Method for preparing graphene-loaded platinum nano catalyst

A graphene and catalyst technology, which is applied in the field of preparation of graphene-supported platinum nano-catalysts, can solve the problems of water repellency and difficult loading process, and achieve the effects of improving utilization rate, improving anti-poisoning ability, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022](1) Graphene (GNS) is based on the improved Hummer's merthod (Li, D.; Muller, M. B.; Gilje, S.; Kaner, R. B.; Wallace, G. G. Nat. Nanotechnol. 2008, 3, 101-105; Hummers, W. S.; Offeman, R. E. J Am Chem Soc. 1958, 80, 1339; Cote, L. J.; Kim, F.; Huang, J. X. J Am Chem Soc. 2009, 131, 1043-1049.) Preparation: 1.0 g graphite and 1.0 g NaNO 3 Add to 46 mL H 2 SO 4 (98%) solution, mechanically stirred in ice bath for 20 minutes, slowly added 6.0 g KMnO 4 and 80 mL of double-distilled water, the temperature was controlled at 90 ± 5 °C, and after stirring for 30 minutes, 200 mL of double-distilled water was added to the reaction system and 6 mL of 30 wt % H 2 o 2 The solution was filtered while it was hot, washed with double distilled water until the filtrate was neutral, and the obtained product was dispersed in 500 mL of double distilled water, and ultrasonicated for 2 hours to obtain uniformly dispersed single-sheet graphene.

[0023] (2) Preparation of PDDA functional...

Embodiment 2

[0027] (1) For the preparation method of GNS and PDDA-GNS, refer to steps (1) and (2) of Example 1.

[0028] (2) Preparation of Pt / GNS catalysts with different Pt loadings: Disperse PDDA-GNS (10.8 mg) in 30 mL double-distilled water, sonicate for 30 min, and then add 10.8, 16.2, 27.0 mg, 37.8, 64.0, 91.8 mg, respectively mg H 2 PtCl 6 , continue to sonicate for 30 min, then slowly add NaBH under the condition of magnetic stirring 4 (0.05 M) solution, after magnetic stirring for 2 h, the obtained product was centrifuged and washed with double distilled water, and the product was vacuum-dried for 48 h at 40 °C to obtain the mass fraction of Pt / GNS catalyst Pt NPs respectively 30 wt %, 40 wt %, 50 wt %, 60 wt %, 72 wt %, 78 wt %.

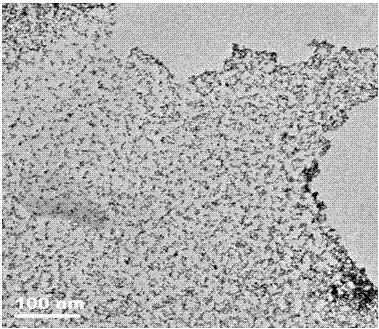

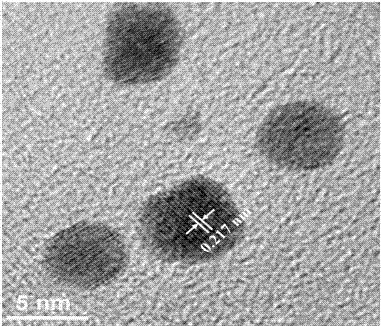

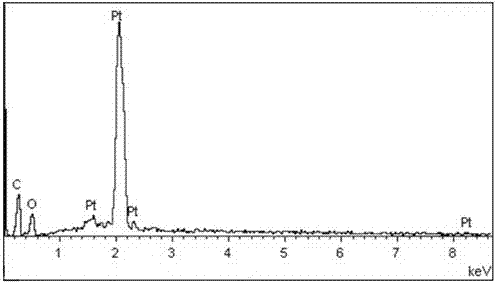

[0029] The transmission electron microscope photo of the prepared Pt / GNS nanocomposite is shown in Figure 5 ,Depend on Figure 5 It can be seen that the particle size of Pt NPs does not change significantly with the increase of the feed ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com