Preparation method of tough wear-resistant silicon nitride based composite ceramic

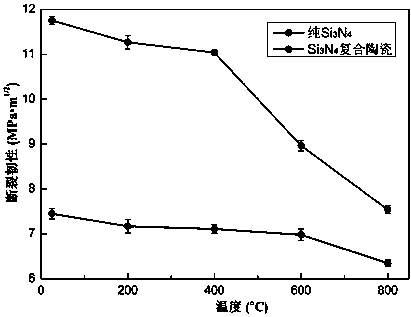

A silicon nitride-based, composite ceramic technology is applied in the field of new materials to achieve high-temperature toughness and anti-wear performance, eliminate gaps, and reduce cost problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

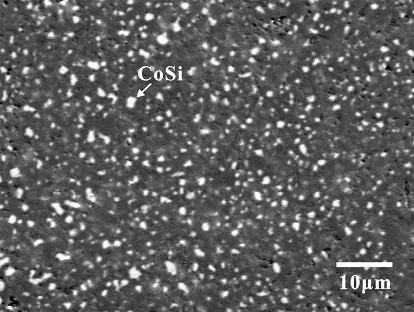

[0028] Example 1 A method for preparing a tough and wear-resistant silicon nitride-based composite ceramic, comprising the following steps:

[0029] ⑴In terms of mass percentage, 95% of α-Si 3 N 4 powder and 5% C 4 h 6 CoO 4 • 4H 2 After mixing the O aqueous solution, stir it magnetically at 100°C at 500rmp for 5h until the solvent is completely evaporated to dryness to obtain the mixed powder;

[0030] (2) After the mixed powder is crushed through a 100-mesh sieve, it is put into a cylindrical steel mold with a diameter of 25 mm for pre-pressing, the pressure is 120 MPa, and the holding time is 10 s to obtain a pre-pressed sample;

[0031] (3) After demolding the pre-compressed sample, put it into a cylindrical graphite with a diameter of 25 mm. The pressure is 30 MPa, the sintering temperature is 1680 ° C, the heating rate is 200 ° C / min, the holding time is 3 min, and the vacuum degree is 10 -2 Under the condition of Pa, it is sintered under high temperature and hig...

Embodiment 2

[0035] Example 2 A method for preparing a tough and wear-resistant silicon nitride-based composite ceramic, comprising the following steps:

[0036] ⑴In terms of mass percentage, 90% of α-Si 3 N 4 powder and 10% C 4 h 6 CoO 4 • 4H 2 After mixing the O aqueous solution, stir it magnetically at 100°C at 500rmp for 5h until the solvent is completely evaporated to dryness to obtain the mixed powder;

[0037] (2) After the mixed powder is crushed through a 100-mesh sieve, it is put into a cylindrical steel mold with a diameter of 25 mm for pre-pressing, the pressure is 120 MPa, and the holding time is 10 s to obtain a pre-pressed sample;

[0038] (3) After demolding the pre-compressed sample, put it into a cylindrical graphite with a diameter of 25 mm. The pressure is 30 MPa, the sintering temperature is 1680 ° C, the heating rate is 200 ° C / min, the holding time is 3 min, and the vacuum degree is 10 -2 Under the condition of Pa, it is sintered under high temperature and hi...

Embodiment 3

[0042] Example 3 A method for preparing a tough and wear-resistant silicon nitride-based composite ceramic, comprising the following steps:

[0043] ⑴In terms of mass percentage, 80% of α-Si 3 N 4 powder and 20% C 4 h 6 CoO 4 • 4H 2 After mixing the O aqueous solution, stir it magnetically at 100°C at 500rmp for 5h until the solvent is completely evaporated to dryness to obtain the mixed powder;

[0044] (2) After the mixed powder is crushed through a 100-mesh sieve, it is put into a cylindrical steel mold with a diameter of 25 mm for pre-pressing, the pressure is 120 MPa, and the holding time is 10 s to obtain a pre-pressed sample;

[0045] (3) After demolding the pre-compressed sample, put it into a cylindrical graphite with a diameter of 25 mm. The pressure is 30 MPa, the sintering temperature is 1680 ° C, the heating rate is 200 ° C / min, the holding time is 3 min, and the vacuum degree is 10 -2 Under the condition of Pa, it is sintered under high temperature and hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com