Patents

Literature

171results about How to "Promotes sintering densification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing extra-coarse grained carbide alloy

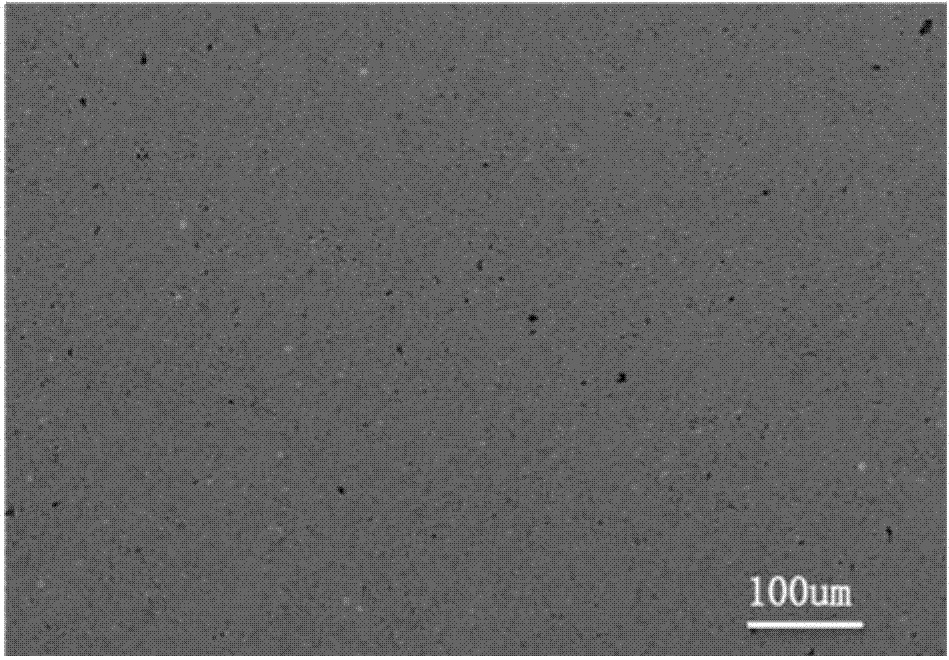

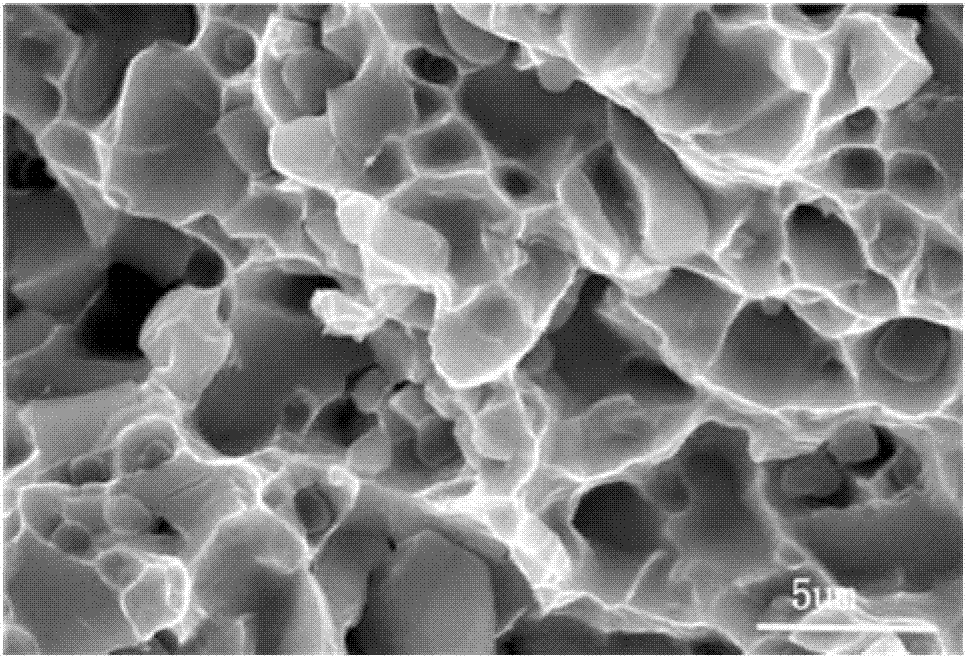

The invention discloses a method for preparing an extra-coarse grained carbide alloy. The method is characterized by comprising the following steps of: pre-mixing extra-coarse tungsten carbide powder having a grinding Fisher particle size of over 6 mu m and cobalt powder; adding molding agents and pressing the mixture to form lumps; pre-sintering the lumps in a degumming furnace having ammonia decomposition gas therein; placing the obtained product, the tungsten carbide powder and the cobalt powder into a ball mill for smashing and wet grinding to prepare a mixture containing 6 to 13 percent cobalt; adding molding agents into the mixture, and pressing to obtain the finished product; after degumming the finished product, sintering the finished product at the high temperature by using a pressurized sintering furnace; and thermally treating the sintered product by using a double-chamber high-pressure gas cooling vacuum furnace, wherein 87 to 94 parts of tungsten carbide, 6 to 13 parts of carbide powder and 0.5 to 2.5 parts of molding agent are pre-mixed. The method avoids the dispersing or grading sieving, and cobalt coating of the tungsten carbide; moreover, the prepared carbide alloy has good compactness, high strength and impact resistance, simple production process and no environment pollution.

Owner:SHANDONG CEMENTED CARBIDE

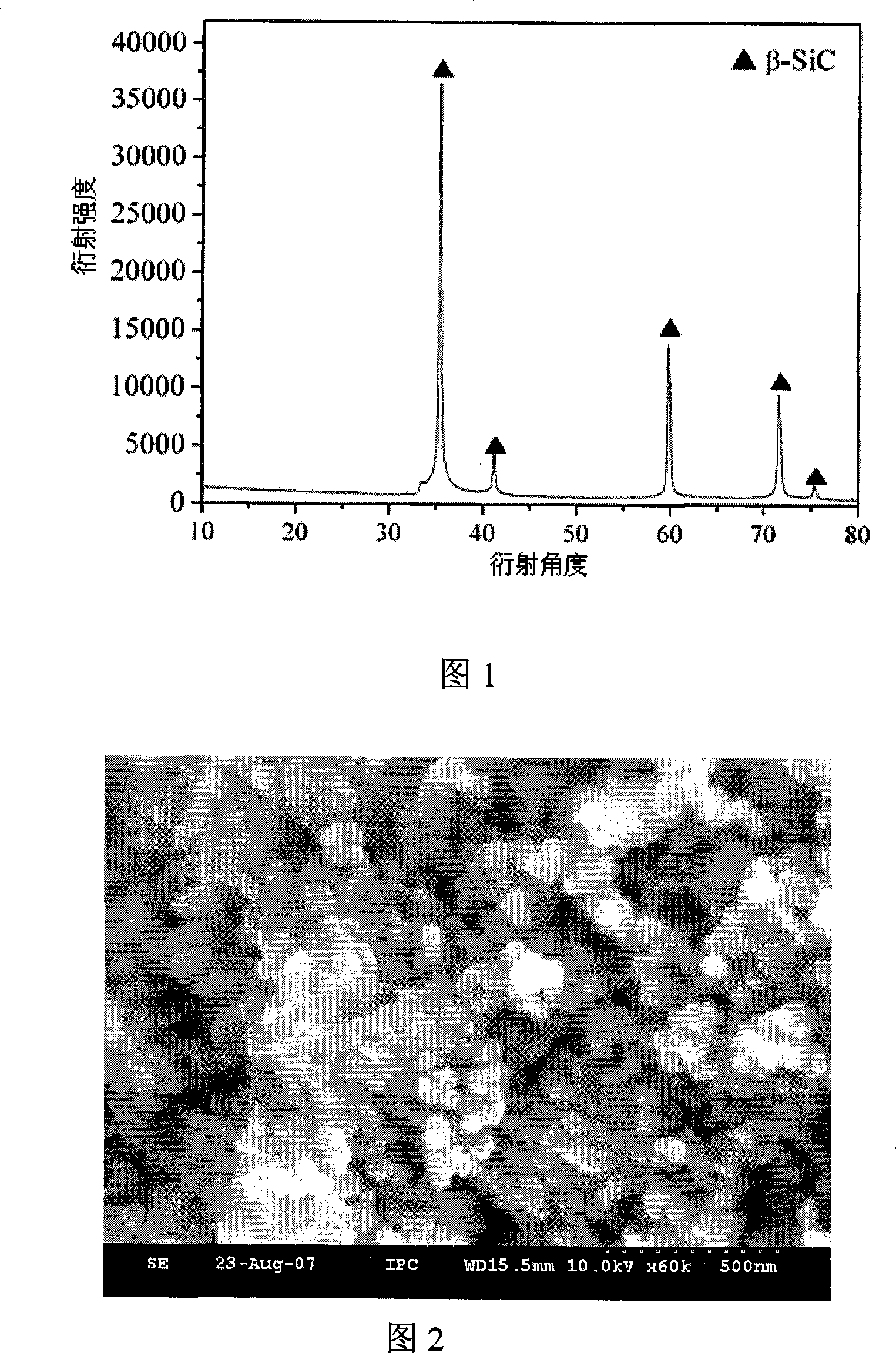

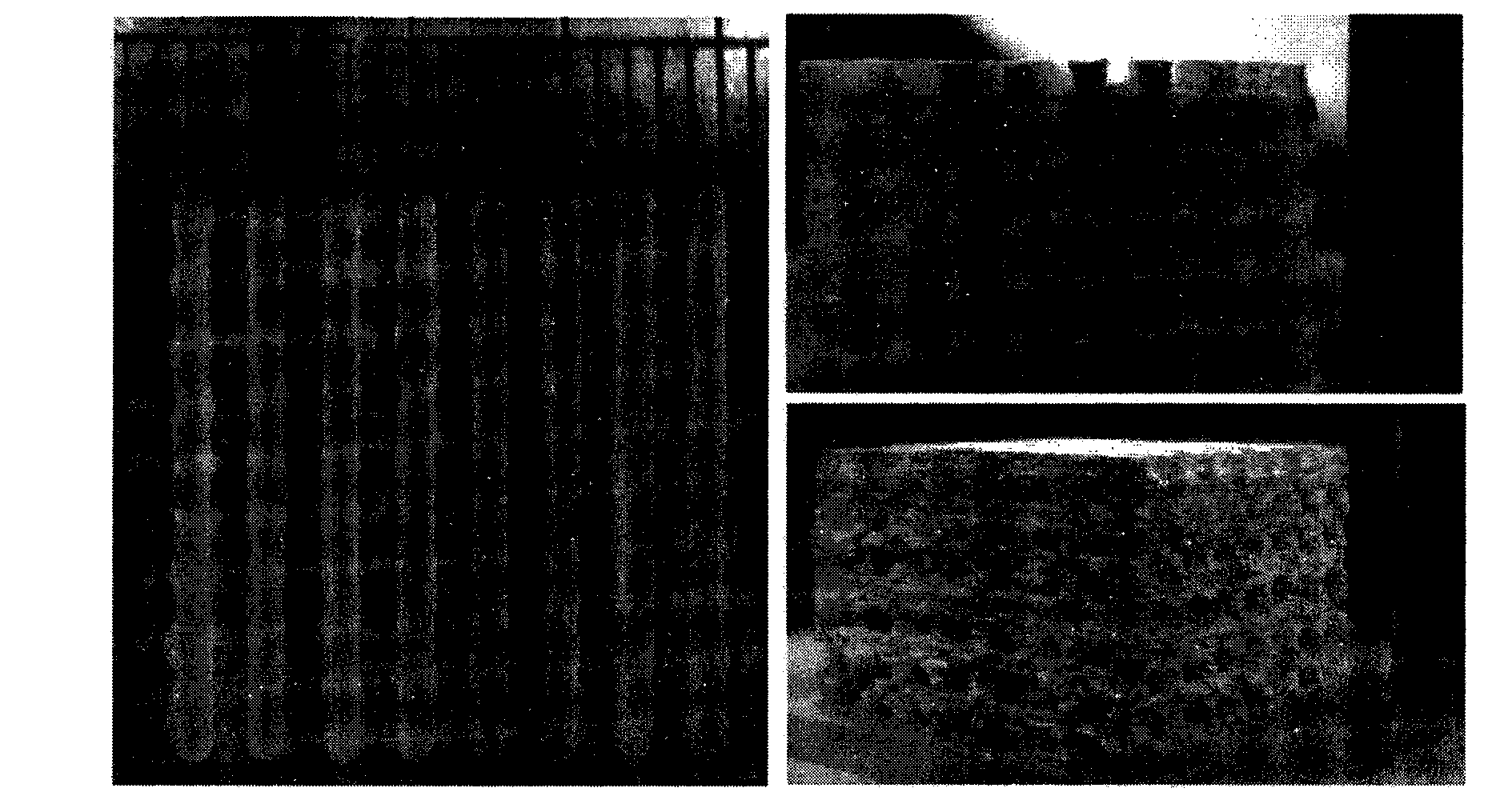

Method for synthesizing homogeneous nano silicon carbide powder by burning

The invention pertains to a preparation technique field of inorganic nano material, in particular to a combustion synthesis method of heterogeneous nano silicon carbide powder. Silicon powder, carbon powder, silicon nitride or silicon carbide additive, and polytetrafluoroethene are adopted as materials, and made into reaction materials according to a certain proportion, and ground and mixed, then held in a praphite crucible, and put into a sealed high pressure reaction synthesis equipment; the reaction equipment is vacuumized and filled with nitrogen to a proper pressure, and the combustion synthesis reaction is triggered by partial electrothermal ignition or partial high frequency induction heating; after the completion of the reaction, the products are collected and treated, and the heterogeneous nano silicon carbide powder with an average crystal particle size less than 100nm can be obtained. The invention realizes the target of preparing high quality nano silicon carbide powder through combustion synthesis technique with low cost, and has the advantages of simple and convenient technique, energy conservative synthesis process, cleanness and pollution free, etc.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Production method of alumina multichannel ceramic membrane support

InactiveCN106242624AHigh bonding strengthImprove flexural strengthCeramic shaping apparatusClay processing apparatusTunnel kilnMicrowave

A production method of an alumina multichannel ceramic membrane support belongs to the technical field of multichannel ceramic membranes. The production method of the alumina multichannel ceramic membrane support comprises the following steps: carrying out a plastic extrusion molding technology on alumina adopted as a main raw material, drying the molded material in a natural drying and microwave drying combination mode, and sintering the dried material in a shuttle kiln or a tunnel kiln. Rare earth oxide, nanometer alumina sol and a sintering aid are mixed, so the flexural strength and the acid and alkali corrosion resistance of the above obtained product are improved; introduction of an organic binder in the production process of an alumina multichannel ceramic membrane greatly reduces deformation of a green body in the extruding, drying and sintering processes and improves the yield of the product; and the nanometer alumina sol has high intergranular binding strength, so the granule morphology is kept, thereby the channels of the produced product are smooth and have small filtering resistance, and the water flux is improved by 20% or above.

Owner:山东华瓷环保设备科技有限公司

Method for preparing porous bone scaffold by laser and increasing performance by adding zinc oxide

InactiveCN103845762AGood biological propertiesHigh densityProsthesisSelective laser sinteringPhosphate

The invention relates to a method for preparing a porous bone scaffold by laser and increasing mechanical and biological performances of the porous bone scaffold by adding zinc oxide with little amount, which belongs to the bone tissue engineering field. Aiming at uncontrollable performances of aperture distribution, shape, space direction and connectivity in the preparation method of a traditional bone scaffold, and aiming at the disadvantages of poor mechanical property and fast resolving rate existed in tricalcium phosphate (beta-TCP), the invention provides the method for preparing the porous bone scaffold by using a selective laser sintering (SLS) technology, and provides the method for increasing performance by adding zinc oxide (ZnO). The method for preparing the porous bone scaffold has the advantages that the porous scaffold which enables three-dimensional interconnection is prepared by SLS, zinc oxide with little amount is added for introducing into a liquid phase, the particles densification can be promoted, crystal grain is refined, and the mechanical performance is improved, simultaneously, cell compatibility is increased, the degradation rate is reduced, and the biological performance is increased, so that the interconnected porous beta-TCP bone scaffold with enhanced mechanical performance and good biological performance can be finally prepared. The method has the advantages of simple preparation technology, convenient operation, low cost, easy control of technical parameter and the like.

Owner:CENT SOUTH UNIV

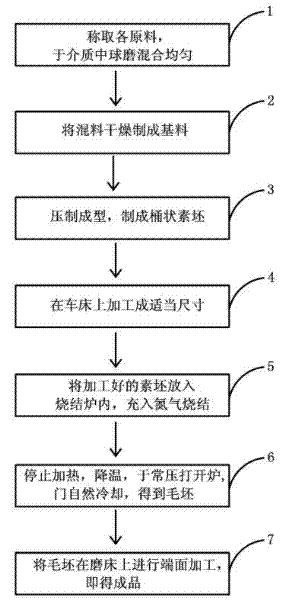

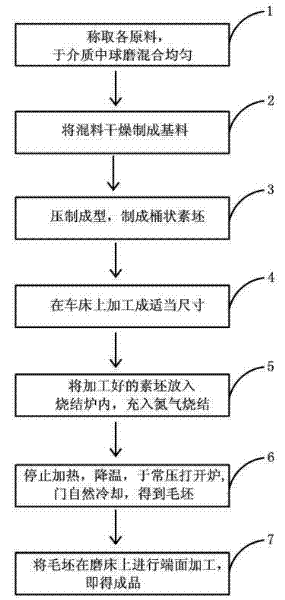

Silicon nitride material and preparation method of heat insulating disc cover prepared from same

The invention relates to a silicon nitride material and a preparation method of a heat insulating disc cover prepared from the same. The silicon nitride material consists of the following raw materials in percentage by weight: 65-87.5 percent of silicon nitride, 5-15 percent of nano-silicon nitride, 8-15 percent of a sintering aid and 0.5-5 percent of tungsten carbide; and the preparation method of the heat insulating disc cover prepared from the silicon nitride material comprises the following steps of: weighing the silicon nitride, nano-silicon nitride, sintering aid and tungsten carbide according to the percentage by weight, performing ball milling and mixing uniformly; drying a mixed material to obtain a substrate; performing press molding to obtain a cylindrical biscuit; processing to a proper size on a lathe; putting the processed biscuit into a sintering furnace, and charging nitrogen gas for sintering; stopping heating, cooling, opening a furnace door under the normal pressure, and cooling naturally to obtain a blank; and performing end face processing on the blank on a grinding machine to obtain a finished product.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD

Preparation method of special low-density grinding column for cement grinding mill

The invention relates to a preparation method of a special low-density grinding column for a cement grinding mill. The preparation method comprises the steps of with bauxite, alumina powder and the like as main raw materials and chromium oxide, zirconium oxide, calcium oxide, magnesium oxide, ferric oxide, manganese oxide, titanium oxide, silicon dioxide and the like as modified raw materials, adding alumina sol, silica sol and metal salt into slurry at a grinding stage; molding by rolling, isostatic pressing or machine pressing to obtain a green body; and calcining after drying the green body to obtain the low-density grinding column. By virtue of scientific proportion design, strict process control and unique calcining system, the special low-density grinding column disclosed by the invention is low in cost, excellent in wear resistance, lower in power load as comparison with a high-density metal grinding body, suitable for substituting a metal grinding body in cement grinding, iron ore grinding and gold ore grinding and capable of reducing the electric consumption for grinding by 30-50%.

Owner:UNIV OF JINAN

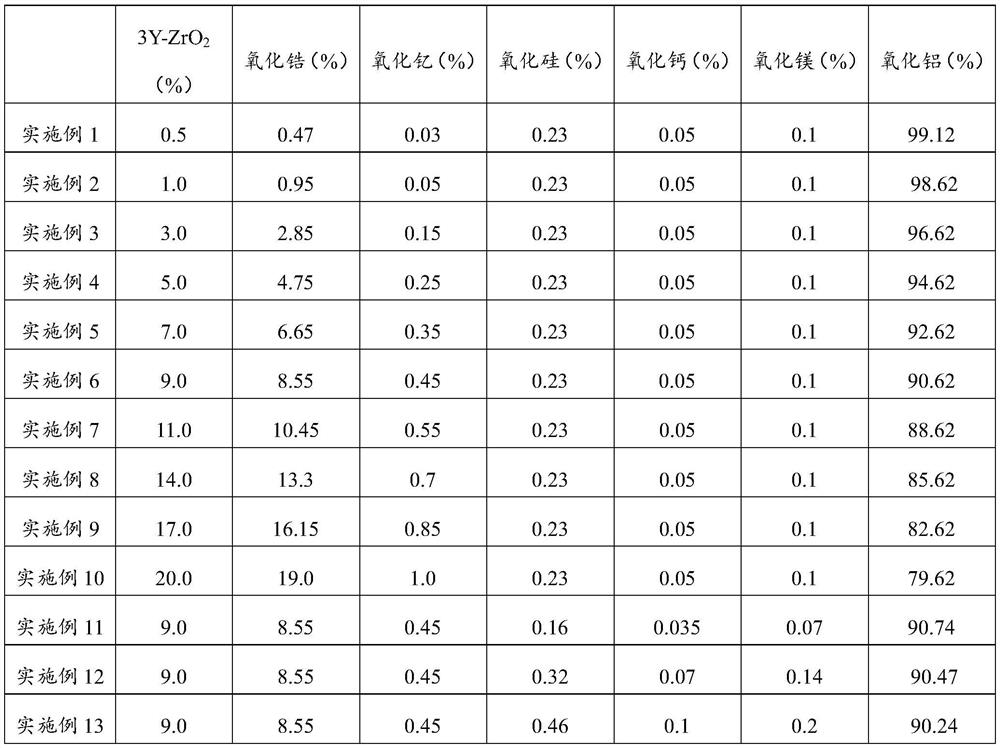

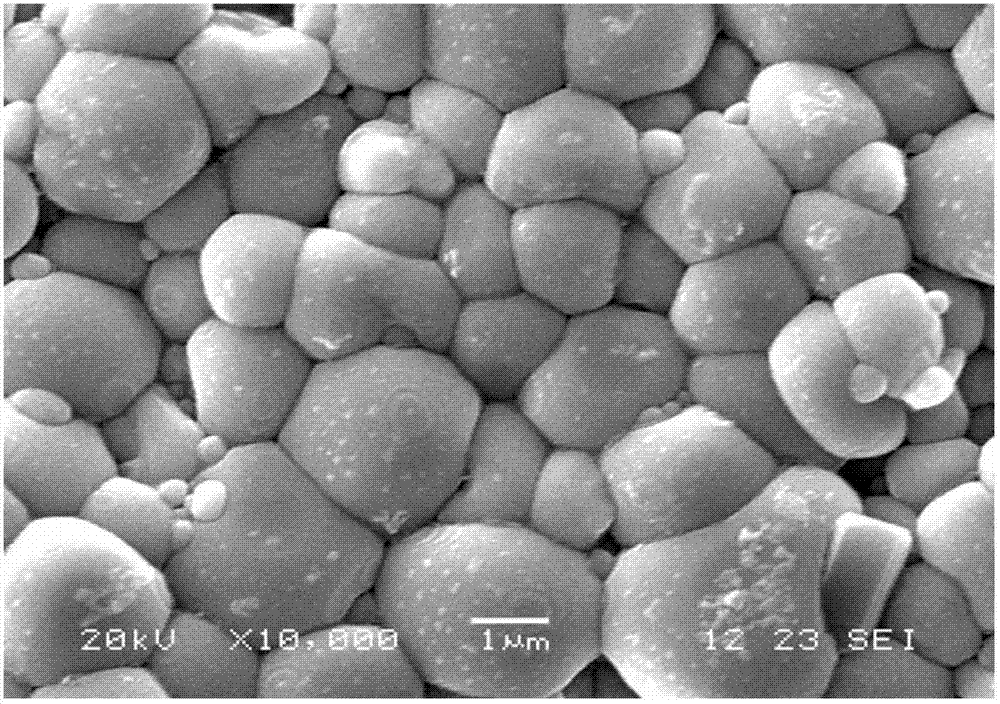

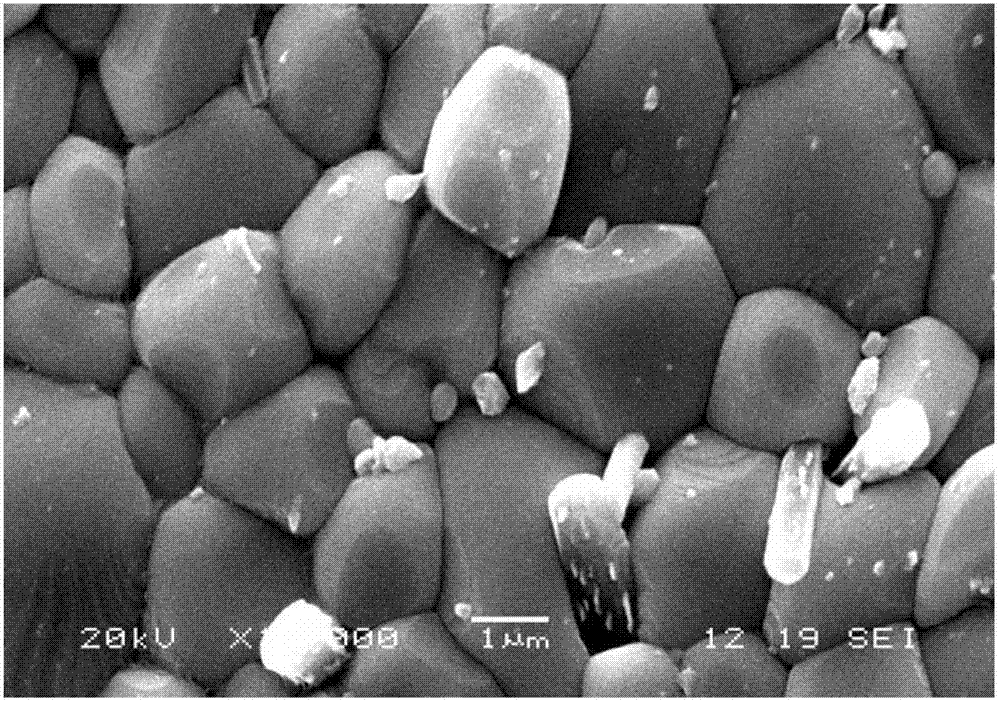

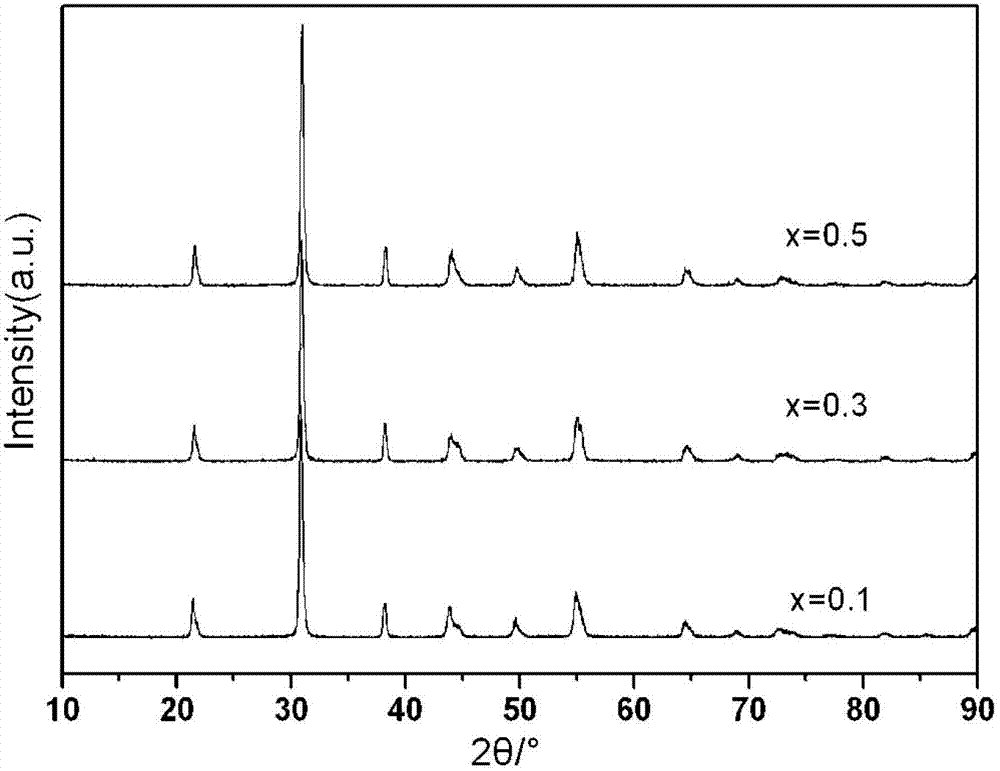

Zirconia composite alumina ceramic sintered body as well as preparation method and application thereof

The invention relates to a zirconia composite alumina ceramic sintered body. The zirconia composite alumina ceramic sintered body comprises the following components in percentage by mass: 0.01-19.0 wt% of a zirconium-containing compound (calculated in the form of zirconium oxide), 0.01-1 wt% of a yttrium-containing compound (calculated in the form of yttrium oxide), 0.16-4.6 wt% of a silicon-containing compound (calculated in the form of silicon oxide), 0.035-1.0 wt% of a calcium-containing compound (calculated in the form of calcium oxide), 0.07-2.0 wt% of a magnesium-containing compound (calculated in the form of magnesium oxide) and the balance of aluminum oxide. According to the zirconia composite alumina ceramic sintered body, 3Y-ZrO2 is taken as an additive, and the synergistic effect of multiple toughening modes such as phase change toughening, microcrack toughening, internal crystal structure strengthening toughening and surface strengthening toughening is achieved; CaCO3, SiO2and MgO are used as sintering aids, the sintering temperature of the aluminum oxide ceramic is reduced through liquid-phase sintering, the sintering rate is increased, sintering densification is promoted, and an aluminum oxide substrate prepared from the zirconia composite alumina ceramic sintered body has good fracture toughness and bending strength.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

Method of preparing high pruity block titanium aluminium carbon material using discharge plasma sintering

A process for preparing high-purity Ti-Al-C block by discharge plasma sintering includes such steps as proportionally mixing Ti3AlC2 powder or Ti powder, Al4C3 powder and active carbon powder, ball grinding, baking sieving, loading in graphite mould, discharging plasma sinter under protection of inertial gas, holding the temp for a certain time and cooling. Its advantages are high purity (90% or more) and high mechanical performance.

Owner:TSINGHUA UNIV

Low temperature sintering piezoelectric ceramic material and preparation method thereof

InactiveCN102850050ALower sintering temperatureReduce manufacturing costDopantElectromechanical coupling coefficient

The invention discloses a low temperature sintering piezoelectric ceramic material, wherein composition of the material is represented by a chemical general formula Pb(0.995-a-b-3c / 2)BaaSrbFec(Zn1 / 3Nb2 / 3)xZryTi(1-x-y)O3+u%Li2CO3+v%M2O3+w%ZnO, M is a trivalent metal element, a molar ratio of Ba to Sr to Fe to (Zn1 / 3Nb2 / 3) to Zr is a:b:c:x:y, a is more than or equal to 0 and is less than or equal to 0.05, b is more than or equal to 0 and is less than or equal to 0.03, c is more than or equal to 0 and is less than or equal to 0.01, x is more than or equal to 0.25 and is less than or equal to 0.35, y is more than or equal to 0.30 and is less than or equal to 0.40, the Pb(0.995-a-b-3c / 2)BaaSrbFec(Zn1 / 3Nb2 / 3)xZryTi(1-x-y)O3 is adopted as matrix ceramic powder, u% represents a weight percentage of Li2CO3 in the matrix ceramic powder, v% represents a weight percentage of M2O3 in the matrix ceramic powder, w% represents a weight percentage of ZnO in the matrix ceramic powder, u is more than 0 and is less than or equal to 1, v is more than 0 and is less than or equal to 2, and w is more than 0 and is less than or equal to 0.2. According to the present invention, an oxide dopant is added and combined, such that a sintering temperature of the ceramic can be reduced to a temperature of 900 DEG C from a temperature of 1200 DEG C, a high piezoelectric constant (d33 is more than or equal to 450 pC / N ), a high electromechanical coupling coefficient (KP is more than or equal to 0.60), a high Curie point (Tc is more than 350 DEG C) and a moderate dielectric constant (epsilonr is 2000-3500) can be obtained, and application requirements on the ceramic material by the laminated piezoelectric driver are met.

Owner:HUAZHONG UNIV OF SCI & TECH

Aluminum oxide-titanium carbide nitride-titanium nickel composite material and preparation method thereof

The present invention relates to an aluminum oxide-carbon titanium nitride-titanium-nickle composite material and the preparing method thereof, the volume percentage of the composite material combination is as follows: Al2O3:60-94, Ti(C, N): 5-35, Ti+Ni: 1-12; the preparation technique process comprises the following two steps of: a first step of raw material mixing and drying: (1) mixing the raw material Al2O3 powder, TiCN powder, ball-grinding medium and surfactant, ball grinding and drying; (2) mixing the raw material Ti powder, Ni powder and ball-grinding medium, and ball-grinding, the ratio of titanium and nickel atom is 1:1-1:4; (3) adding ball-grinding medium into the powder which is mixed and dried in the procedure (1) and (2), ball-grinding and drying, the adding amount of Ti and Ni powder is 1-12vol%, the second step is powder molding and sintering: the mixed powder processed in the procedure (3) is added into the hot pressing stove and is hot pressed for molding in the argon atmosphere, temperature of 1400-1700DGE C and pressure of 25-35MPa. The material of the invention has the following advantages: evident increased material combined properties of hardness, strength and toughness, and the material is more suitable for the cutter material used in the mechanical industry.

Owner:NORTHEASTERN UNIV

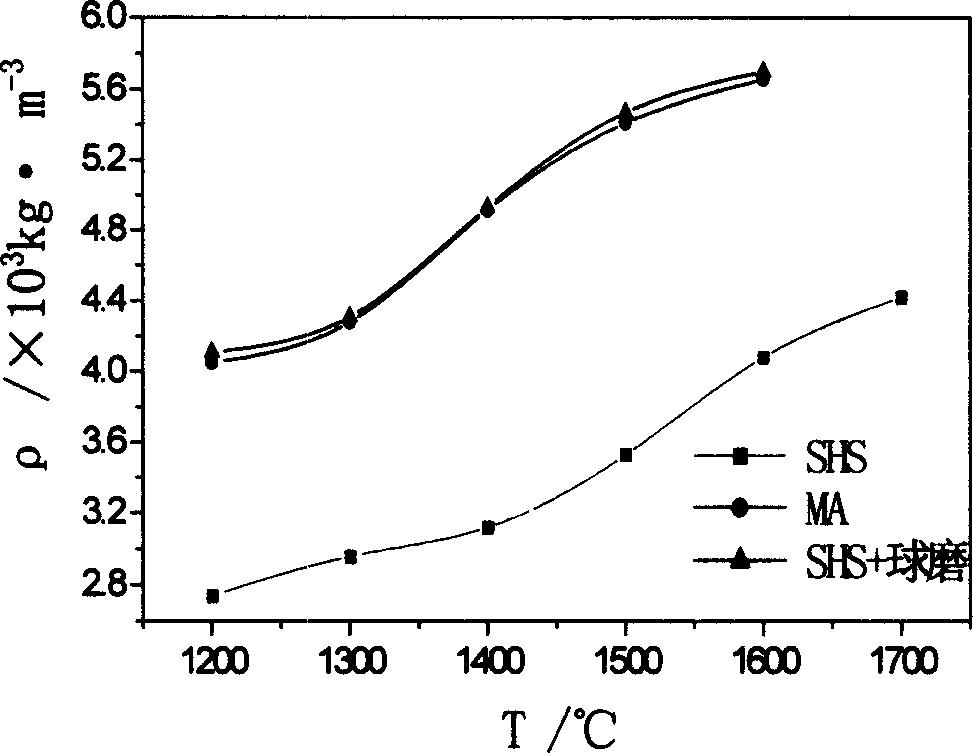

Speed preparing composite material powder with MoSi2 base and its method of sintered body

InactiveCN1560302AHigh densitySimple processRare-earth elementSelf-propagating high-temperature synthesis

The invention is a method of rapidly preparing MoSi2 based composite powder and its sintered body, mainly adopting self-propagating high-temperature synthesis (SHS) to combine with ball-milling process, simultaneously adding in rare-earth elements, and rapidly completing sintering at 1400-1600 deg.C; because it adopts a project of SHS to rapidly prepare MoSi2 based composite combining with ball-milling particle-fining process, and simultaneously introducing rare-earth elements, overcoming the difficult problems of obtaining high-density MoSi2 at above 1700 deg.C only by singly adopting SHS and long time of synthesizing MoSi2 by MA (mechanical alloying) process; as compared with hot press process and hot isostatic pressing (HIP) process, it has the advantages of simplifying process, saving energy, increasing production efficiency and easy for industrial production; obviously acclerates the sinter-densifying course, obtains sintered body with compactibility up to 96%, and reduces sintering temperature by 200 deg.C.

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of high-toughness pressureless sintered boron carbide ceramic

InactiveCN108911753AReduce temperature sensitivityHigh particle size concentrationBoron carbideSlurry

The invention relates to a preparation method of high-toughness pressureless sintered boron carbide ceramic. 65 to 78 wt% of boron carbide powder, 10 to 17 wt% of a sintering aid and 8-20 wt% of a ceramic additive are added into a stirring mill, and a certain amount of solvent is added, stirring ball milling-sand mill treatment-stirring ball milling process is performed, the solid content of ceramic slurry is 45 to 60 wt%, granulated powder is obtained by centrifugal spray granulation, the granulated powder is pressed into a green body, the green body is placed in a graphite sagger, graphite balls are placed around the green body, the graphite sagger is placed in a high-temperature vacuum sintering furnace for pressureless sintering, and finally the boron carbide ceramic is obtained. The low-price large-particle boron carbide powder is used as a raw material, and a multi-component eutectic non-oxide liquid phase is introduced to promote the densification of the boron carbide ceramic.

Owner:扬州北方三山工业陶瓷有限公司

Slurry of high-performance aluminum nitride ceramic substrate and preparation method thereof

The invention provides slurry of a high-performance aluminum nitride ceramic substrate and a preparation method thereof. The slurry is prepared from the following components in parts by mass: 100 parts of aluminum nitride powder, 1-8 parts of a sintering aid, 0.1-4 part of sialon particles, 1-6 parts of a dispersing agent, 38-68 parts of a solvent, 3-12 parts of a binder and 3-10 parts of a plasticizer. The sintering aid is prepared from the following components in parts by mass: 0-8 parts of Y2O3, 0-5 parts of Sm2O3, 0-1 part of La2O3 and 0.05-3 part of metal aluminum powder; wherein the solvent is one or more of absolute ethyl alcohol, isopropanol and n-butyl alcohol. Sialon particles are dispersed in a slurry system to play a toughening role; the multi-element sintering aid is helpful for reducing the sintering temperature and promoting the sintering compactness; the metal aluminum powder can react with oxygen impurities, the heat conductivity is effectively improved, generation ofaluminum nitride is facilitated in the nitrogen atmosphere, and sintering densification is further promoted. The product is applied to alcohol and other non-toxic, low-toxicity and low-cost solvents for replacing benzene, ketone and other toxic solvents, and the problem that preparation of the aluminum nitride ceramic is not friendly to human beings and the environment is solved.

Owner:GUANGDONG UNIV OF TECH

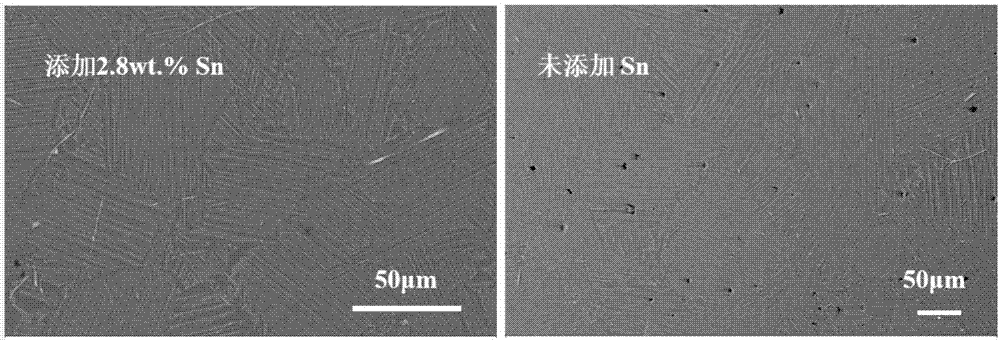

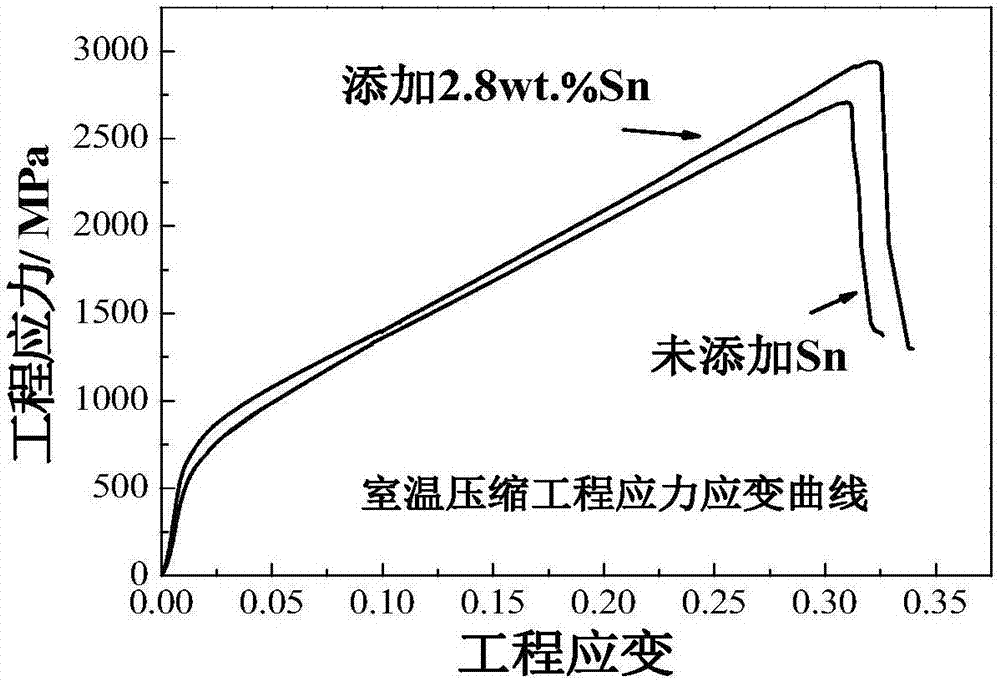

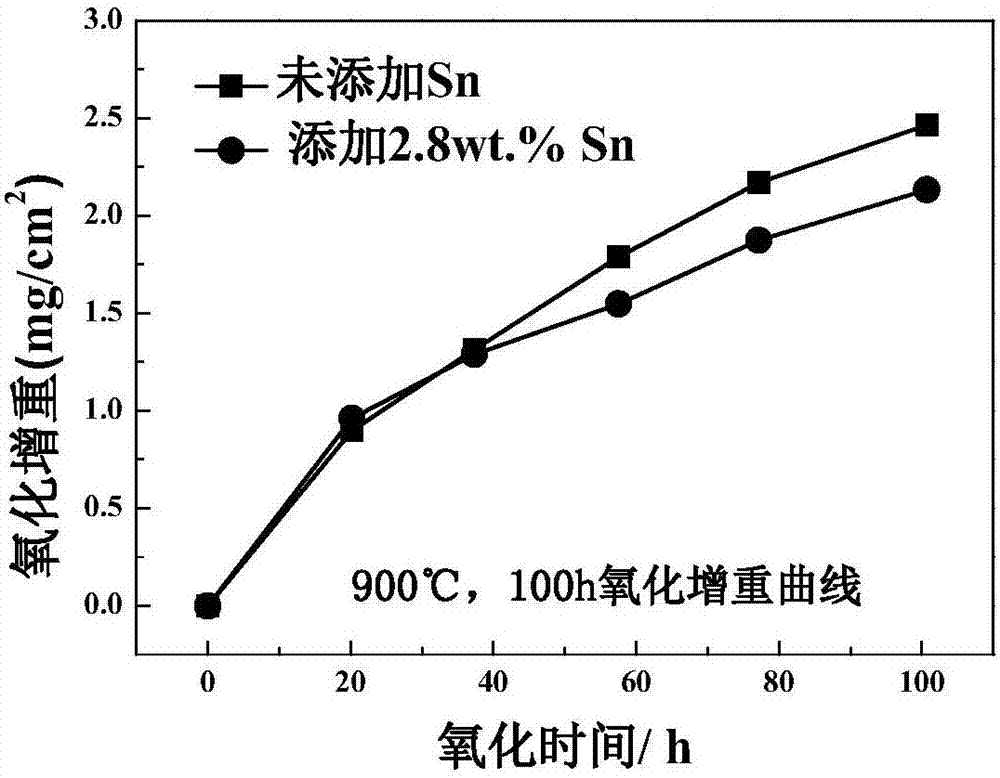

Method for adding Sn reinforcing sintering powder metallurgy TiAl base alloy

The invention relates to a method for an adding Sn reinforcing sintering powder metallurgy TiAl base alloy. The method for the adding Sn reinforcing sintering powder metallurgy TiAl base alloy is characterized in that the method includes the following steps that S1, powder raw materials are prepared, TiAl pre-alloy powder and Sn powder are selected, and the proportion of the TiAl pre-alloy powder and the Sn powder is determined; S2, mixing, the powder raw materials prepared in the step S1 are placed in a blender mixer to mix uniformly; S3, blank preparing, the mixed powder in the step S2 are prepared into a blank material; and S4, sintering, the blank material in the step S3 are placed in a sintering furnace, pressureless sintering is conducted under the vacuum condition or the inert gas protection condition; heat preservation is finished, and cooling with the furnace, then the adding Sn reinforcing sintering powder metallurgy titanium-aluminium alloy is obtained. According to the method, the density of the adding Sn reinforcing sintering titanium-aluminium alloy material is high, the compositions are uniform, the tissues are finer, the mechanical property of the adding Sn reinforcing sintering titanium-aluminium alloy material is superior to a non-adding Sn reinforcing sintering titanium-aluminium alloy material, and the method for adding Sn reinforcing sintering powder metallurgy TiAl base alloy has no bad impact on the matrix high temperature mechanical property and the high temperature antioxidant property.

Owner:UNIV OF SCI & TECH BEIJING

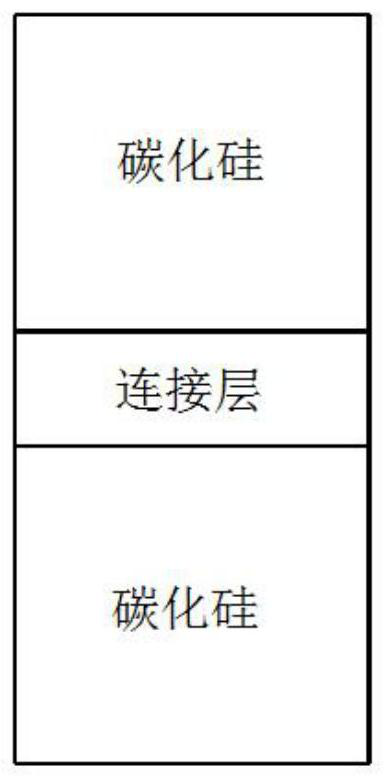

Connecting material for connecting silicon carbide ceramics and application method thereof

InactiveCN111892418AIncrease the surface energy of the interfaceInterface surface energy increaseCarbide siliconHigh entropy alloys

The invention discloses a method for electric field assisted connection of silicon carbide ceramic and a connecting material adopted by the method, and belongs to the field of silicon carbide ceramicmaterial. The method comprises the following steps: clamping a connecting layer between to-be-connected silicon carbide ceramic materials, and connecting the to-be-connected SiC materials together byheating a connecting interface to a connecting temperature of 1000 DEG C or above under the assistance of an external electric field; wherein the connecting layer is a high-entropy alloy sheet with the thickness smaller than 1 mm. And the connecting layer is made of a CoFeCrNiCuTix high-entropy alloy. The requirement for an external heat source is low, the connecting speed is high, the mechanicalstrength performance of the connected silicon carbide ceramic material is good, cost saving is facilitated, the industrial production difficulty is lowered, and rapid and high-quality connection is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

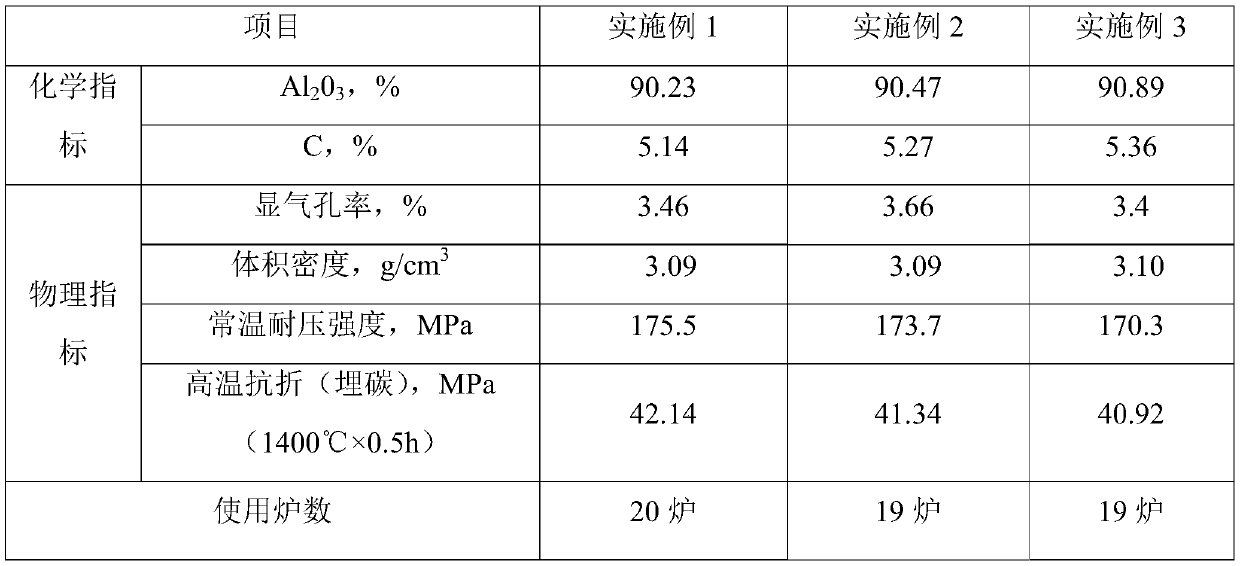

Al4SiC4 ternary non-oxide converter slag-stopping sliding plate and preparation method thereof

The invention discloses an Al4SiC4 ternary non-oxide converter slag-stopping sliding plate and a preparation method thereof, and belongs to the technical field of sliding plates. The sliding plate includes the following components: 25-33 wt% of plate-shaped corundum particles having a particle size of 2.3-1 mm, 16-24 wt% of plate-shaped corundum particles having a particle size of 1-0.5 mm, 20-26wt% of plate-shaped corundum particles having a particle size of 0.5-0.045 mm, 10-15 wt% of plate-shaped corundum fine powder having a particle size of 0-0.045 mm, 5-8 wt% of active alpha-Al2O3 micropowder, 2-6 wt% of Al4SiC4 fine powder, 2-3 wt% of carbon black, 4-8 wt% of active metal aluminum powder, and 4 wt% of a composite antioxidant; and a compound liquid resin binder accounting for 4-5% ofthe total weight is added. The thermal shock stability, high-temperature thermal strength and high-temperature oxidation resistance of the converter sliding plate are improved, and the service life of the sliding plate is prolonged.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

Low temperature fast preparation method of AlON crystalline ceramics

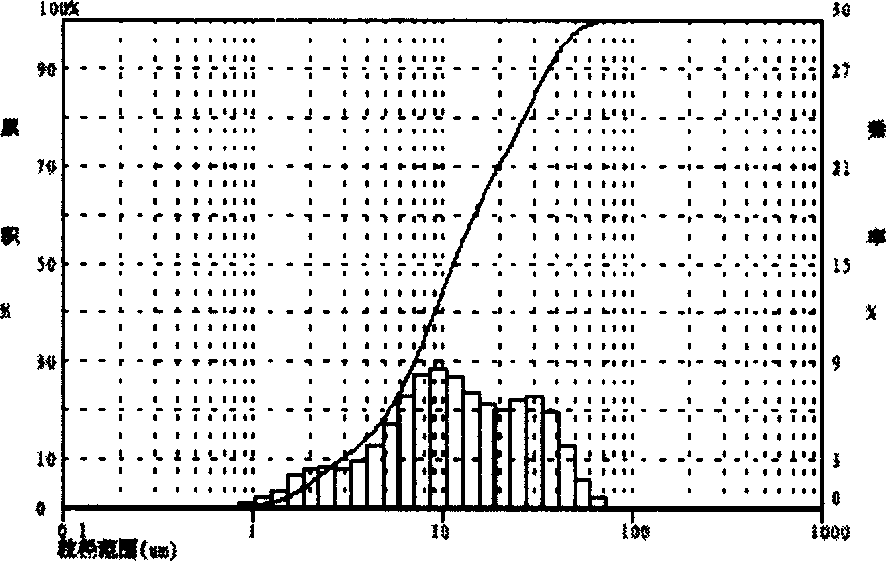

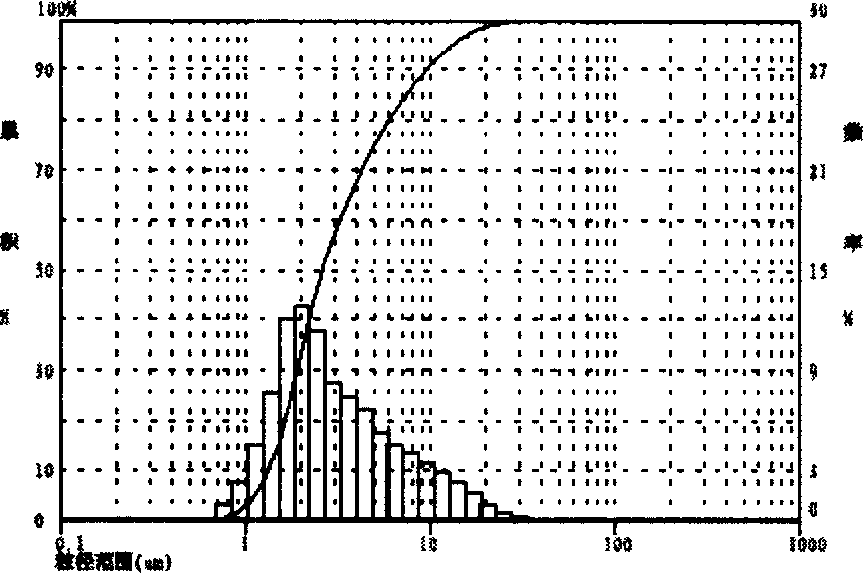

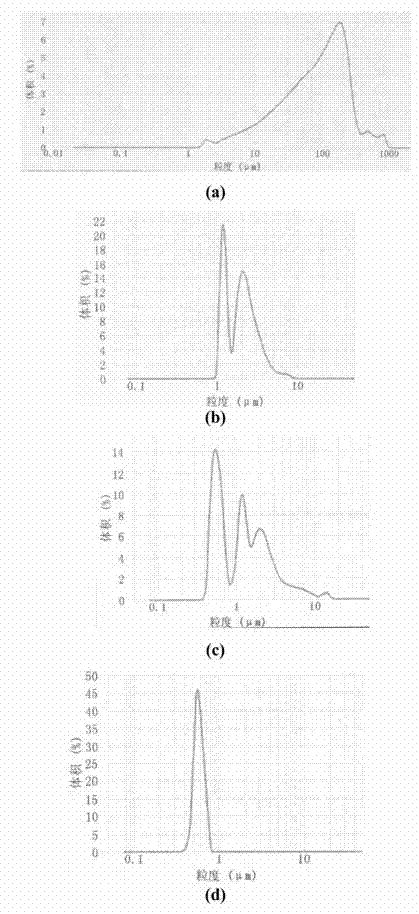

The invention relates to a low temperature fast preparation method of AlON crystalline ceramics, and belongs to the technical field of crystalline ceramic preparation. The preparation method provided by the invention applies ball-milling modification to AlON powder by adopting a planetary ball mill, the modified powder has tiny particles, and has the grain size distribution characteristics of single-modal, double-modal, multi-modal and the like, while possessing the characteristic of narrow molecular distribution, so as to be beneficial to improve the compactness of blank bodies and promote the sintered densification. The AlON powder which is manufactured through ball-milling modification and has the grain size distribution characteristics can be formed through preforming without adding binder, and further isostatic cool pressing is not required. The compactness of the blank bodies is high, and AlON crystalline ceramics with transmittance greater than 80% can be obtained through keeping the heat of the blank bodies at a temperature below 1900 DEG C with the effect of sintering agents. The preparation method has the advantages of low sintering temperature, short heat preservation time and good energy-saving effect; and the requirement for equipment is not high. The preparation method can be used for preparing construction members in abnormal shapes, so that the applied range is wide, the cost is low, the operation is simple and easy, and the industrialization is easy to realize.

Owner:DALIAN MARITIME UNIVERSITY

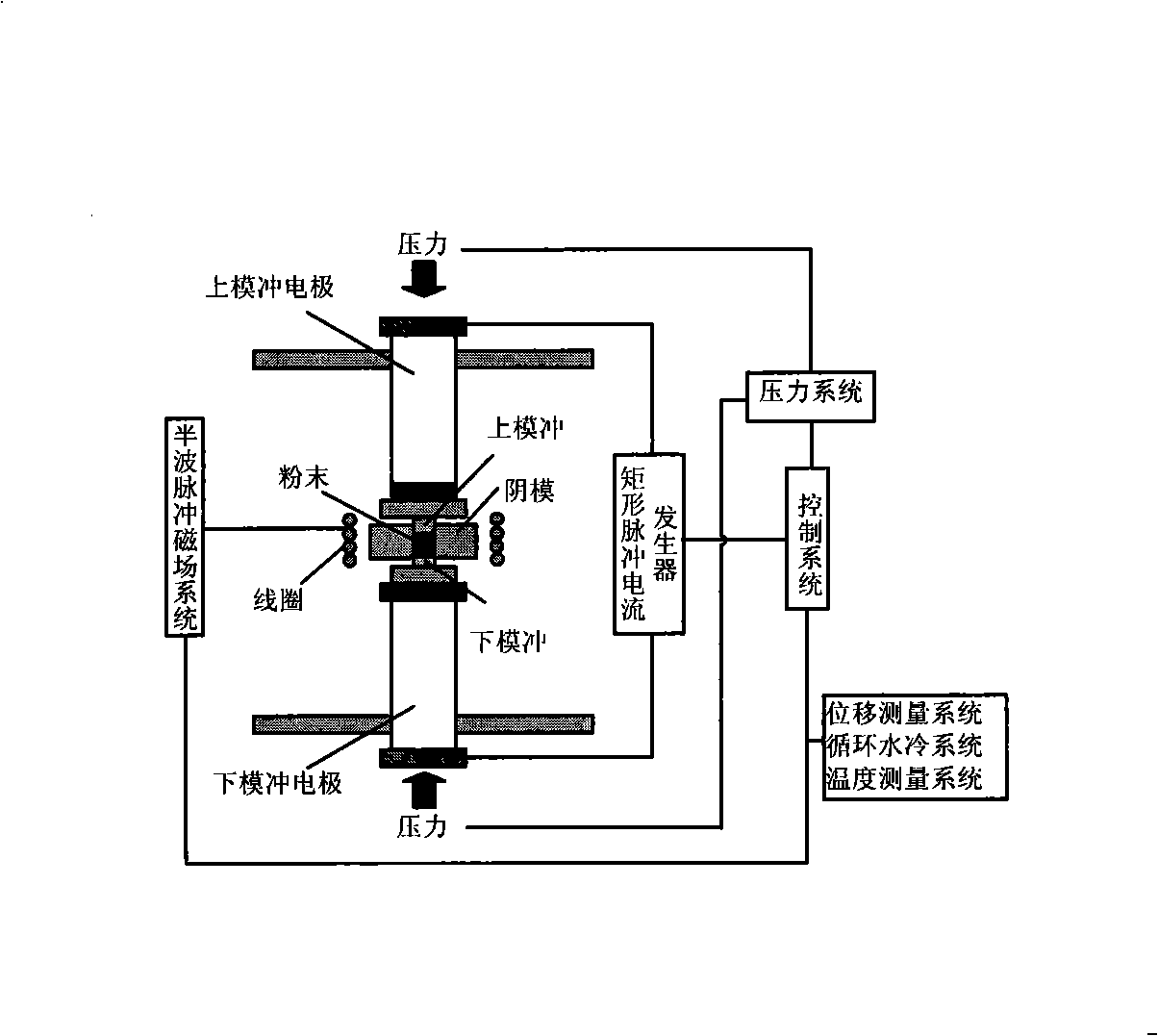

Method for preparing nanocrystalline block iron-base alloy material by four-field coupling sintering

InactiveCN101323917AImprove uniformityImprove comprehensive mechanical propertiesPeak valueIron based alloy

The invention provides a method for preparing a bulk nano iron matrix composite by four-field coupling sintering. The four-field coupling adopted by the method refers to simultaneously applying rectangular pulse current and axial semi-wave pulse magnetic field and sintering pressure, wherein, the sintering pressure of positive and negative electrodes applied to power is 10MPa to 50MPa and time for sintering is 1 to 6 minutes. The peak value, base value, frequency, duty ratio of the rectangular pulse current and the strength of the additional axial semi-wave pulse magnetic field increase with the increasing of the size of sintering material. The method significantly improves the uniformity of the axial temperature field of sintering, promotes the comprehensive mechanical performance of iron matrix alloy in sintering state and prepares the bulk iron matrix composite that is characterized by being nearly completely compact, high strength and nanocrystal. The method obviously reduces the requirements for equipment, shortens period, improves efficiency, is especially beneficial to the domestic production of the bulk nano iron matrix composite and has good prospect of promotion and application.

Owner:SOUTH CHINA UNIV OF TECH

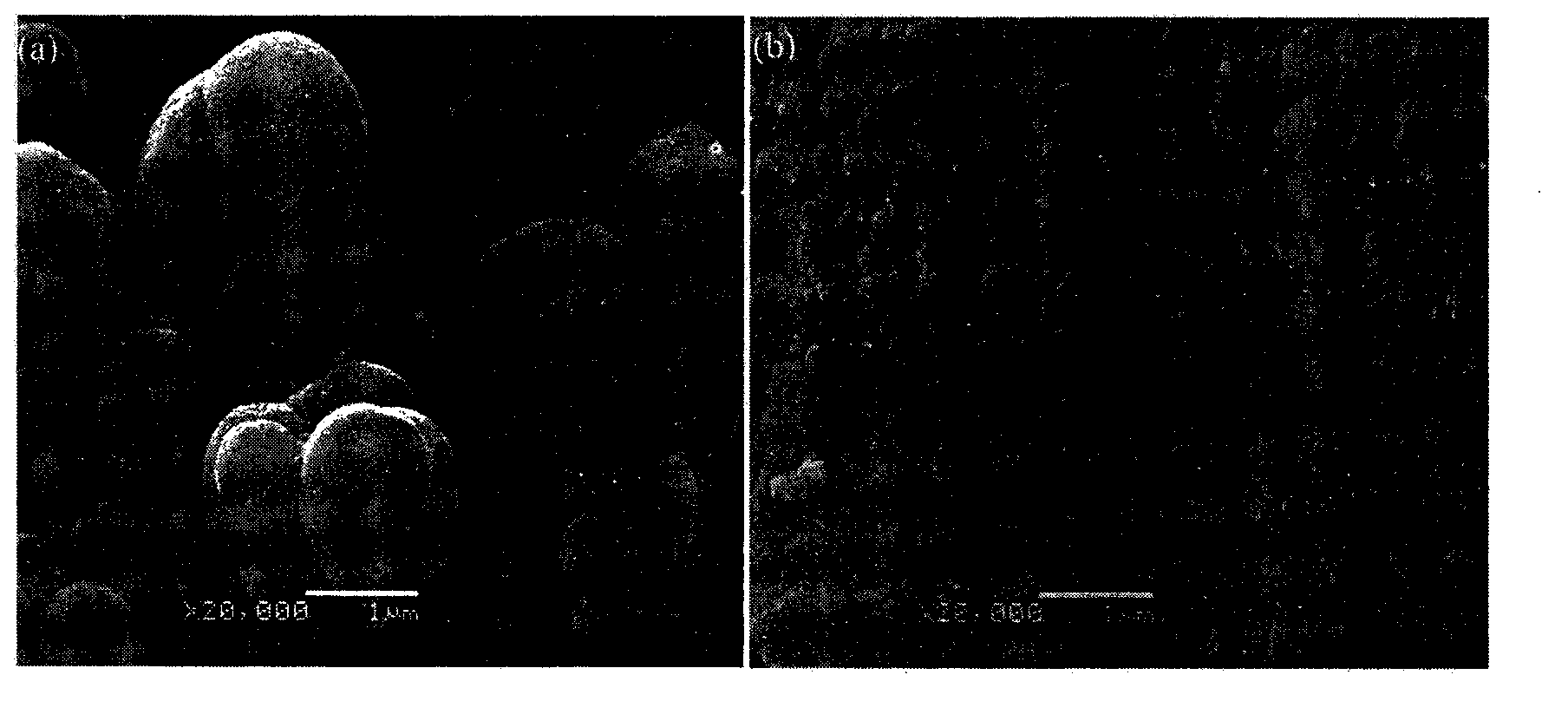

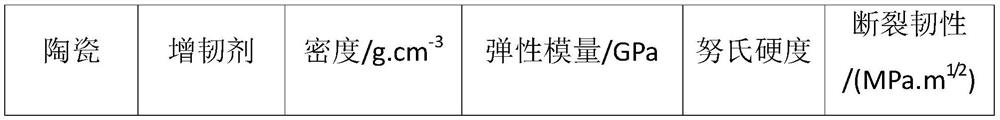

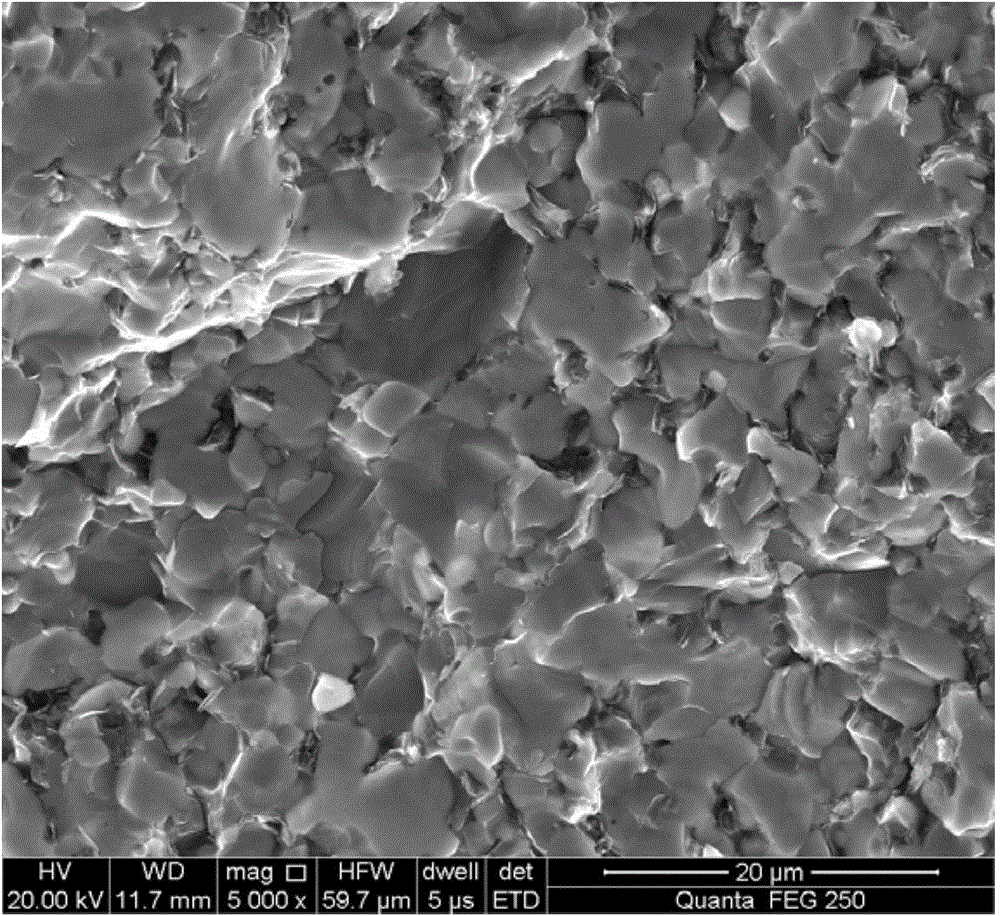

Preparation method of boron carbide composite ceramic plate and bulletproof flashboard

ActiveCN112174672AEvenly distributedPromotes sintering densificationArmour platesComposite ceramicGraphite

The invention provides a preparation method of a boron carbide composite ceramic plate and a boron carbide titanium alloy composite bulletproof flashboard. The preparation method of the boron carbidecomposite ceramic plate comprises the steps of selecting boron carbide powder as a raw material, selecting a graphene material as a sintering aid, dispersing the graphene material by adopting a high-pressure homogenization process, then adding the boron carbide powder and the graphene suspension into a three-roll grinder for mixing, conducting granulating and drying to obtain granulated powder, filling the granulated powder into the graphite mold with a prefabricated shape, carrying out two-stage heating in a vacuum environment, introducing nitrogen while carrying out second-stage heating, carrying out heat preservation, quickly cooling to 2200 DEG C, and carrying out heat preservation for 1-1.5 hours. According to the preparation method of the boron carbide composite ceramic plate, sintering densification of boron carbide ceramic can be effectively promoted, overlarge growth of boron carbide ceramic grains can be avoided on the microcosmic level, and the fracture toughness of the boron carbide ceramic plate can be effectively improved.

Owner:香河星通科技有限公司

Preparation method of molybdenum-based alloy coating

ActiveCN110257679ASolve the problem of inconsistent thermal expansion coefficientImprove bindingThermal expansionHearth

The invention discloses a preparation method of a molybdenum-based alloy coating, and belongs to the field of preparation of alloy coatings. The method comprises the following steps of, 1, an iron base and a metal foil are taken, and pretreatment is carried out on the iron base and the metal so as to making the iron base and the metal foil reach the use requirements; 2, a graphite die is taken, and the graphite die comprises an upper pressure head, a lower pressure head and a hollow female die; and the iron base, the metal foil and molybdenum-containing metal powder are put into the female die successively, and the graphite die is pressed by the upper pressure head and the lower pressure head; and 3, the graphite die is placed into a hearth of a discharge plasma sintering system, the current is introduced, and sintering and bonding are carried out on the iron base and the molybdenum-containing metal powder. According to the preparation method, the problem that the thermal expansion coefficient between the coating and a base body is not consistent when a high-temperature coating is prepared on a low-melting-point base body is effectively solved, and the bonding strength is relatively high.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

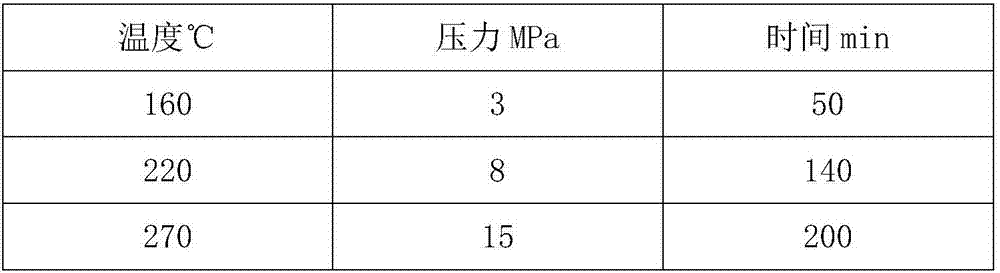

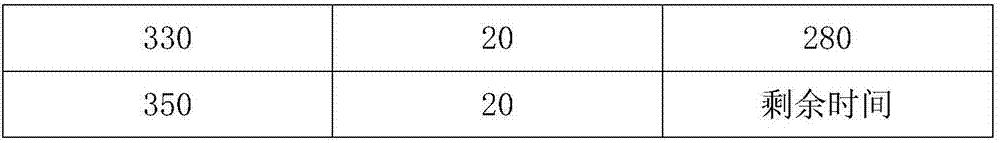

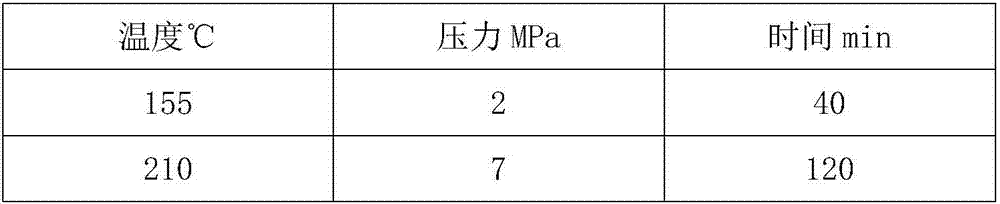

Preparation method for compact aluminum titanate ceramic

The invention belongs to the technical field of a ceramic material and specifically relates to a preparation method for a compact aluminum titanate ceramic. The method comprises the following steps: by taking tetrabutyl titanate and aluminum nitrate as raw materials, taking an alcohol solution containing a dispersing agent as a solvent and taking butyl silicate as an internal additive; introducing ammonia gas, refluxing, aerating and reacting, thereby acquiring a gel solution; by taking ferric chloride as an external additive, adding a curing agent, reducing pressure and distilling, thereby acquiring the gel; adding the gel into a mold, vibrating, heating and curing; and raising temperature in gradient, pressurizing, drying and sintering in a muffle furnace, thereby acquiring the compact aluminum titanate ceramic. The invention solves the problem of complex preparation process of the liquid phase compound in the prior art; the method provided by the invention is high in plasticity and is capable of customizing the ceramic shape according to the requirement; the prepared aluminum titanate is high in purity, fine in structure and high in uniformity.

Owner:无锡特科精细陶瓷有限公司

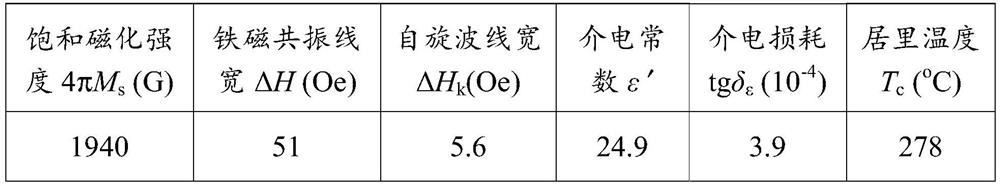

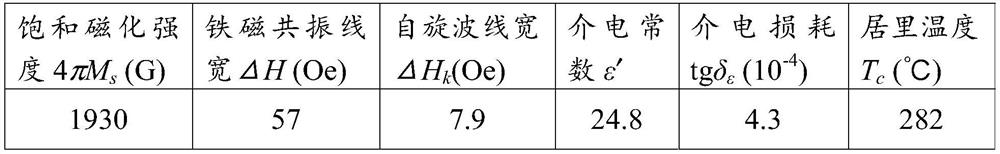

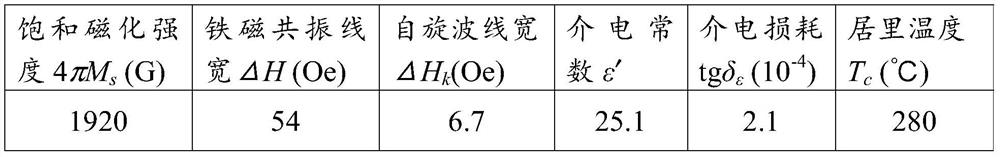

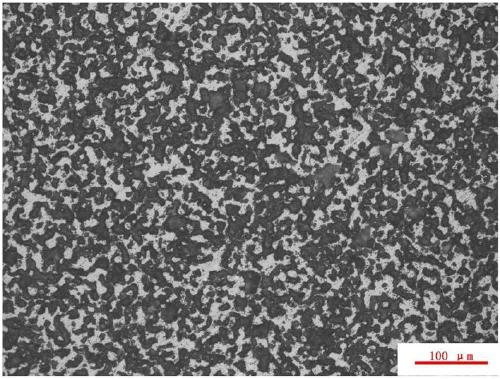

Preparation method of garnet with high power and high dielectric constant and garnet

The invention discloses a preparation method of garnet with high power and high dielectric constant, which comprises the following steps: (1) burdening according to a chemical formula Y < 3-x-z-z '-y-2x'-z ''-p-q>Bi < x > Sm < z > Gd < z '> Ca < 2x' + y + z '' + p + q>Zr < y > Sn Ti < q > Ge < z '> In<p'> V < x '> Mn < w > Al < w' > Fe < 5-x '-y-z' '-p-q-w-w'-delta-p >O < 12 >, wherein 0<=x<=1.3, 0<=x'<=0.70, 0<=y'<=0.70, 0<=z<=1.0, 0<=z'<=1.0, 0<=z''<=1.5, 0<=p<=0.50, 0<=q<=0.50, 0<=w<=1.30, 0<=p'<=0.50, 0<=w'<=0.10, and the iron deficiency delta is 0 <= delta<= 0.50; (2) primary ball milling; (3) drying, and pre-sintering in an oxidizing atmosphere for the first time; (4) secondary ball milling; (5) after drying, carrying out secondary pre-sintering in an oxidizing atmosphere; (6) carrying out third-time ball milling; (7) drying and granulating, primarily pressing granules into a blank, and then carrying out cold isostatic pressing; and (8) putting a formed blank into a furnace in an oxidizing atmosphere to be sintered at the sintering temperature from 900 DEG C to 1450 DEG C, and the heat preservation time from 30 hours to 100 hours. The high-magnetic-moment garnet material with relatively low delta H, relatively high delta Hk and a high dielectric constant epsilon' is obtained by promoting the solid-phase reaction degree, reducing the formation of a Bi-rich phase and utilizing rare earth ions Sm < 3 + > for substitution in the formula.

Owner:绵阳市维奇电子技术有限公司

Boron carbide nuclear neutron absorbing material and preparation method

InactiveCN109592982AImprove absorption efficiencyLarge absorption surface areaCeramicwareNuclear gradeBoron carbide

The invention relates to a boron carbide nuclear neutron absorbing material and a preparation method. The preparation method comprises the following steps: putting the three raw materials including 85percent by weight to 98.5 percent by weight of boron carbide powder (nuclear-grade powder), 1 percent by weight to 5 percent by weight of solid phase sintering additives and 0.5 percent by weight to10 percent by weight of liquid phase sintering additives into a ball mill mixing container; adding a polymer material as a soft template and adding deionized water to perform balling milling and pulping to obtain the slurry, wherein the solid phase content of the slurry is 40 percent by weight to 70 percent by weight; processing the slurry by using a spray drying granulating machine to obtain granulating powder; pressing the granulating powder by adopting the processes of dry pressing molding or cold isostatic pressing molding under the pressure of 50MPa to 300MPa to form green bodies; and putting the green bodies into a vacuum furnace, keeping a temperature for 0.5 hour to 5 hours under the temperature of 2000 DEG C to 2300 DEG C by adopting a vacuum or constant-pressure sintering way soas to complete sintering to obtain boron carbide ceramics. The boron carbide nuclear neutron absorbing material and the preparation method disclosed by the invention have the advantages that by usingthe boron carbide nuclear-grade powder as a raw material and the polymer material as the soft template, the boron carbide nuclear neutron absorbing material is prepared; the boron carbide nuclear neutron absorbing material has the advantages of low cost, batch production, low free carbon content and high neuron absorption efficiency, is suitable for preparing large-sized protection parts with complicated shapes, and has good application prospect in small nuclear reactor outer-layer protection and other types of nuclear reactor protection.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

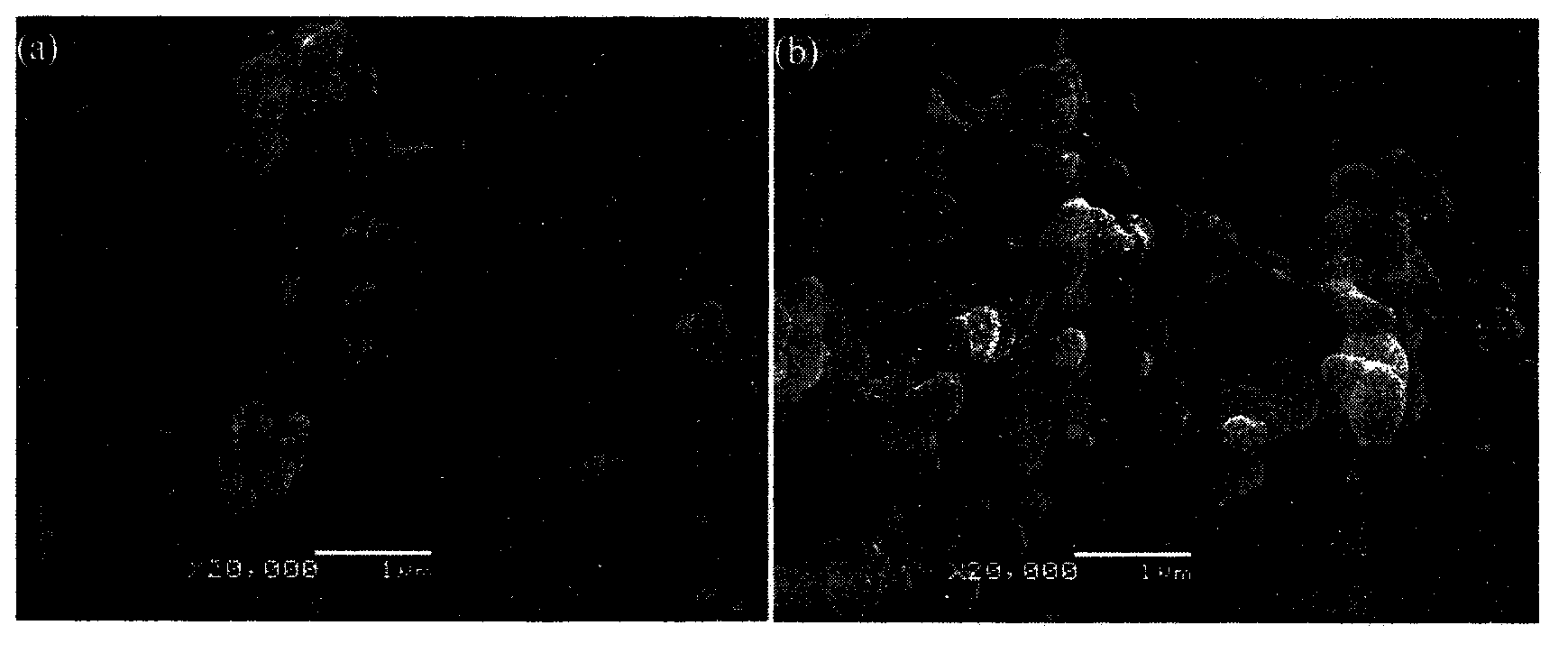

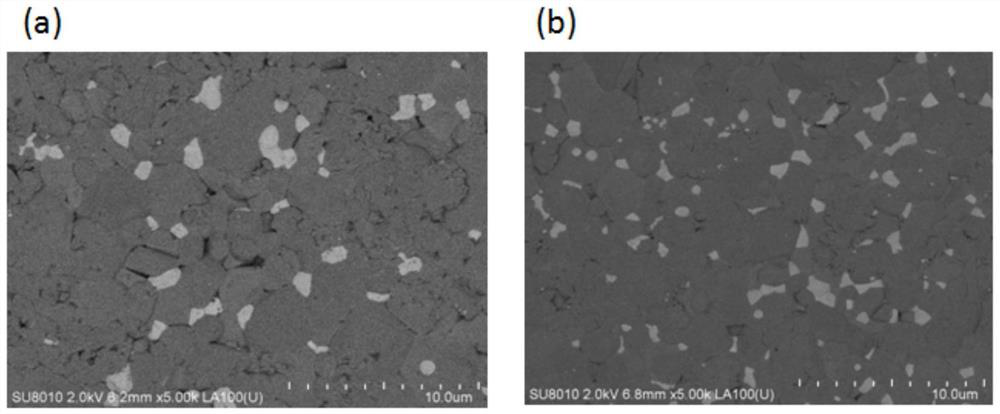

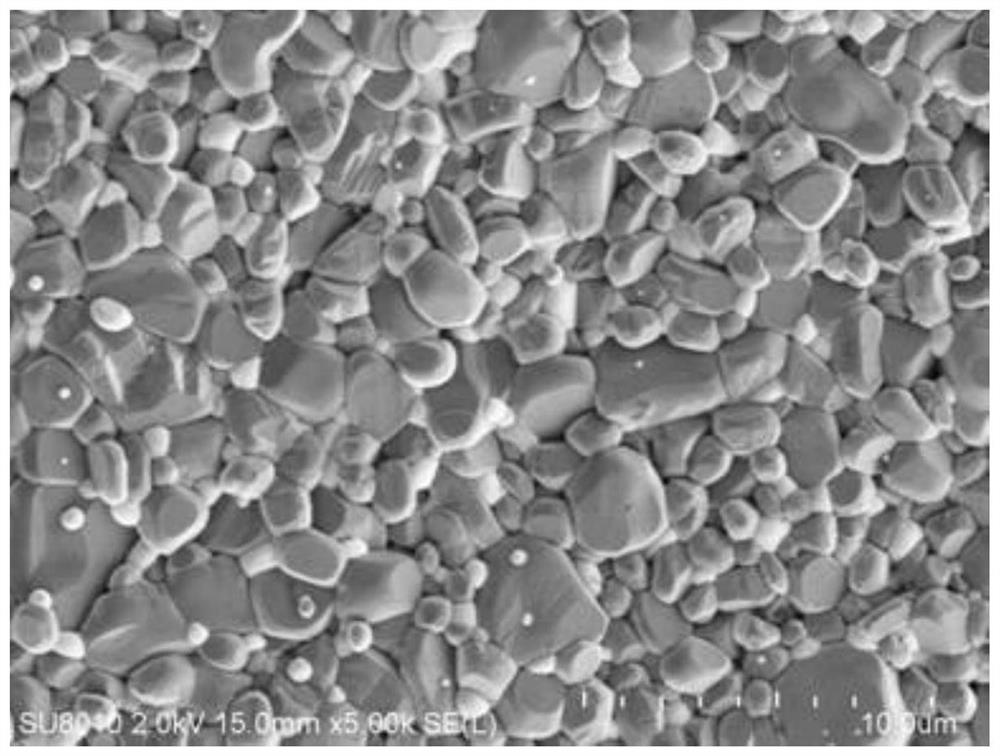

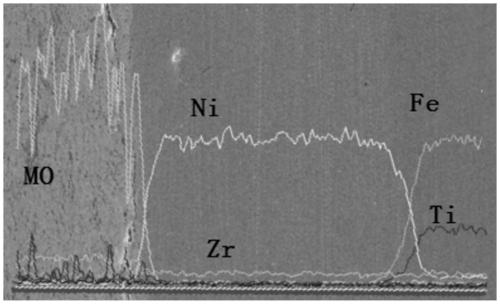

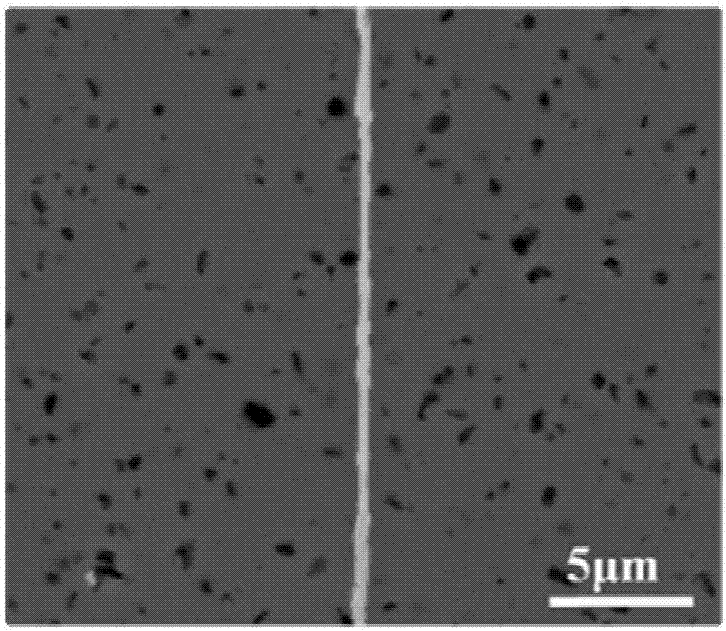

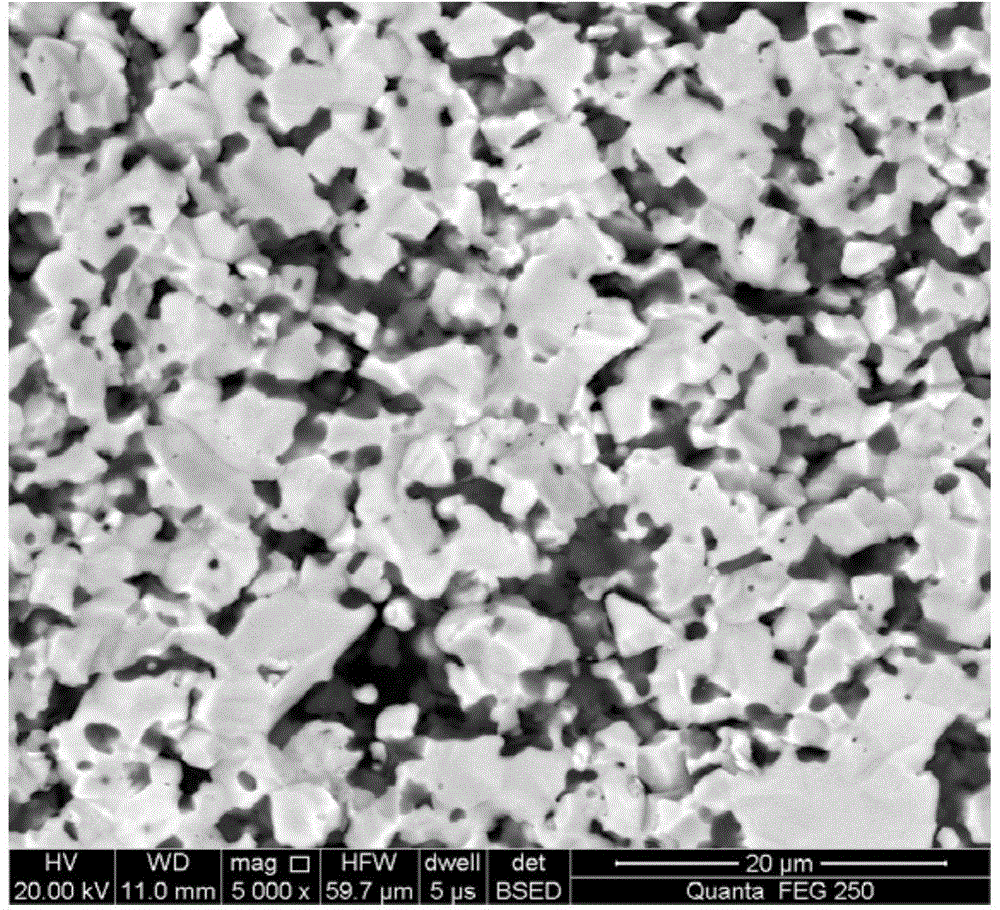

Silicon carbide particle reinforced 316L stainless steel substrate composite material and preparation method thereof

The invention relates to a silicon carbide particle reinforced 316L stainless steel substrate composite material and a preparation method thereof. The silicon carbide reinforced 316L stainless steel substrate composite material comprises a 316L stainless steel substrate and silicon carbide particles evenly distributed in the 316L stainless steel substrate. The volume fraction of the silicon carbide particles is 2-30%. According to the preparation method of the silicon carbide particle reinforced 316L stainless steel substrate composite material, raw material powder is prepared into slurry and ball-milling is conducted by using a KD-1 polyester polyamine compound dispersant, so that the silicon carbide particles and the metal powder are fully mixed, agglomeration is avoided, therefore the powder which is subjected to ball-milling has a larger specific surface area, and later sintering densification is facilitated; and hot-pressing sintering is conducted so that the silicon carbide particle reinforced stainless steel substrate composite material with the high density and strength can be obtained. The preparation method of the silicon carbide particle reinforced 316L stainless steel substrate composite material is simple in process and short in preparation period, the material is high in density and strength.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

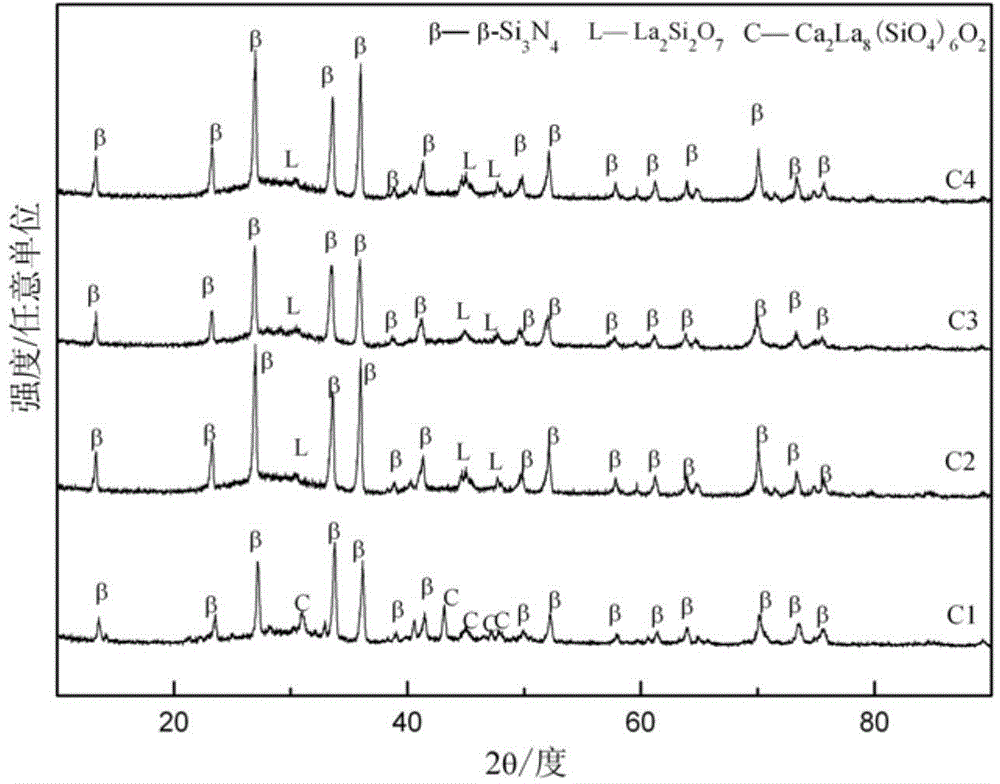

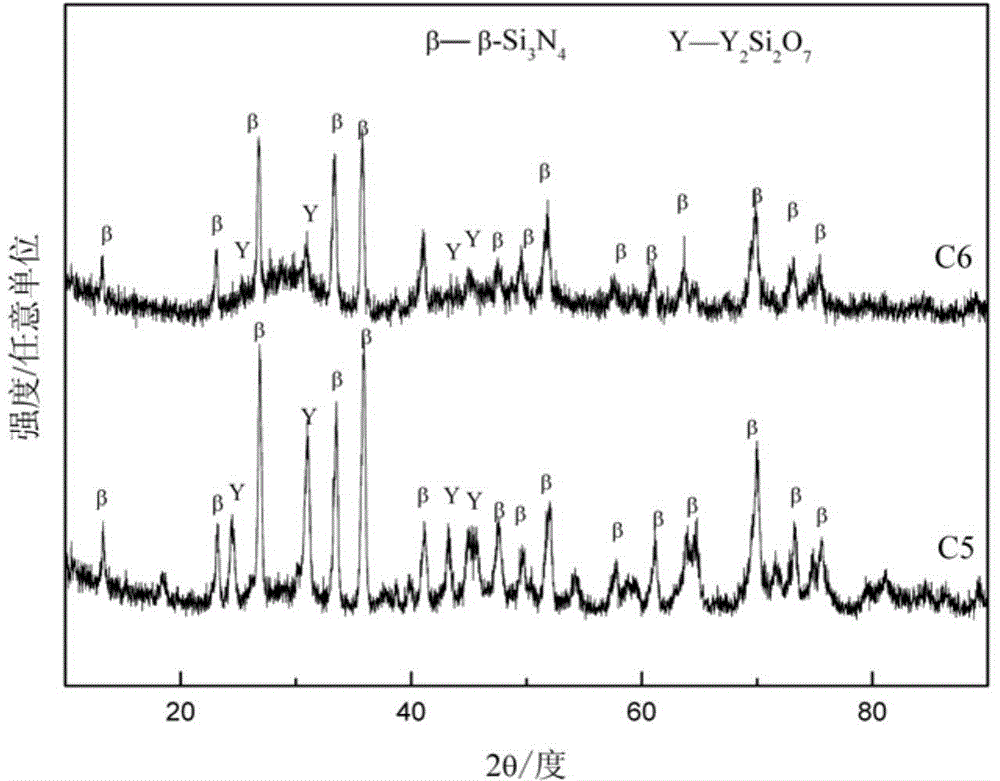

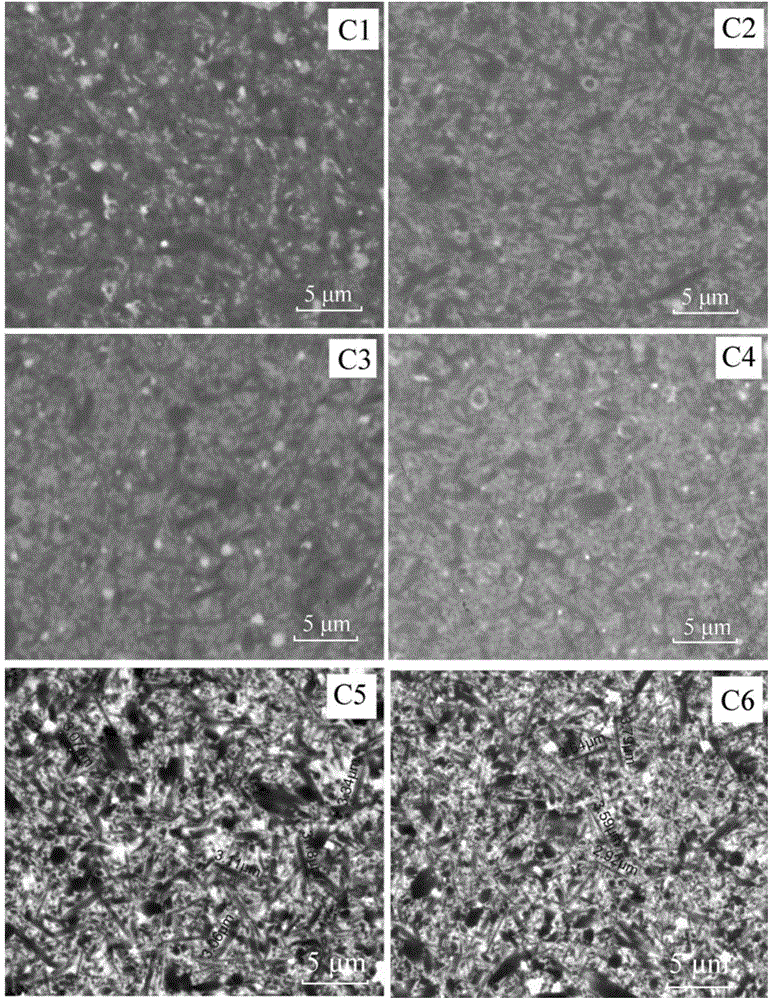

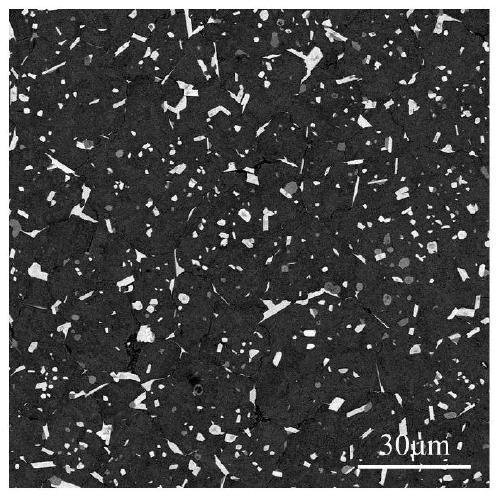

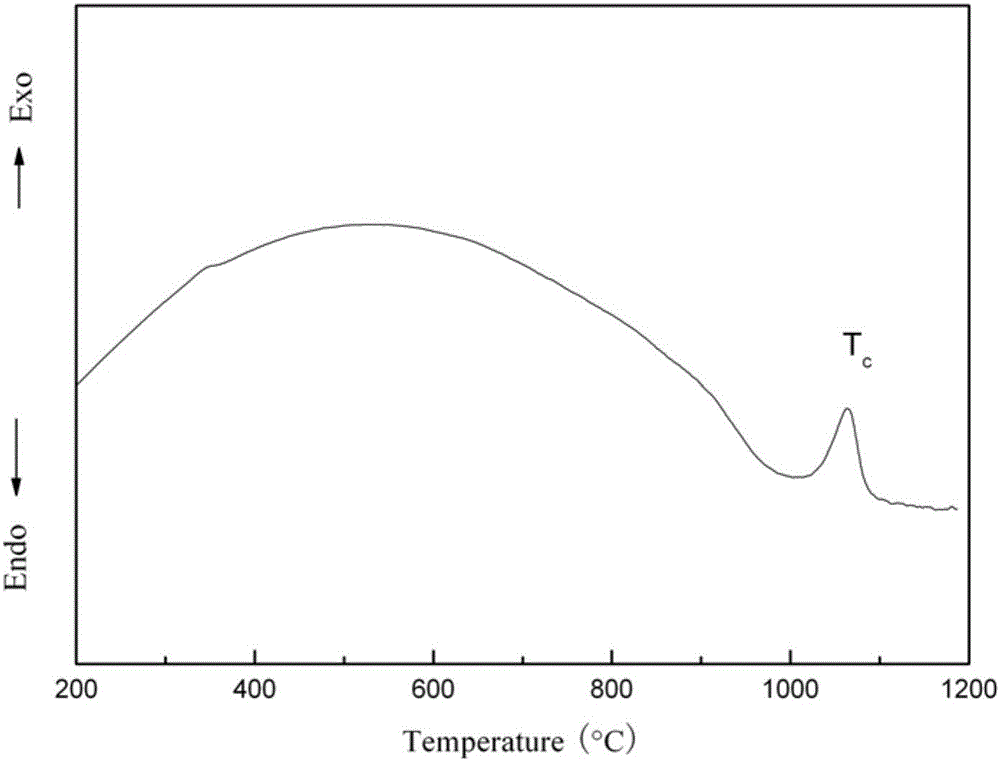

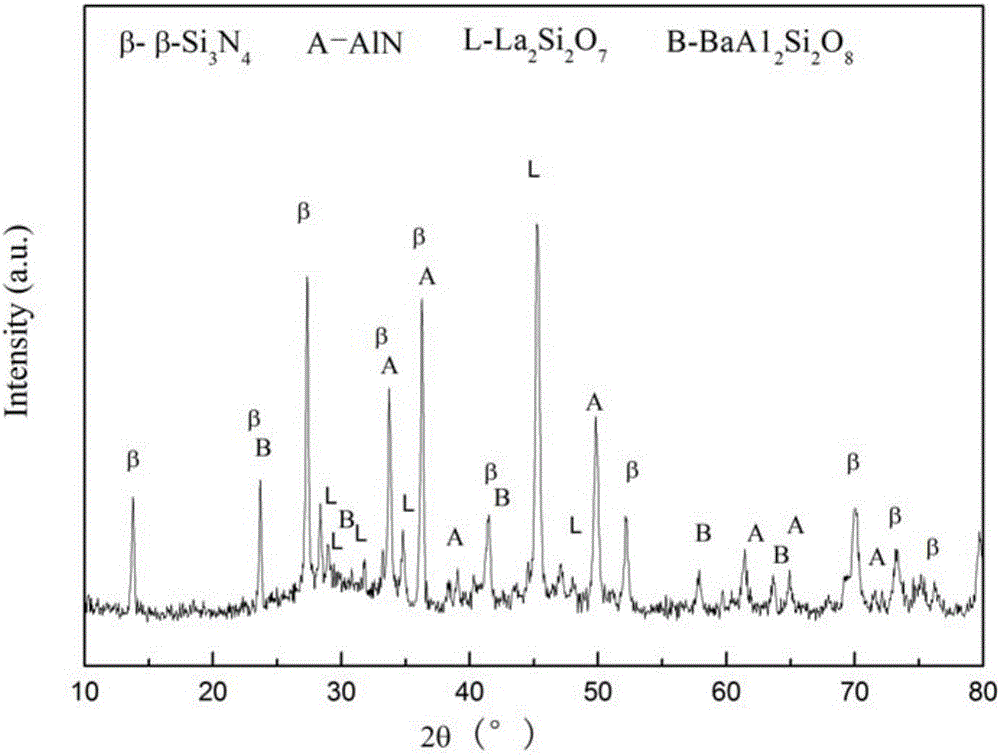

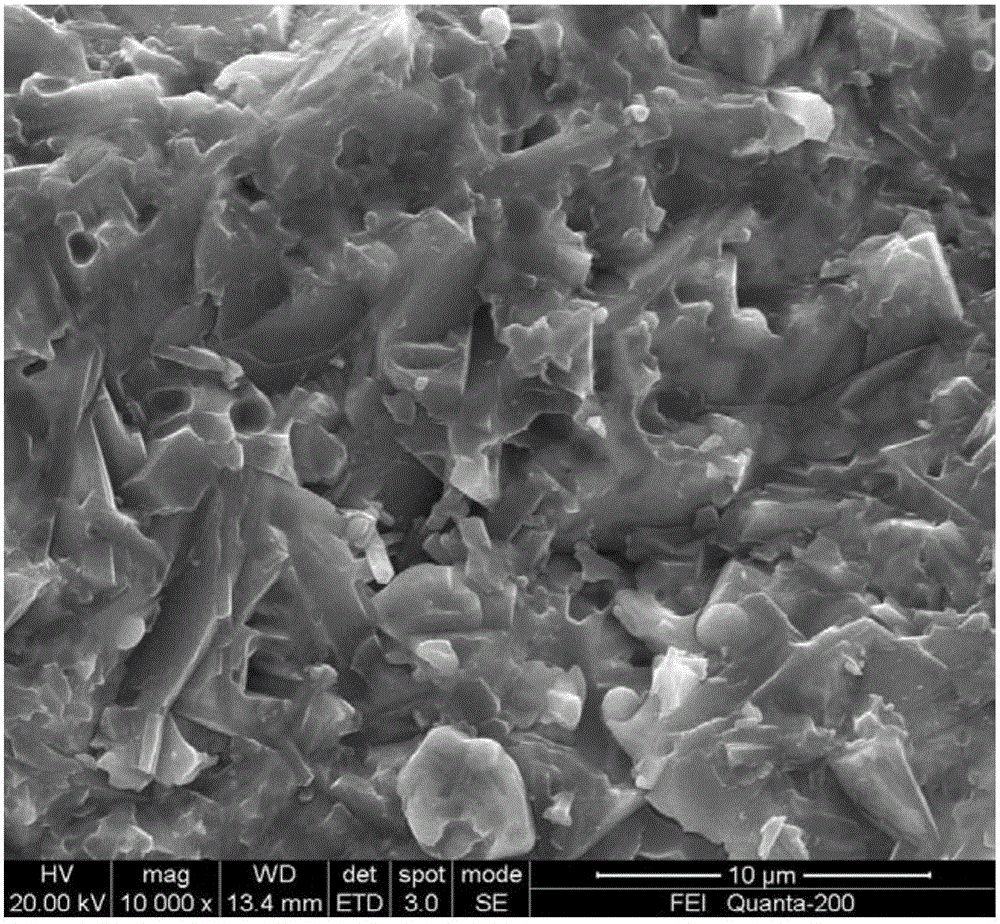

In-situ growth beta-Si3N4 fiber/rod-like crystal enhanced glass-ceramic composite material and preparation method thereof

The invention discloses an in-situ growth beta-Si3N4 fiber / rod-like crystal enhanced glass-ceramic composite material and a preparation method thereof. The preparation method of the composite material comprises the steps that melt cooling and water quenching are carried out on La2O3, Y2O3, CaCO3, MgO, Li2CO3, Al2O3, SiO2 and other raw materials to prepare rare earth doped aluminosilicate glass powder, compression molding, drying and sintering are carried out on the glass powder and alpha-Si3N4 powder, and therefore the in-situ growth beta-Si3N4 fiber / rod-like crystal enhanced glass-ceramic composite material with the characteristics of being high in strength, low in coefficient of thermal expansion, high in heat conductivity and the like is obtained. The preparation technology is simple, low in sintering temperature, environmentally friendly and low in production cost. The obtained composite material has the wide application prospect, and can partially replace carbon / carbon, silicon carbide, carbon / silicon carbide, silicon nitride and other ceramic base high temperature structural materials to be used in the high-tech field of aerospace, aviation, national defense military industries, advanced manufacturing and the like.

Owner:CENT SOUTH UNIV

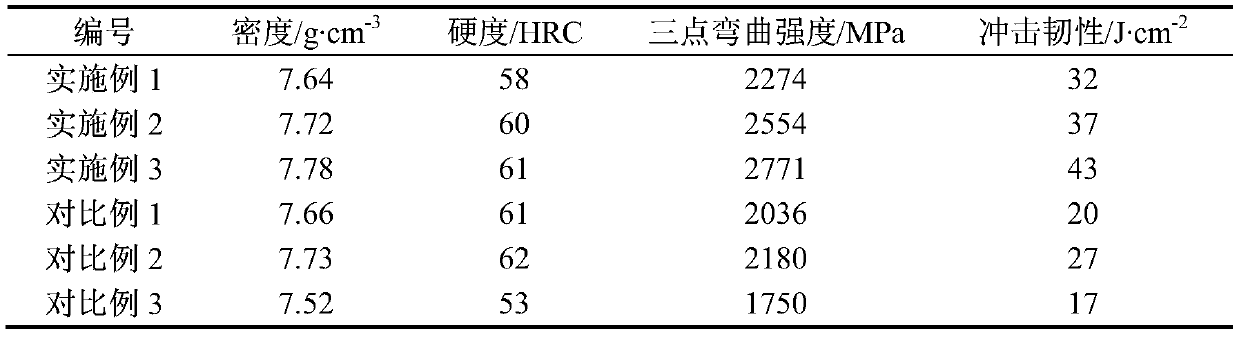

High-performance powder metallurgy pressing sintering type semi-high-speed steel and preparation method thereof

The invention discloses high-performance powder metallurgy pressing sintering type semi-high-speed steel and a preparation method thereof. Preparation of the high-performance powder metallurgy semi-high-speed steel is achieved by adopting carbonyl iron powder and carbide powder as raw materials through the processes of ball-milling mixing, cold pressing forming, thermal degreasing, vacuum sintering and the like. The prepared semi-high-speed steel is uniform in chemical component, fine in grain and capable of achieving overall dispersion distribution of carbides, the problems such as componentsegregation and thick carbides existing in a traditional casting method are avoided, and the strength and the toughness of the material are significantly improved. The high-performance powder metallurgy pressing sintering type semi-high-speed steel has the advantages that the technological process is simple, the production cost is low, and the components are easy to control. Compared with semi-high-speed steel prepared through a casting method, the semi-high-speed steel has the advantage that the bending strength and the impact toughness are obviously improved at the same compactness.

Owner:CENT SOUTH UNIV

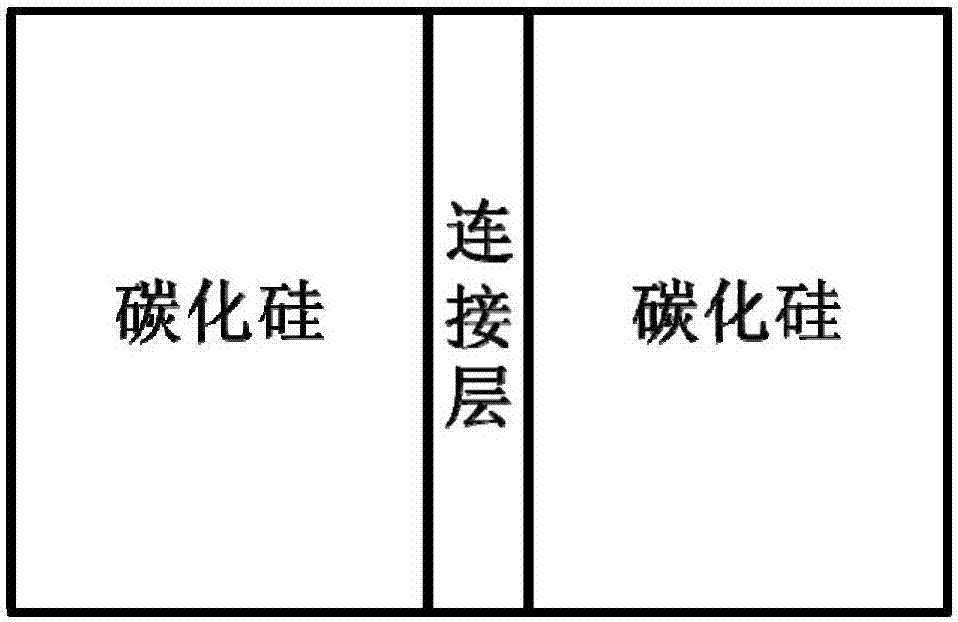

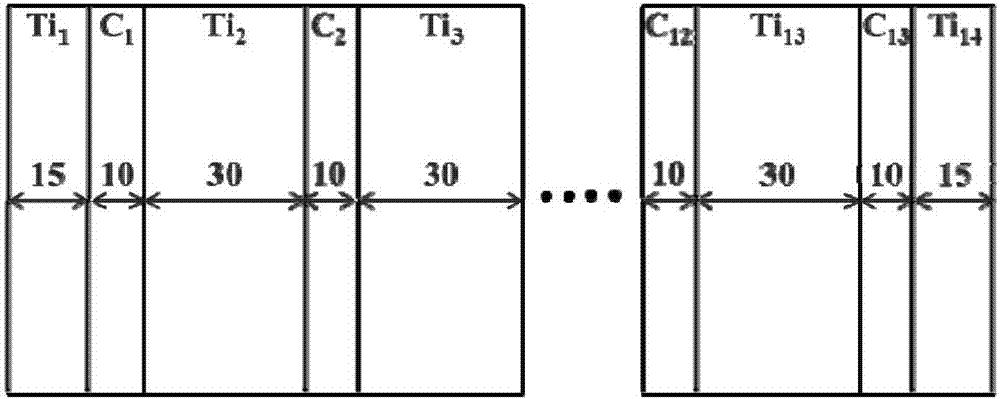

Connection material for connecting silicon carbide ceramics, and method for connecting silicon carbide ceramics

ActiveCN107488046APromotes sintering densificationIncrease the surface energy of the interfaceCarbide siliconCarbon layer

The present invention provides a connection material for connecting silicon carbide ceramics. The connection material has a left-right stacked structure, and comprises at least two titanium layers, wherein a carbon layer is arranged between the adjacent titanium layers. According to the present invention, the connection material is sandwiched between silicon carbide ceramic materials to be connected, and the nanometer titanium layer and the nanometer carbon layer are subjected to an exothermic reaction when the SiC materials to be connected are integrally connected by heating the connection interface through an external heat source, such that the middle connection layer can release the partial heat so as to reduce the energy supply of the external heat source, easily save the cost, and reduce the industrial production difficulty.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Titanium calcium aluminate-silicon carbide complex phase refractory material and preparation method thereof

The invention relates to a titanium calcium aluminate-silicon carbide complex phase refractory material and a preparation method thereof. The preparation method is characterized by taking 18 to 23 weight percent of alpha-Al2O3 powder, 5 to 10 weight percent of silicon micropowder and 1 to 3 weight percent of vanadium pentoxide are used as a first raw material; 55 to 60 weight percent of titanium calcium aluminate particles, 5 to 10 weight percent of silicon carbide particles and 4 to 6 weight percent of silicon carbide fine powder are used as a second raw material; the first raw material and the second raw material form raw materials; the second raw material, the first raw material subjected to ball grinding and an aluminum dihydrogen phosphate solution accounting for 3 to 4 weight percentof raw materials are subjected to mixing rolling, formation and drying; then, a dried blank body is put into an aluminum oxide sagger paved with crystalline flake graphite at the bottom; the crystalline flake graphite is used for filling and burying; heat insulation is performed for 3 to 4h under the condition of 1400 to 1450 DEG C; cooling is performed along with a furnace; the titanium calciumaluminate-silicon carbide complex phase refractory material is prepared. The characteristics of resource comprehensive utilization, energy saving and environment protection are realized; the preparedproduct has the advantages of high rupture strength, high compressive strength, low heat conductivity coefficient, excellent thermal shock resistant performance and good alkaline gas erosion resistantperformance.

Owner:WUHAN UNIV OF SCI & TECH +1

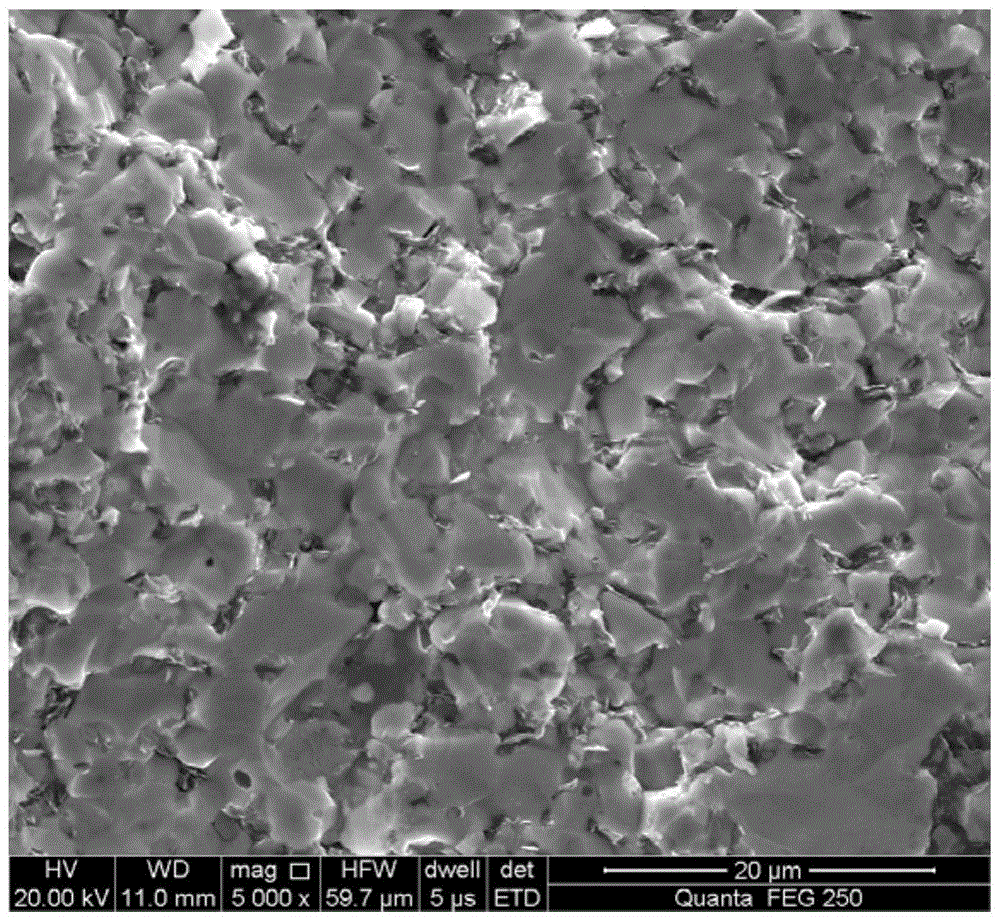

Self-enhancement-toughening silicon nitride/ aluminium nitride/ lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and preparing method of ternary composite material

InactiveCN106830690ASmall coefficient of thermal expansionExcellent hot corrosion resistanceSilicon nitrideLanthanum

The invention discloses a self-enhancement-toughening silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and a preparing method of the ternary composite material. The ternary composite material adopts lanthanum barium silicate glass powder, aluminum nitride powder and alpha-silicon nitride powder as raw materials, is prepared through blanking and sintering, and contains beta-silicon nitride rod-like crystal. The silicon nitride / aluminum nitride / lanthanum barium silicate glass ceramics ternary composite material has the advantages of being low in density, high in strength, high in fracture characteristic, high in dielectric constant, low in inflation coefficient, high in conductivity and the like. The preparing method of the ternary composite material is simple in preparing process and low in the glass melting temperature and the composite material sintering temperature, and the ternary composite material is friendly to environment and low in production cost. The prepared ternary composite material has a good application prospect, can partially replace an existing high temperature structure material, and is applied in the fields of national defense and military industries, electronic devices, high thermal conductivity ceramic baseplates, high-end ceramic parts and the like.

Owner:CENT SOUTH UNIV

Method for preparing zirconium diboride based ceramic composite material at low temperature

The invention relates to a method for preparing a zirconium diboride based ceramic composite material at a low temperature, and belongs to the technical field of preparation of inorganic composite materials. Pre-produced ceramic powder obtained by mixing zero-valent iron and ceramic powder is subjected to pressure sintering, and the zirconium diboride based ceramic composite material whose density is larger than or equal to 93% is obtained; the ceramic powder comprises zirconium boride powder; the pressure sintering temperature ranges from 1,200 DEG C to 2,000 DEG C, and the pressure ranges from 5 MPa to 100 MPa; the mass of the zero-valent iron is 0.1%-15% of that of the ceramic powder. The preparation process is simple; the prepared zirconium diboride based ceramic composite material has excellent performance; the problems of high energy consumption, low finished product rate, over-high brittleness of a finished product and the like in a conventional preparation process are solved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com