Patents

Literature

32results about How to "In situ generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

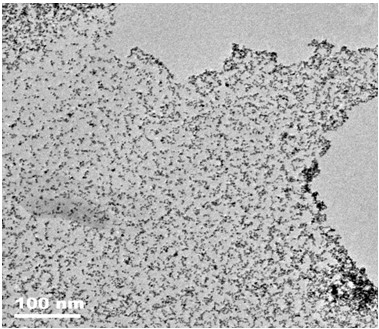

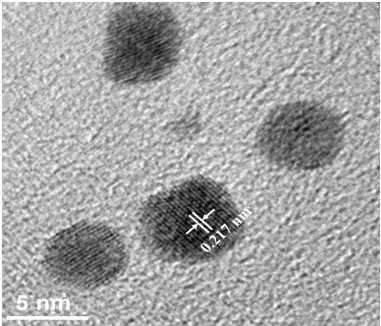

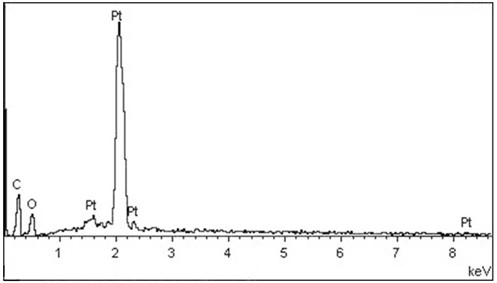

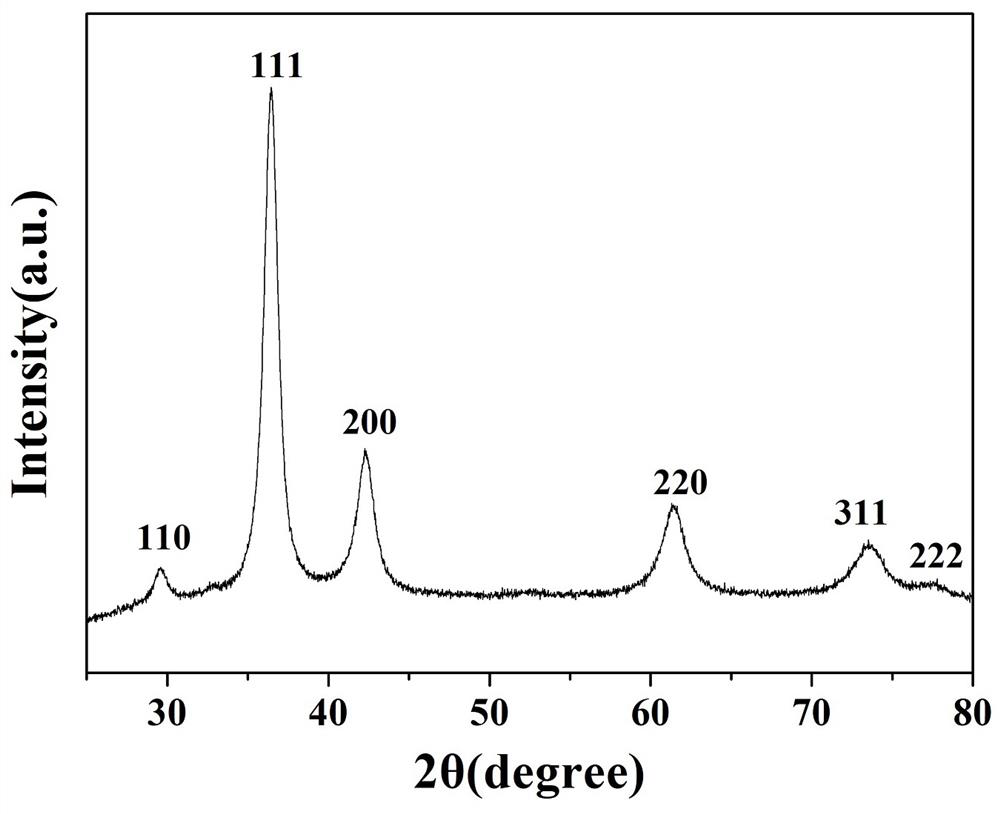

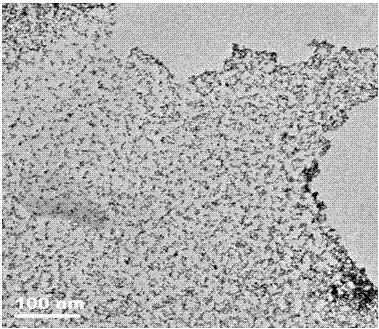

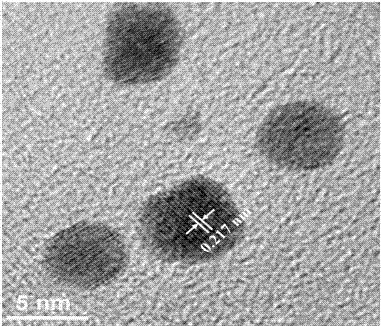

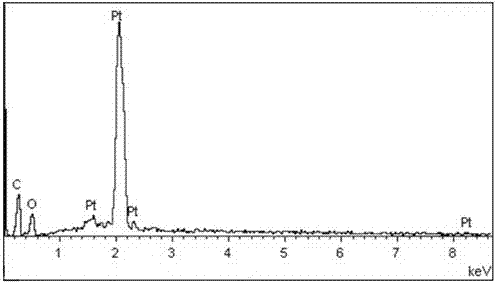

Method for preparing graphene-loaded platinum nano catalyst

InactiveCN101966453AUniform particle sizeSolve the technical problem of reunionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystPlatinum

The invention discloses a method for preparing a graphene-loaded platinum nano catalyst, which comprises the following steps of: (1) preparing graphene (GNS); (2) preparing polydiallyl dimethyl ammonium chloride (PDDA) functional graphene; and (3) preparing the graphene-loaded platinum nano (Pt / GNS) catalyst. The method has the advantages of uniformly adsorbing and distributing PtCl6<2-> with negative charge on the surface of the GNS through electrostatic adhesion by using positive charge uniformly distributed on the surface of the PDDA-modified GNS, solving the technical problem that metallic particles per se aggregate, realizing higher loading rate of PtNPs and having uniform grain size and controllable size.

Owner:NANCHANG UNIV

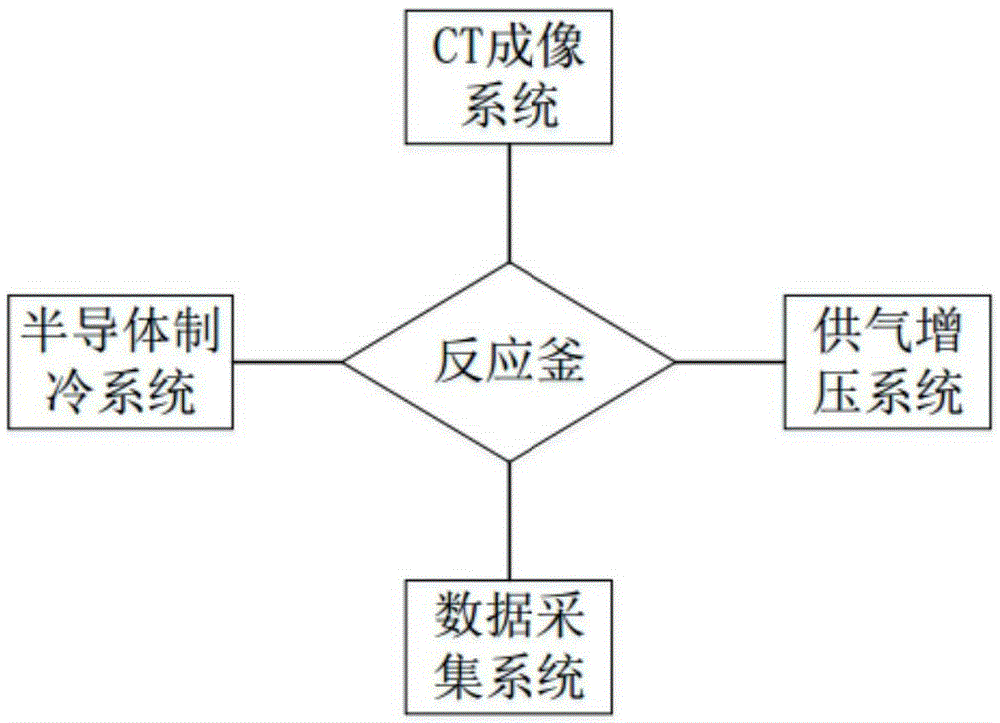

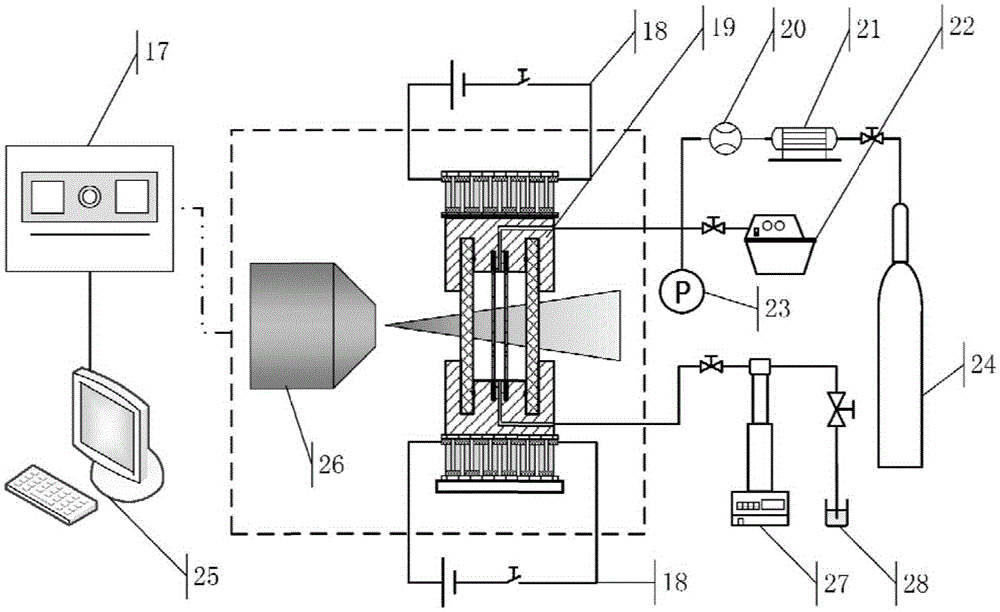

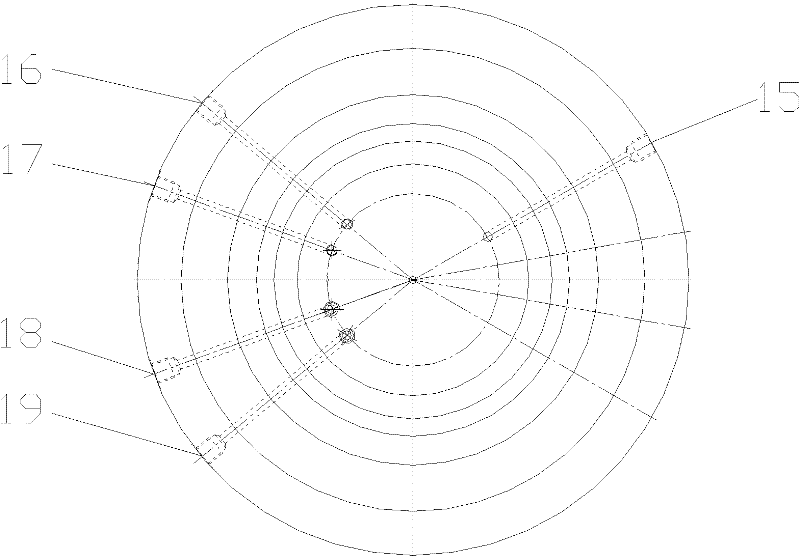

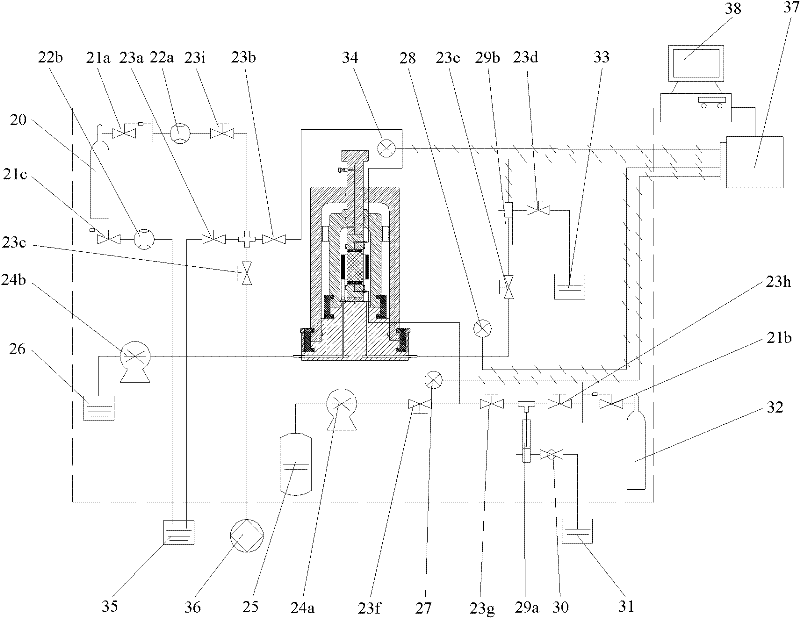

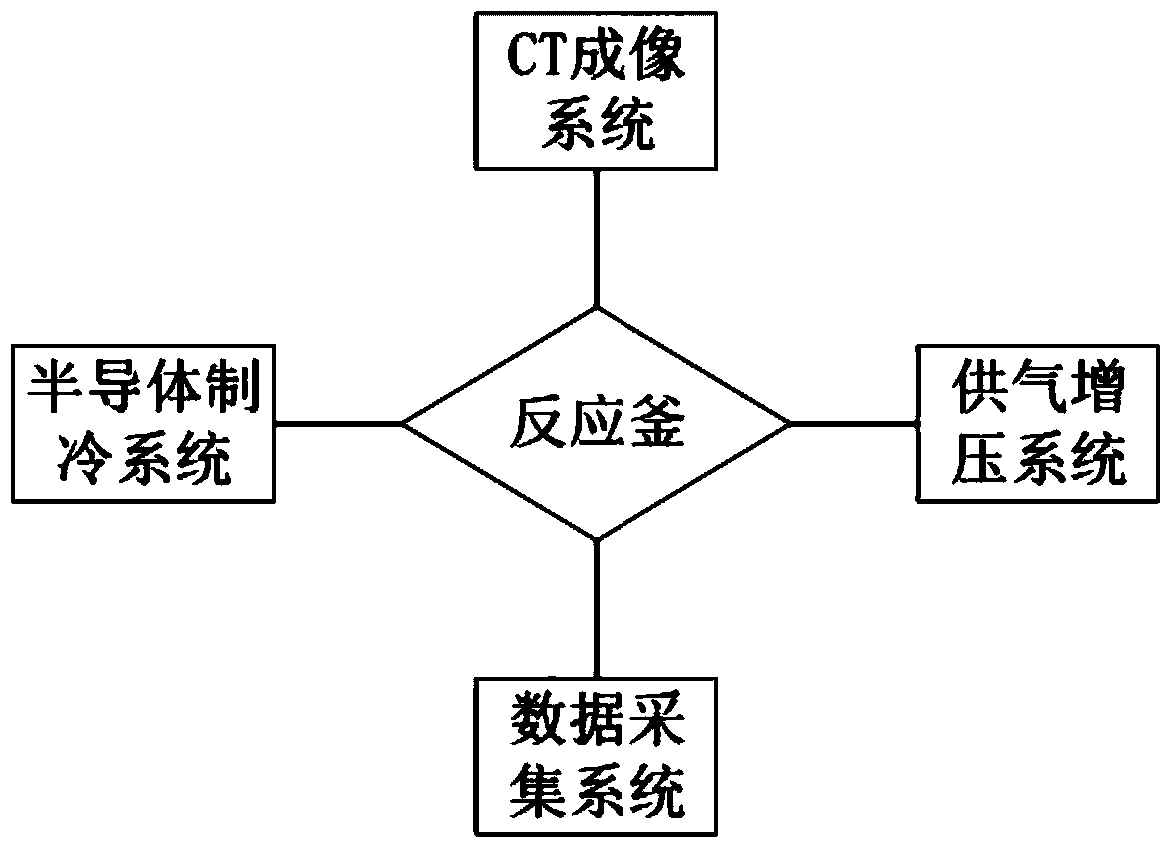

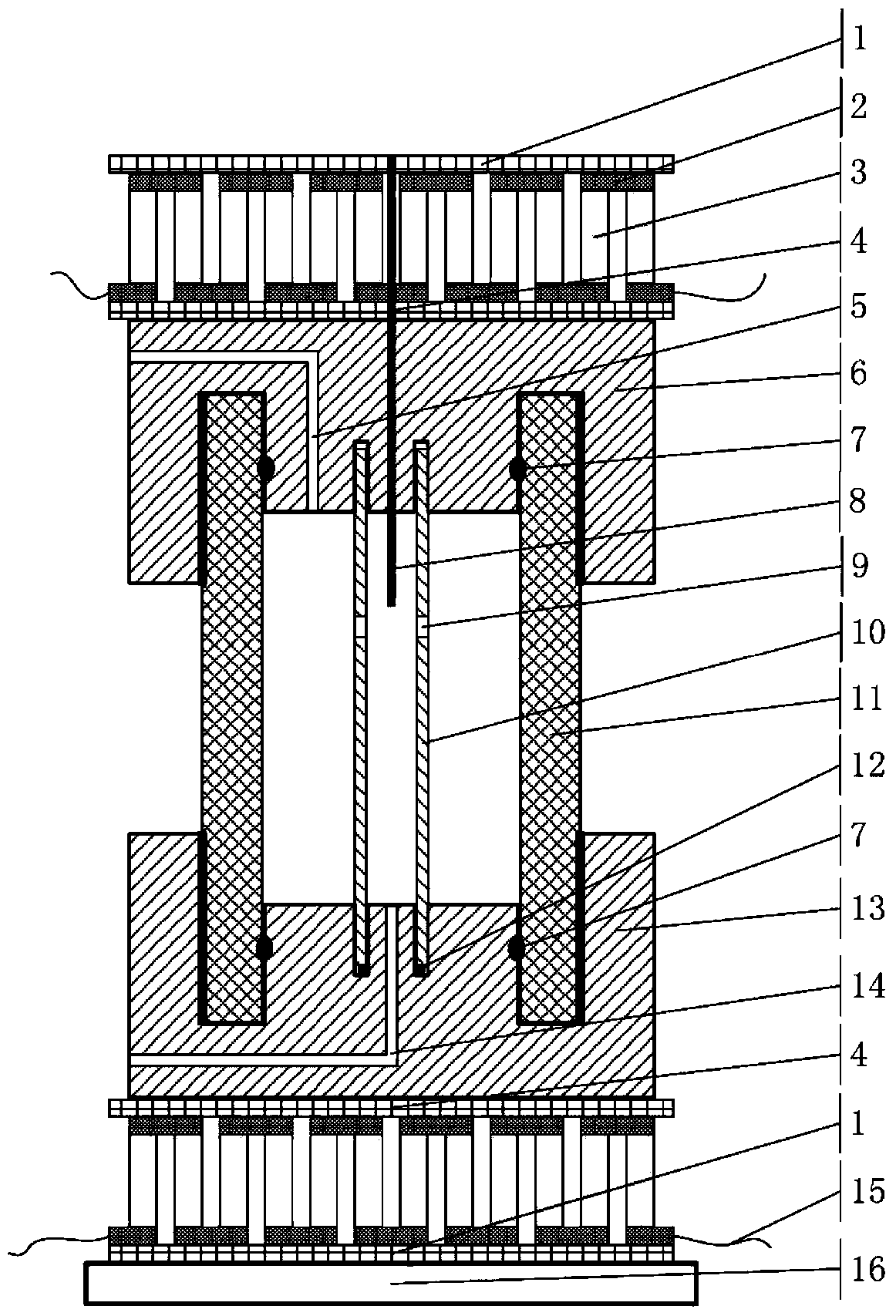

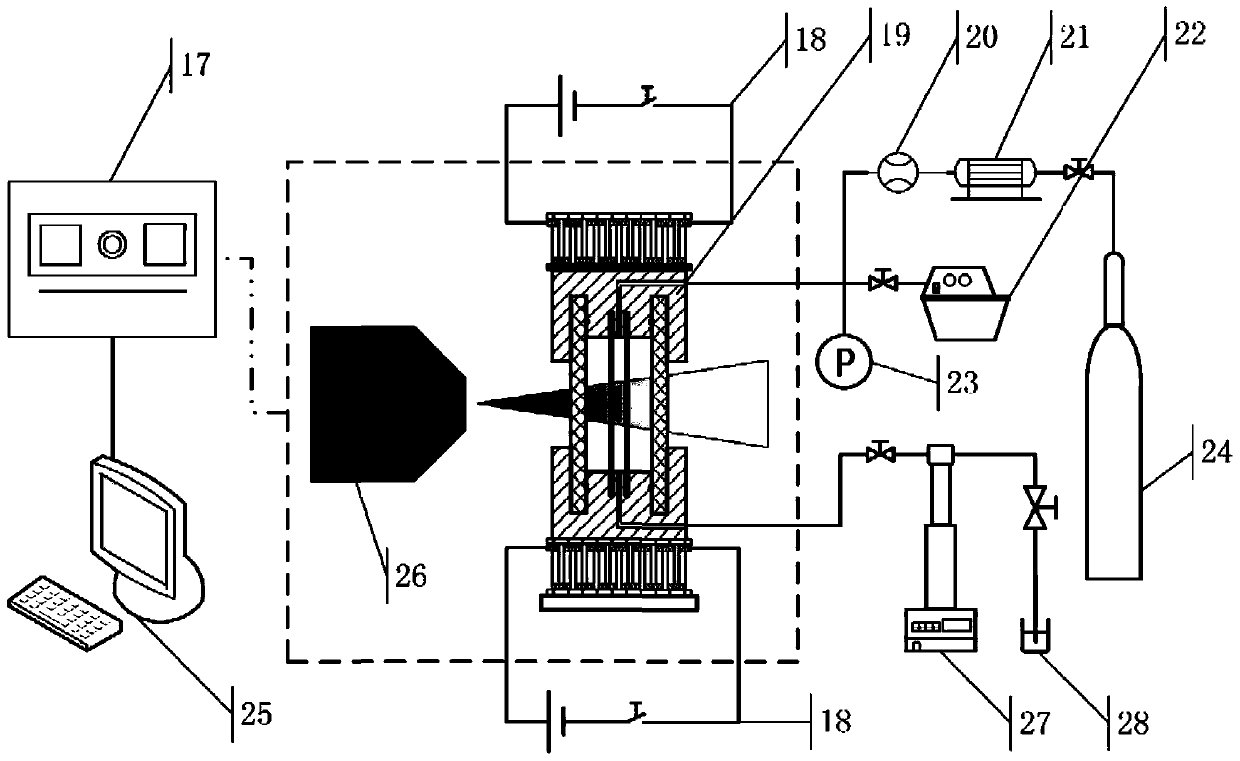

Low-temperature high-pressure control device for observing aquo-complex generation and decomposition characteristics through X-ray CT device

ActiveCN105424734AMeet the conditions for generationPrecise temperature controlProcess control/regulationPressure vessels for chemical processDecompositionX-ray

The invention relates to a low-temperature high-pressure control device for observing aquo-complex generation and decomposition characteristics through an X-ray CT device, and belongs to the field of oil and gas production scientific research apparatuses. A reaction still has design pressure of 0-10 MPa and design temperature of 268-288 K, and the temperature and pressure conditions of aquo-complex generation and stable existence are met. The temperature of the reaction still is controlled through the upper end and the lower end of a semiconductor refrigerating element, noise does not exist, the acting speed is high, reliability is high, and operation is convenient. The reaction still is composed of an inner pipe and an outer pipe, wherein the inner pipe is made from titanium alloy and is mainly used for heat conduction, and the outer pipe is made from polyimide belonging to a low-heat-conductivity material and is mainly used for heat preservation and pressure preservation; according to the characteristics, the heat conduction and the heat preservation and pressure preservation are controlled independently and can be more easily controlled in the terms of engineering. The low-temperature high-pressure control device can be put on a carrying table of the CT device and generate aquo-complex in situ; through the three-dimensional imaging of the CT device, the generation and decomposition characteristics of aquo-complex can be visually studied.

Owner:DALIAN UNIV OF TECH

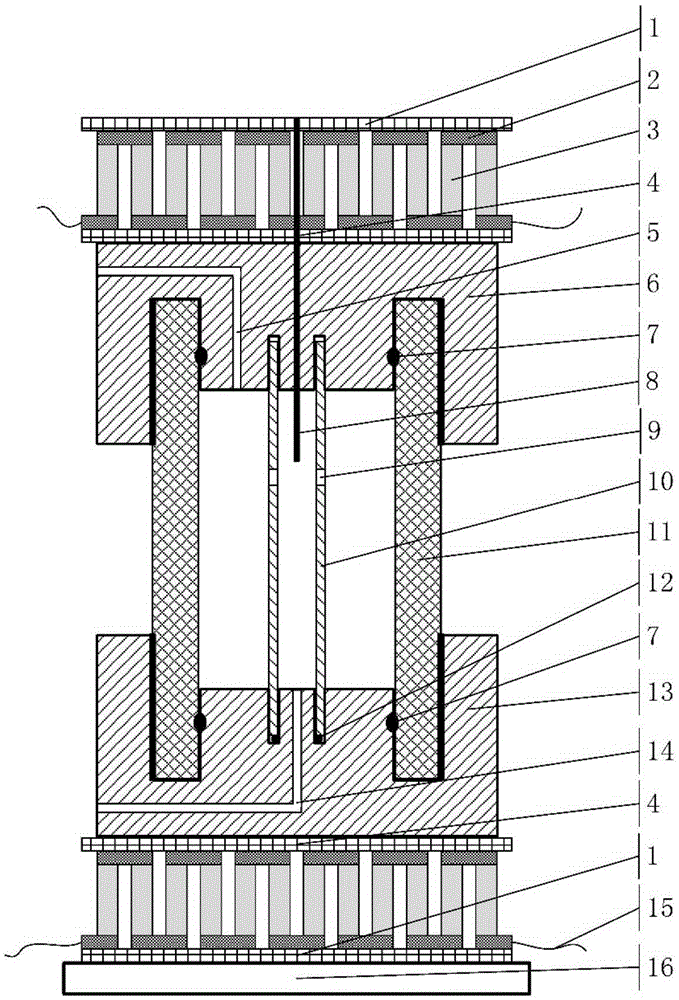

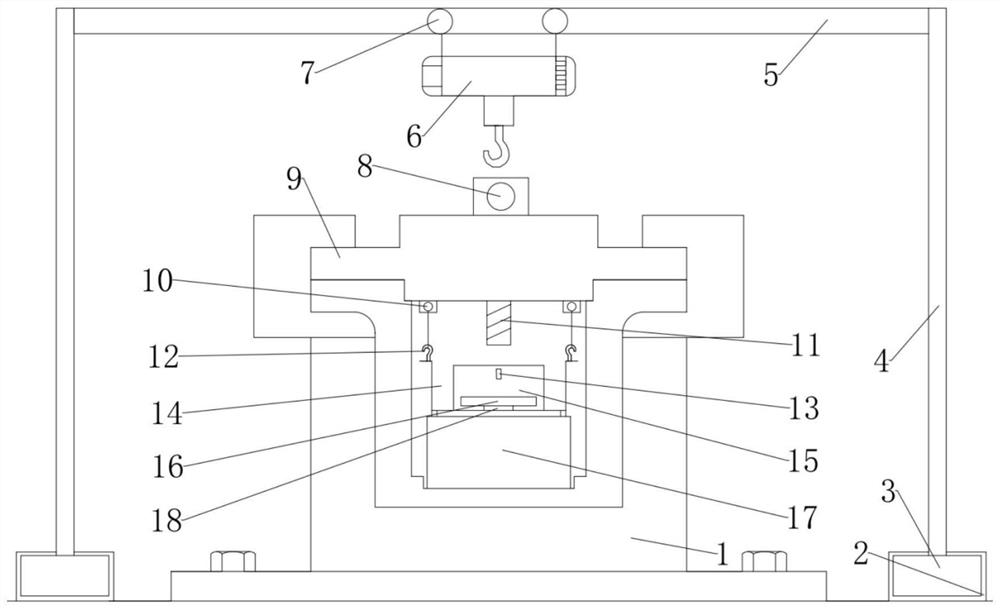

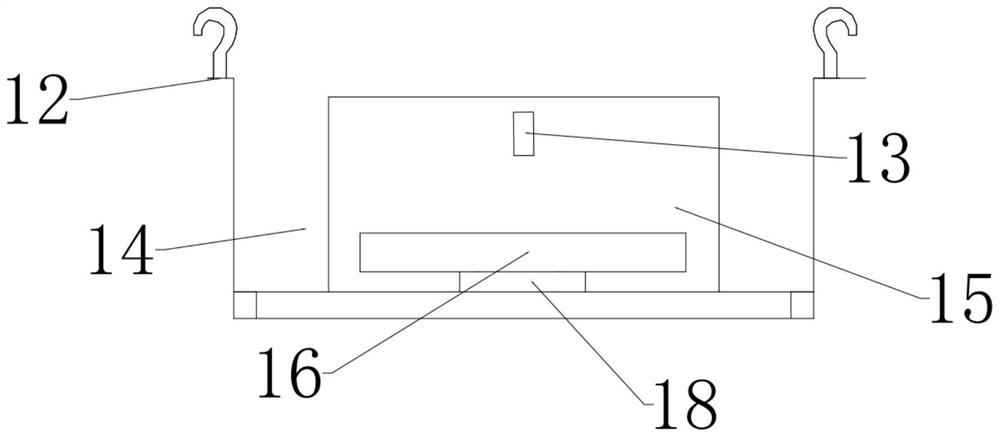

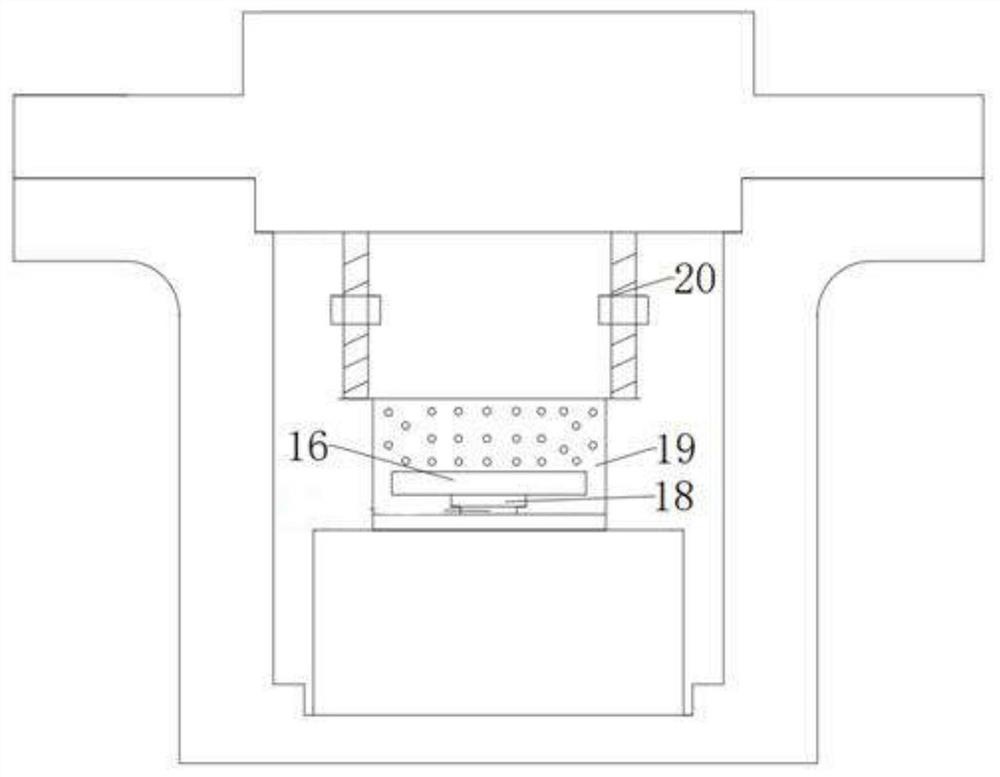

Triaxial test device for in-situ generation and decomposition of natural gas hydrate

ActiveCN102162779AIn situ generationAchieve decompositionPressurized chemical processMaterial strength using tensile/compressive forcesTriaxial shear testDecomposition

The invention provides a triaxial test device for in-situ generation and decomposition of a natural gas hydrate. The device comprises a closed pressure chamber consisting of an outer cover barrel and a base; an inner cover barrel is arranged in the closed pressure chamber; the inner cover barrel is fixed on the base through a clamping ring; at least one oil inlet and outlet hole, at least one airinlet hole and at least one water inlet hole are formed on the base of the inner cover barrel; the oil inlet and outlet hole, the air inlet hole and the water inlet hole are formed on the inner cavity of the inner cover barrel; pistons are arranged on the tops of the outer cover barrel and the inner cover barrel; air exhaust holes are formed on the pistons; a lower pressure pad and an upper pressure pad which correspond to each other are arranged in the inner cavity of the inner cover barrel; the upper pressure pad corresponds to the positions of the pistons; and the lower pressure pad is fixed on the base.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Process for in-situ polymerization preparation of nylon 6/epoxy resin/silicon dioxide nano composite materials

The invention discloses an in-situ polymerization method for preparation of nylon 6 / epoxide resin / silica dioxide nanocomposite, which consists of the following steps:a)preparing epoxide resin siloxane solution by graft reaction and hydrolytic reaction; b) before or in the aminocaprolactam cycle-open reaction, introducing the epoxide resin siloxane solution into the mediator of the said aminocaprolactam cycle-open reaction, simultaneously adding the water and the anti-oxidant; c) making the aminocaprolactam open ring and polymerize to prepare high-strength and super ductility nylon-6 / epoxide resin / silica dioxide nanocomposite. The invention makes the silicate react with the hydroxy group of the epoxide resin under the accelerating effect, then dissolvent, water and acid (or alkali) are added to hydrolyze. Because the silicasol surface graft and adsorb epoxide resin, the agglomeration of the earth silicon nanoparticles can be effectively avoided. On the other hand, because the epoxy radicals can react with the amidol and the carboxyl of the nylon-6 molecular chain to form partial interpenetration network architecture, accordingly the diphasic boundary action can be effectively improved. It has a good cooperating knife-bar with the nano earth silicon, so it can largely improve the bruise resistance of the materials as well as the hot strength of the composite, in which the hot strength has increased by 30 % compared with nylon-6 and the bruise resistance is 3-5 times of the nylon-6.

Owner:XIANGTAN UNIV

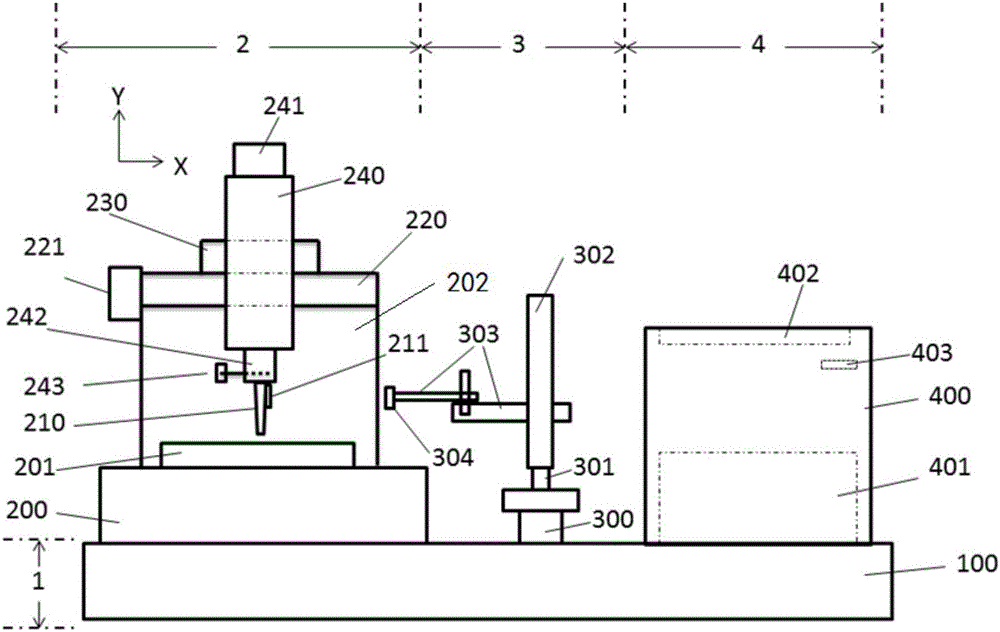

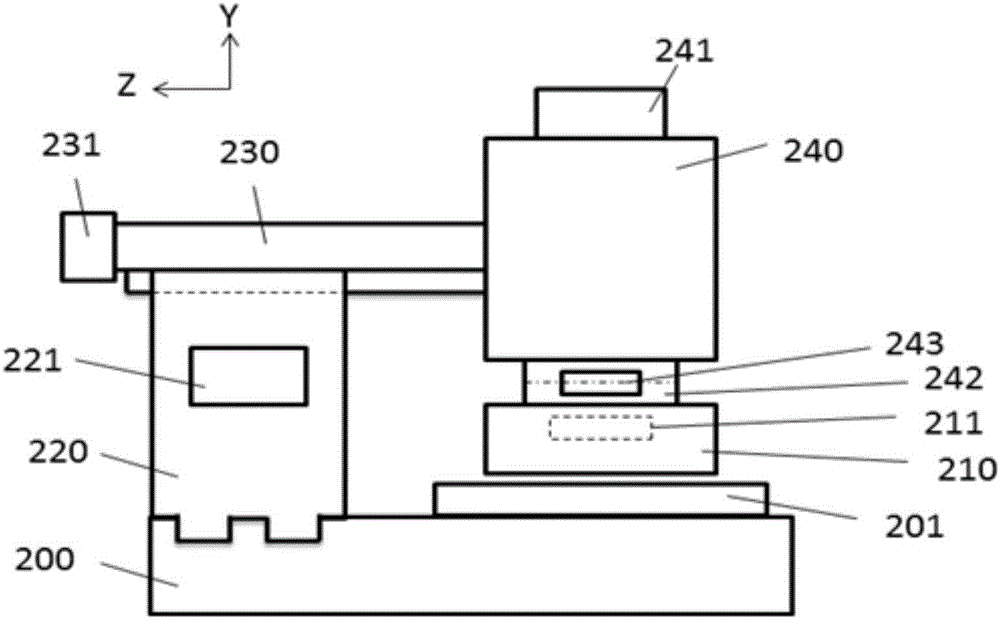

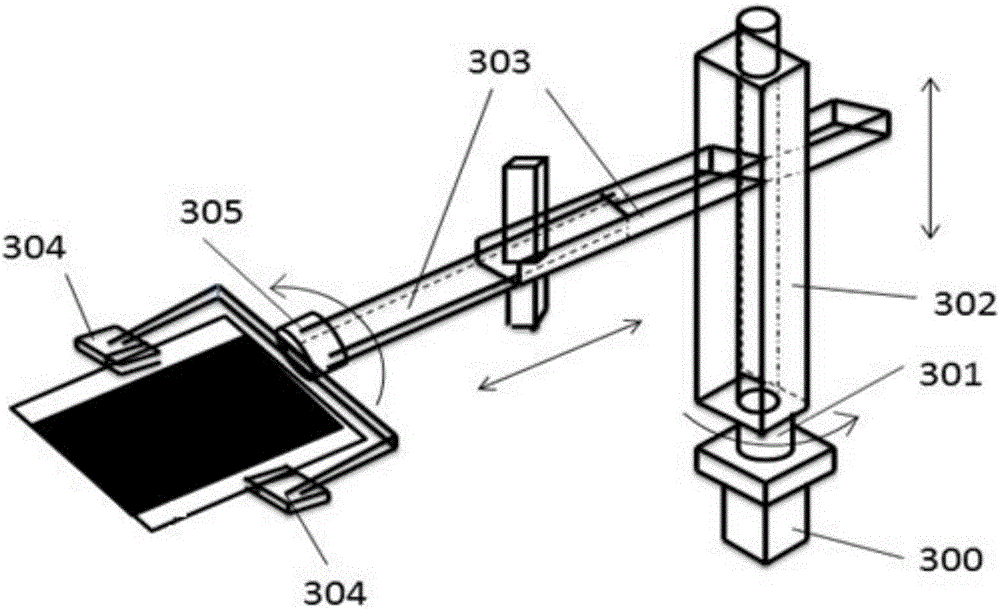

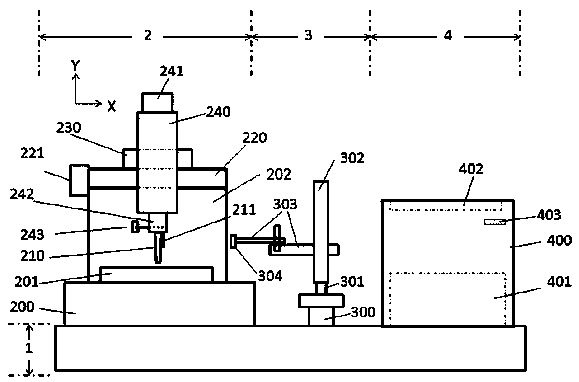

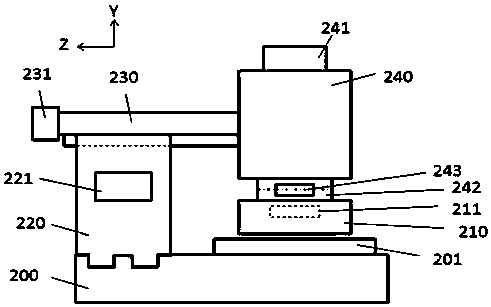

Coating mechanism, slit coating device and film preparation method

ActiveCN105880104AEasy to moveReduce movementLiquid surface applicatorsFinal product manufactureAgricultural engineeringPolymer

The invention discloses a coating mechanism, a slit coating device and a film preparation method. The coating mechanism comprises a base, a supporting table, a movable supporting part and a fluid storage tank with a nozzle, wherein both the supporting table and the movable supporting part are fixed on the base; the fluid storage tank is fixed on the movable supporting part and driven by the movable supporting part to move relative to the supporting table; and when the fluid storage tank moves, a fluid material in the fluid storage tank is sprayed by the nozzle onto a to-be-coated sample fixed on the supporting table for direct film formation. By adoption of the coating mechanism, the slit coating device and the film preparation method provided by the invention, the technical problems that a conventional gel polymer lithium battery film formation device and method are high in cost and low in film formation quality can be solved. Furthermore, the slit coating device provided by the invention is low in cost and uniform in coating effect.

Owner:山西能际智能科技有限责任公司

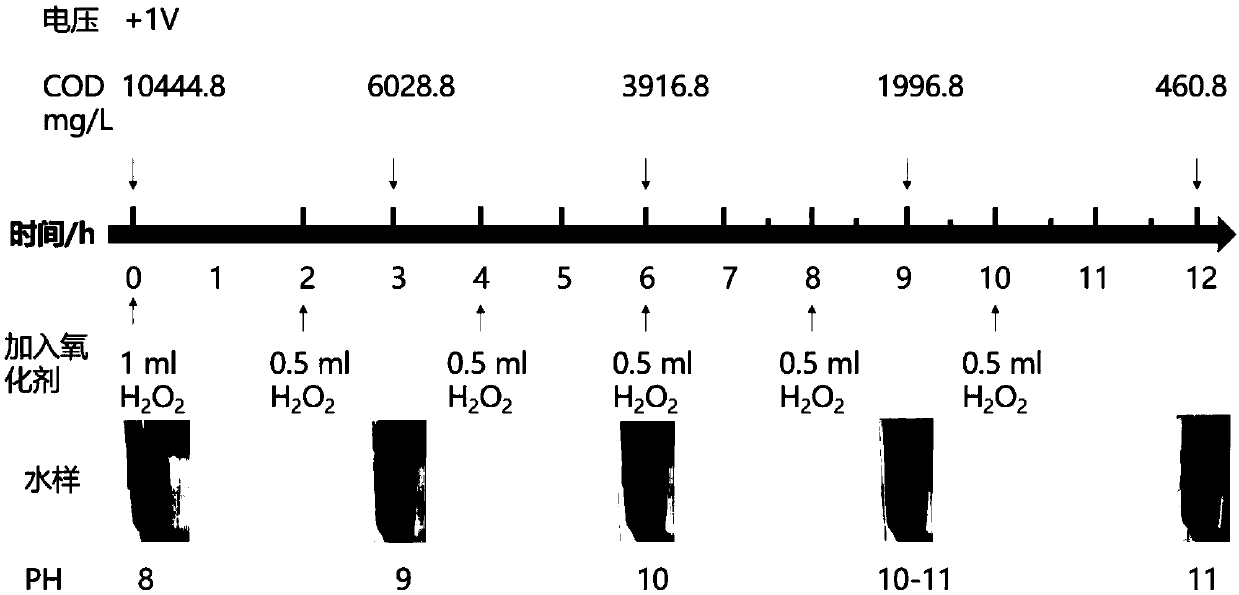

Fenton method for efficiently degrading organic pollutants in water

ActiveCN107686156AIn situ utilizationIncrease profitWater/sewage treatment by oxidationCarbon nanotubeOxygen

The invention discloses a Fenton method for efficiently degrading organic pollutants in water. The method includes the steps: adding magnesium-carbon nano-tube compound particles and iron vitriol intowaste water; stirring mixture under the condition of oxygen inlet; controlling a pH (potential of hydrogen) value of solution to reach acidity; adjusting the pH value of the solution to reach 6-9 after reaction; performing solid-liquid separation, and taking liquid supernatant as treatment outlet water. According to the method, hydrogen peroxide of generated by reaction among magnesium-carbon nano-tubes and oxygen and added ferrous ions act to generate strongly oxidizing species such as -OH, and the organic pollutants in the water are completely mineralized into inorganic substances and removed. The method is wide in raw material source, low in price and cost, simple in process, convenient to operate, mild in reaction condition and applicable to large-scale industrial production, and theorganic pollutants are efficiently degraded.

Owner:HAO WEI ENVIRONMENTAL TECH NANTONG CO LTD

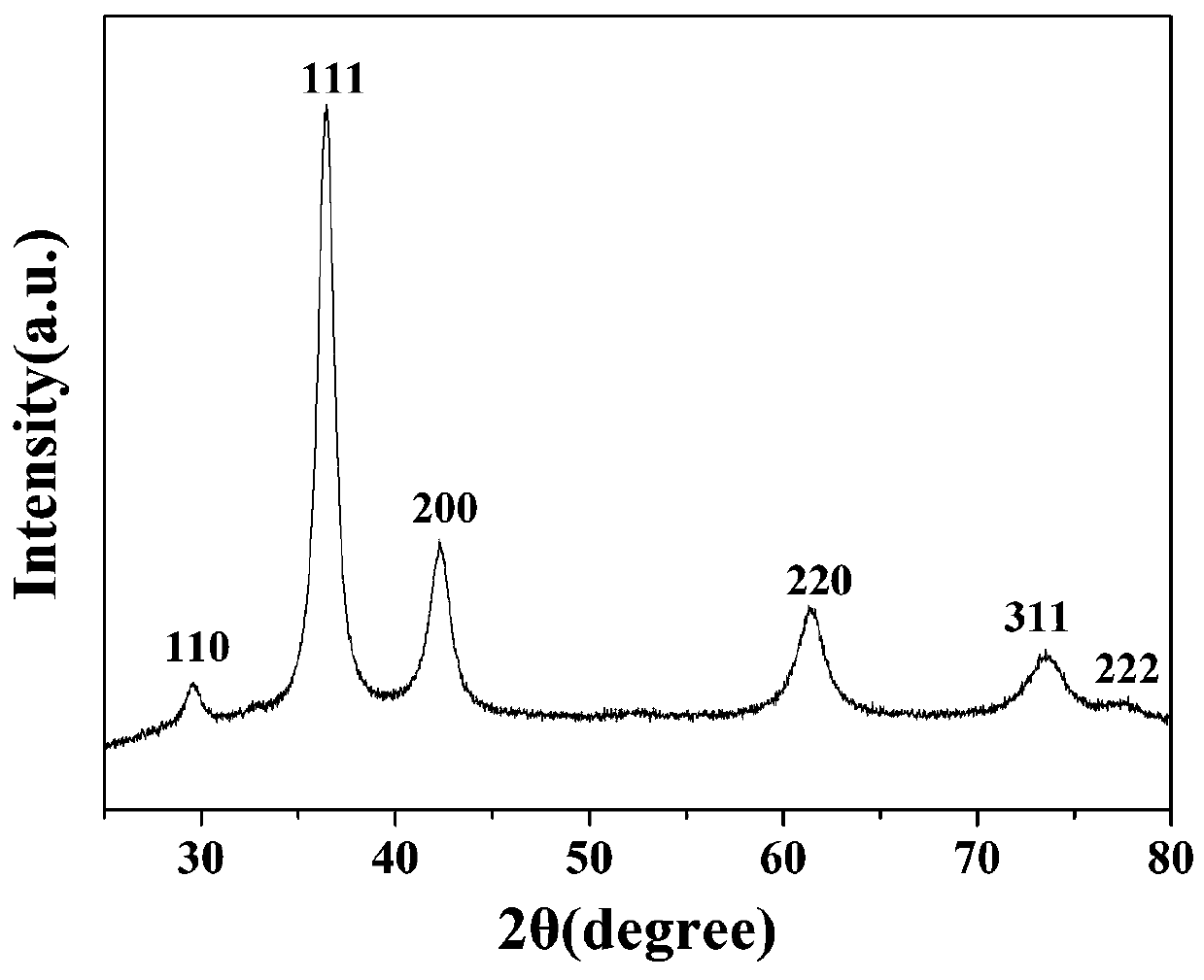

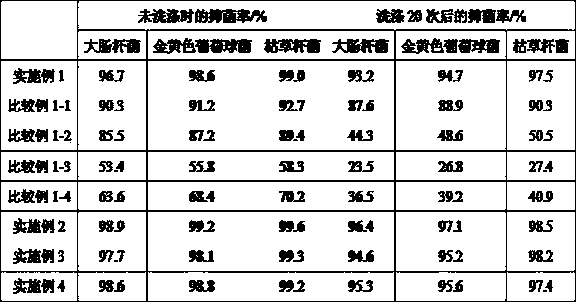

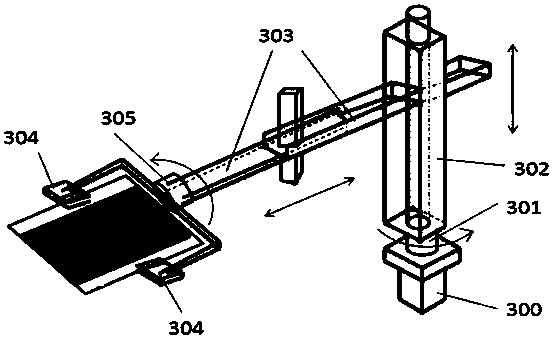

Preparation method of indigotic dyeing antibacterial textile

ActiveCN110656510AImprove permeabilityGood adhesionDyeing processPyrrolidinonesAntibacterial activity

The invention provides a preparation method of an indigotic dyeing antibacterial textile. According to the method, natural indigos are super-thinned by an ultrasonic crushing mode, the textile is padded by a super-thin natural indigotic dye suspension solution and rolled by copper salt solution, and dyeing of indigotic dyes and in-situ formation of cuprous oxide on a fabric are achieved by a one-step hydrothermal method. Polyvinylpyrrolidone in the suspension solution serves as dispersing agents of the indigotic dyes, the complexing action between the polyvinylpyrrolidone and Cu<2+> is formedwhen the copper salt solution is padded, and glucose serves as reducing agents of the natural indigotic dyes and also serves as reducing agents for converting Cu<2+> into Cu<+> in the hydrothermal reaction process. The textile prepared by the method is deep in color, good in color fastness and washing fastness and high in antibacterial activity.

Owner:CHANGZHOU UNIV

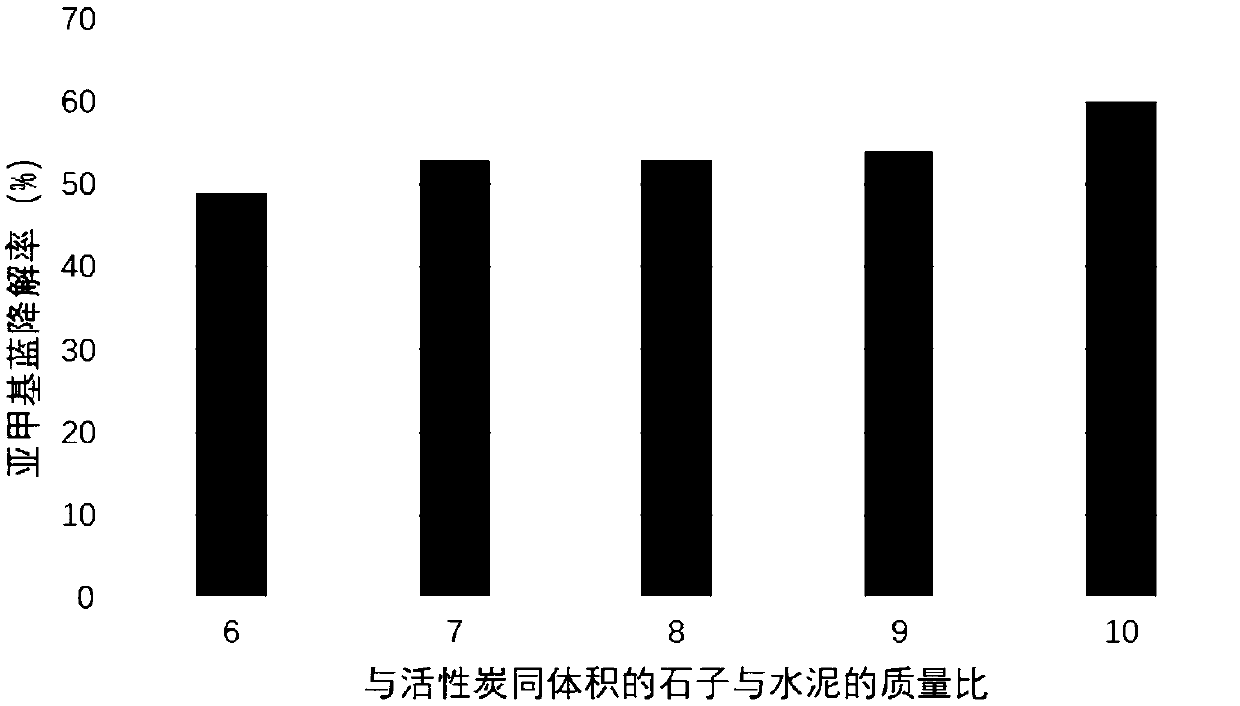

Hardened porous electrode of TiO2-C catalytic material as well as preparation method and application of hardened porous electrode

PendingCN109592751AGood chemical stabilityAvoid cases of softening and chippingWater treatment compoundsWater contaminantsActivated carbonPorous electrode

The invention relates to a hardened porous electrode of a TiO2-C catalytic material as well as a preparation method and application of the hardened porous electrode. The electrode comprises a TiO2-C catalytic material, a binder and activated carbon; the TiO2-C catalytic material is uniformly mixed with a binder, activated carbon is doped into the TiO2-C catalytic material to form a framework, andan electrode is internally provided with a pore structure. The TiO2-C composite catalytic material is combined with activated carbon, the catalytic material with the same surface area is reduced, andthe usage amount of the TiO2-C composite catalytic material is greatly reduced, so that the cost of the catalytic material is greatly reduced, meanwhile, the good catalytic performance is still kept,the recycle of an electrode material can also be realized, and the reusability is good.

Owner:SHANDONG UNIV

Preparation method of cuprous oxide antibacterial textile

ActiveCN110205797AIncrease loadImprove bonding fastnessBiochemical fibre treatmentUltrasonic/sonic fibre treatmentSolubilityCellulose fiber

The invention provides a preparation method of cuprous oxide antibacterial textile. The preparation method includes: pretreating cellulose fiber fabric with a low-temperature plasma, introducing an amino group to the surface of the fabric, and meanwhile, etching the surface of the cellulose fiber fabric; coating with a silk peptide solution; soaking and rolling with a copper acetate solution, reducing the water solubility of silk peptides and improving the binding fastness of silk peptides and copper ions to the textile by using -COOH and -HN2 coordination on copper ions and silk peptide molecules; performing in-situ formation of cuprous oxide on the textile to obtain the antibacterial textile. The textile is good in antibacterial resistance and resistant to washing.

Owner:CHANGZHOU UNIV

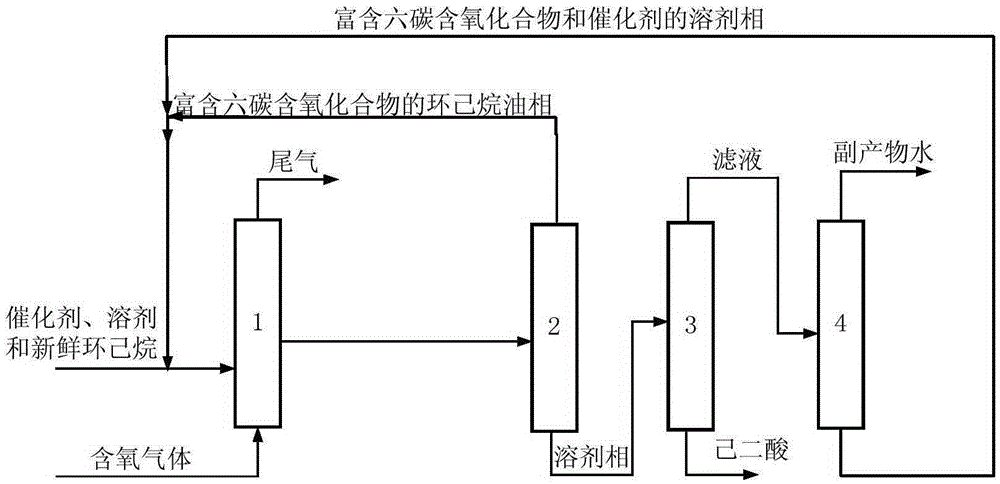

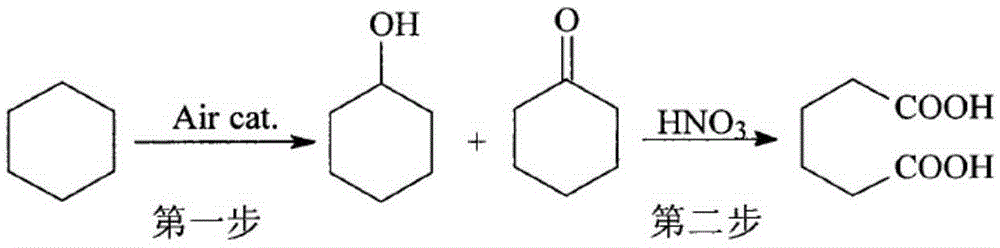

Process method of adipic acid by cyclohexane oxidation

ActiveCN105384622ALow costIncrease profitOrganic compound preparationCarboxylic preparation by oxidationAdipic acidOil phase

The invention discloses a process method of adipic acid by cyclohexane oxidation. The process method comprises the following steps: a step (a) of oxidation, namely introducing cyclohexane, solvent, catalyst and oxygen-containing gas continuously into an oxidation reactor to react, so as to obtain a oxidation reaction solution containing adipic acid and six-carbon oxygen-containing compound; a step (b) of liquid-liquid stratification, namely stratifying the oxidation reaction solution obtained in the step (a) at the temperature of 50-160 DEG C and the pressure of 0.1-1.2MPa, so that an upper oil-phase containing cyclohexane and six-carbon oxygen-containing compound and a lower solvent-phase containing adipic acid and six-carbon oxygen-containing compound are obtained; step (c) of separation of adipic acid, namely cooling, crystallizing and filtrating the lower solvent-phase obtained in the step (b), so that the filtrate and the adipic acid product are obtained. The process method has the advantages of simple technology, low cost, high efficiency, high raw material conversion rate and good target product selectivity; the conversion rate of the cyclohexane is higher than 99% and the selectivity of the adipic acid is higher than 91%.

Owner:山东有言环保科技有限公司

AlN-MgB2 particle-reinforced magnesium-base composite material and preparation method thereof

The invention relates to an AlN-MgB2 particle-reinforced magnesium-base composite material and a preparation method thereof. Nano-level AlN and submicron-level MgB2 which are generated in situ are uniformly distributed on a magnesium-base composite material matrix; the mass percentage of AlN is 5.0-30.0, and the size of AlN is 10nm-100nm; and the mass percentage of MgB2 is 2.0-20.0, and the size of MgB2 is 0.2-0.8 micron. The preparation method comprises the steps of preparing the raw materials in a proportion, carrying out low-speed ball milling on magnesium powder and aluminum powder for 12-48 hours, carrying out high-speed ball milling on the magnesium powder in an argon atmosphere, then carrying out high-speed ball milling on the aluminum powder, boron nitride powder and graphene for 0.5-8 hours, carrying out degassing and packaging on the materials obtained in two ball milling processes, pressing the materials into prefabricated bodies in a cold / hot isostatic press, and maintaining the temperature at 450-680 DEG C for 10-180 minutes by virtue of a vacuum sintering furnace, so as to obtain the AlN-MgB2 particle-reinforced magnesium-base composite material. The preparation method is safe and reliable.

Owner:SHANDONG UNIV

Process for in-situ polymerization preparation of nylon 6/epoxy resin/silicon dioxide nano composite materials

The invention discloses an in-situ polymerization method for preparation of nylon 6 / epoxide resin / silica dioxide nanocomposite, which consists of the following steps:a)preparing epoxide resin siloxane solution by graft reaction and hydrolytic reaction; b) before or in the aminocaprolactam cycle-open reaction, introducing the epoxide resin siloxane solution into the mediator of the said aminocaprolactam cycle-open reaction, simultaneously adding the water and the anti-oxidant; c) making the aminocaprolactam open ring and polymerize to prepare high-strength and super ductility nylon-6 / epoxide resin / silica dioxide nanocomposite. The invention makes the silicate react with the hydroxy group of the epoxide resin under the accelerating effect, then dissolvent, water and acid (or alkali) are added to hydrolyze. Because the silicasol surface graft and adsorb epoxide resin, the agglomeration of the earth silicon nanoparticles can be effectively avoided. On the other hand, because the epoxy radicals can react with the amidol and the carboxyl of the nylon-6 molecular chain to form partial interpenetration network architecture, accordingly the diphasic boundary action can be effectively improved. It has a good cooperating knife-bar with the nano earth silicon, so it can largely improve the bruise resistance of the materials as well as the hot strength of the composite, in which the hot strength has increased by 30 % compared with nylon-6 and the bruise resistance is 3-5 times of the nylon-6.

Owner:XIANGTAN UNIV

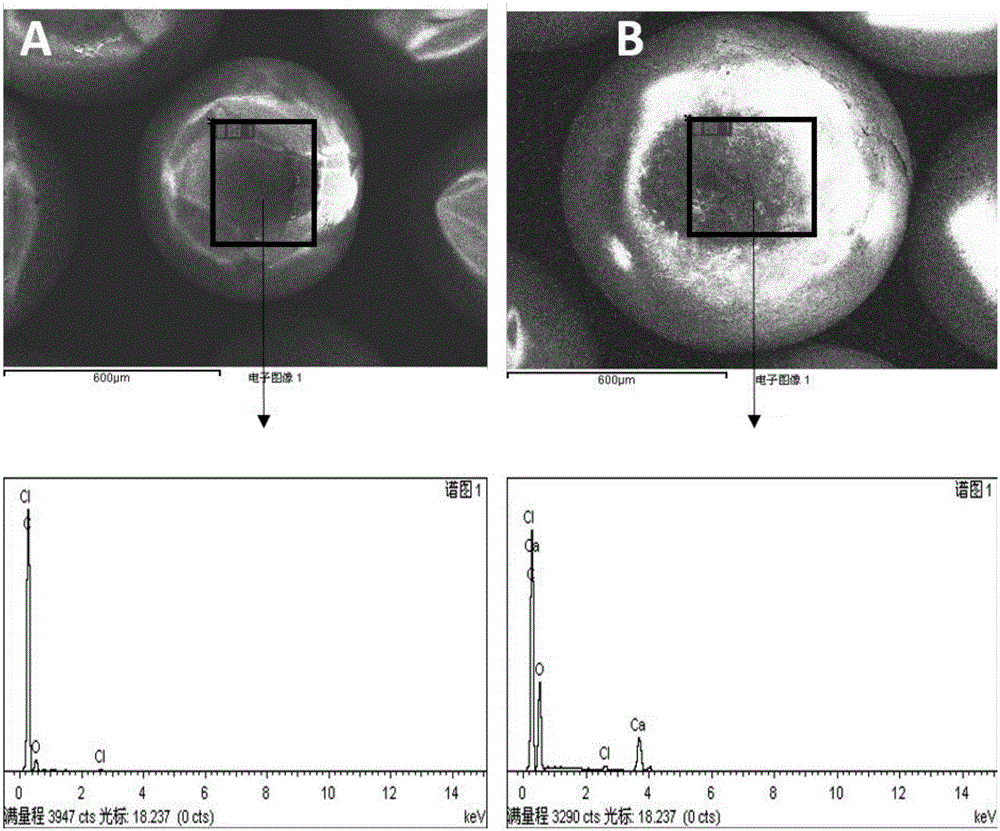

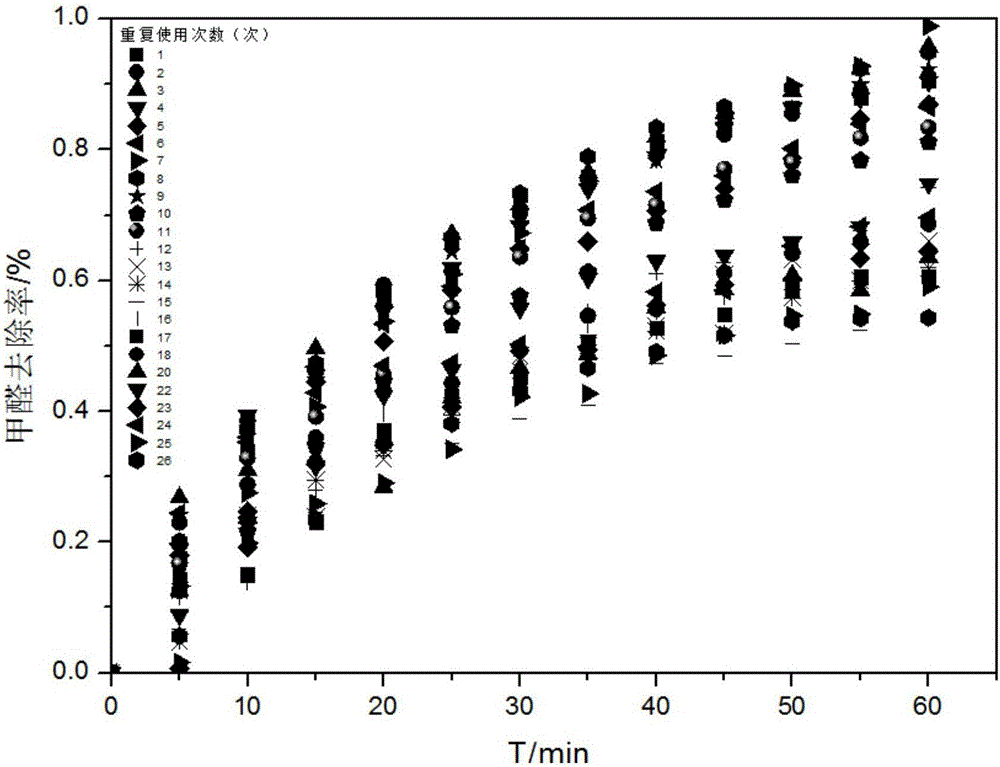

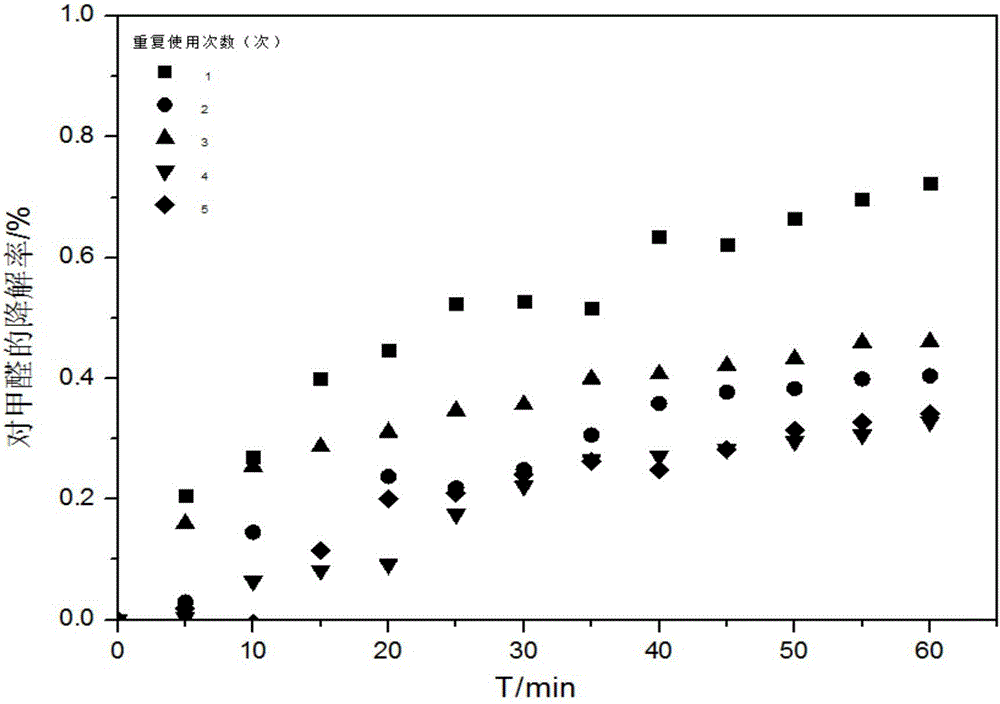

Nano calcium peroxide resin matrix composite for removing formaldehyde in air and preparation method of nano calcium peroxide resin matrix composite

InactiveCN106178923AReduce contact areaEasy reunionGas treatmentDispersed particle separationCalcium formateMass ratio

The invention discloses a nano calcium peroxide resin matrix composite for removing formaldehyde in air and a preparation method of the nano calcium peroxide resin matrix composite, and belongs to the field of indoor air pollution control. The nano calcium peroxide resin matrix composite comprises an oxidizing agent and a carrier, the carrier is macroporous adsorption type styrene resin SD300, the oxidizing agent is in-situ generated nanoscale CaO2 (nCaO2) on SD300, the reagent used for in-situ generation of nCaO2 comprises CaCl2, ammonia water and H2O2, and the mass ratios between resin and CaCl2, ammonia water and H2O2 are 1:(0.5-10), 1:(0.1-5) and 1:(5-15) respectively. The prepared nCaO2-SD300 composite has the advantages of large CaO2 supported quantity and difficulty in stripping off; formaldehyde can be converted into calcium formate, CO2 and H2O rapidly and enduringly at room temperature, secondary pollution is avoided, and safety is high; the composite is simple in production process, low in cost, convenient to use and wide in application range.

Owner:NANJING UNIV

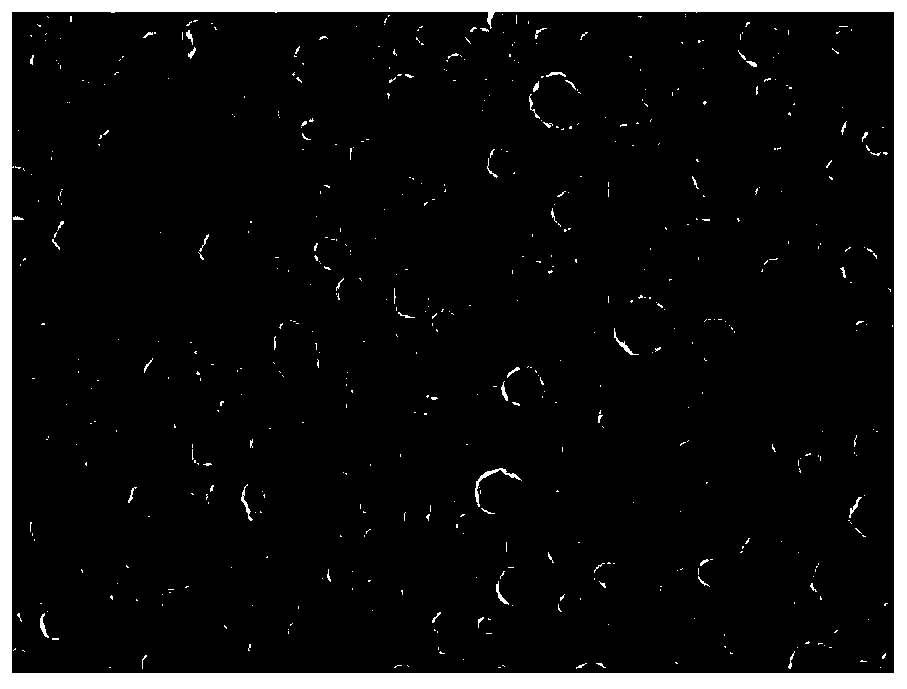

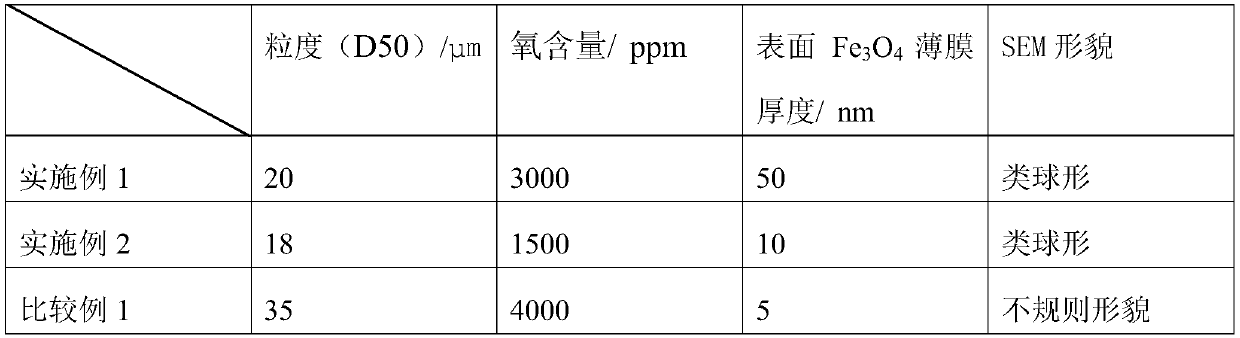

Fe-based soft magnetic composite material and preparation method thereof

InactiveCN109727745ASubtle hasSphericalInductances/transformers/magnets manufactureMagnetic materialsMetalCoating

The embodiment of the invention discloses an Fe-based soft magnetic composite material and a preparation method thereof. The method comprises the following steps of: performing plasma spheroidizationtreatment on Fe-based magnetic powder; obtaining spheroidal magnetic powder; and performing surface bluing treatment on the spheroidal magnetic powder to obtain a Fe-based soft magnetic composite material. According to the embodiment of the invention, the powder is subjected to plasma spheroidization treatment to obtain fine and spheroidal Fe-based soft magnetic alloy powder. The spheroidal Fe-based soft magnetic alloy powder is subjected to bluing treatment to perform in-situ generation of a magnetic insulating coating layer at the surface of the Fe-based magnetic powder to finally obtain thespheroidal Fe-based metal soft magnetic powder with the uniform and dense coating layer so as to achieve the purpose of improving the magnetic permeability and the saturation flux density of the magnetic powder cores.

Owner:BEIJING COMPO ADVANCED TECH

Yttrium-aluminum-garnet-containing spinel refractory raw material and preparation method thereof

The invention relates to a yttrium-aluminum-garnet-containing spinel refractory raw material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: uniformly mixing a raw material composed of 35-60 wt% of magnesite powder, 15-40 wt% of aluminum oxide powder, 20-30 wt% of spinel powder and 0.5-7 wt% of dry mixture with binder accounting for 3-7 wt% of the raw material, and molding by machining; drying the molded blank at 110 DEG C for 12-36 hours, and firing at 1450-1650 DEG C for 2-8 hours to obtain the yttrium-aluminum-garnet-containing spinel refractory raw material. The yttrium-aluminum-garnet-containing spinel refractory raw material has higher volume density and lower apparent porosity; and the refractory material prepared from the yttrium-aluminum-garnet-containing spinel refractory raw material can have excellent thermal shock stability and high-temperature mechanical properties, and especially have more obvious effect when being used as a high-efficiency spinel refractory material.

Owner:WUHAN UNIV OF SCI & TECH

Spinel-yttrium aluminum garnet fireproof material and preparation method thereof

InactiveCN103396145APromotes sintering densificationHigh bulk densityMetallic aluminumAluminium powder

The invention relates to a spinel-yttrium aluminum garnet fireproof material and a preparation method thereof. The preparation method comprises the following steps: firstly with 40-50wt% of magnesia particles, 10-30wt% of spinel particles, 10-20wt% of magnesia powder, 10-20wt% of alumina powder, 3-7wt% of spinel powder and 0.5-7wt% of dry blend material as raw materials, additionally adding a binding agent accounting for 3-7wt% of the raw material, stirring uniformly, and carrying out mechanical pressing; and then drying a moulded green body for 12-36 hours at 110 DEG C, then baking at 1450-1650 DEG C, preserving heat for 2-8 hours to obtain the spinel-yttrium aluminum garnet fireproof material. The preparation method of the dry blend material comprises the following steps: firstly with 20-40wt% of metal aluminum powder, 25-40wt% of aluminum nitride and 30-50wt% of compound containing yttrium as the raw materials, putting the raw materials into a ball mill for dry blending uniformly, and preparing the dry blend material. The prepared spinel-yttrium aluminum garnet fireproof material not only has higher refractoriness, refractoriness under load and high temperature strength, but also has good anti-erosion performance and thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

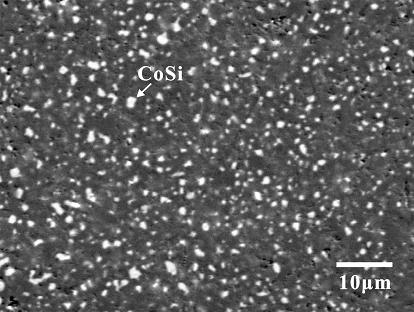

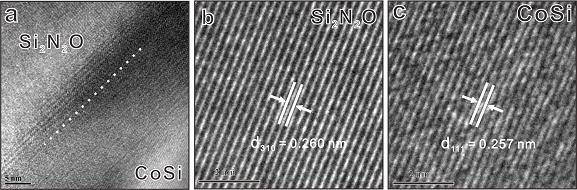

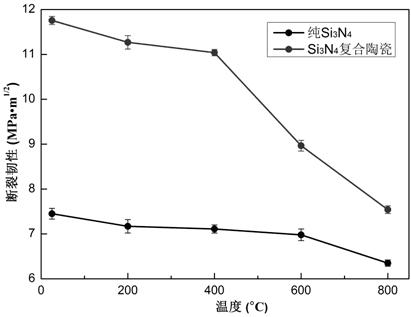

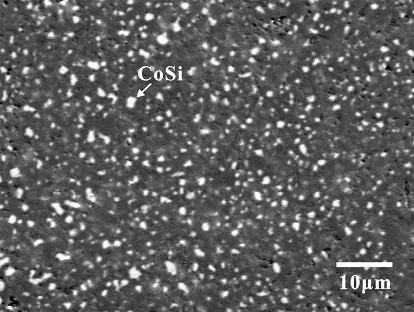

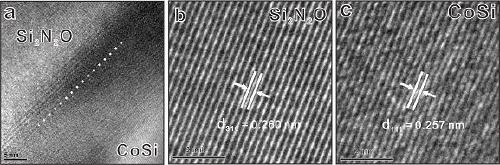

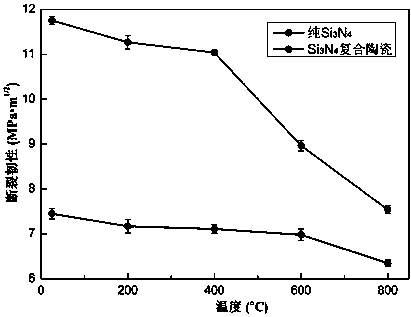

Preparation method of a tough and wear-resistant silicon nitride-based composite ceramic

The invention relates to a preparation method of a tough and wear-resistant silicon nitride-based composite ceramic, comprising the following steps: (1) by mass percentage, adding 80 to 95% of α-Si 3 N 4 powder and 5~20% C 4 h 6 CoO 4 • 4H 2 After the O aqueous solution is mixed, it is magnetically stirred under heating conditions until the solvent is completely evaporated to dryness to obtain a mixed powder; (2) the mixed powder is crushed through a 100-mesh sieve and put into a steel mold for pre-pressing to obtain a pre-pressed sample; (3) The pre-pressed sample is sintered at high temperature and high pressure, and then cooled with the furnace to obtain a blank; (4) After the blank is subjected to surface polishing treatment, a silicon nitride-based composite ceramic is obtained. The process of the invention is simple and controllable, the production efficiency is high, the powder does not need special treatment, and is suitable for mass production. The prepared finished product has excellent high-temperature toughness and anti-wear performance, and greatly prolongs the service life of ceramic parts in a high-temperature environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Collagen fiber modification method

The invention discloses a collagen fiber modification method. The collagen fiber modification method comprises weighing 2-5 parts by weight of collagen fibers, adding the collagen fibers into 200 parts by weight of a barium chloride solution with a concentration of 0.5-2%, carrying out stirring for 4h, carrying out standing for 12h, slowly and dropwisely adding 100 parts by weight of a sodium sulfate or potassium sulfate solution with a concentration of 3% into the mixture under the condition of stirring and a dropwise addition rate of 0.5 drops per second, then carrying out standing for 5min, carrying out suction filtration, carrying out water washing, and carrying out vacuum drying at a temperature of 60-80 DEG C fort 5-8h to obtain the collagen fiber / barium sulfate hybrid material. The modified collagen fibers have low water absorption, high mechanical strength and high heat stability, has the characteristics of flame retardation and antibiosis and greatly widens an application field of collagen fibers. The collagen fiber modification method can be operated simply, realizes a reaction at a normal temperature under normal pressure, has a low equipment requirement and a low raw material cost and is suitable for large scale production.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of tough wear-resistant silicon nitride based composite ceramic

The invention relates to a preparation method of a tough wear-resistant silicon nitride based composite ceramic. The preparation method comprises following steps: (1) mixing following components in percentage by weight: 80 to 95% of alpha-Si3N4 powder and 5 to 20% of a C4H6CoO4.4H2O water solution, and stirring the solution by a magnetic force under a heating condition until the solvent is totally evaporated to obtain mixed powder; (2) crushing the mixed powder, sieving the mixed powder by a 100-mesh sieve, filling the mixed powder into a steel die, and pre-pressing the mixed powder to obtain a pre-pressed sample; (3) sintering the pre-pressed sample at a high temperature under a high pressure, and cooling the sample in the furnace to obtain a blank; and (4) polishing the surface of the blank to obtain silicon nitride based composite ceramic. The technology is simple and controllable, the production efficiency is high, the powder does not need any special treatment, and the preparation method is suitable for massive production. The high temperature toughness and wear resistant performance of the prepared finished product are excellent. The service life of ceramic parts in a high temperature environment is largely prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A low-temperature and high-pressure control device for X-ray CT equipment to observe hydrate formation and decomposition characteristics

ActiveCN105424734BMeet the conditions for generationPrecise temperature controlProcess control/regulationPressure vessels for chemical processDecompositionX-ray

Owner:DALIAN UNIV OF TECH

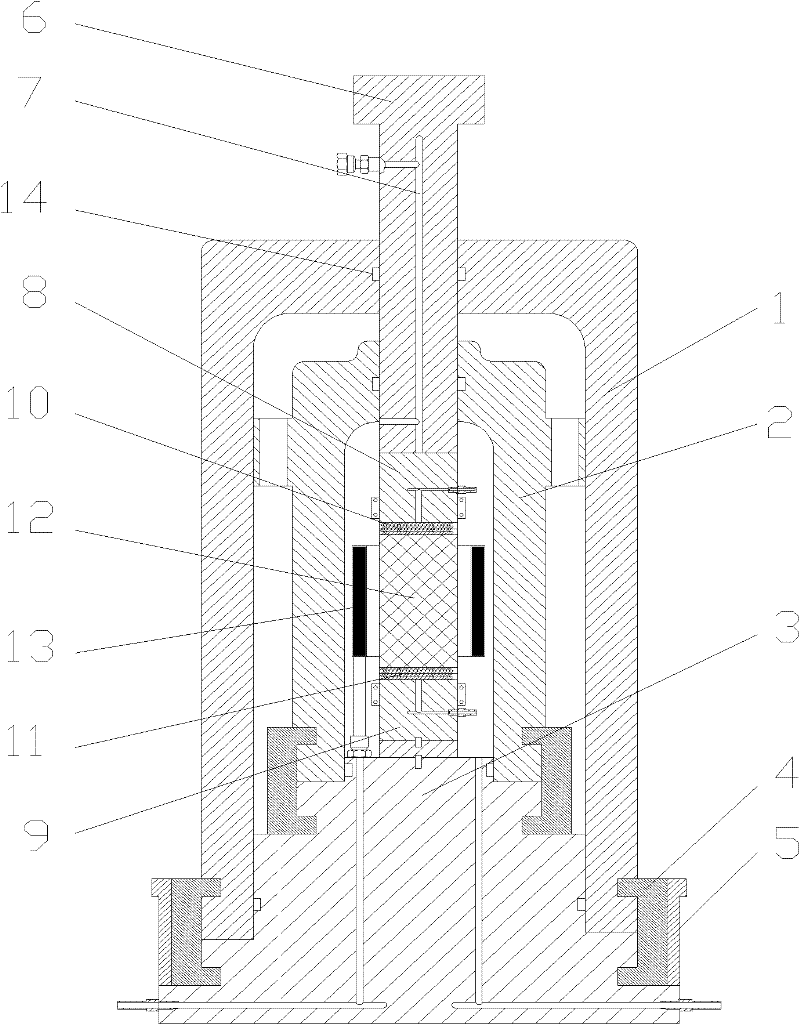

Generation device and observation method for interface nanobubbles

ActiveCN113184699AIn situ generationGuaranteed reliabilityPreparing sample for investigationGaseous fuelsObservational methodEngineering

The invention discloses a generation device and an observation method for interface nanobubbles.The device comprises a reaction kettle composed of a kettle body and a kettle cover, a base is arranged in the reaction kettle, a liquid tank is arranged on the base, a placement bottom sheet is arranged in the liquid tank, and a bubble forming substrate is arranged on the placement bottom sheet. By adopting the device, the detachable liquid tank is arranged in the reaction kettle, and then the bubble forming substrate is arranged in the liquid tank, so that in-situ generation of the interface nanobubbles is realized, and compared with a generation mode of transferring decomposition liquid to a hydrophobic substrate, a bubble nucleation mode is consistent with a process of actually decomposing natural gas hydrate to form the interface nanobubbles, the mode is close to objective conditions of natural gas hydrate depressurization decomposition and interface nanobubble formation in an actual reservoir, meanwhile, the influence of substrate properties on experimental results is reduced, and the reliability of observation results is ensured.

Owner:CENT SOUTH UNIV

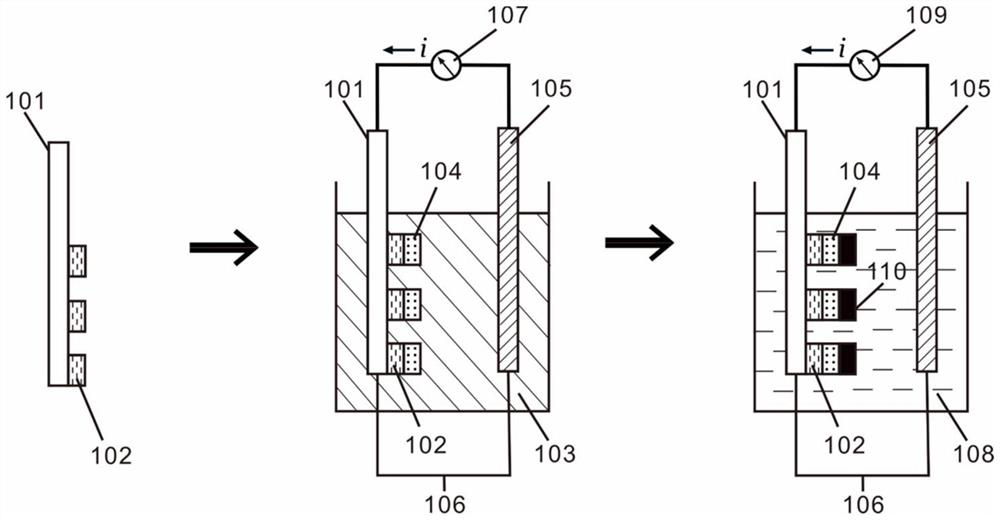

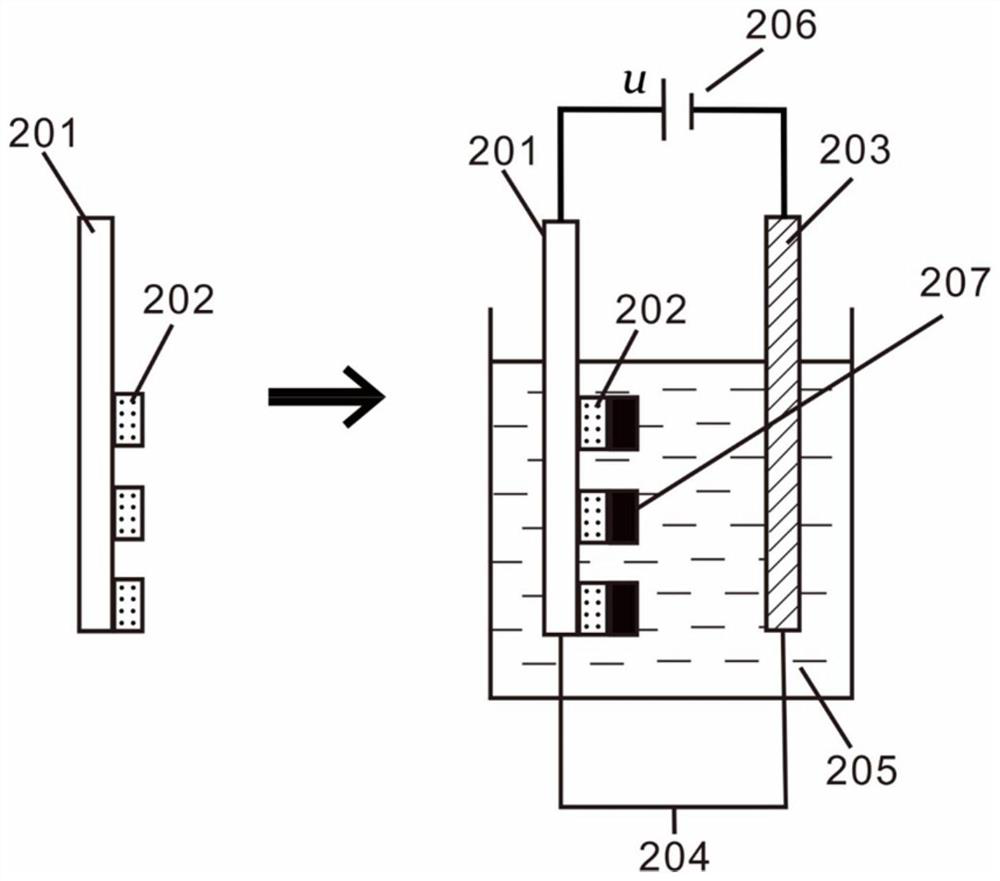

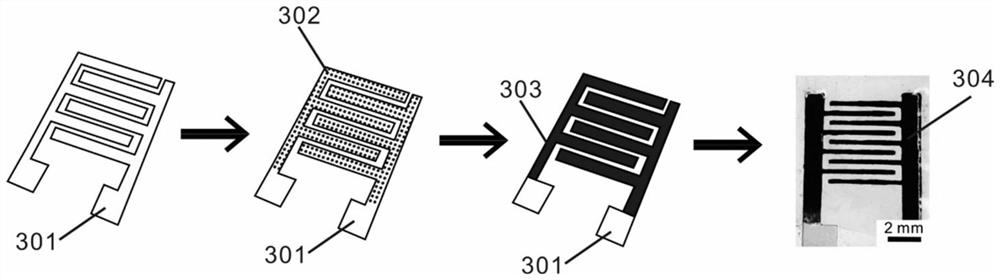

A kind of preparation method and application of porous mxene hydrogel based on electrogel process

ActiveCN112981497BIn situ generationPatterned realizationHybrid capacitor electrolytesElectrophoretic coatingsEngineeringElectrochemistry

The invention discloses a preparation method and application of a porous MXene hydrogel based on an electrogelling process. The present invention utilizes the electrochemical oxidation process of sacrificial metals, so that MXene can directly and controllably form a hydrogel with porous microstructure on a target substrate. The preparation method is as follows: firstly, a sacrificial metal layer is formed on a target substrate, combined with a standard electrode to form an electrochemical system and placed in an MXene dispersion liquid, and then an electric field is applied to the electrochemical system to complete the electrogelation process. The spatial controllability and precision controllability of this preparation method make it suitable for patterning and controllable modification of porous MXene hydrogels for various electronic devices, which solves the limitation that current porous MXene hydrogels cannot be patterned. The further development of MXene hydrogels in the field of electronic devices provides the possibility.

Owner:ZHEJIANG UNIV

aln and mgb 2 Particle reinforced magnesium matrix composite material and preparation method thereof

ActiveCN109182856BReduce generationHigh degree of homogenizationMagnesium matrix compositeArgon atmosphere

The invention relates to an AlN-MgB2 particle-reinforced magnesium-base composite material and a preparation method thereof. Nano-level AlN and submicron-level MgB2 which are generated in situ are uniformly distributed on a magnesium-base composite material matrix; the mass percentage of AlN is 5.0-30.0, and the size of AlN is 10nm-100nm; and the mass percentage of MgB2 is 2.0-20.0, and the size of MgB2 is 0.2-0.8 micron. The preparation method comprises the steps of preparing the raw materials in a proportion, carrying out low-speed ball milling on magnesium powder and aluminum powder for 12-48 hours, carrying out high-speed ball milling on the magnesium powder in an argon atmosphere, then carrying out high-speed ball milling on the aluminum powder, boron nitride powder and graphene for 0.5-8 hours, carrying out degassing and packaging on the materials obtained in two ball milling processes, pressing the materials into prefabricated bodies in a cold / hot isostatic press, and maintaining the temperature at 450-680 DEG C for 10-180 minutes by virtue of a vacuum sintering furnace, so as to obtain the AlN-MgB2 particle-reinforced magnesium-base composite material. The preparation method is safe and reliable.

Owner:SHANDONG UNIV

A kind of modification method of collagen fiber

The invention discloses a collagen fiber modification method. The collagen fiber modification method comprises weighing 2-5 parts by weight of collagen fibers, adding the collagen fibers into 200 parts by weight of a barium chloride solution with a concentration of 0.5-2%, carrying out stirring for 4h, carrying out standing for 12h, slowly and dropwisely adding 100 parts by weight of a sodium sulfate or potassium sulfate solution with a concentration of 3% into the mixture under the condition of stirring and a dropwise addition rate of 0.5 drops per second, then carrying out standing for 5min, carrying out suction filtration, carrying out water washing, and carrying out vacuum drying at a temperature of 60-80 DEG C fort 5-8h to obtain the collagen fiber / barium sulfate hybrid material. The modified collagen fibers have low water absorption, high mechanical strength and high heat stability, has the characteristics of flame retardation and antibiosis and greatly widens an application field of collagen fibers. The collagen fiber modification method can be operated simply, realizes a reaction at a normal temperature under normal pressure, has a low equipment requirement and a low raw material cost and is suitable for large scale production.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of collagen fiber/silver chloride hybrid material

ActiveCN105386290ALow water absorptionHigh mechanical strengthHeat resistant fibresAnimal fibresFiberRoom temperature

The present invention discloses a preparation method of a collagen fiber / silver chloride hybrid material. The method is mainly as follows: weighing 2-5 parts by weight of collagen fiber, adding into 200 parts by weight of a silver nitrate solution with the concentration of 2.5% to 4%, stirring for 4 hours, then standing for 12 hours; while stirring, slowly adding dropwise 100 parts by weight of a sodium chloride solution with the concentration of 3.5%, wherein the dropping rate of the sodium chloride solution is controlled in 0.5 drop / sec; after the dropwise addition is complete, standing for 5 minutes, then filtering by suction, and washing with water; and finally, drying in vacuum for 5 to 8 hours at a temperature of 60-80 DEG C to obtain the collagen fiber / silver chloride hybrid material. Through the method, the defects of being high in water absorption, hygroscopic, low in thermal stability, perishable, low in mechanical strength and the like of the collagen fiber can be improved, the antibacterial properties of the material can be greatly enhanced, the scope of application in industry can be broadened; the technology is simple, the reaction is carried out at room temperature in ordinary pressure, device requirements are not critical, and the method is suitable for mass production.

Owner:HUNAN UNIV OF SCI & TECH

A kind of preparation method of cuprous oxide antibacterial textile

ActiveCN110205797BIncrease roughnessIncrease loadBiochemical fibre treatmentUltrasonic/sonic fibre treatmentCellulose fiberLow temperature plasma

Owner:CHANGZHOU UNIV

Method for preparing graphene-loaded platinum nano catalyst

InactiveCN101966453BUniform particle sizeSolve the technical problem of reunionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystPlatinum

Owner:NANCHANG UNIV

A fenton method for efficiently degrading organic pollutants in water

ActiveCN107686156BIn situ utilizationIncrease profitWater/sewage treatment by oxidationCarbon nanotubeOxygen

The invention discloses a Fenton method for efficiently degrading organic pollutants in water. The method includes the steps: adding magnesium-carbon nano-tube compound particles and iron vitriol intowaste water; stirring mixture under the condition of oxygen inlet; controlling a pH (potential of hydrogen) value of solution to reach acidity; adjusting the pH value of the solution to reach 6-9 after reaction; performing solid-liquid separation, and taking liquid supernatant as treatment outlet water. According to the method, hydrogen peroxide of generated by reaction among magnesium-carbon nano-tubes and oxygen and added ferrous ions act to generate strongly oxidizing species such as -OH, and the organic pollutants in the water are completely mineralized into inorganic substances and removed. The method is wide in raw material source, low in price and cost, simple in process, convenient to operate, mild in reaction condition and applicable to large-scale industrial production, and theorganic pollutants are efficiently degraded.

Owner:HAO WEI ENVIRONMENTAL TECH NANTONG CO LTD

Coating mechanism, slit coating device and film preparation method

ActiveCN105880104BEasy to moveReduce movementLiquid surface applicatorsFinal product manufactureStructural engineeringLithium-ion battery

The invention discloses a coating mechanism, a slit coating device and a film forming method. The coating mechanism comprises: a base, a support platform, a movable support part and a fluid storage tank with nozzles; the support platform and the movable support part Both are fixed on the base; the fluid storage tank is fixed on the movable supporting part to move relative to the pallet driven by the movable supporting part; during the movement of the fluid storage tank, the fluid material in the fluid storage tank passes through the nozzle Apply to the sample to be coated fixed on the pallet to form a film directly. The mechanism, device and method provided by the invention are used to solve the technical problems of high cost and poor film-forming quality existing in the gel polymer lithium ion battery film-forming device and method in the prior art. A slit coating device with low cost and uniform coating is provided.

Owner:山西能际智能科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com