A kind of preparation method of natural indigo dyed antibacterial textile

A technology of antibacterial textiles and natural indigo, applied in the textile field, can solve the problems of fibers having no affinity and not conforming to ecological environment protection, etc., and achieve the effect of increasing the adhesion amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

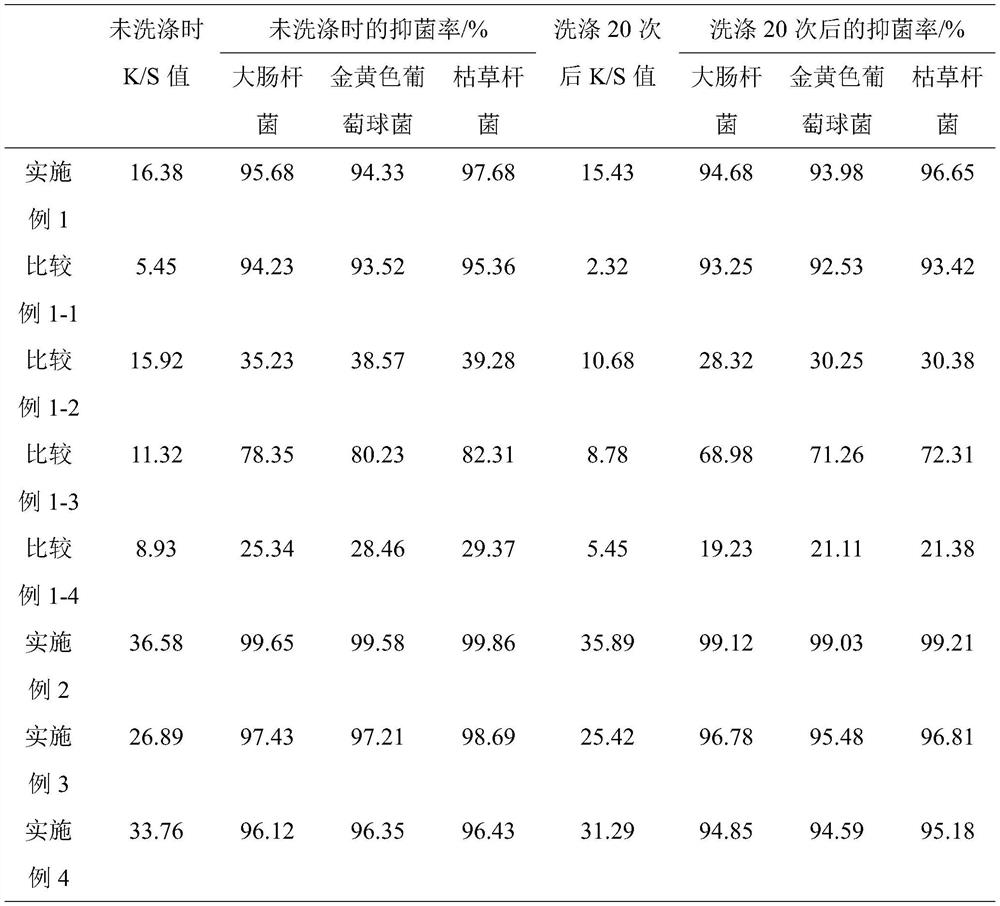

Examples

Embodiment 1

[0021] (1) Preparation of the mass fraction of 1% aqueous solution of natural indigo dyes, natural indigo was added accounting 20% by mass of polyvinylpyrrolidone, after complete dissolution, a mechanical stirrer / min. Stirring speed 400r 25min, to obtain pre-dispersion; and 15mm diameter probe tip inserted into a pre-alloy ultrasonic dispersion, ultrasonic dispersion 20min at 100W power, natural indigo dye to prepare a suspension solution;

[0022] (2) mixing desizing, scouring, bleaching of cotton fabrics are immersed in natural indigo dye suspension solution, after 30 seconds calender roll, two rolls two dipping, rolling over 80%, 60 deg.] C after drying 10min, padding concentration of 8g / L of an aqueous solution of copper acetate, two two dip rolling, rolling rate of more than 80%, 60 ℃ vacuum dried for later use;

[0023] (3) In the autoclave having a Teflon and the preparation concentration 5g / L glucose and the concentration of 2g / L of a sodium hydroxide solution; in ...

Embodiment 2

[0041] (1) The preparation mass fraction is 5% natural indigo-dyed water solution, and then adding polyvinylpyrrolidone comprising the natural indigo dye. After it is completely dissolved, the mechanical mixer is stirred at 600 r / min at a rate of 15 min to obtain a pre-dispersion liquid; Tip diameter 15mm titanium alloy ultrasonic probe inserted into a pre-dispersion solution, ultrasonic dispersion of 10 min at 200W power, and produced a natural indigo dye suspension solution;

[0042] (2) Immerse it, boiled, bleached, is immersed in a natural indigo dye suspension solution, and the roll roll is rolled after 30 seconds, the two immersion two rolling, the yield is 100%, 80 ° C for 5 minutes, soak The rolling mass concentration is 16 g / L, a copper sulfate solution, two immersion two rolling, and the grease rate of 100%, 80 ° C, vacuum drying, and spare;

[0043] (3) In the high pressure reactor having a polytetrafluoroethylene, a mixture of sodium hydroxide and a mass concentrat...

Embodiment 3

[0045] (1) The preparation mass fraction is 2.5% natural indigo-dyed water solution, and then the polyvinylpyrrolidone comprising natural indigo dye is added. After it is completely dissolved, the mechanical mixer is stirred at 500 r / min at a rate of 20 min to obtain a pre-dispersion liquid; Tip diameter 15mm titanium alloy ultrasonic probe inserted into the pre-dispersion, ultrasonic dispersion at 150 W power, and produced a natural indigo dye suspension solution;

[0046] (2) Immerse it, boiled, bleached viscose fabric into the natural indigo dye suspension solution, after 30 seconds, roll rolling, two immersion two rolling, 90%, 70 ° C for 8 minutes, The copper solution of the immersion quality is 12 g / L, two immersion two rolling, 90% yield rate, 70 ° C, vacuum drying, spare;

[0047] (3) In the high pressure reactor having a polytetrafluoroethylene, a mixture of sodium hydroxide having a mass concentration of 8 g / L is prepared; the fabric treated by step (2) is put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com