Low temperature fast preparation method of AlON crystalline ceramics

A transparent ceramic, fast technology, applied in the field of low-temperature rapid preparation, can solve problems such as restricting the shape of products, and achieve the effects of reducing impurities, good energy saving, and short holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

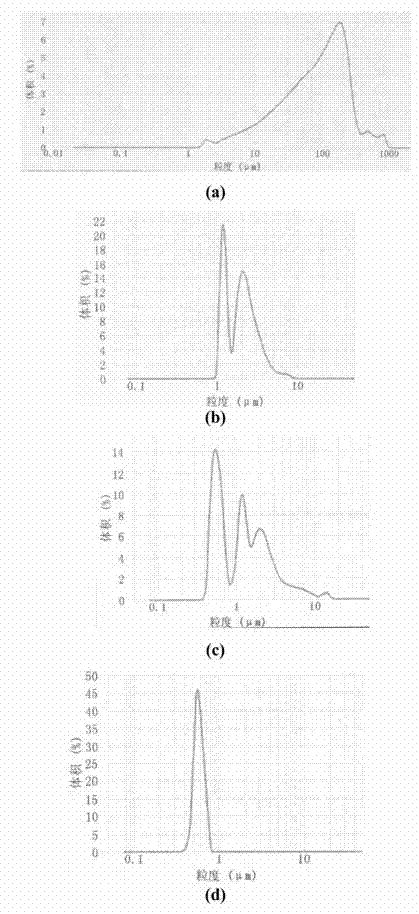

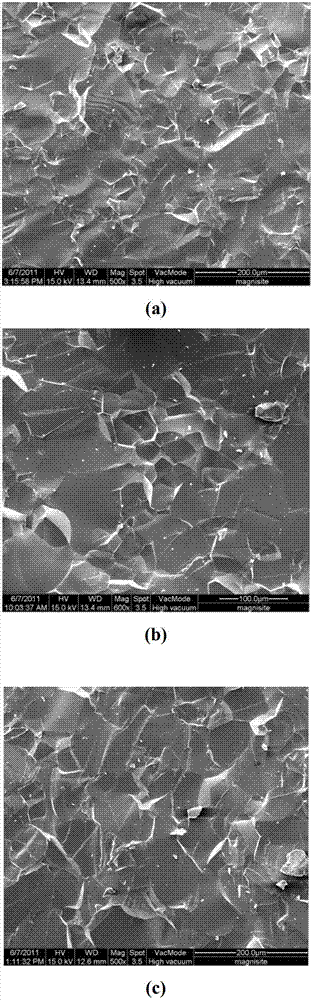

[0051] ①Ball milling: AlON powder and 0.5wt.% Y 2 o 3 Silicon nitride balls of 10mm, 8mm, and 5mm were used as the ball milling medium, the gradation of the balls was 1:0.8:1.2, the ball-to-material ratio was 6:1, and anhydrous ethanol 4 times the powder mass was added as the dispersion medium, and the poly Ball mill at 170r / min for 24h in a tetrafluoroethylene jar. like figure 1 (b) and figure 2 As shown in (b), the obtained powder has a small particle size and has a bimodal and narrow particle size distribution. SEM of the powder before ball milling see figure 1 (a), particle size distribution see figure 2 (a).

[0052] ②Drying and molding: Dry the AlON ceramic powder slurry obtained in step ① on a hot plate at 150°C for 60 minutes, pass through a 50-mesh sieve, and then dry-press on a tablet machine with a pressure of 100MPa to obtain an AlON green body.

[0053] ③Pre-vacuumize the sintering furnace: Put the green body formed in step ② into the graphite crucible,...

Embodiment 2

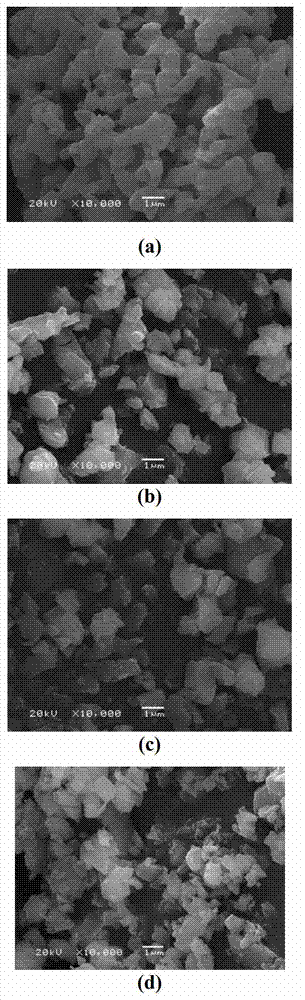

[0056] Other steps are the same as in Example 1, except that the ball mill speed is 250r / min, and the time is 24h. like figure 1 (c) and figure 2 As shown in (c), the obtained powder has the characteristics of fine particle size and three-peak particle size distribution. The sintering temperature is 1900°C, and the holding time is 60 minutes. The prepared ceramic phase composition is AlON transparent ceramics, see image 3 (b), microstructure see Figure 4 (b).

Embodiment 3

[0058] Other steps are the same as in Example 2, except that the ball milling time is 36h. like figure 1 (d) and figure 2 As shown in (d), the obtained powder particles are fine and have a unimodal particle size distribution characteristic, and the particle size distribution range is narrow. The sintering temperature is 1820 °C and the holding time is 120 min. The prepared ceramic phase composition is AlON transparent ceramics, see image 3 (c), microstructure see Figure 4 (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com