A kind of preparation method of cuprous oxide antibacterial textile

An antibacterial textile and cuprous oxide technology, applied in the textile field, can solve the problems of poor bonding fastness between cuprous oxide and textiles, and the antibacterial textiles are not washable, and achieve the effect of improving the bonding fastness and increasing the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

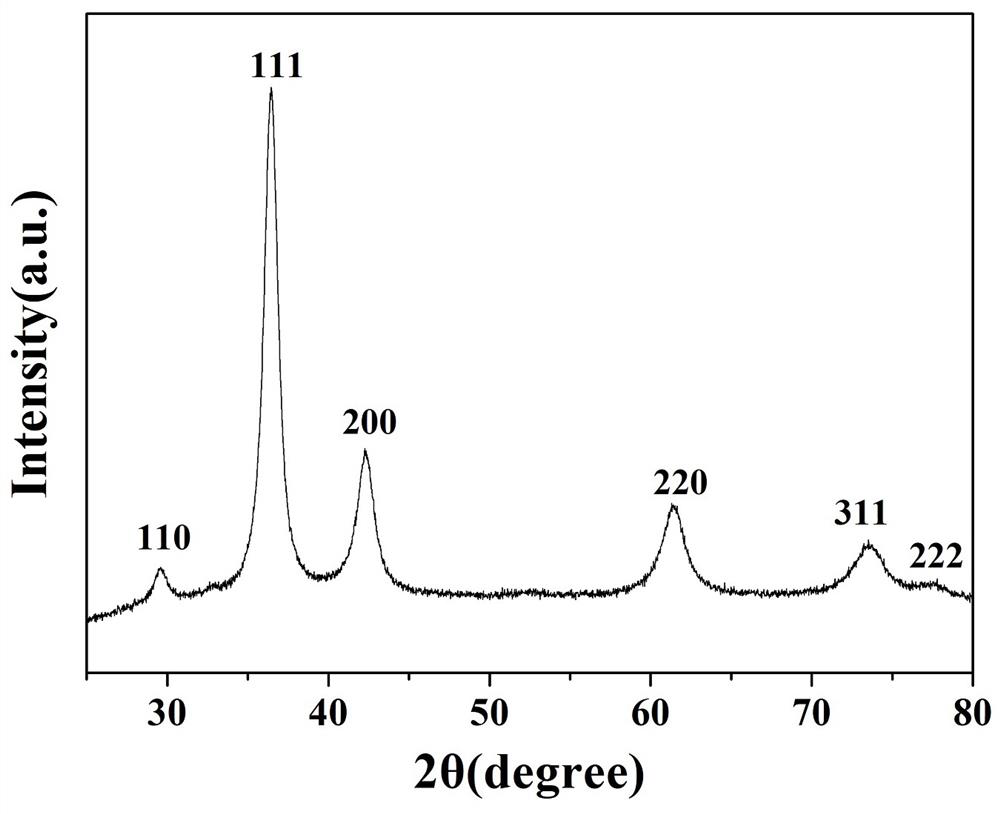

Image

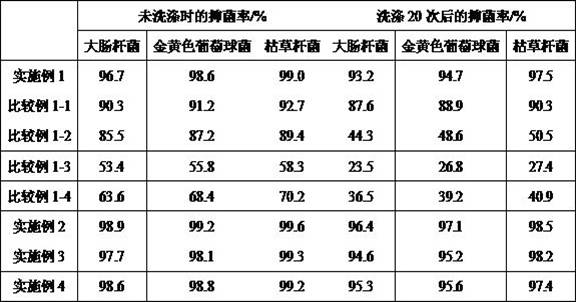

Examples

Embodiment 1

[0021] (1) Place the cellulose fiber fabric in the shelf in the DT-01 low-temperature plasma treatment instrument produced by Suzhou Ops Plasma Technology Co., Ltd., open the vacuum pump, when the vacuum in the reaction cavity is 5Pa, Nitrogen into the plasma cavity, regulating gas flow to the vacuum in the reaction cavity of 20 Pa; stabilizing 3 min after glow discharge, discharge power 50W, discharge time 15 min, after discharging, the fabric is taken out and then immediately enter the next operation;

[0022] (2) The molecular weight 500-5000 is sold in the deionized water, and the morally fraction of the mass fraction is 1%; then the cellulose fiber fabric treated by step (1) is then immersed in the thorns solution. After 30 minutes of treatment at 30 ° C, after the treatment, it was dried at 80 ° C, then at 130 ° C for 5 min, and finally after washing 3 times with deionized water, 60 ° C drying, spare;

[0023] (3) Copper copper with acetate in deionized water, formulated a c...

Embodiment 2

[0040] (1) Place the cellulose fiber fabric in the shelf in the DT-01 low-temperature plasma treatment instrument produced by Suzhou Ops Plasma Technology Co., Ltd., open the vacuum pump, when the vacuum in the reaction cavity is 5Pa, Nitrogen to the plasma cavity, regulating gas flow to the vacuum in the reaction chamber is 50 Pa; stabilizing 3 min after glow discharge, discharge power 150W, discharge time 5 min, after discharge, immediately remove the next step after removal;

[0041] (2) The molecular weight is sold in a mine-based peptide powder of 500-5000, dissolved in deionized water, and formulates a thorns of mass fraction of 10%; then the cellulose fiber fabric treated by step (1) is subjected to a thorns solution solution. In 50 ° C for 30 min, after the treatment, it was dried at 85 ° C, then baked at 145 ° C for 3 min, and finally washed 5 times with deionized water, dried at 80 ° C, spare;

[0042] (3) Cop copper is dissolved in deionized water, formulated a mass con...

Embodiment 3

[0044] (1) Place the cellulose fiber fabric in the shelf in the DT-01 low-temperature plasma treatment instrument produced by Suzhou Ops Plasma Technology Co., Ltd., open the vacuum pump, when the vacuum in the reaction cavity is 5Pa, Nitrogen to the plasma cavity, regulating gas flow to the vacuum in the reaction cavity of 40 Pa; stabilizing 4 min after glow discharge, discharge power 100W, discharge time 10 min, after discharging, immediately remove the next step after removal;

[0045] (2) The molecular weight is sold in the commercially available silk peptide powder in the mid-deionized water, and the mass fraction is 5%; then the cellulose fiber fabric treated by step (1) is then immersed in a thorns solution solution. In 40 ° C for 40 min, after the end of treatment, it was dried at 82 ° C, then at 135 ° C for 4 min, and finally washed 4 times with deionized water, 70 ° C drying, spare;

[0046] (3) Copper copper acetate in deionized water, formulated a mass concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com