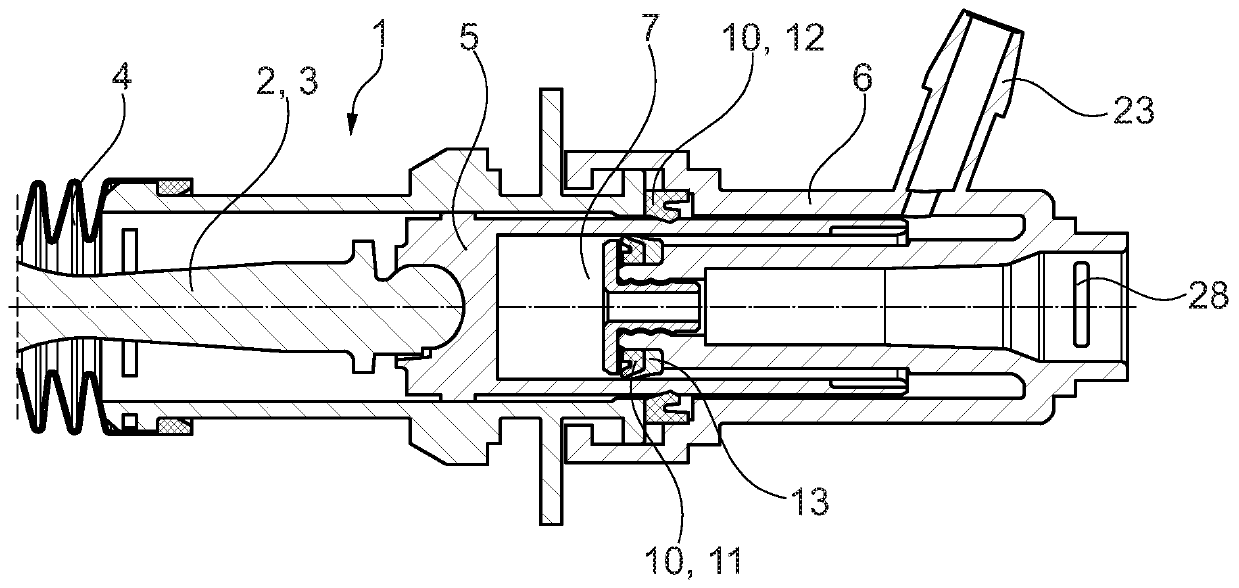

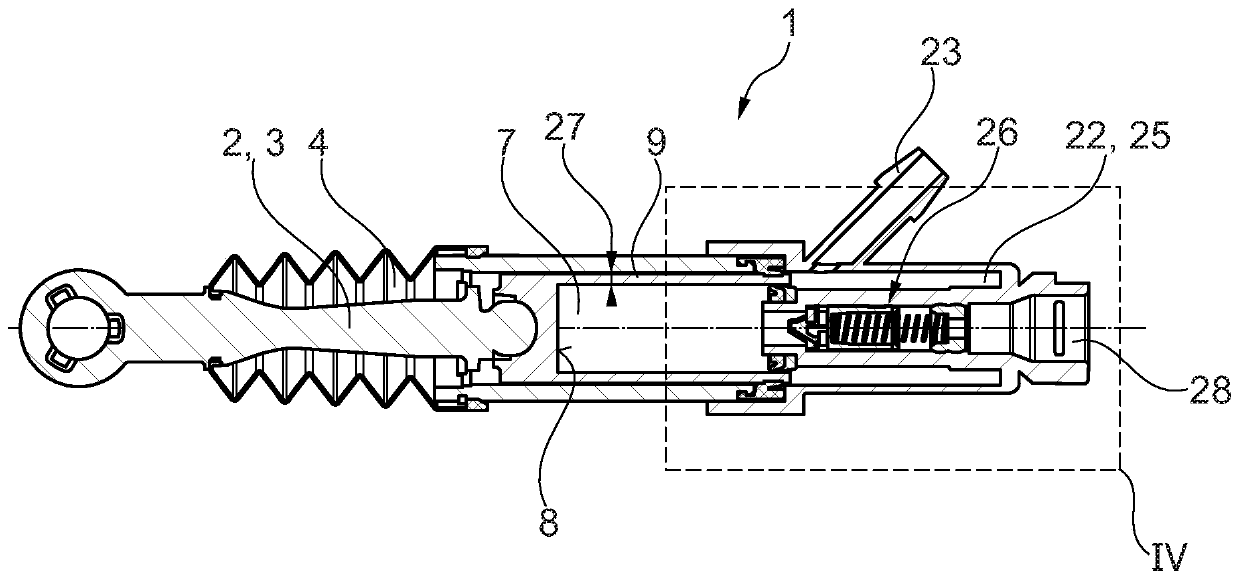

[0046] The drawings are partly of a schematic nature and are only used for the understanding of the invention. The figures relate to a longitudinal section, ie a section which extends along a longitudinal axis through the clutch drive, in particular along a rotational axis through the piston. Identical elements are provided with the same reference numerals. The features of the individual exemplary embodiments can also be combined with one another. That is, they can be interchanged with each other.

[0047] exist figure 1 shows an active clutch device 1 according to the invention. The clutch drive 1 is installed in a single clutch or a double clutch. The active clutch device is intended to be installed in a motor vehicle, such as a passenger car, a truck or other commercial vehicles. The clutch drive 1 is mechanically connected to an adjusting element 2 (eg lever 3 ). The rod 3 is surrounded by a bellows 4 . Rod 3 is connected to piston 5 . Piston 5 is mounted axially m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com