Method for adding Sn reinforcing sintering powder metallurgy TiAl base alloy

A powder metallurgy and enhanced sintering technology, applied in the field of powder metallurgy, can solve the problems of alloy high-temperature mechanical properties and high-temperature oxidation resistance, etc., and achieve the effects of shortening sintering time, saving energy and equipment consumption, and easy control of alloy components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] -400 mesh Ti-45Al-8.5Nb-0.5 (B, W, Y) (meaning Al45% by atomic percentage, Nb8.5%, the total content of B, W and Y is 0.5%, the balance is Ti , the same below) pre-alloyed powder as raw material, adding -500 mesh Sn powder as a sintering aid, after adding Sn, the content of Sn element in the mixed powder is 2.8wt.%. After the powders are uniformly mixed, they are put into a steel mold and pressed into a green body in one direction, and the relative density of the green body is 70%, and then the obtained green body is placed in a vacuum tube furnace for sintering. The sintering process is as follows: rapidly raise the temperature to 1100°C at 7°C / min, and hold the heat for 60 minutes; then slowly raise the temperature to 1500°C at 2°C / min, hold for 120 minutes, and then cool to room temperature with the furnace to obtain a TiAl-based alloy block body material.

[0037] Performance testing:

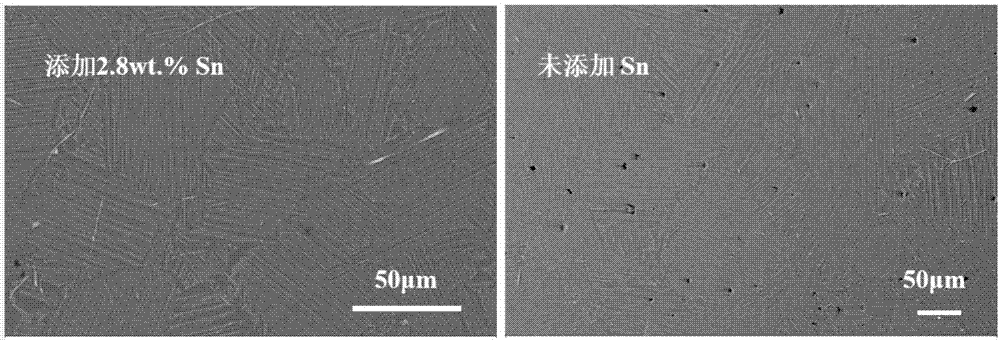

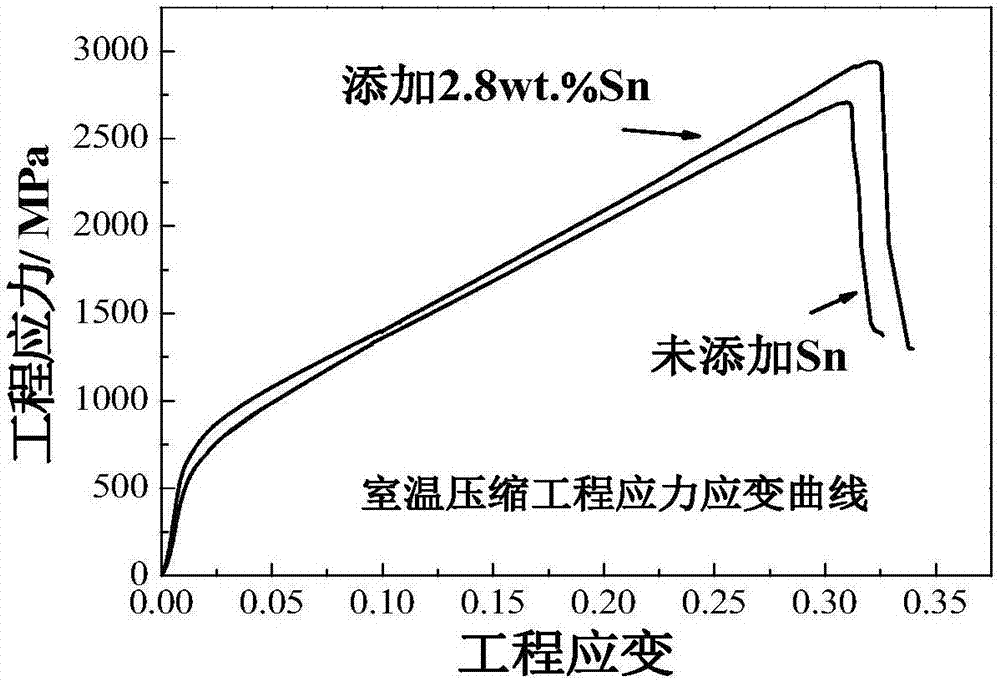

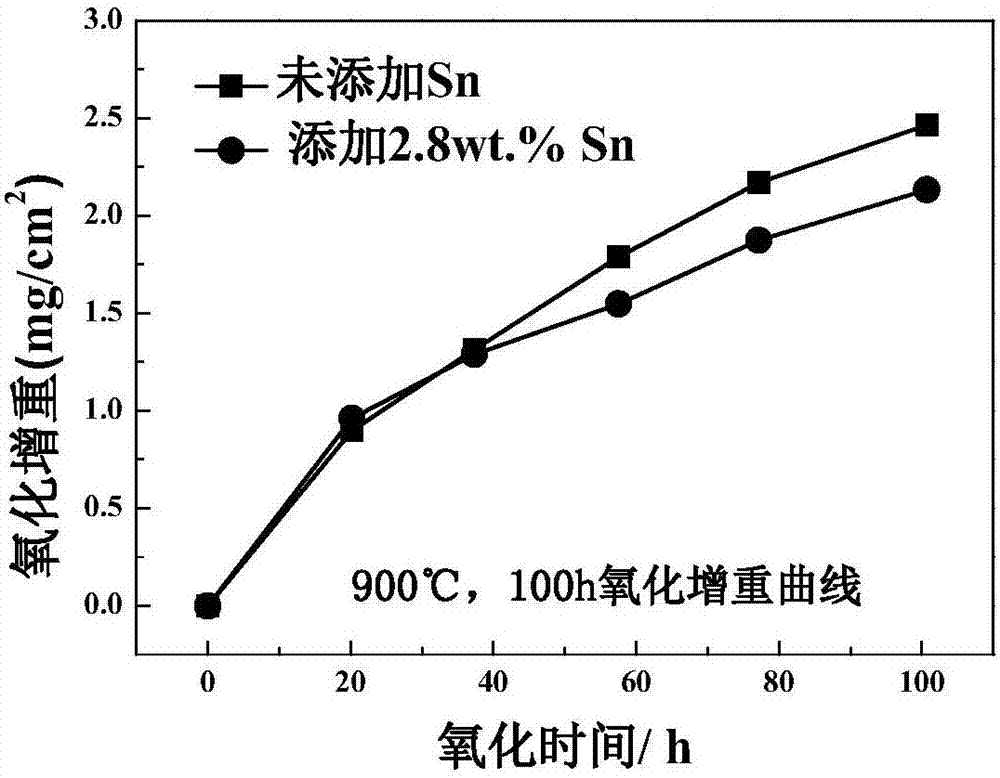

[0038] 1) Microstructure: The powder metallurgy sintered TiAl alloy and the po...

Embodiment 2

[0043] -400 mesh Ti-45Al-9Nb pre-alloyed powder is used as raw material, and -500 mesh Sn powder is added as a sintering aid. After adding Sn, the content of Sn element in the mixed powder is 8wt.%Sn. After the powders are evenly mixed, they are loaded into a steel mold and bi-directionally pressed to form a green body with a relative density of 75%, and then the obtained compact is placed in a vacuum tube furnace for sintering. The sintering process is as follows: the temperature is rapidly raised to 1300°C at 10°C / min, and the heat preservation time is 30 minutes; then the temperature is slowly raised to 1480°C at 2°C / min, and the temperature is maintained for 120 minutes, and then cooled to room temperature with the furnace to obtain a TiAl-based alloy block body material.

[0044] The relative density and mechanical properties were tested, and the results were as follows: the relative density of the alloy increased from 95.8% without addition to 98.5%; the compressive stre...

Embodiment 3

[0046] -200 mesh Ti-45Al-5Nb pre-alloyed powder is used as raw material, and -500 mesh Sn powder is added as a sintering aid, and the content of Sn element in the mixed powder after adding Sn is 0.8wt.%Sn. After the powders are uniformly mixed, put into a soft mold and cold isostatically press to form a green body with a relative density of 85%, and then place the obtained green body in a vacuum tube furnace for sintering. The sintering process is as follows: the temperature is rapidly raised to 1150°C at 10°C / min, and the heat preservation time is 30 minutes; then the temperature is slowly raised to 1480°C at 2°C / min, and the temperature is maintained for 120 minutes, and then cooled to room temperature with the furnace to obtain a TiAl-based alloy block body material.

[0047] The relative density and mechanical properties were tested, and the results were: the relative density of the alloy was increased from 96.8% without addition to 97.8%; the compressive strength, yield s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compression ratio | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com