Fe-based soft magnetic composite material and preparation method thereof

A soft magnetic composite material, iron-based technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as reducing the magnetic permeability and saturation magnetic induction intensity of magnetic powder cores, and affecting the performance of magnetic powder cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

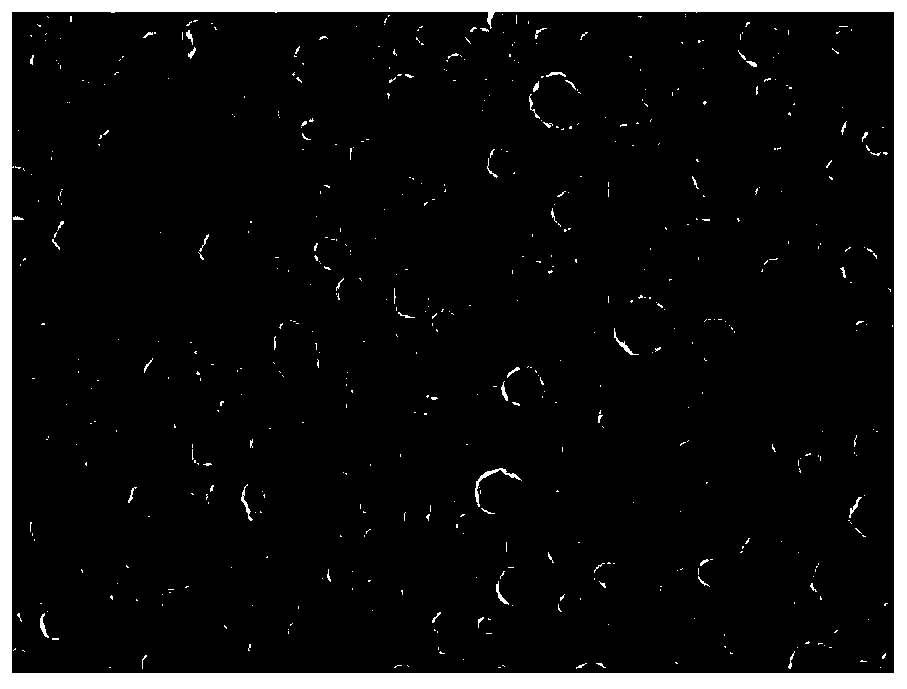

Image

Examples

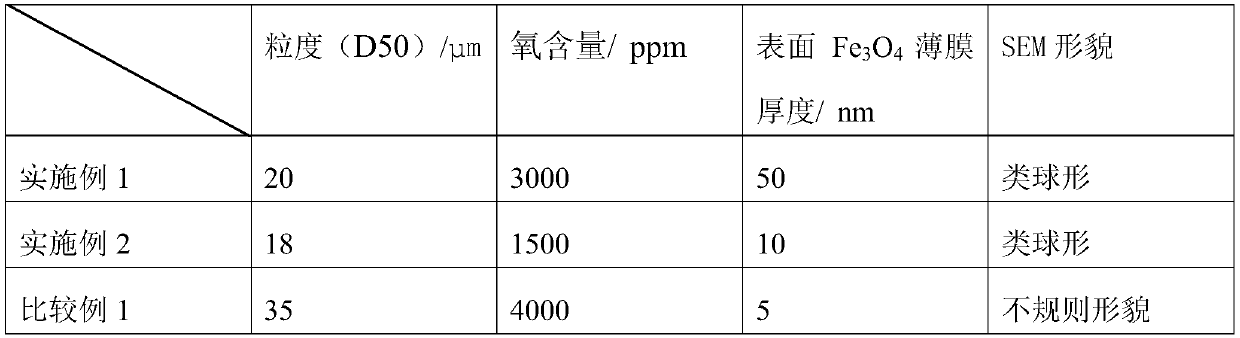

Embodiment 1

[0023] This embodiment relates to a method for preparing an iron-based soft magnetic composite material, comprising the following steps:

[0024] Firstly, industrial pure iron, polysilicon, aluminum-silicon master alloy, electrolytic nickel and electrolytic manganese are selected as raw materials, and the ingredients are calculated according to the mass percentage of FeSiAl alloy as Fe 84.5%, Si 9.5% and Al 5.5%, wherein the content of Ni and manganese is 0.1%. Add the above-mentioned raw materials of pure iron, polysilicon, electrolytic nickel and manganese to the intermediate frequency smelting furnace, the alloy melting temperature is 1500-1600 ℃, keep warm for 3 minutes, and then add the silicon-aluminum master alloy;

[0025] The alloy melt is prepared into alloy powder by water atomization pulverization process. It should be noted that compared with other pulverization methods, the water atomization pulverization method mainly has low segregation, high solidification rat...

Embodiment 2

[0033] This embodiment relates to a method for preparing an iron-based soft magnetic composite material, comprising the following steps:

[0034] First select industrial pure iron and electrolytic nickel as raw materials, calculate the ingredients according to the mass percentage of FeNi alloy as Fe 50% and Ni 50%, put the above raw materials into the intermediate frequency melting furnace, the alloy melting temperature is 1520-1610 ℃, and keep warm for 2 minutes;

[0035] The alloy melt was prepared into alloy powder by water atomization pulverization process, the water atomization pressure was 70 MPa, the diameter of the catheter was 6 mm, and the water flow rate was 40 L / min. The average particle size D50 of the prepared powder is 15 μm, and the oxygen content is 1000 ppm;

[0036] Dry the prepared water atomized FeNi50 alloy powder, and sieve the -200 mesh finished powder. Then, the dried and sieved FeNi50 alloy powder is spheroidized by the plasma spheroidization equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com