Triaxial test device for in-situ generation and decomposition of natural gas hydrate

A triaxial test and in-situ generation technology, applied in the method of using atmospheric pressure to chemically change substances, using stable tension/pressure to test material strength, chemical/physical processes, etc., can solve problems that cannot be simulated well Problems such as the cementation state of the seabed hydrate sediment, the low hydrate saturation of the sample, and the inability to restore the formation process of the seabed hydrate have achieved the effect of meeting the requirements of high-precision experiments and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

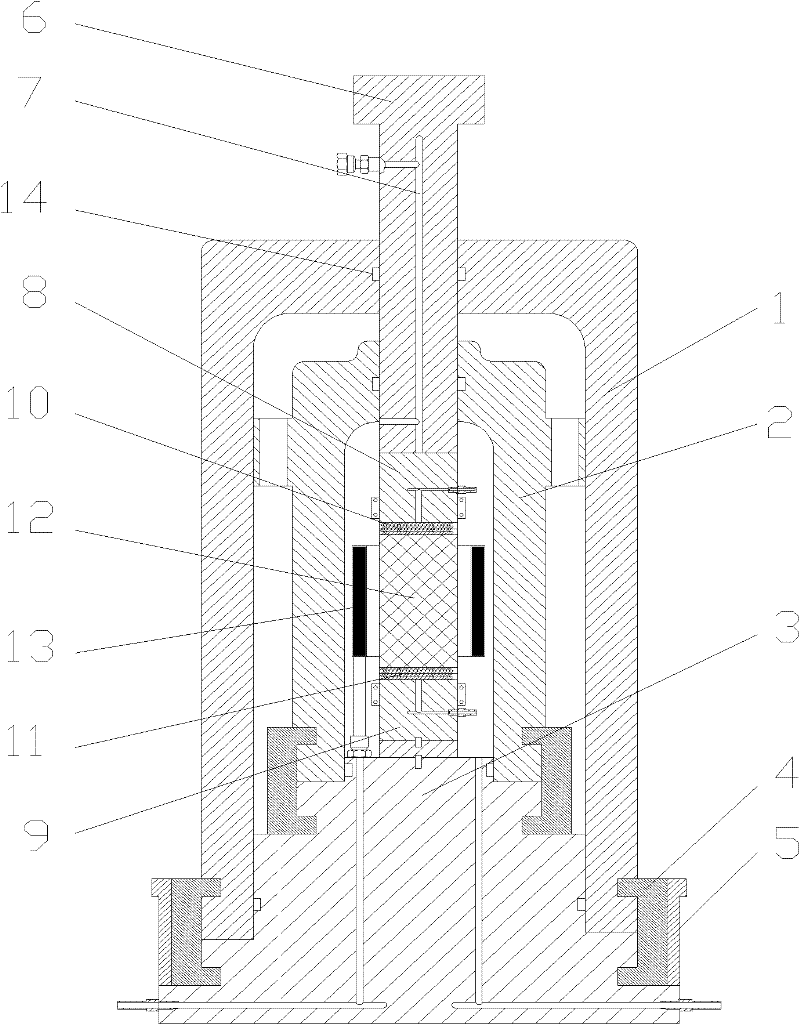

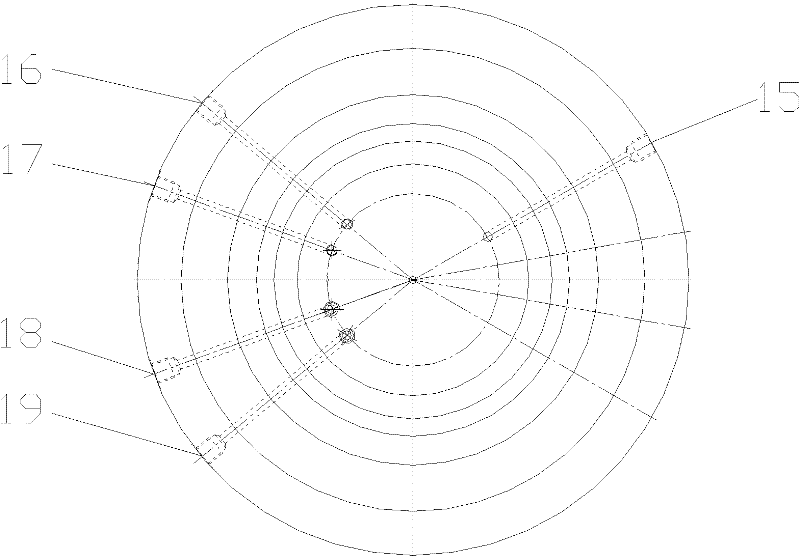

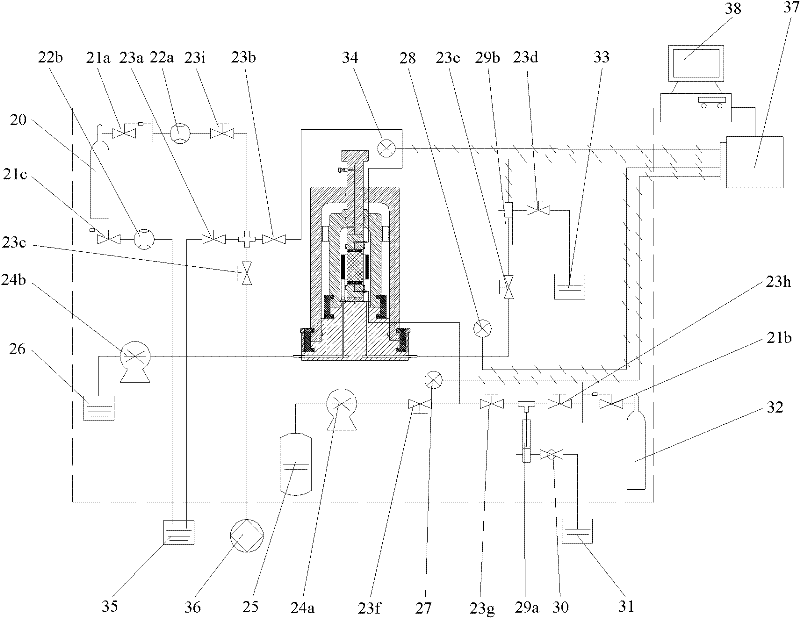

[0027] The structure diagram of the triaxial test device for the in-situ generation and decomposition of natural gas hydrate provided by the present invention is as follows figure 1 , figure 2 As shown, the flow chart of using the device for testing is as follows image 3 As shown, the marks in the figure are as follows: 1 outer cover tube, 2 inner cover tube, 3 base, 4 snap ring, 5 snap ring fixing sleeve, 6 piston, 7 exhaust hole, 8 upper pressure pad, 9 lower pressure pad, 10 Upper seepage plate, 11 Lower seepage plate, 12 Natural gas hydrate deposit sample, 13 Heat exchanger, 14 Seal ring, 15 Hydraulic oil inlet and outlet holes, 16 Water inlet hole, 17 Air inlet hole, 18 Refrigerant circulating fluid inlet hole , 19 refrigerant circulating liquid outlet, 20 methane cylinder, 21a, 21b, 21c bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com