Nano calcium peroxide resin matrix composite for removing formaldehyde in air and preparation method of nano calcium peroxide resin matrix composite

A technology of calcium peroxide and composite materials, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problem of reducing the reaction rate and removal efficiency of pollutant removal, secondary pollution of difficult-to-remove pollutants, and reduction of pollutant exposure Area and other issues, to achieve the effect of accelerating the degradation rate, high mechanical strength, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A nano calcium peroxide resin-based composite material for removing formaldehyde in the air comprises an oxidizing agent and a carrier, and the oxidizing agent generated in situ is on the carrier.

Embodiment 2

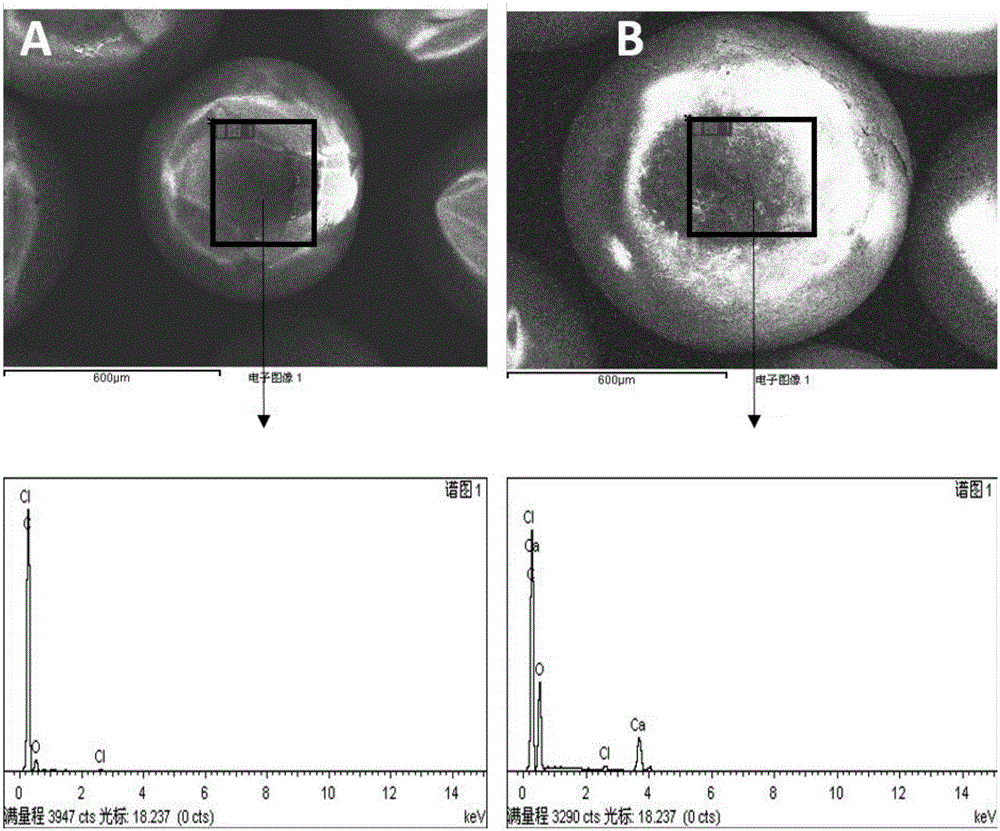

[0048] combine figure 1 , a nano-calcium peroxide resin-based composite material for removing formaldehyde in the air, which includes an oxidizing agent and a carrier, the carrier has an oxidizing agent generated in situ, and the carrier is resin SD300; the oxidizing agent is nano-scale nCaO generated in situ 2 , the mass ratio of oxidant and carrier is 1:(5-12), and there is nanoscale nCaO generated in situ on resin SD300 2 . In the specific implementation and application of this embodiment, multiple application schemes are arranged, and the mass ratio of the oxidizing agent and the carrier can be selected as values such as 1:5, 1:12, 1:8 and 1:10.

Embodiment 3

[0050] A kind of nano-calcium peroxide resin-based composite material that removes formaldehyde in the air of the present embodiment is similar to the scheme in embodiment 1 and embodiment 2, wherein, the difference is that the mass ratio of oxidizing agent and carrier is 1:( 5-12). In the specific implementation and application of this embodiment, multiple application schemes are arranged, and the mass ratio of the oxidizing agent and the carrier can be selected as values such as 1:5, 1:12, 1:8 and 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com