Method for synthesizing homogeneous nano silicon carbide powder by burning

A nano-silicon carbide, combustion synthesis technology, applied in the field of inorganic nano-material preparation, can solve the problems of coarse, generally micron or even tens of millimeters, difficult to scale production, expensive raw materials, etc., to achieve easy sintering densification, production The effect of short cycle time and high phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

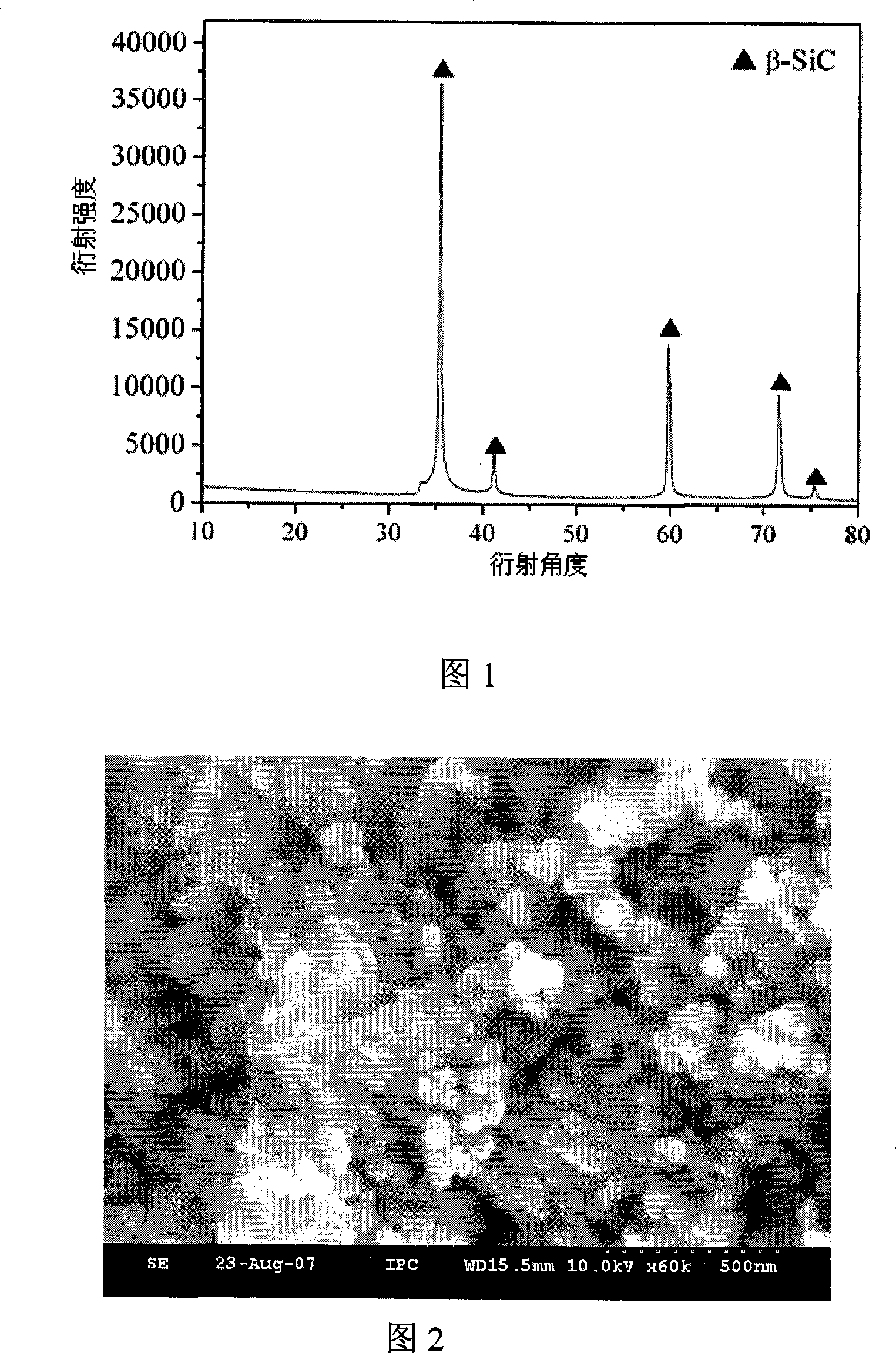

[0030] Si powder with an average particle size of 2.0 μm (purity higher than 99%) and carbon black with an average particle size of 20nm (purity higher than 98.5%) are weighed and mixed according to a mass ratio of 70:30, and then put into the SiC lining. The stainless steel ball mill tank of the grinding layer was ground and mixed with a vibrating ball mill for 1 hour for pretreatment. The pretreated mixed material is evenly packed in a graphite crucible, and the bulk density is about 0.6g / cm 3 . Put the graphite crucible and materials together into the high-pressure reaction device for combustion synthesis, wind a helical coil with a tungsten wire with a diameter of 0.5mm, and fix it above the materials. After vacuuming the reaction device, fill it with high-purity nitrogen to 9MPa. A 10-30A direct current is passed through the tungsten wire coil to trigger the reaction. The combustion synthesis reaction lasted about 18 minutes. After the synthesized product is fully coo...

Embodiment 2

[0032] Si powder with an average particle size of 17 μm (purity higher than 99%), carbon black with an average particle size of 20 nm (purity higher than 98.5%) and Si powder with an average particle size of 5 μm 3 N 4 According to the mass ratio of 66.5: 28.5: 5.0, the raw materials were weighed and mixed, and then put into a stainless steel ball mill jar lined with a SiC wear-resistant layer and ground and mixed for 1 hour with a vibrating ball mill for pretreatment. The pretreated mixed material is evenly packed in a graphite crucible, and the bulk density is about 0.8g / cm 3 . Put the graphite crucible and materials together into the high-pressure reaction device for combustion synthesis, wind a helical coil with a tungsten wire with a diameter of 0.5mm, and fix it above the materials. After vacuuming the reaction device, fill it with high-purity nitrogen to 6MPa. A 10-30A direct current is passed through the tungsten wire coil to trigger the reaction. The combustion sy...

Embodiment 3

[0034] Si powder (purity higher than 99%) with an average particle diameter of 70 μm, carbon black (purity higher than 98.5%) and polytetrafluoroethylene powder with an average particle diameter of 30 nm are weighed and mixed according to the mass ratio of 67.9: 29.1: 3.0, Then put it into a stainless steel ball mill tank lined with a SiC wear-resistant layer and use a vibration ball mill to grind and mix for 1 hour for pretreatment. The pretreated mixed material is evenly packed in a graphite crucible, and the bulk density is about 0.8g / cm 3. Put the graphite crucible and materials together into the high-pressure reaction device for combustion synthesis, wind a helical coil with a tungsten wire with a diameter of 0.5mm, and fix it above the materials. After vacuuming the reaction device, fill it with high-purity nitrogen to 6MPa. A 10-30A direct current is passed through the tungsten wire coil to trigger the reaction. The combustion synthesis reaction lasted about 21 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com