High-performance powder metallurgy pressing sintering type semi-high-speed steel and preparation method thereof

The technology of powder metallurgy pressing and semi-high speed steel is applied in the field of high-performance powder metallurgy pressing and sintering semi-high speed steel and its preparation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

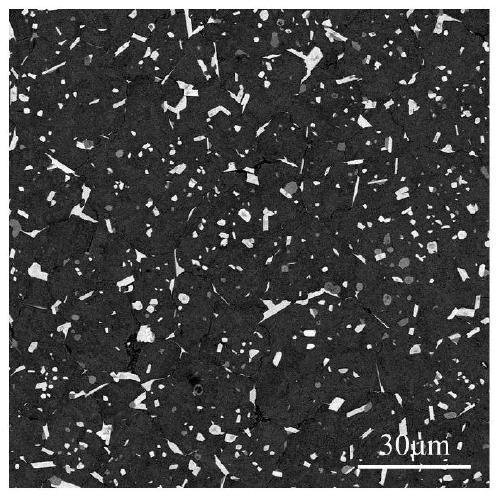

Image

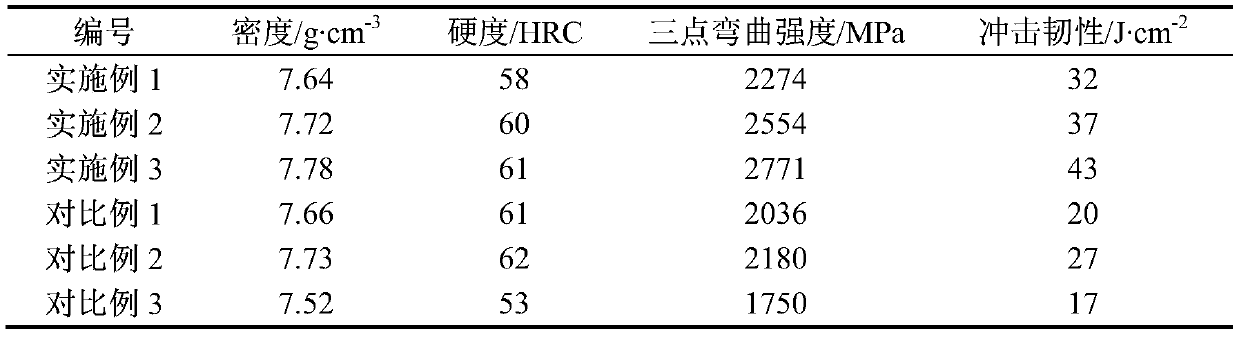

Examples

Embodiment 1

[0035] 93.48wt.% carbonyl iron powder, 0.54wt.% WC powder, 2.13wt.% Mo 2 C powder, 2.37wt.%Cr 2 C 3 Powder, 1.48wt.% VC powder is placed in a planetary ball mill container for high-speed ball milling. The material of the tank and the balls are hard alloy. The ball-to-material ratio is 8:1. Water and ethanol; then, add 0.5wt.% paraffin powder into the ball mill jar, and continue ball milling for 4 hours at a speed of 200r / min.

[0036] Then pour the ball-milled powder into a tray, lay it flat and place it in an oven for blast drying at a drying temperature of 70°C and a drying time of 90 minutes, and then pass the powder through a 100-mesh sieve for granulation to obtain a fully dried mixture .

[0037] The mixed material was weighed and formed in a mold, and bidirectional pressing was adopted, with a pressing pressure of 600 MPa and a holding time of 3 s, and then demoulding to obtain a green compact.

[0038] Put the compact into a hydrogen atmosphere sintering furnace fo...

Embodiment 2

[0043] 88.04wt.% carbonyl iron powder, 1.08wt.% WC powder, 3.19wt.% Mo 2 C powder, 4.73wt.%Cr 2 C 3 Powder, 2.96wt.% VC powder is put into the planetary ball mill container for high-speed ball milling. The material of the tank and the balls are hard alloy. The ball-to-material ratio is 9:1. water and ethanol; then, add 1.0wt.% paraffin powder into the ball mill jar, and continue ball milling for 5 hours at a speed of 230r / min.

[0044] Then pour the ball-milled powder into a tray, lay it flat and place it in an oven for blast drying at a drying temperature of 75°C and a drying time of 110 minutes, and then pass the powder through a 100-mesh sieve for granulation to obtain a fully dried mixture .

[0045] The mixed material was weighed and formed in a mold, and bidirectional pressing was adopted, with a pressing pressure of 650 MPa and a holding time of 4 s, and then demolded to obtain a green compact.

[0046] Put the compact into a hydrogen atmosphere sintering furnace fo...

Embodiment 3

[0051] 83.12wt.% carbonyl iron powder, 1.62wt.% WC powder, 3.72wt.% Mo 2 C powder, 7.10wt.%Cr 2 C 3 Powder, 4.44wt.% VC powder is put into the planetary ball mill container for high-speed ball milling. The material of the tank and the balls are hard alloy, the ball-to-material ratio is 10:1, the ball milling time is 50h, the speed is 250r / min, and the ball milling medium is none Water and ethanol; subsequently, 1.5wt.% paraffin powder was added into the ball mill jar, and ball milling was continued for 6 hours at a speed of 250r / min.

[0052] Then pour the ball-milled powder into a tray, lay it flat and place it in an oven for blast drying at a drying temperature of 80°C and a drying time of 120 minutes, and then pass the powder through a 100-mesh sieve for granulation to obtain a fully dried mixture .

[0053] The mixed material was weighed and formed in a mold, and bidirectional pressing was adopted, with a pressing pressure of 700 MPa and a holding time of 5 s, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com