Hardened porous electrode of TiO2-C catalytic material as well as preparation method and application of hardened porous electrode

A technology of porous electrodes and catalytic materials, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of weak acid and alkali resistance, fragility, and low porosity of electrodes, and achieve Increase the specific surface area, enhance the strength, and enhance the effect of acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of TiO 2 The preparation method of -C catalytic material hardened porous electrode, comprises steps as follows:

[0051] (1) TiO 2 Preparation of -C catalytic material

[0052] Add 15mL of butyl titanate to 45mL of absolute ethanol, stir magnetically for 10min, add 5g of pretreated graphite powder to make solution A; add 6mL of deionized water and 1.2mL of nitric acid to 45mL of absolute ethanol to make solution B solution; add solution B to solution A drop by drop until the reaction system becomes an immobile gel system to obtain a gel; place the gel in a blast dryer and dry at a constant temperature of 105°C for 8 hours until the organic solvent is completely Volatilize to get a gray-black powder, which is ground into an ultrafine powder; put the powder in a muffle furnace and calcinate at 450°C for two hours to get TiO 2 -C catalytic material;

[0053] (2) Preparation of powder mixture

[0054] 39.8g of cement, 31.84g of TiO 2 -C catalytic material (mass...

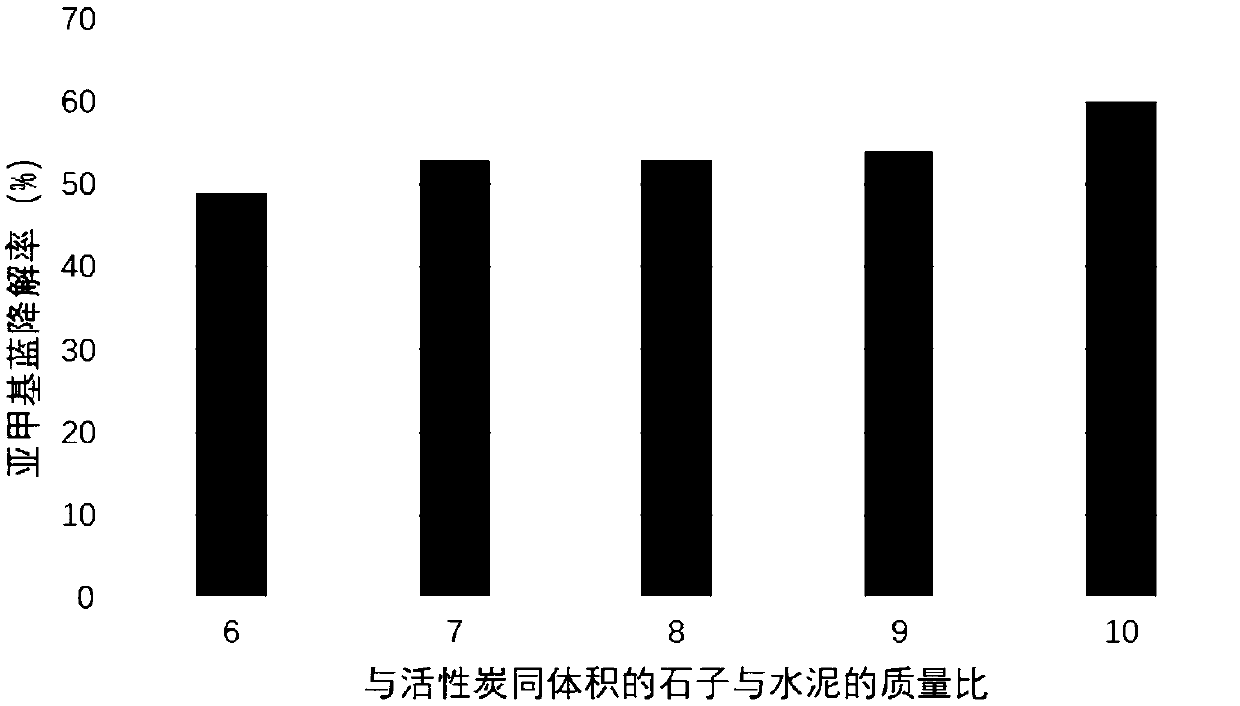

Embodiment 2

[0058] TiO as described in Example 1 2 -C Catalytic material hardened porous electrode preparation method, the difference is:

[0059] The amount of activated carbon added in step (3) is 358.2g (the mass ratio of cement to cement is 9:1) equal to the volume of stones, and other conditions are the same.

Embodiment 3

[0061] TiO as described in Example 1 2 -C Catalytic material hardened porous electrode preparation method, the difference is:

[0062] The amount of activated carbon added in step (3) is 318.4g (the mass ratio to cement is 8:1) equal to the volume of stones, and other conditions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com