Self-enhancement-toughening silicon nitride/ aluminium nitride/ lanthanum barium silicate glass ceramics ternary composite material with self-enhancement-toughening and preparing method of ternary composite material

A barium aluminosilicate, strengthening and toughening technology, applied in the field of ceramic materials, can solve the problems of no β-silicon nitride strengthening and toughening, thermal properties mismatch, poor compatibility, etc., and achieves good thermal stability. , good high temperature mechanical properties, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

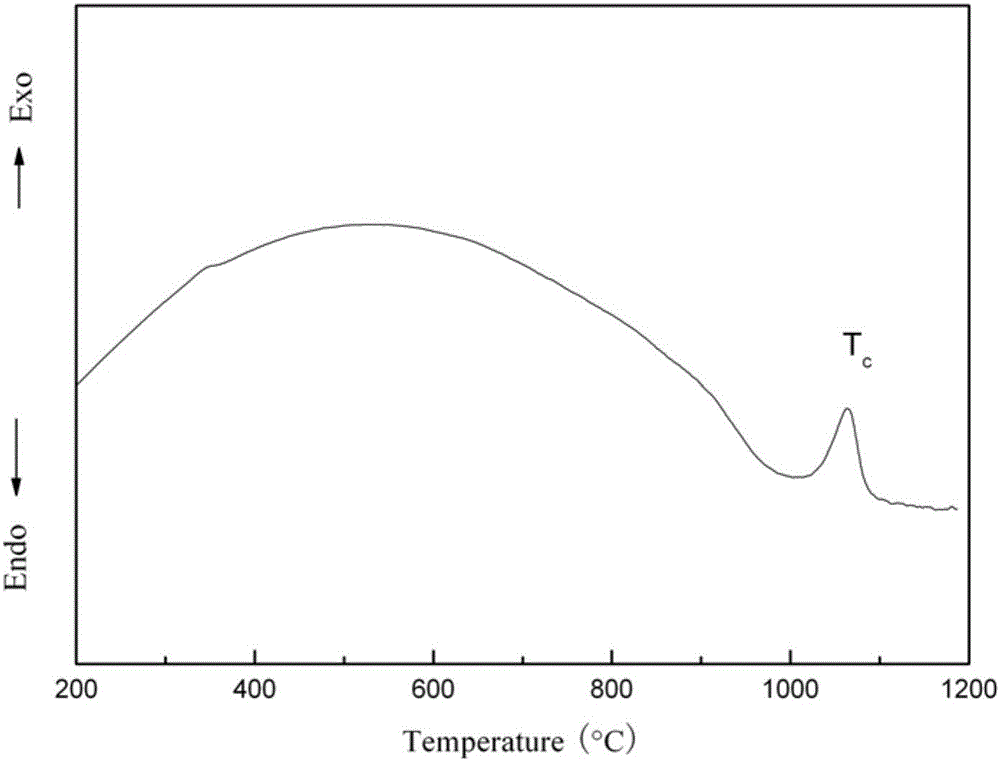

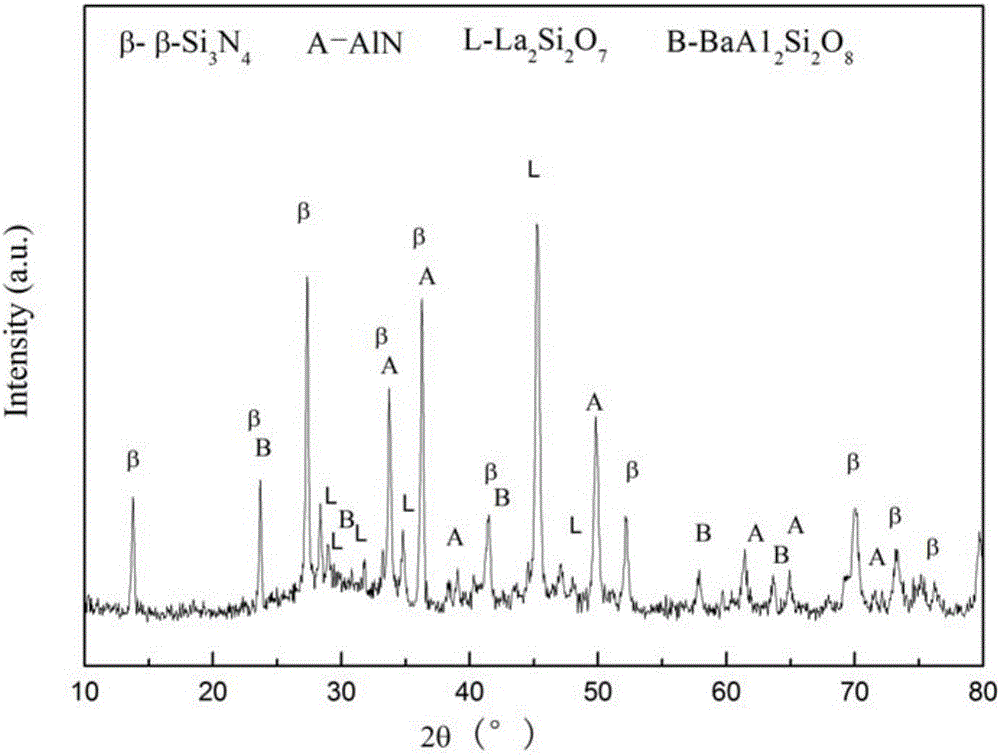

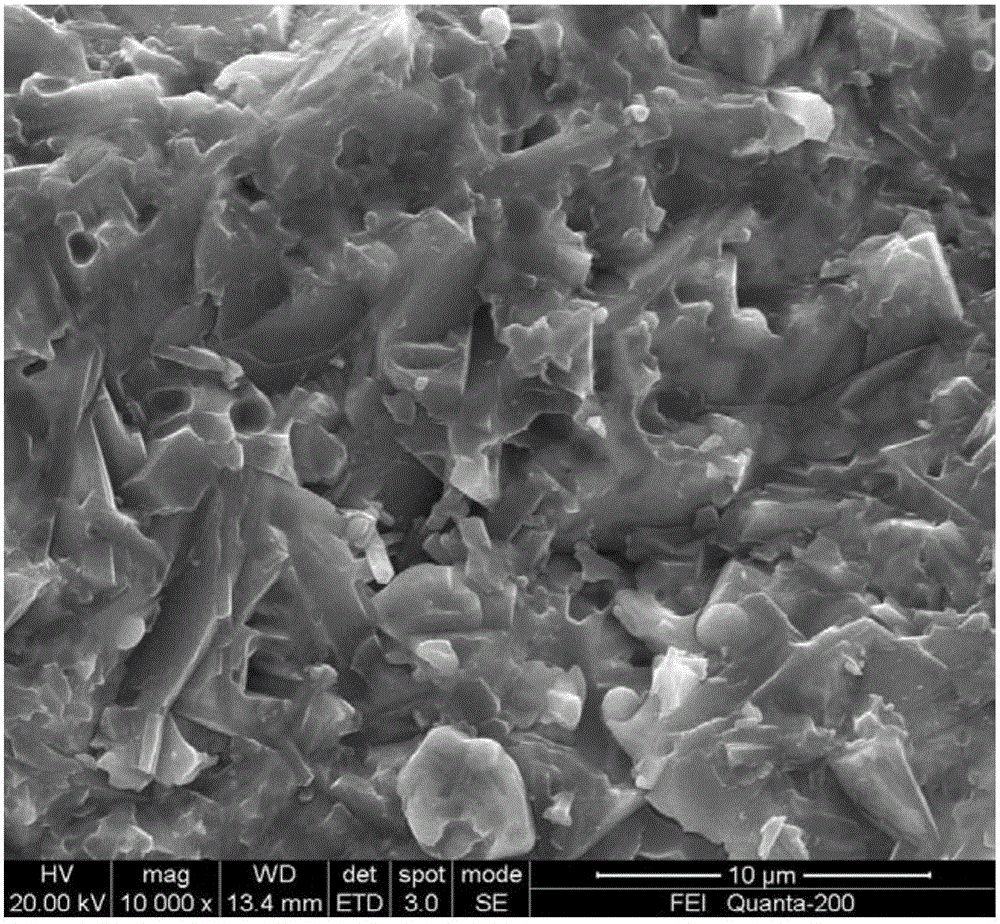

Method used

Image

Examples

Embodiment 1

[0052] The raw material components include lanthanum barium aluminosilicate glass powder, aluminum nitride and α-silicon nitride powder, the mass percent of which is glass powder content 27.0%, aluminum nitride powder content 16.0%, α-silicon nitride powder content 57.0% %. The mass percentage of each oxide component in its lanthanum barium aluminosilicate glass: La 2 o 3 25.0%, BaO 10.0%, Al 2 o 3 10.0%, SiO 2 was 55.0%.

Embodiment 2

[0054] The raw material components include lanthanum barium aluminosilicate glass powder, aluminum nitride and α-silicon nitride powder, the mass percent of which is glass powder content 27.0%, aluminum nitride powder content 20.0%, α-silicon nitride powder content 53.0% %. The mass percentage of each oxide component in its lanthanum barium aluminosilicate glass: La 2 o 3 22.0%, BaO 8.0%, Al 2 o 3 10.0%, SiO 2 was 60.0%.

Embodiment 3

[0056] The raw material components include lanthanum barium aluminosilicate glass powder, aluminum nitride and α-silicon nitride powder, the mass percent of which is glass powder content 30.0%, aluminum nitride powder content 18.0%, α-silicon nitride powder content 52.0% %. The mass percentage of each oxide component in its lanthanum barium aluminosilicate glass: La 2 o 3 28.0%, BaO 12.0%, Al 2 o 3 10.0%, SiO 2 is 50.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com