Patents

Literature

61 results about "Polycrystalline aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycrystalline aluminum nitride material and method of production thereof

ActiveUS20120021175A1High purityIncrease in sizeNitrogen compoundsSynthetic resin layered productsPolycrystalline aluminumHigh density

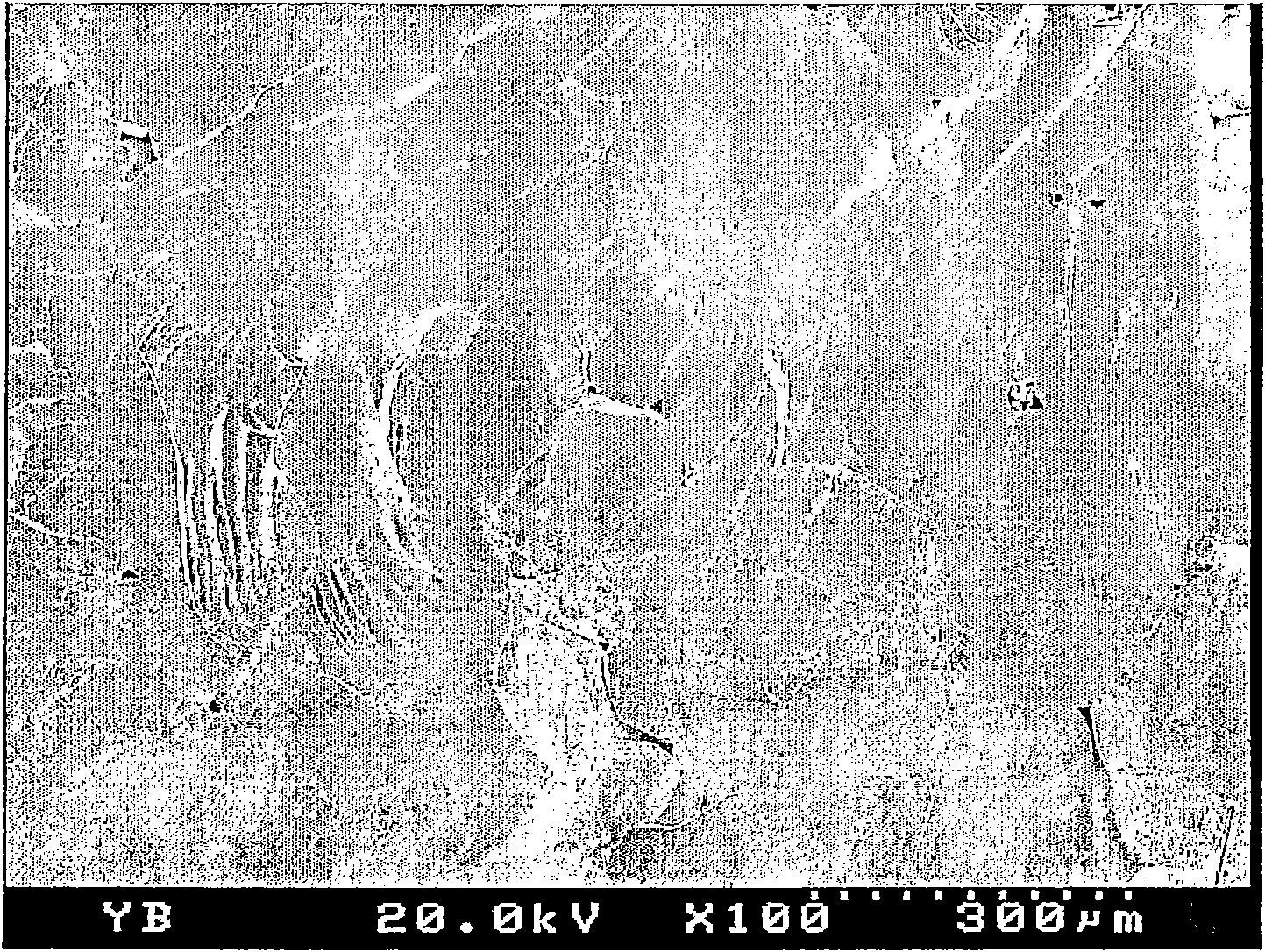

Methods of preparing polycrystalline aluminum nitride materials that have high density, high purity, and favorable surface morphology are disclosed. The methods generally comprises pressing aluminum nitride powders to form a slug, sintering the slug to form a sintered, polycrystalline aluminum nitride boule, and optionally shaping the boule and / or polishing at least a portion of the boule to provide a finished substrate. The sintered, polycrystalline aluminum nitride materials beneficially are prepared without the use of any sintering aid or binder, and the formed materials exhibit excellent density, AlN purity, and surface morphology.

Owner:INTERSOUTH PARTNERS VI +5

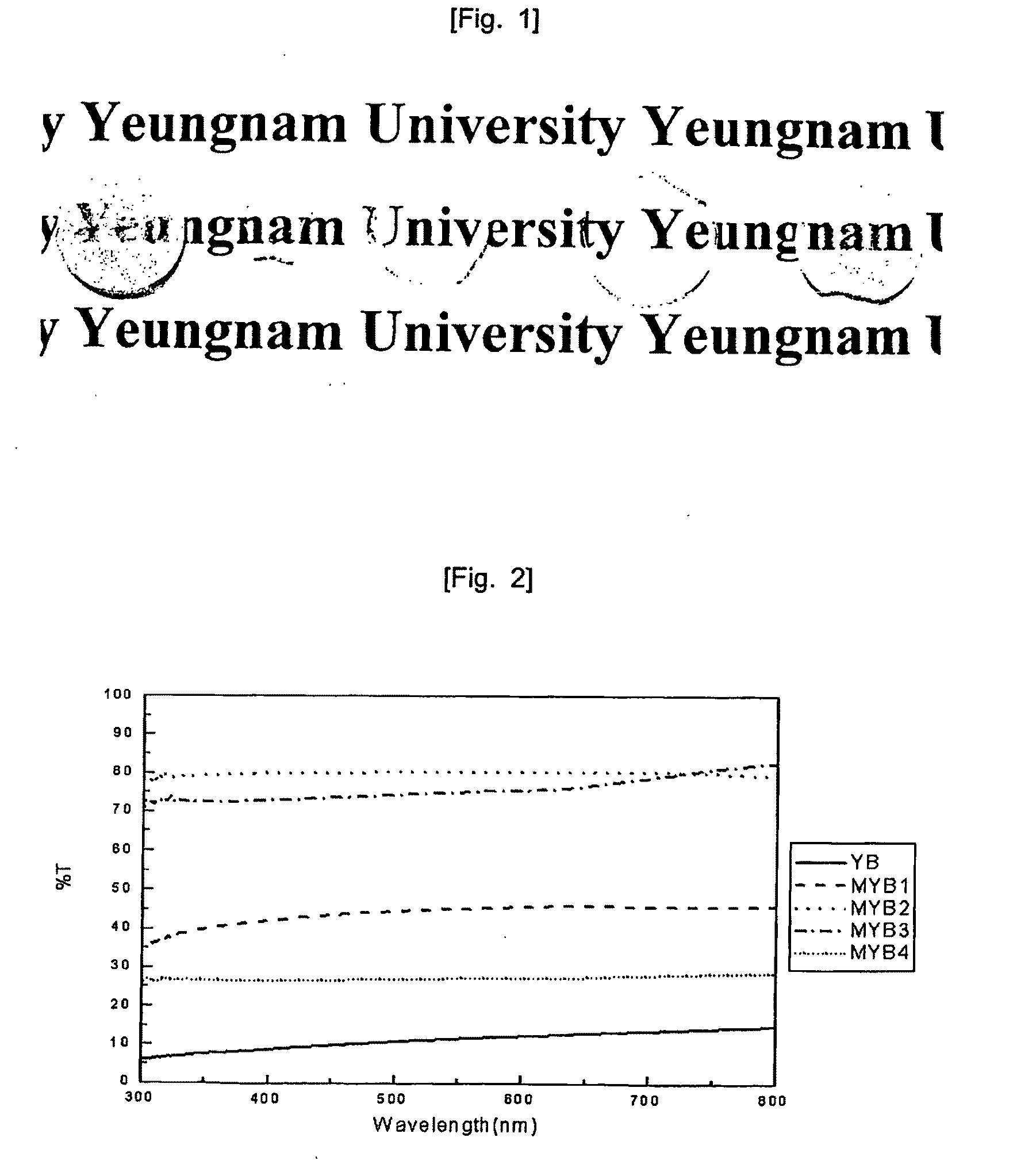

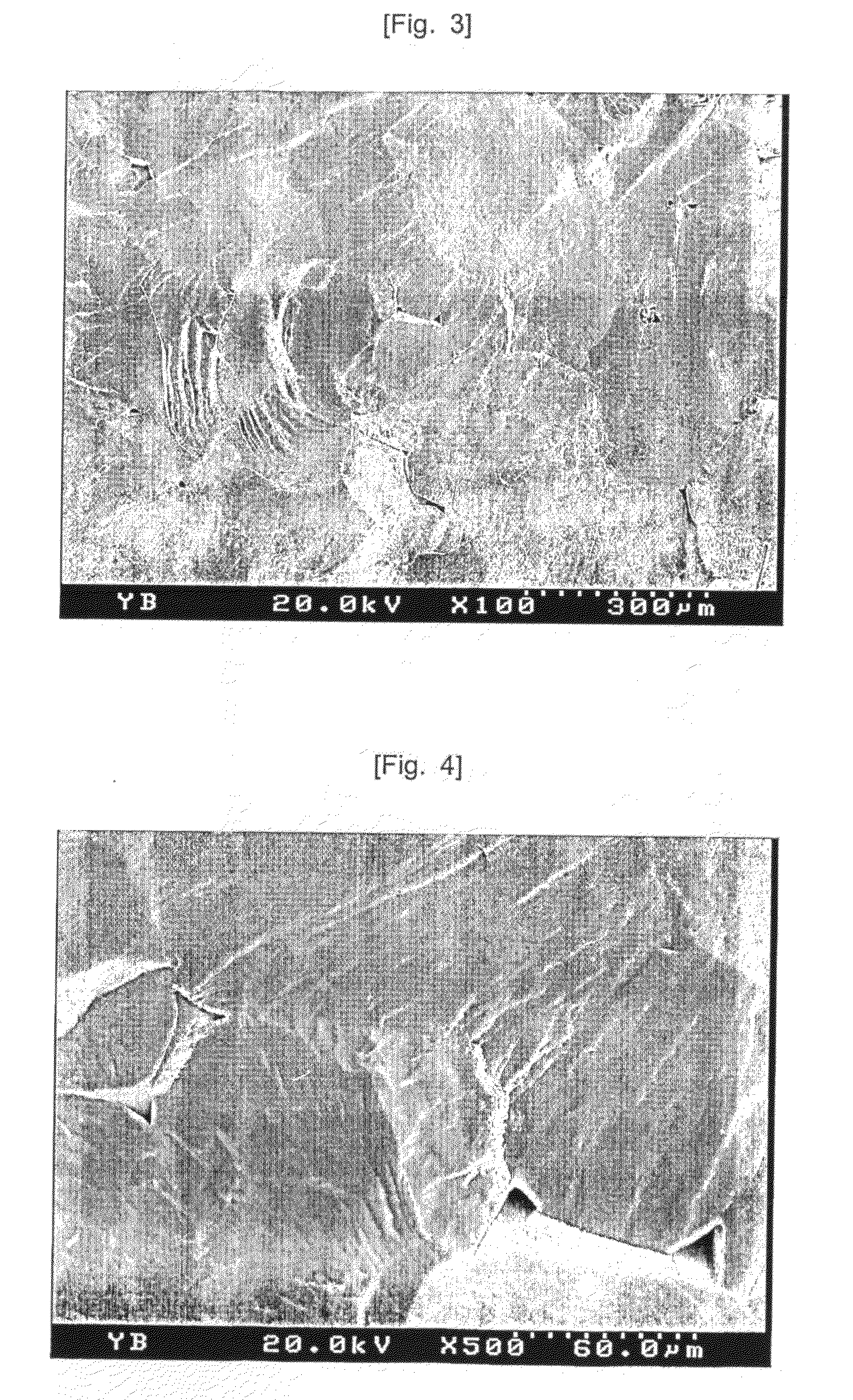

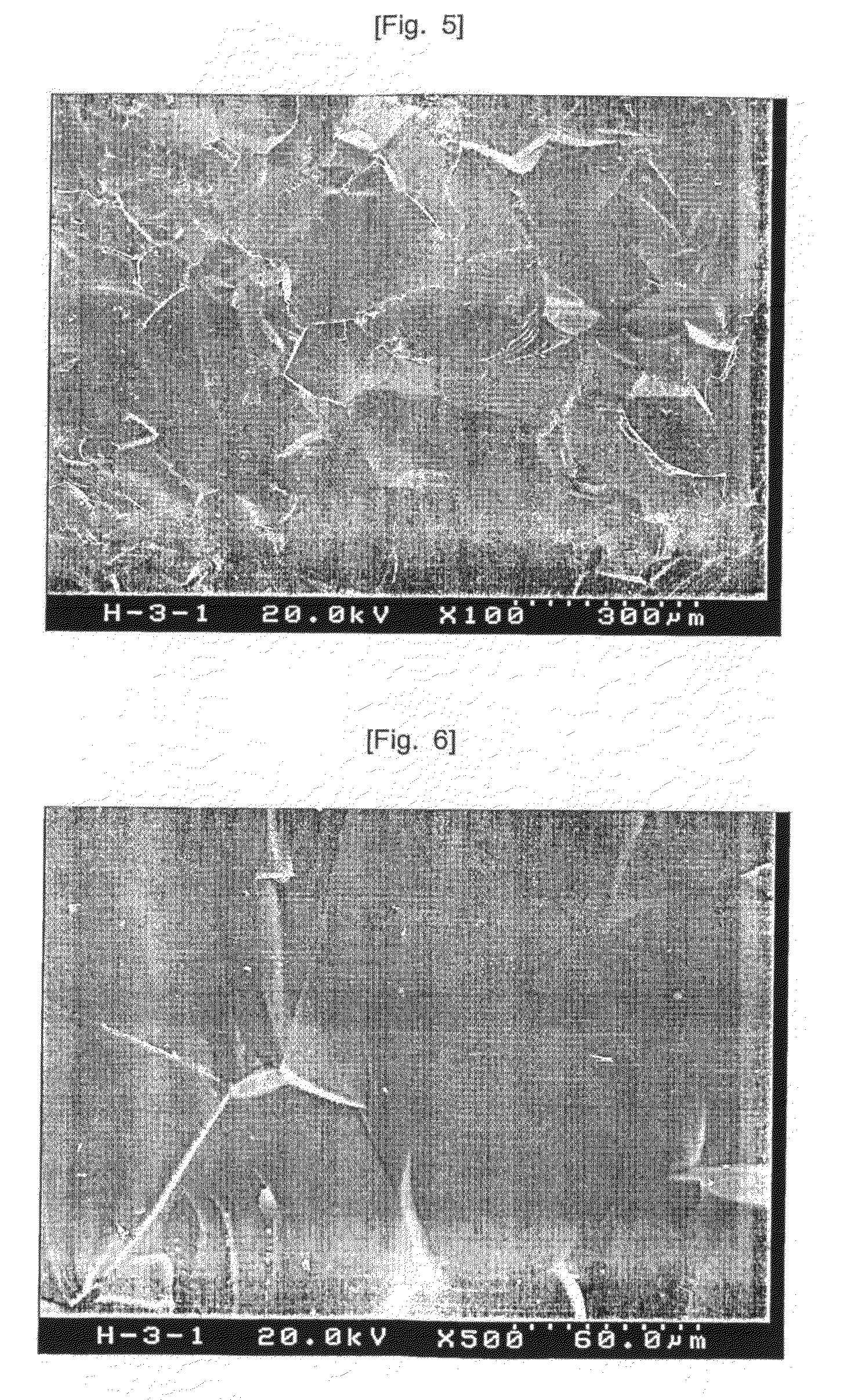

Method for manufacturing transparent polycrystalline aluminum oxynitride

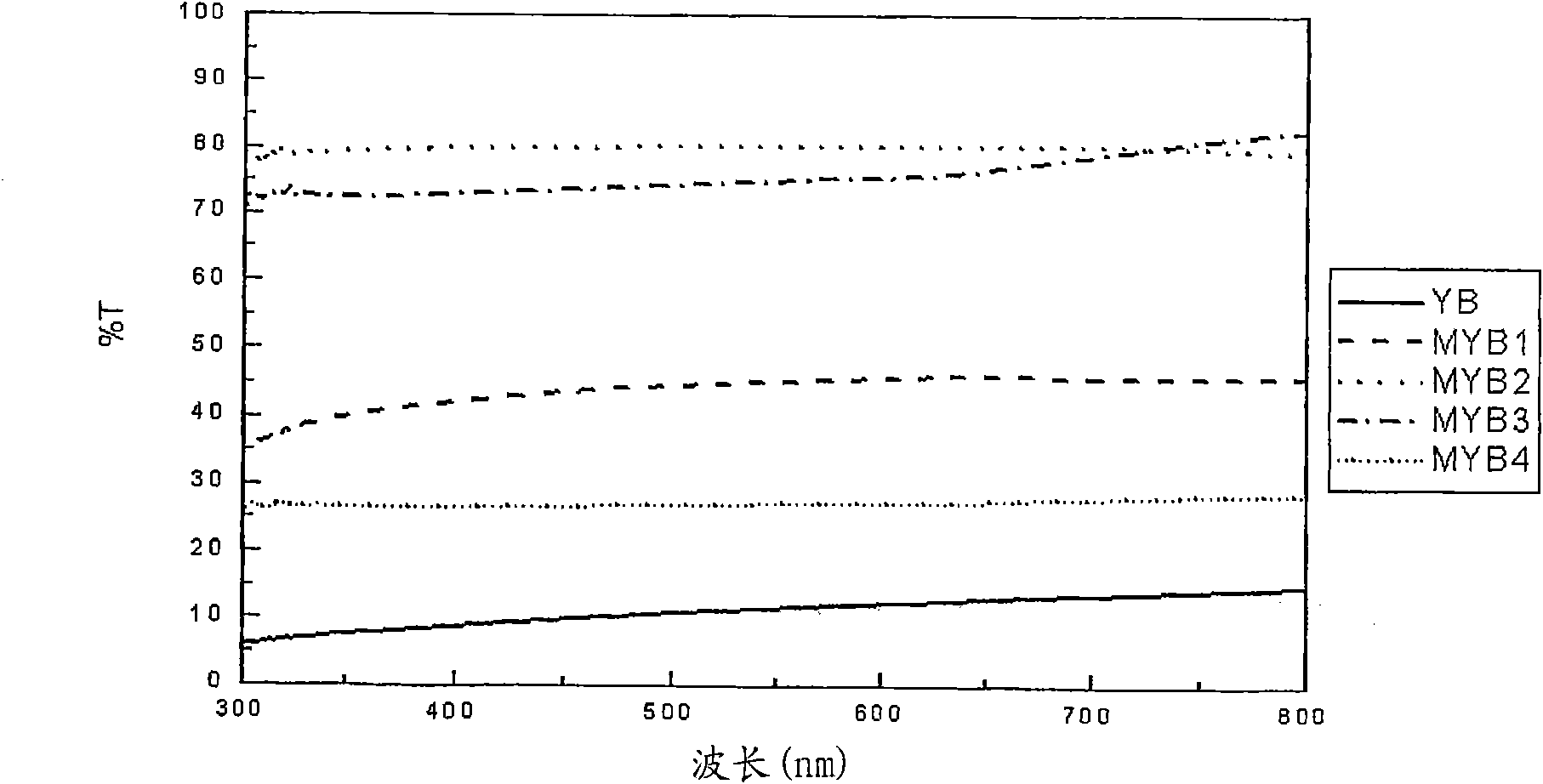

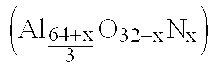

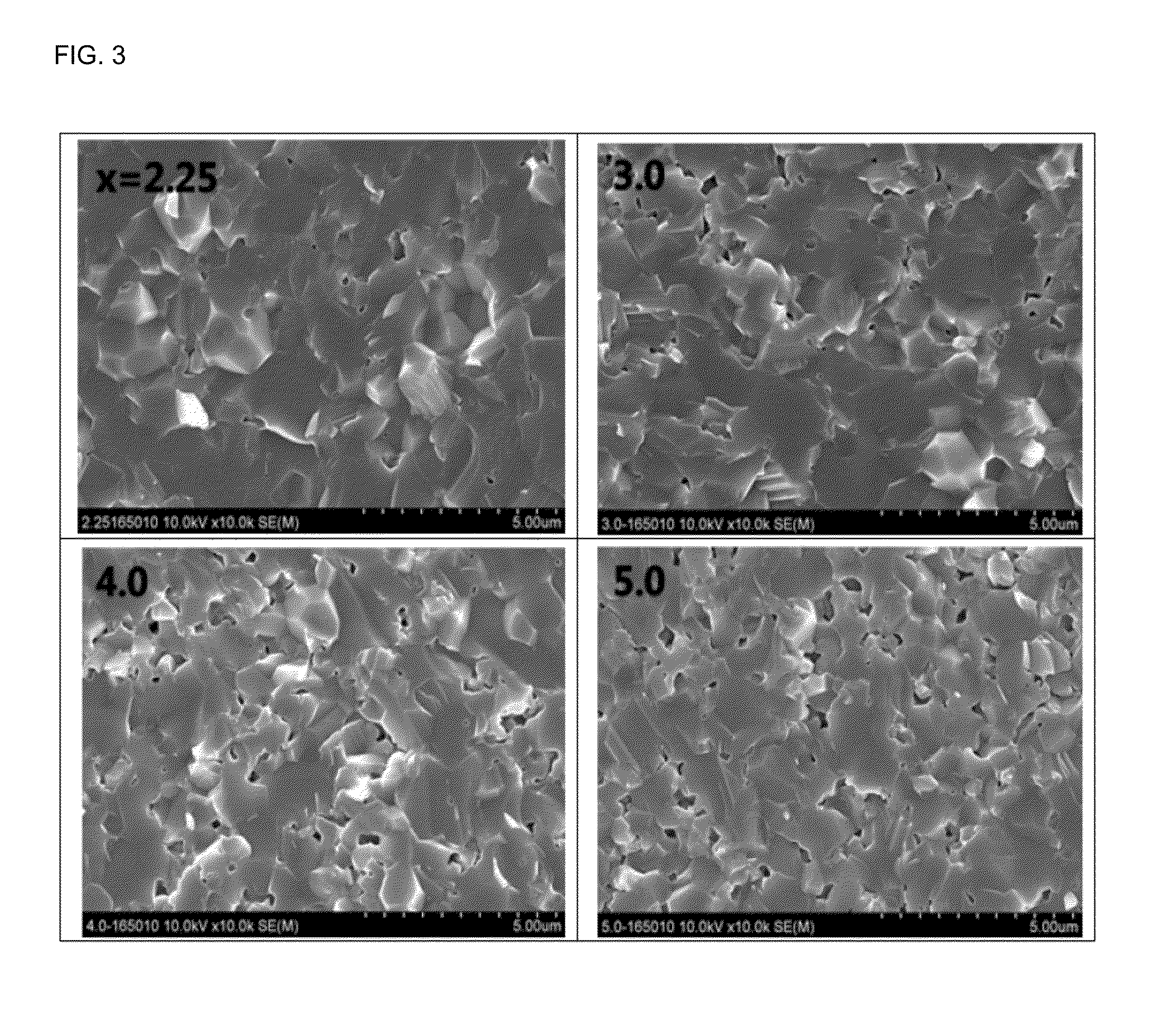

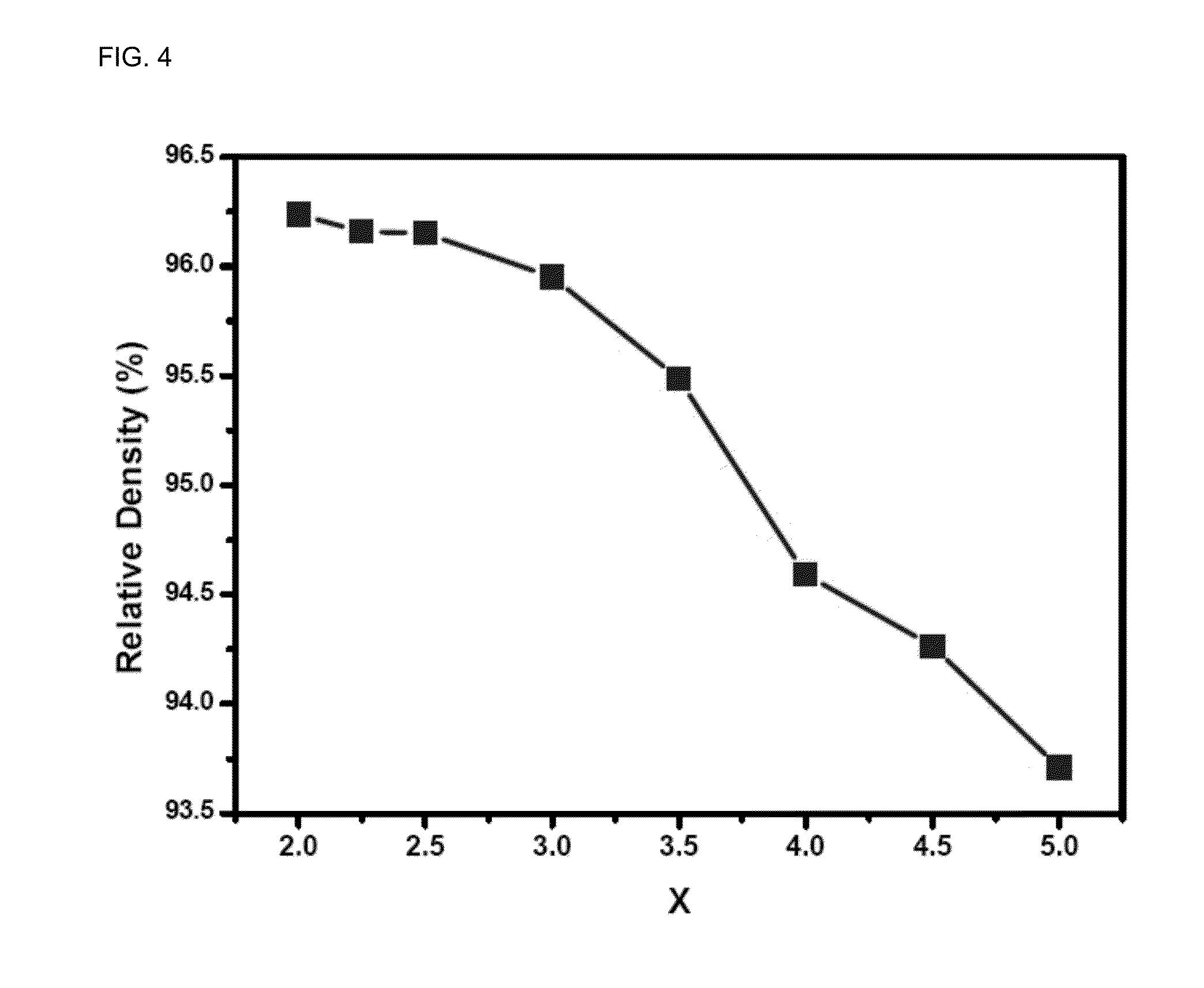

The present invention relates to a method of manufacturing a transparent polycrystalline aluminum oxynitride. Aluminum oxynitride manufactured by prior art methods has a great number of porosities therein and thus has low transparency. The present invention is directed to solving such a problem. In the method of manufacturing aluminum oxynitride of the present invention, a sintering additive added to a source powder includes less than 0.5wt.% MgO. Further, the source powder is presintered at 1550 DEG C to 1750 DEG C so that a relative density becomes 95% or more and is then resintered at 1900 DEG C or more so that a relative density higher than that of presintering can be accomplished. According to the present invention, a cubic-phased polycrystalline aluminum oxynitride ceramic can be obtained, wherein porosities therein are nearly eliminated and its substantial transparency becomes 95% or more.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Method for making dense polycrystalline aluminum oxynitride

InactiveUS7163656B1Consistently and uniformly dense and economically producedReduce wearCeramic shaping apparatusClaywaresPolycrystalline aluminumPowder mixture

A dense polycrystalline aluminum oxynitride body is produced. According the method of production, aluminum oxide (alumina) powder and 26 to 40 mole % aluminum nitride powder is mixed to form a very fine powder mixture. The powder mixture is shaped and hot pressed at a moderate temperature, preferably about 1600° C., which is below the temperature of aluminum oxynitride (AlON) formation to produce a dense intermediate body. The dense intermediate body is reacted to produce a highly dense polycrystalline aluminum oxynitride body. The dense body is particularly useful for ballistic armor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Thermal expansion engineering for polycrystalline aluminum nitride sintered bodies

ActiveUS20120146023A1Easy to optimizeReduce material lossPolycrystalline material growthSemiconductor/solid-state device manufacturingPolycrystalline aluminumSemiconductor materials

Disclosed are methods and materials useful in the preparation of semiconductor devices. In particular embodiments, disclosed are methods for engineering polycrystalline aluminum nitride substrates that are thermally matched to further materials that can be combined therewith. For example, the polycrystalline aluminum nitride substrates can be engineered to have a coefficient of thermal expansion (CTE) that is closely matched to the CTE of a semiconductor material and / or to a material that can be used as a growth substrate for a semiconductor material. The invention also encompasses devices incorporating such thermally engineered substrates and semiconductor materials grown using such thermally engineered substrates. The thermally engineered substrates are advantageous for overcoming problems caused by damage arising from CTE mismatch between component layers in semiconductor preparation methods and materials.

Owner:INTERSOUTH PARTNERS VI +5

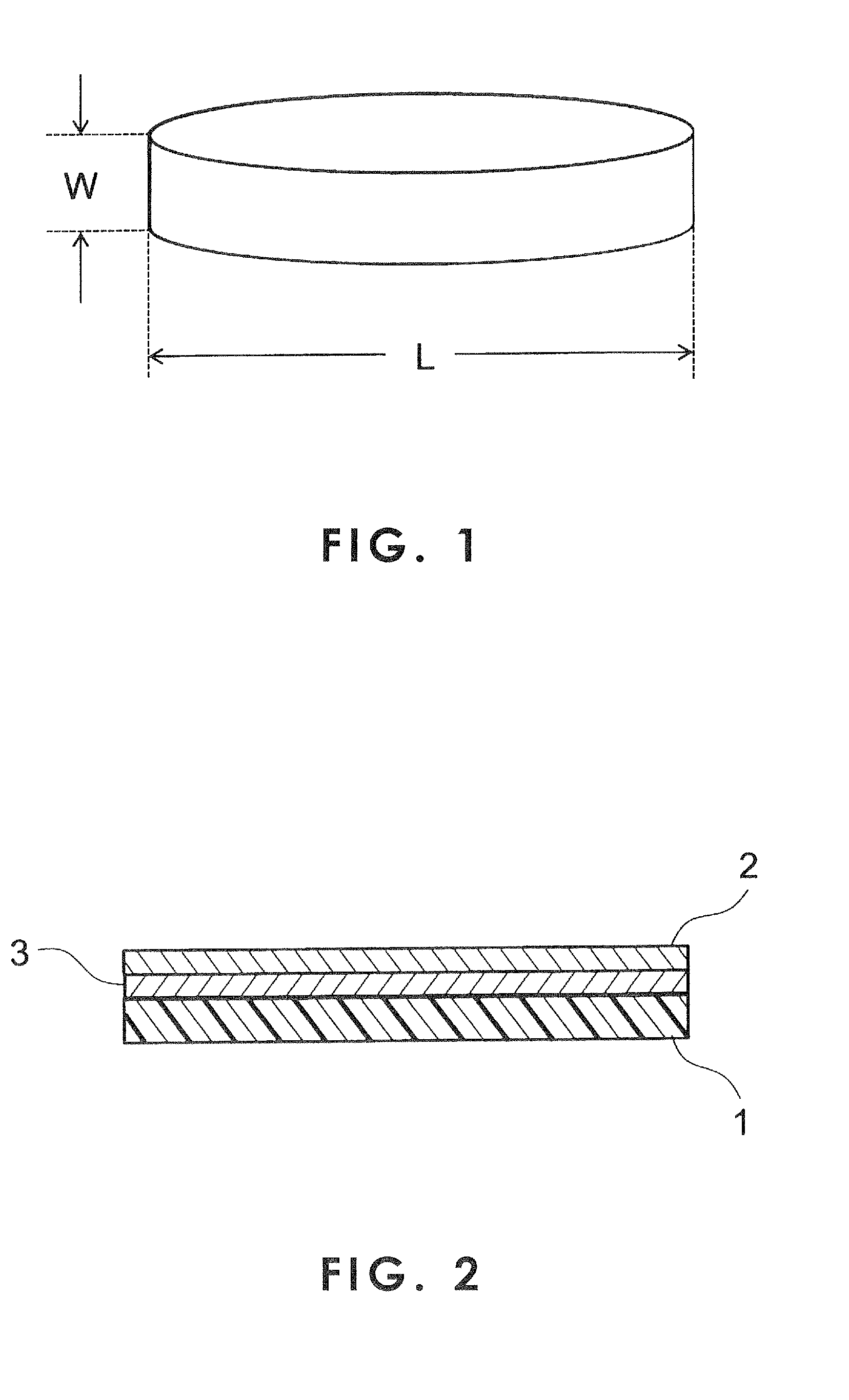

POLYCRYSTALLINE ALUMINUM NITRIDE BASE MATERIAL FOR CRYSTAL GROWTH OF GaN-BASE SEMICONDUCTOR AND METHOD FOR MANUFACTURING GaN-BASE SEMICONDUCTOR USING THE SAME

InactiveUS20130157445A1High yieldPolycrystalline material growthSynthetic resin layered productsPolycrystalline aluminumNitride

There is provided a polycrystalline aluminum nitride base material having a linear expansion coefficient similar to GaN. The polycrystalline aluminum nitride base material as a substrate material for crystal growth of GaN-base semiconductors has a mean linear expansion coefficient of 4.9×10−6 / K to 6.1×10−6 / K between 20° C. and 600° C. and 5.5×10−6 / K to 6.6×10−6 / K between 20° C. and 1100° C.

Owner:KK TOSHIBA +1

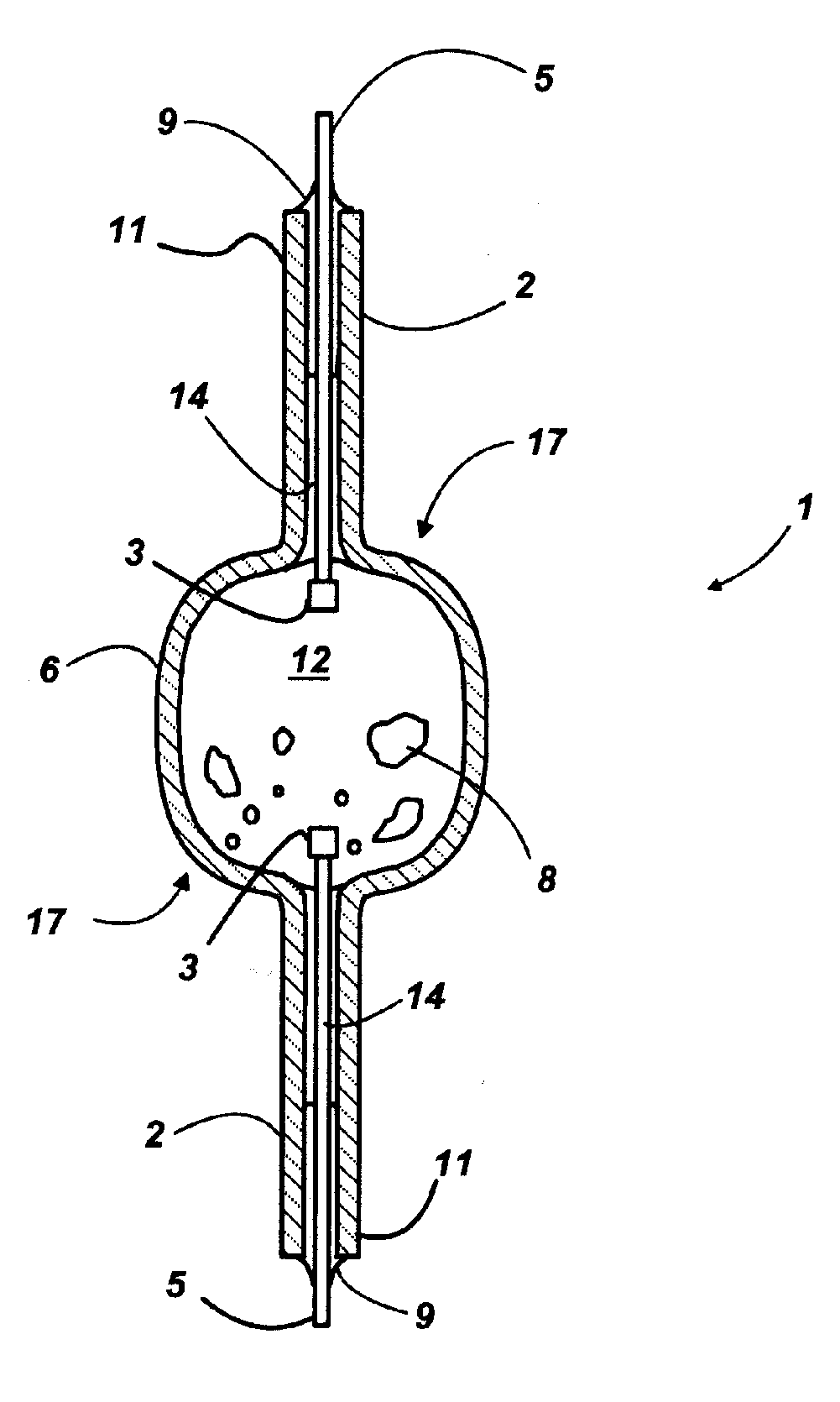

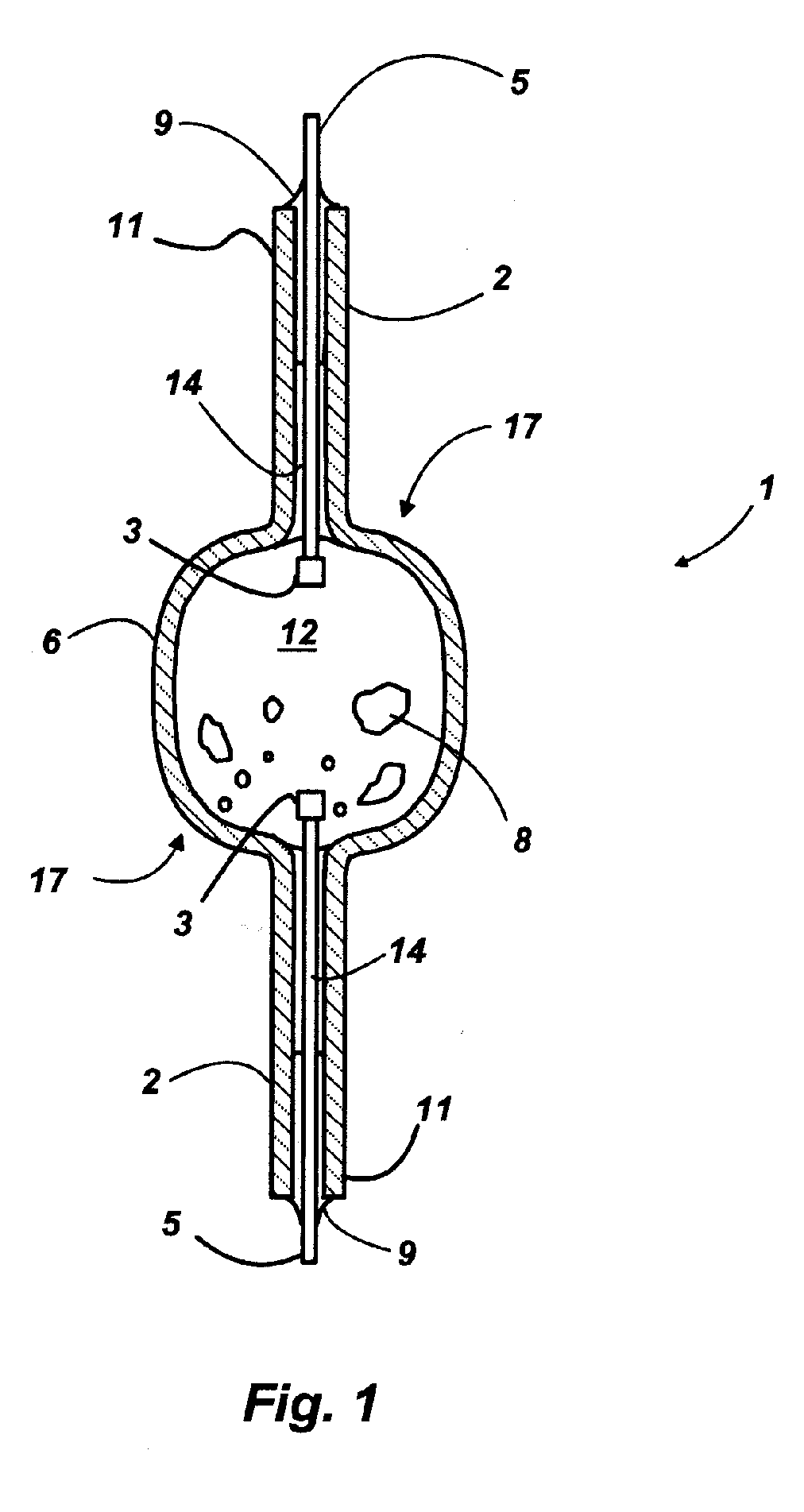

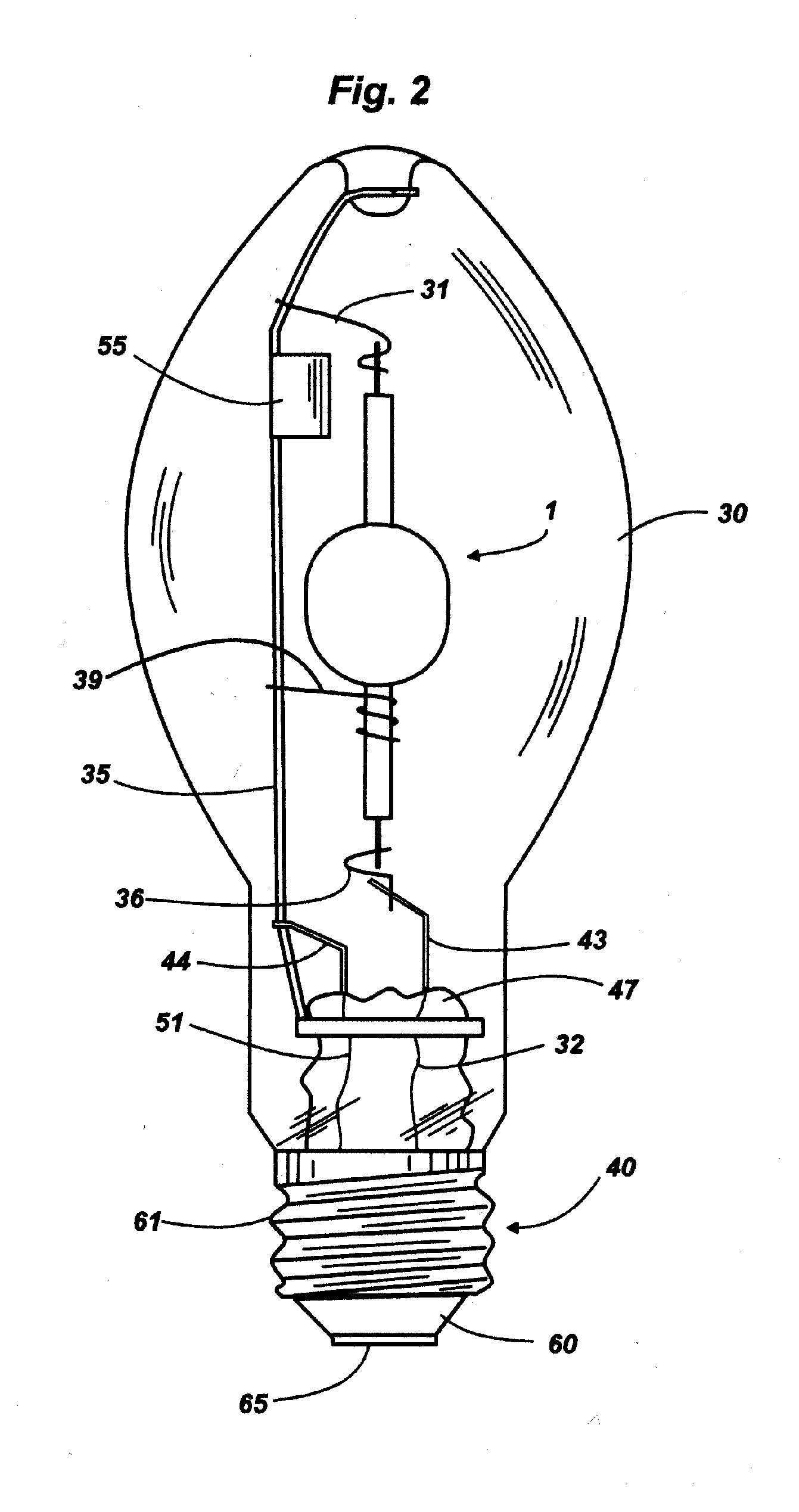

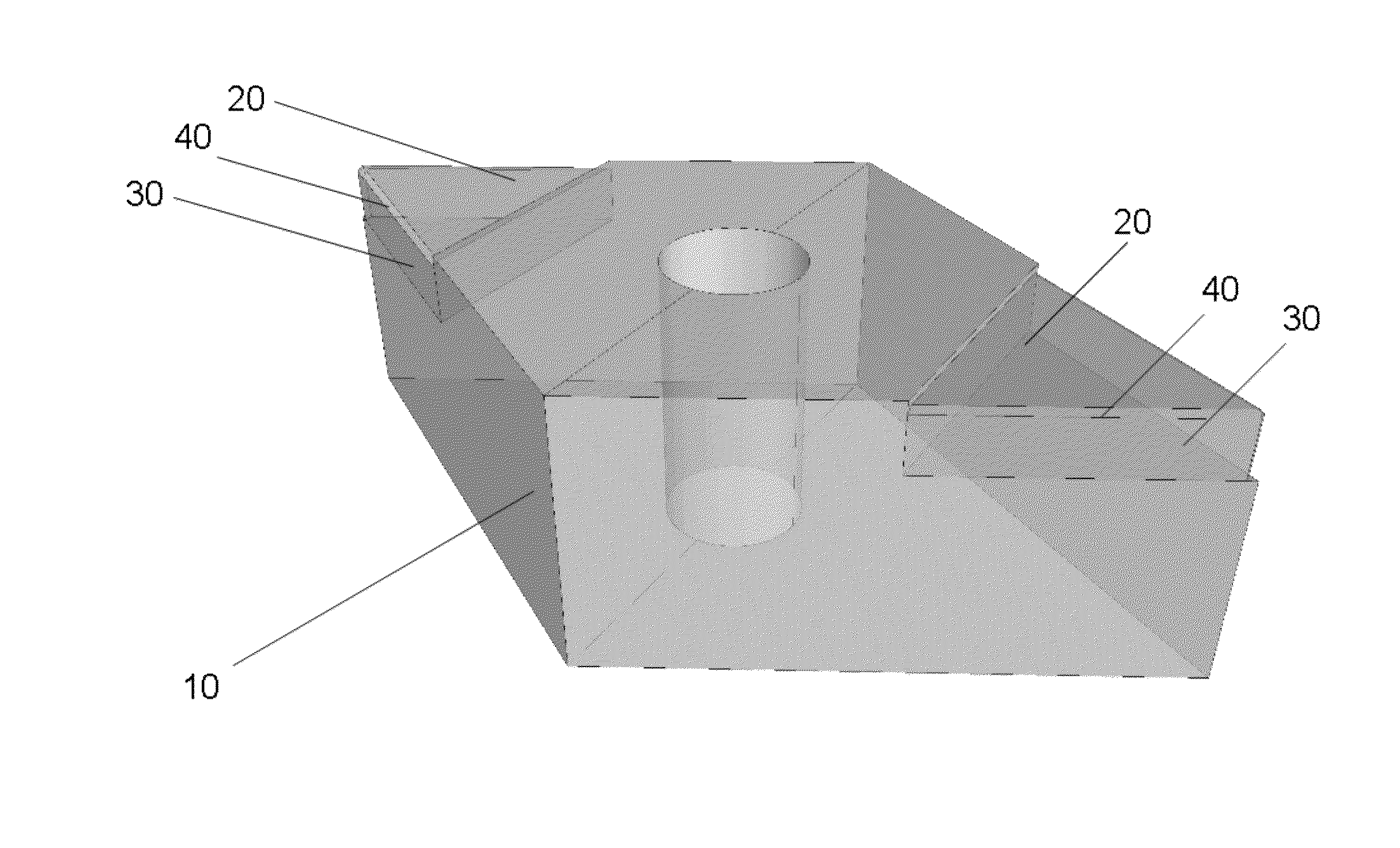

Rapid Warm-up Ceramic Metal Halide Lamp

InactiveUS20060290285A1Short warm-up timeLess heatSolid cathode detailsGas discharge lamp detailsPolycrystalline aluminumMetal-halide lamp

A ceramic metal halide lamp is provided wherein the ceramic discharge vessel is comprised of dysprosium oxide. The lamp has a warm-up time that is less than about 50%, and preferably less than about one-third, of the warm-up time of a similarly constructed and operated lamp having a ceramic discharge vessel made of polycrystalline aluminum oxide.

Owner:OSRAM SYLVANIA INC

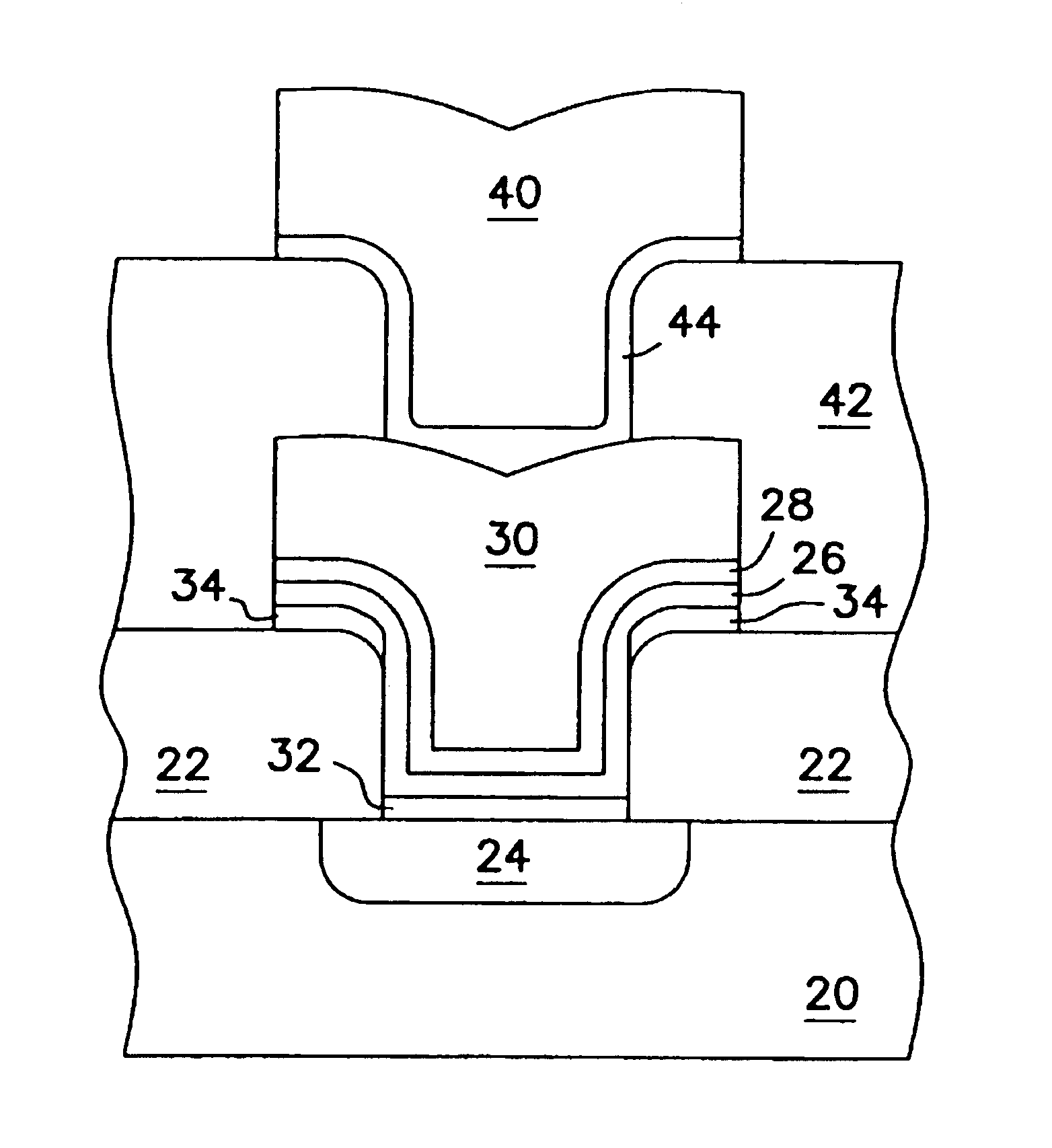

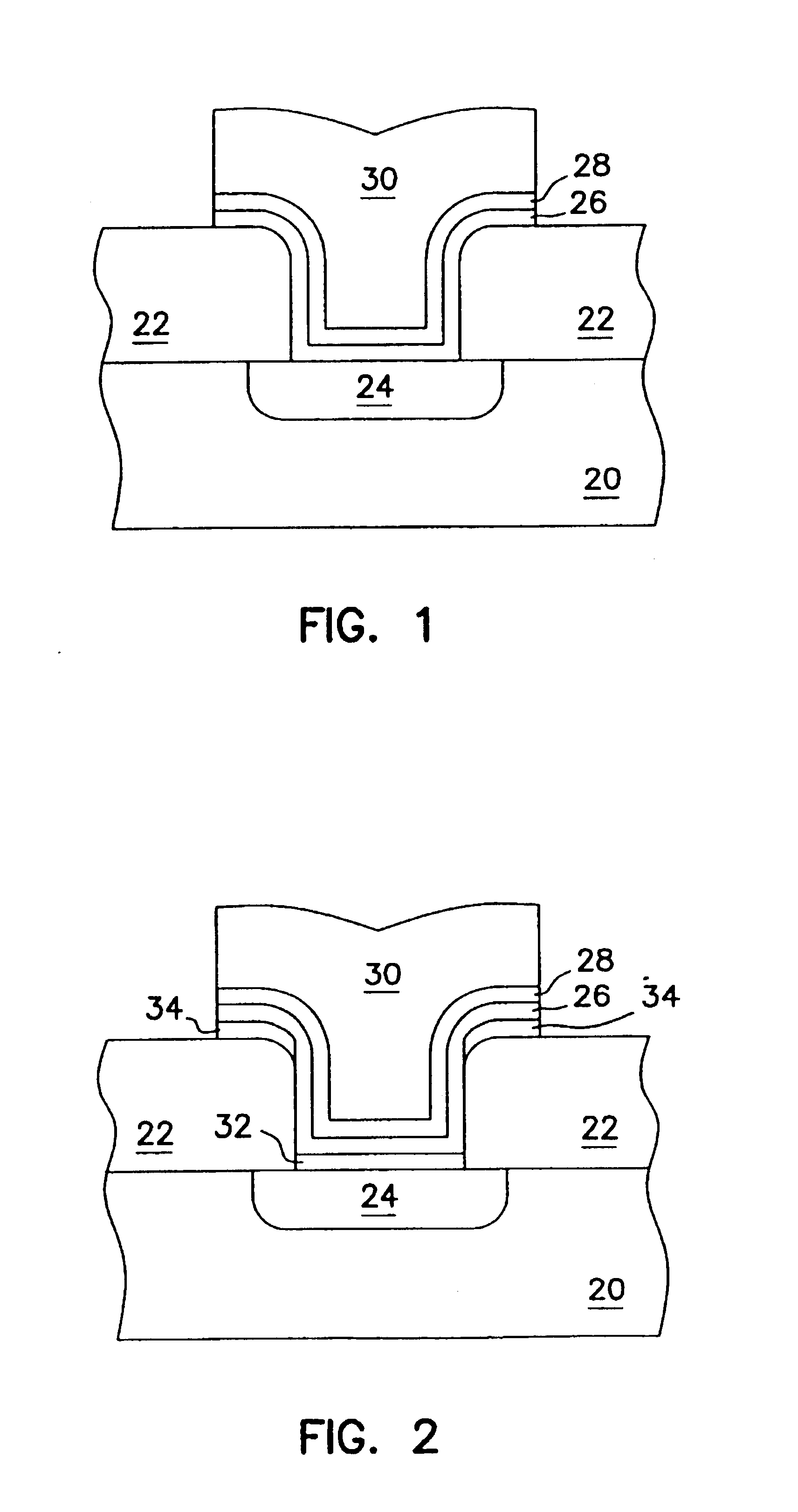

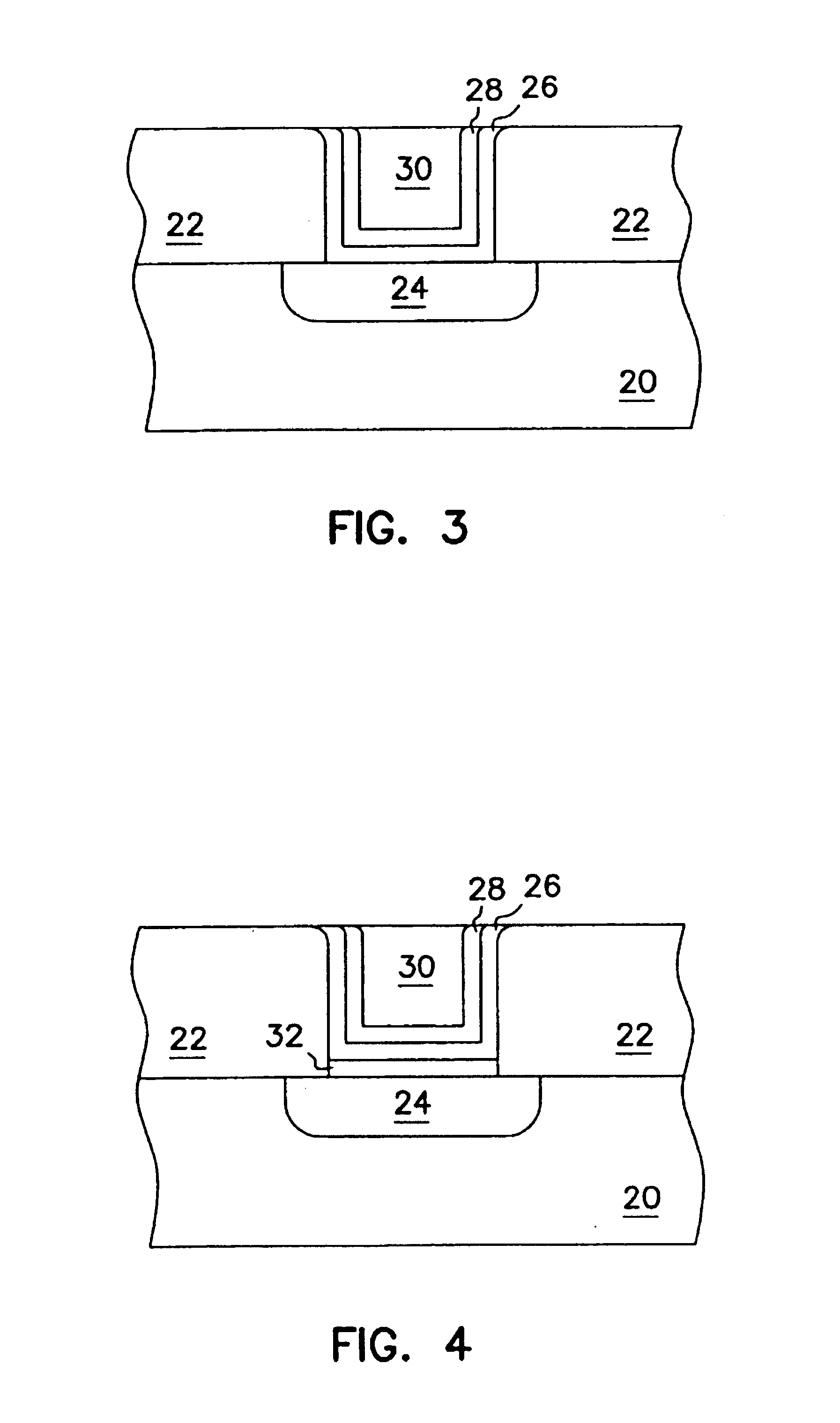

Small grain size, conformal aluminum interconnects and method for their formation

InactiveUS6946393B2Improve ohmic characteristic of contactEasy to spreadSemiconductor/solid-state device detailsSolid-state devicesPolycrystalline aluminumMetallurgy

A first layer of titanium nitride (TiN) is formed on a semiconductor structure, such as an interconnect via. Then, a second layer of TiN is formed on the first layer of TiN. The first layer of TiN is amorphous. The second layer of TiN is polycrystalline, having a mixed grain orientation. Finally, an aluminum film is formed on the second layer of titanium nitride. Optionally, a titanium silicide layer is formed on the semiconductor structure prior to the step of forming the first layer of titanium nitride. Interconnects formed according to the invention have polycrystalline aluminum films with grain sizes of approximately less than 0.25 microns.

Owner:MICRON TECH INC

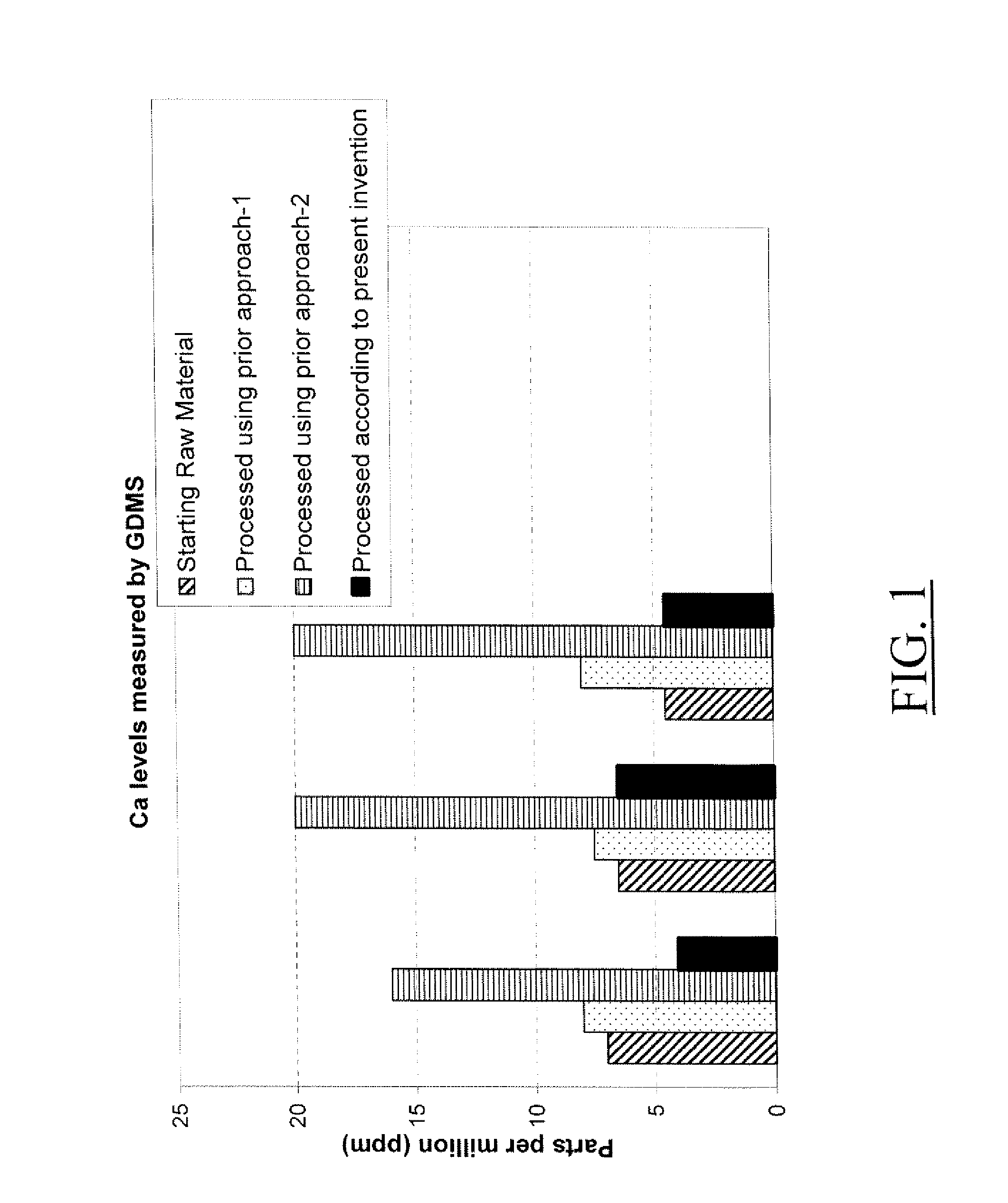

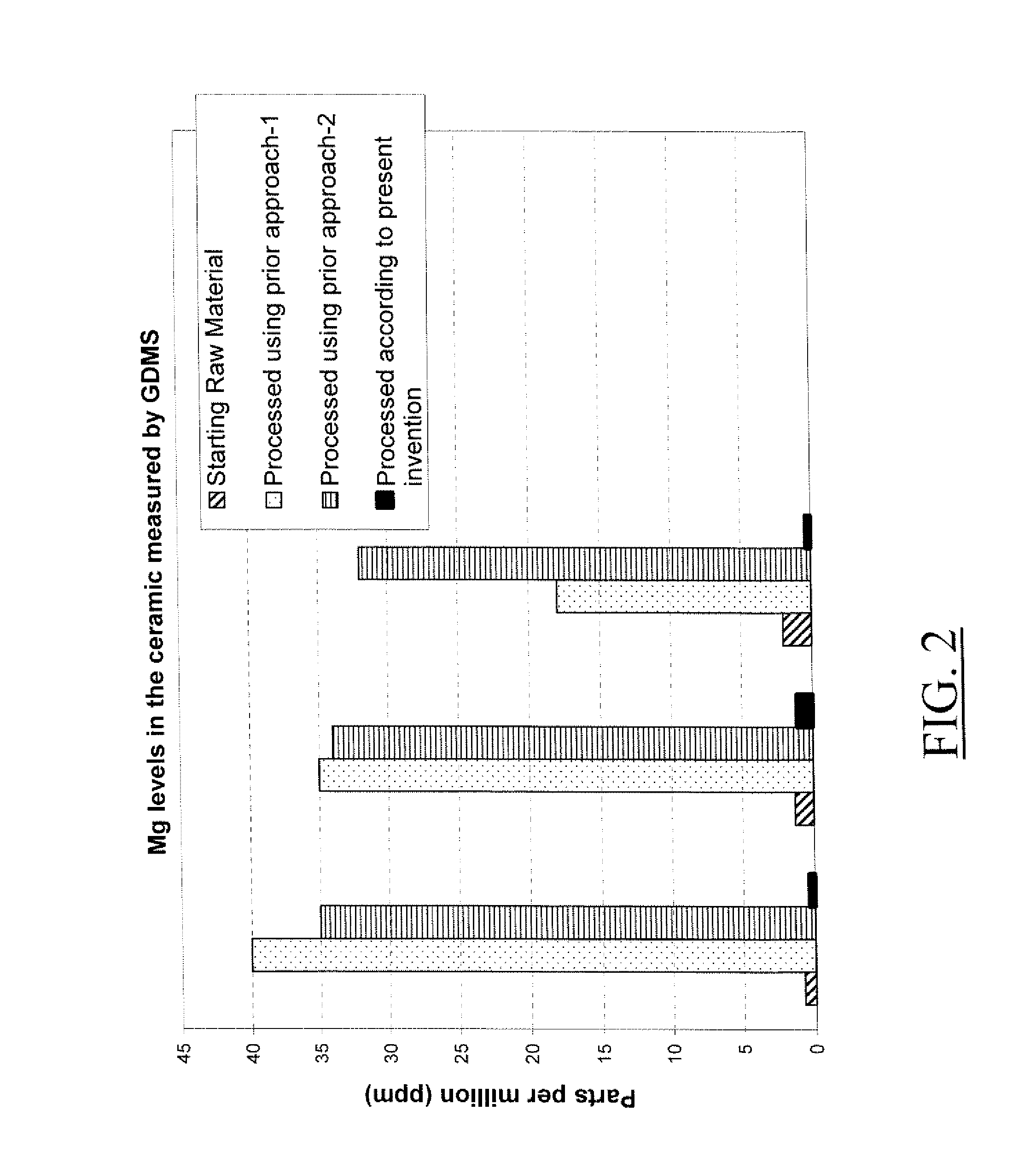

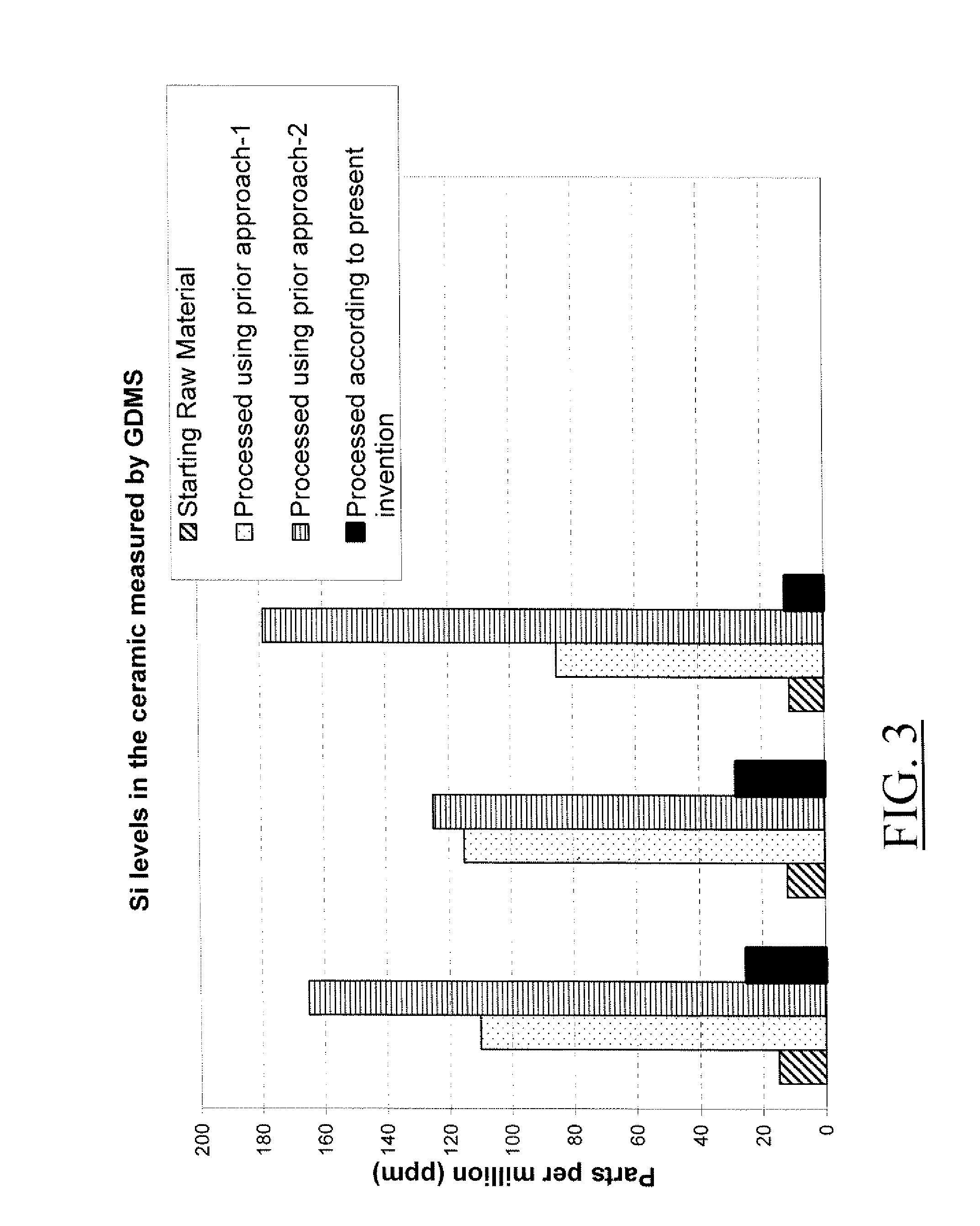

Method of making high purity polycrystalline aluminum oxynitride bodies useful in semiconductor process chambers

ActiveUS20150115507A1Small particle sizeCeramic shaping apparatusNon-woven fabricsPolycrystalline aluminumMetallurgy

A method of making high purity crystalline AlON bodies by synthesizing and calcining AlON powders having less than 80 ppm Si, Mg, Ca, Na, and K impurities. The AION powders are milled to reduce the particle size of the AlON powders using a high purity milling media. An AlON body is formed from the milled AlON powders. Such AlON bodies are particularly suitable for semiconductor process chamber components.

Owner:SURMET

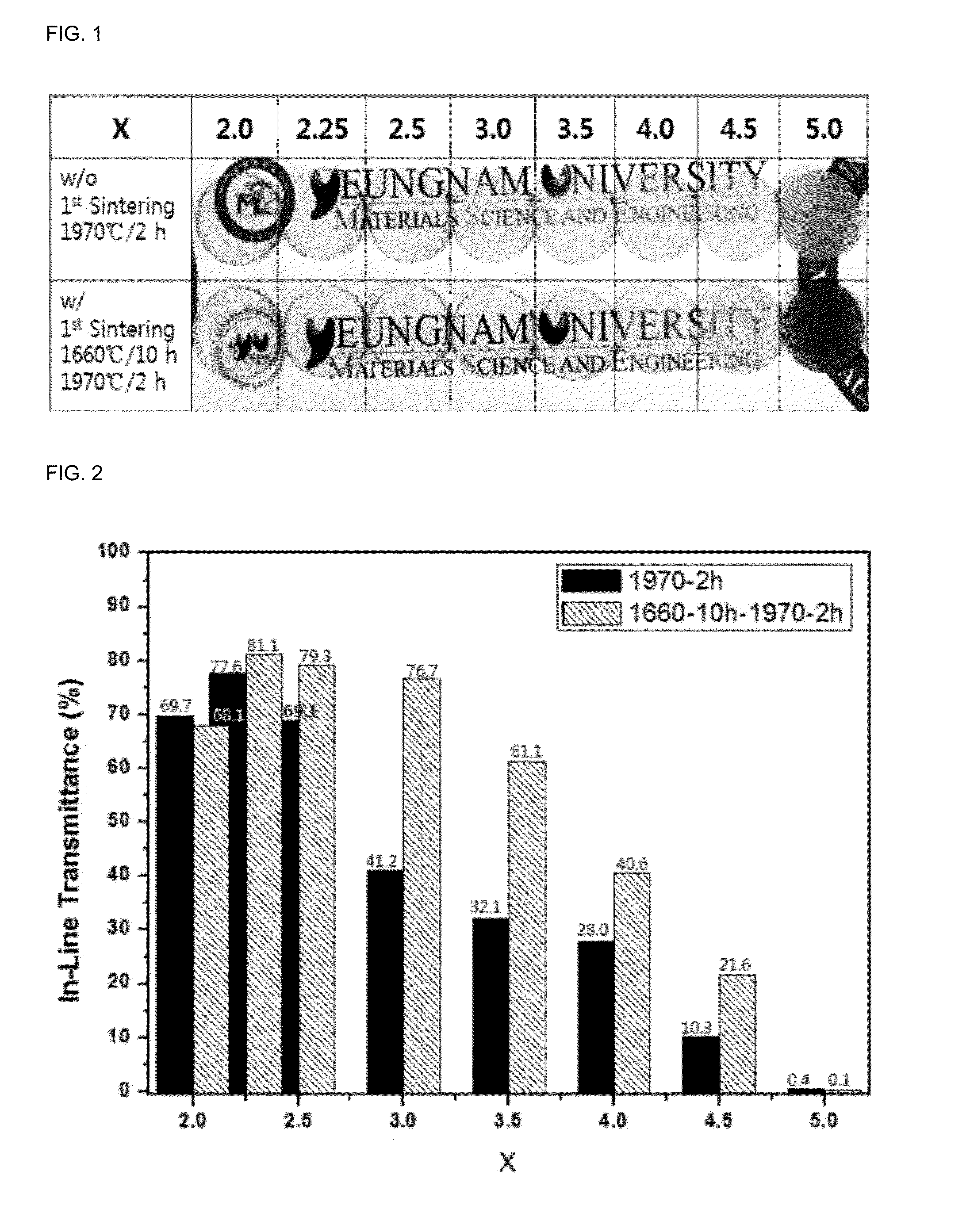

Method for preparing polycrystalline aluminum oxynitride having enhanced transparency

ActiveUS20130337993A1Low costShort sintering timeNitrogen compoundsPolycrystalline aluminumPowder mixture

Disclosed is a method for preparing polycrystalline aluminum oxynitride having enhanced transparency, and preparing polycrystalline aluminum oxynitride by sintering a powder mixture of Al2O3 and AlN under atmospheric pressure, wherein the content of AlN is set to 17 to 26 mol %, a first sintering is performed at 1,575° C. to 1,675° C. so as to enable raw-material powders to have a relative density of 95% or higher, and a second sintering is performed so as to enable the raw-material powders to have a higher relative density.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

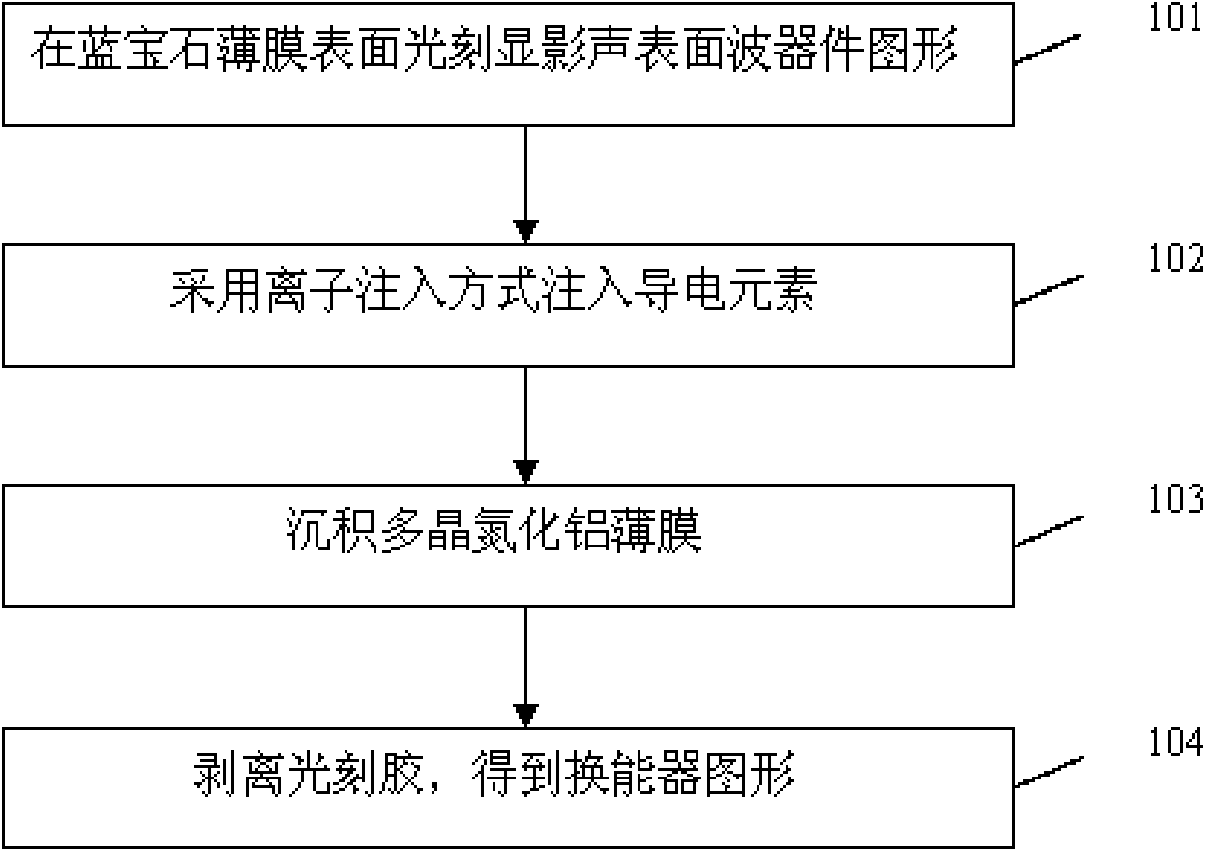

Method for producing sapphire surface acoustic wave transducer

InactiveCN101540591ALower surface resistivityGuarantee processing qualityImpedence networksPolycrystalline aluminumManufacturing technology

The invention discloses a method for producing a sapphire surface acoustic wave transducer, belongs to the technical field of manufacture of surface acoustic wave devices. The method comprises the following steps of: firstly lithographing and developing a graph of the surface acoustic wave transducer on the surface of a sapphire, and then adopting the ion injection method to inject metal aluminum or copper element; then depositing a polycrystalline aluminum nitride piezoelectric thin film on the surface of the sapphire after ion injection; and finally removing a photoresist and obtaining the graph of the surface acoustic wave transducer. The method greatly reduces the surface resistivity of the sapphire by injecting the ions and greatly enhances the electric conductivity, thereby replacing the original deposition of a conductive thin film. The method does not need to deposit an Al or Au thin film and does not need the etching process either. Therefore, the operation is greatly simplified, and the anti-power bearing force of the device is also greatly enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Wear-Resistant, High Durability Industrial Ceramic Cutting Edges and Tools made from Sintered Polycrystalline Composites Based on Aluminum Nitride

InactiveUS20140349117A1Pigmenting treatmentOther chemical processesSurface finishPolycrystalline aluminum

The invention pertains to hardware such as cutting tools with improved performance, wear-resistance and durability made from sintered polycrystalline aluminum nitride based ceramic composites containing secondary or dispersed phases for enhanced toughness. The articles of this invention provide good hardness, toughness, chemical inertness, thermal stability, lubricity, wear-resistance, and the ability to operate in the presence of liquid coolants, yielding good surface finish and long lifetime. The cutting tools of this invention are applicable to a wide range of industrial, biomedical, commercial and other applications.

Owner:SURMET

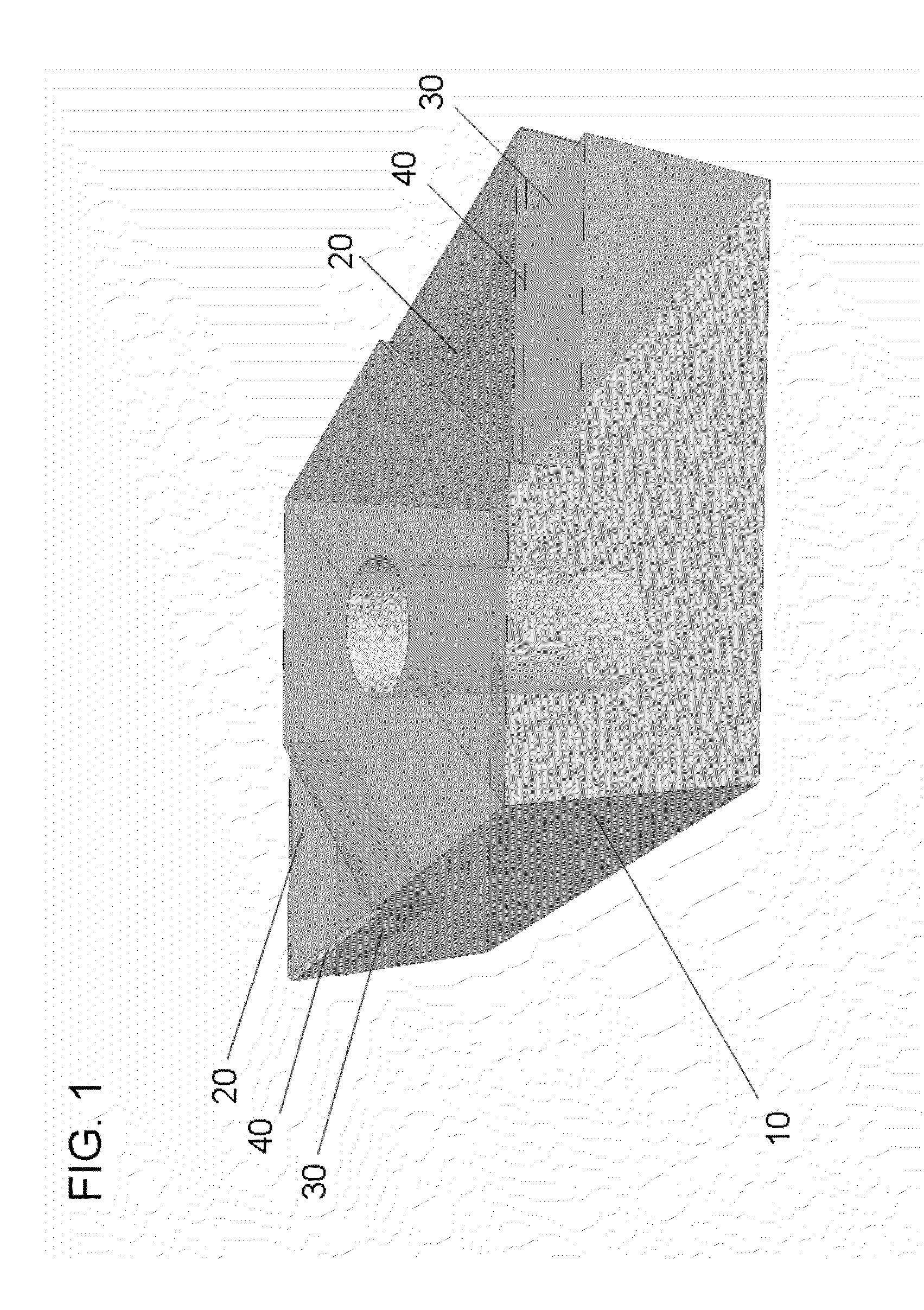

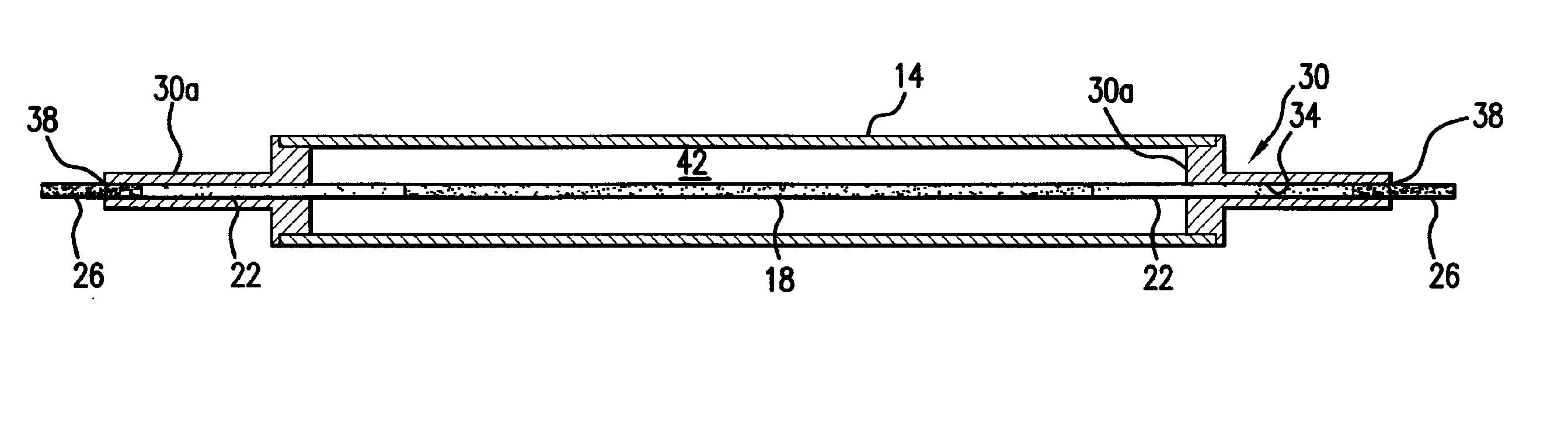

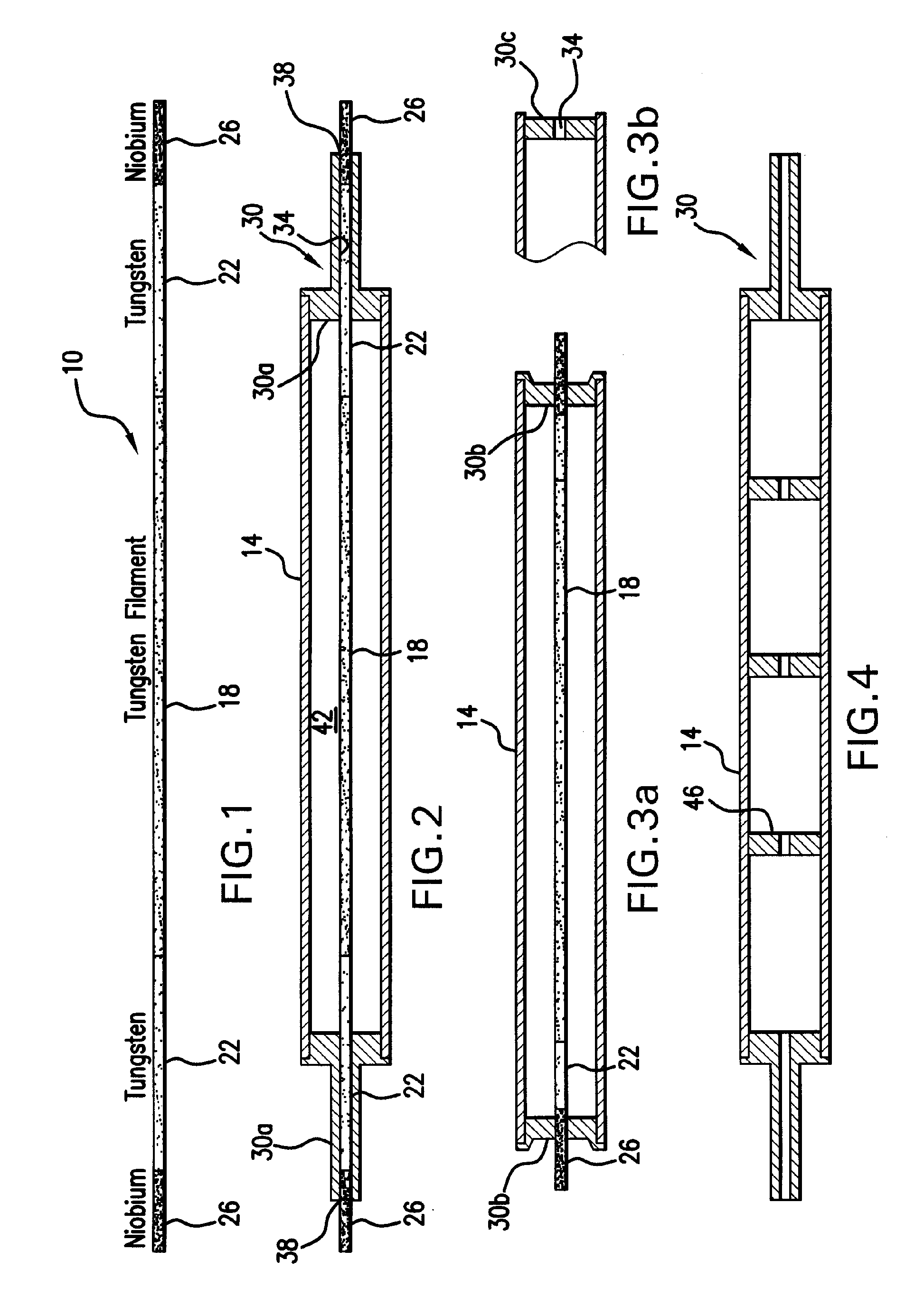

Incandescent lamp that emits infrared light and a method of making the lamp

An incandescent lamp that emits infrared light and a method of making the lamp includes a filament assembly inside a polycrystalline aluminum oxide (PCA) envelope, where the filament assembly preferably has a coiled tungsten filament, solid metal ends of tungsten or molybdenum attached to the coiled tungsten filament, and leads at distal ends of the solid metal ends. End caps are attached to ends of the envelope and have openings through which a respective one of the leads extends, where the leads are each made of an electrically conductive material having a coefficient of thermal expansion compatible with the end caps, such as niobium. The leads are attached to the end caps with glass-ceramic sealing frits. The end caps and sealing frits seal a suitable gas inside the envelope.

Owner:OSRAM SYLVANIA INC

Method for manufacturing transparent polycrystalline aluminum oxynitride

InactiveUS20100167907A1Simple processOptimizing the sintering processNitrogen compoundsPorosityPolycrystalline aluminum

The present invention relates to a method of manufacturing a transparent polycrystalline aluminum oxynitride. Aluminum oxynitride manufactured by prior art methods has a great number of porosities therein and thus has low transparency. The present invention is directed to solving such a problem. In the method of manufacturing aluminum oxynitride of the present invention, a sintering additive added to a source powder includes less than 0.5 wt. % MgO. Further, the source powder is presintered at 1550° C. to 1750° C. so that a relative density becomes 95% or more and is then resintered at 1900° C. or more so that a relative density higher than that of presintering can be accomplished. According to the present invention, a cubic-phased polycrystalline aluminum oxynitride ceramic can be obtained, wherein porosities therein are nearly eliminated and its substantial transparency becomes 95% or more.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

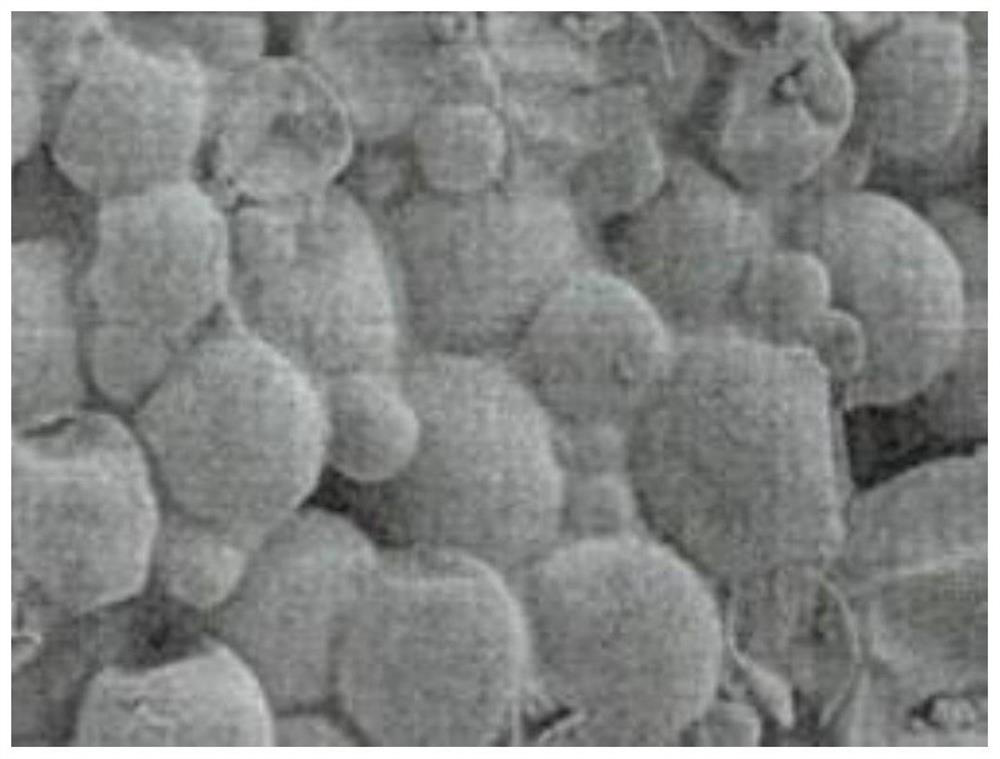

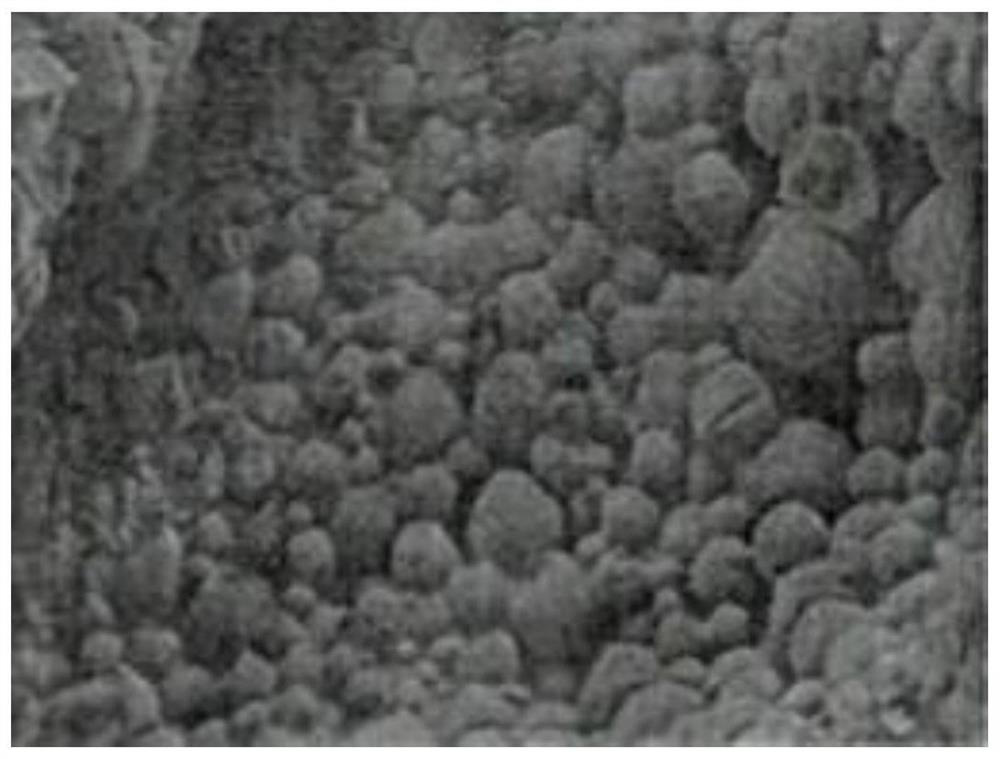

Method for preparing aluminum oxide micro-sphere

InactiveCN101214984ASimple processShorten the production cycleChemical industryAluminium oxide/hydroxide preparationDecompositionMicrosphere

A process for preparing aluminum oxide microsphere concretely includes the following steps: (1) placing raw materials in a crucible, (2) heat decompositing the raw materials placed in the crucible at the temperature between 1150-1350DEG C by a sintering furnace, (3) heat decompositing and insulating for 0.5-1.5 hours and (4) cooling the furnace to room temperature. Compared with the prior art, the utility model has the advantages that perfect spheroidal structure of the aluminum oxide microsphere is formed by employing the decomposition of polymeric compound pre-substance without any protective atmosphere and catalyst, not only the device and the process are simple, but also the production circle is short, the purity of the product is high, simultaneously, the controllability and the repeatability of the process are extremely fine, the single crystalline or polycrystalline aluminum oxide microsphere can be obtained by controlling the heat decomposition temperature, the grain diameter of the microsphere can be adjusted and controlled by controlling the heat preservation time. The high purity aluminum oxide microsphere, especially a single crystalline alumina microsphere, as a grinding medium, will be widely used in electronics industry, fine process of non-metallic minerals, building and sanitary ceramics and hydrodynamic lubrication and the like, which is a widely used energy-saved material.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +2

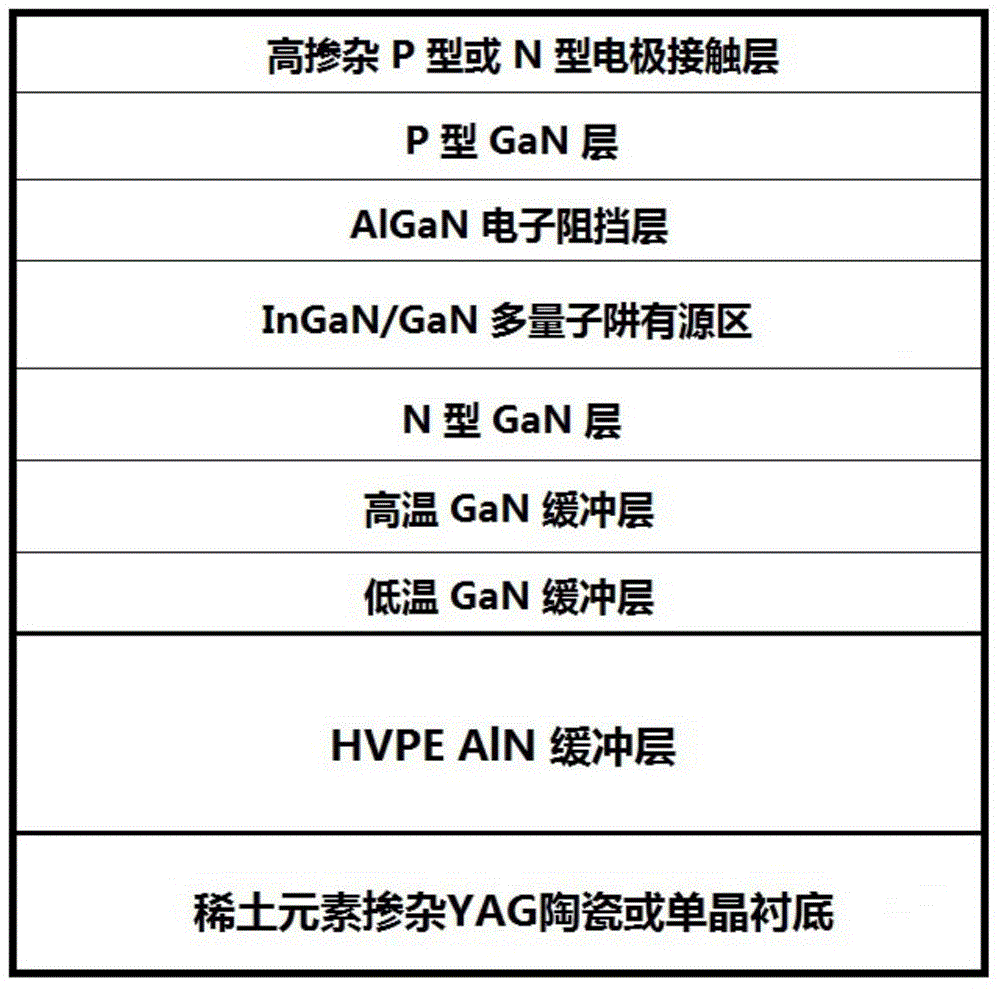

Production method of GaN-based white LED epitaxial structure

ActiveCN104952986AHigh light efficiencyExtend your lifeFrom chemically reactive gasesSemiconductor devicesRare-earth elementGas phase

A production method of a GaN-based white LED epitaxial structure includes the steps of preparing a monocrystalline or polycrystalline aluminum nitride buffer layer on a rare earth element doped YAG (yttrium aluminum garnet) ceramic or monocrystalline substrate by means of hydride vapor phase epitaxy; growing a GaN-based LED epitaxial structure on the monocrystalline or polycrystalline aluminum nitride buffer layer by means of metal-organic chemical vapor deposition. The GaN-based LED epitaxial structure comprises a low-temperature GaN buffer layer, a high-temperature GaN layer, an N-type GaN layer, an InGaN / GaN multiple quantum well active area, an AlGaN electronic barrier layer, a P-type GaN layer and a high-doped P-type or N-type electrode contact layer sequentially from bottom to top. The GaN-based LED epitaxial structure has the advantages that optical and physical features of fluorescent material, such as doping, thickness and quality, can be accurately controlled, integration of the fluorescent material high in repeatability and uniformity is achieved, and the problem that in traditional phosphor coating, unavailable non-uniform phosphor content occurs to the different parts of a same wafer and the different wafers due to the production process is solved.

Owner:XI AN JIAOTONG UNIV

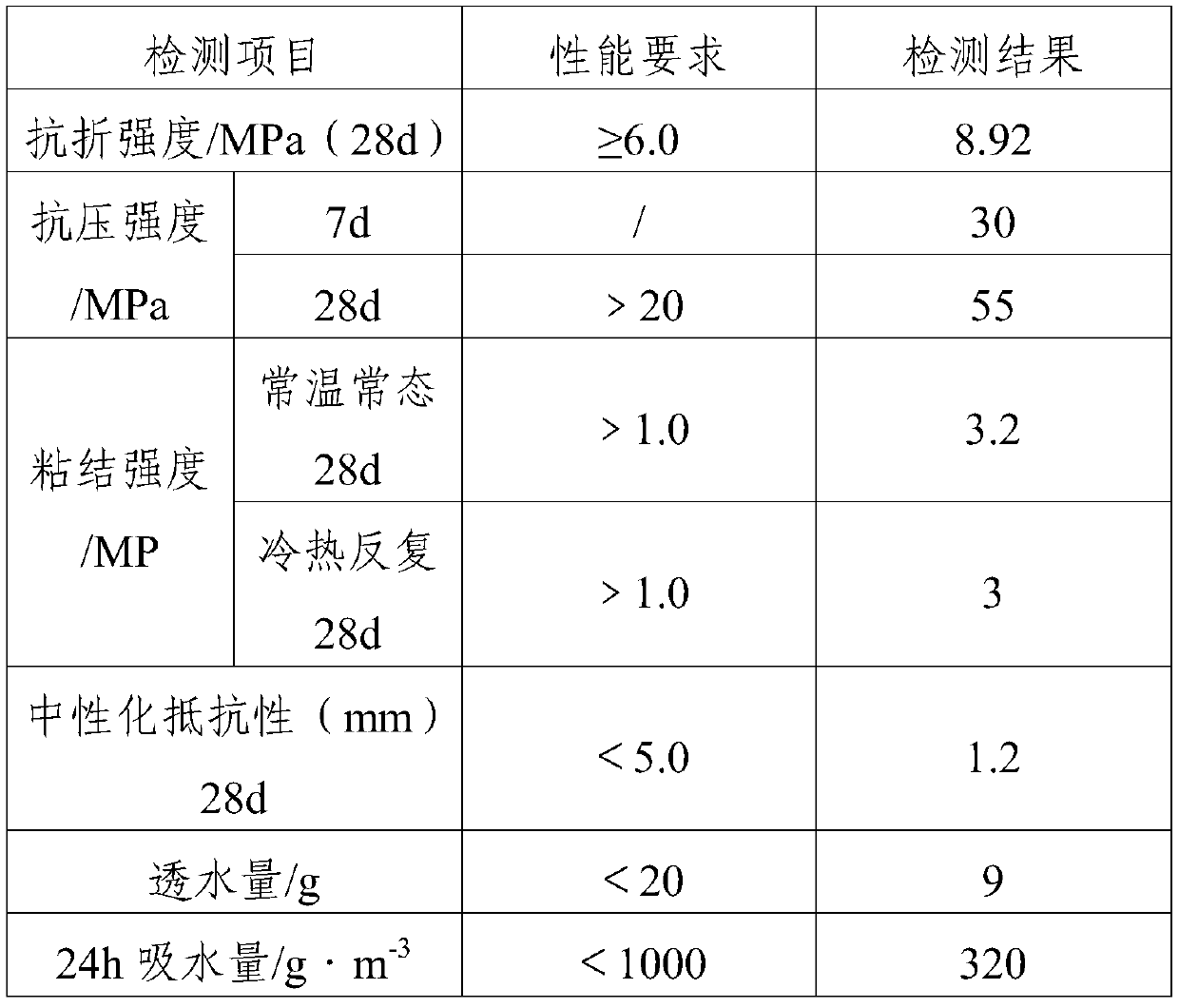

High polymer molecule modified waterproof and anticorrosive resin mortar and preparation method thereof

InactiveCN111073593APrevent flow dropEasy toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseFiber

The invention provides high polymer molecule modified waterproof and anticorrosive resin mortar and a preparation method thereof, and relates to the field of resin mortar materials. The composition comprises the following components in parts by weight: 60-80 parts of POSS modified epoxy resin; 5-10 parts of liquid chloroprene rubber, 5-10 parts of liquid polysulfide rubber, 5-10 parts of carboxyl-terminated polybutadiene, 10-15 parts of talcum powder, 10-15 parts of modified clay, 1-5 parts of N550 carbon black, 4-8 parts of expanded and vitrified micro bubbles, 4-8 parts of expanded polyphenyl particles, 5-10 parts of polycrystalline aluminum oxide fibers, 1-3 parts of 2, 4, 6-tri (dimethylaminomethyl) phenol, 1-3 parts of polypropylene glycol diglycidyl ether, 0.1-1 part of aminosilane,0.1-1 part of vinyltriethoxysilane, 3-6 parts of polyethylene wax, 1-3 parts of hydroxyethyl cellulose, 1-3 parts of a thixotropic agent, 5-10 parts of a binding agent, 5-10 parts of a diluent and 1-2parts of a curing agent. The high polymer molecule modified waterproof and anticorrosive resin mortar has excellent mechanical properties and excellent crack resistance, impermeability, compression resistance, alkali resistance, acid resistance and salt corrosion resistance, and all the properties meet the use requirements.

Owner:安徽云秒源通讯科技有限公司

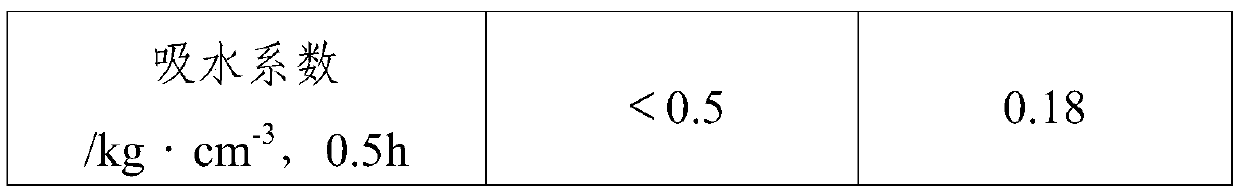

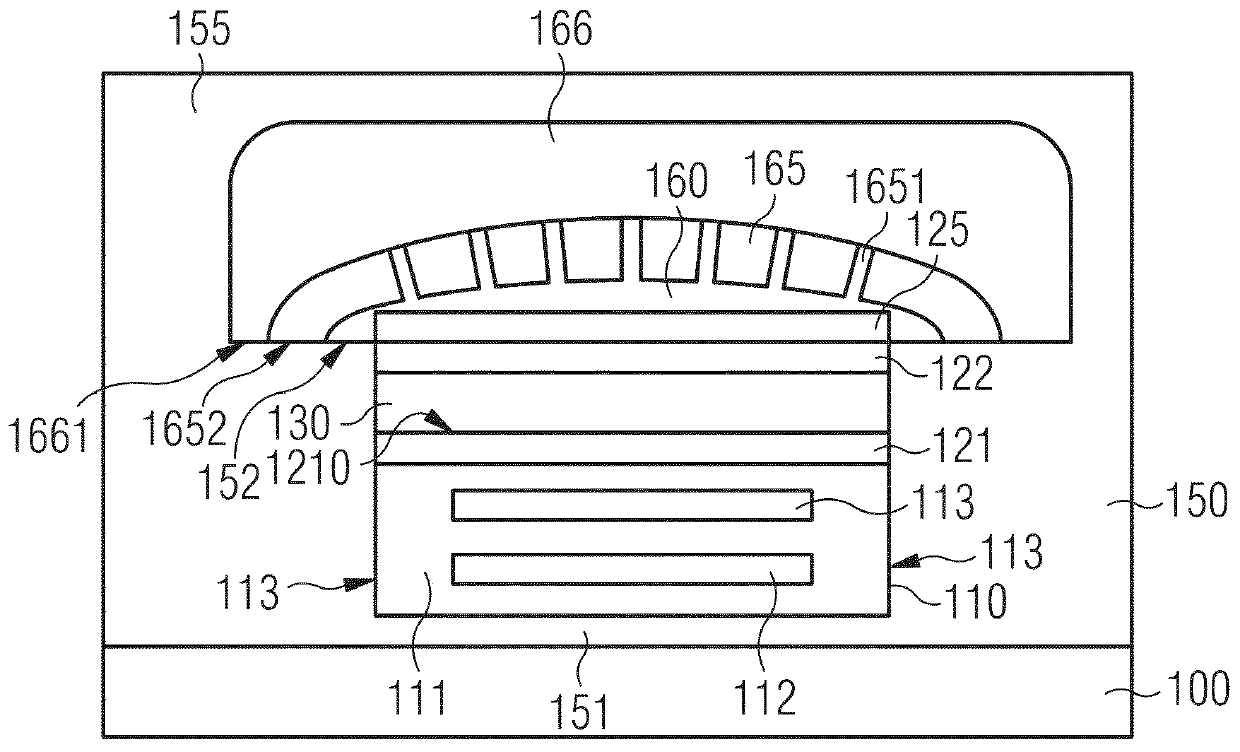

Electro-acoustic resonator device and method of manufacturing thereof

An electro-acoustic resonator device comprises a substrate (100), bottom and top electrodes (121, 122), and a piezoelectric layer (130) disposed therebetween. A bragg mirror element (110) is disposedbetween the bottom electrode and the substrate. A thermally conductive material comprises amorphous or polycrystalline aluminum nitride (150, 151, 155) that contacts the piezoelectric layer and the substrate to form a thermally conductive path to sink heat generated in the acoustically active region of the resonator device during its operation.

Owner:RF360新加坡私人有限公司

High-temperature-resistant cladding optical fiber temperature sensor

InactiveCN109238500AHigh detection sensitivityThe result is accurateCladded optical fibreThermometers using physical/chemical changesFiberPolycrystalline aluminum

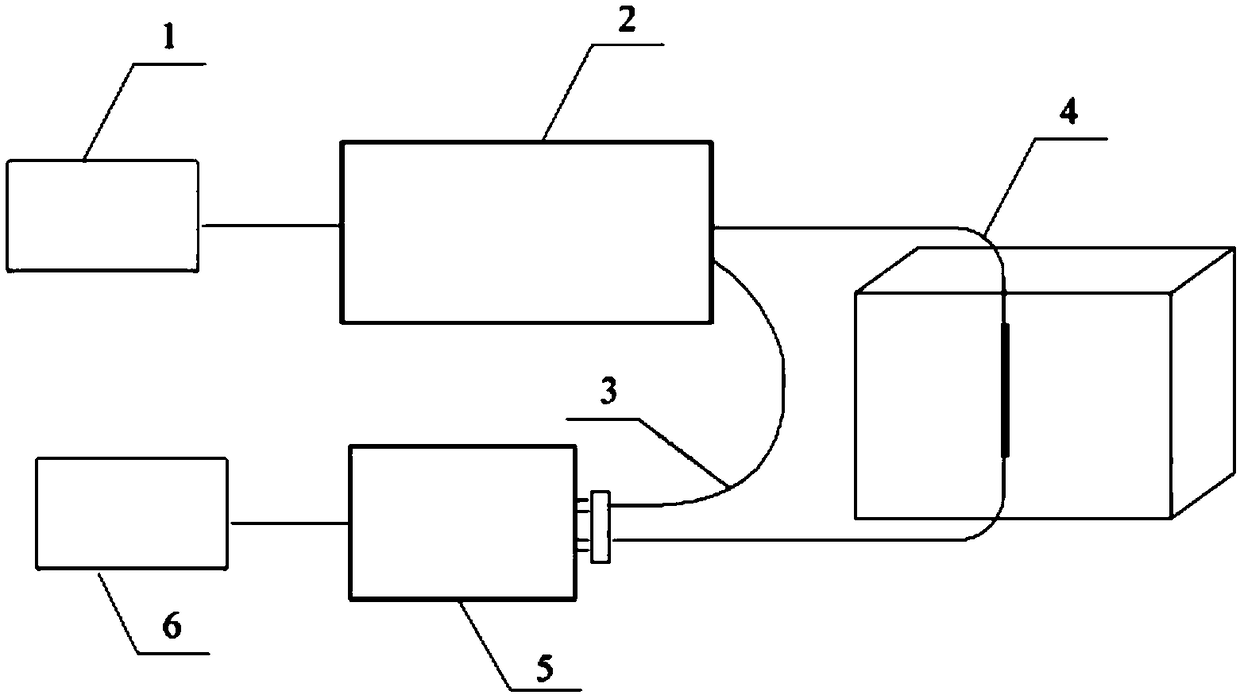

The invention provides a high-temperature-resistant cladding optical fiber temperature sensor. The high-temperature-resistant cladding optical fiber temperature sensor comprises a light source, a light splitter, a reference light path, a sensitive light path, an optical power meter and a data processing and storage device, wherein the reference light path and the sensitive light path are connectedin parallel; one ends of the reference light path and the sensitive light path are connected with the light splitter and the light source in sequence, and the other ends of the reference light path and the sensitive light path are connected with the optical power meter and the data processing and storage device in sequence; and each of the reference light path and the sensitive light path is a sensitive optical fiber. The high-temperature-resistant cladding fiber temperature sensor adopts a sapphire crystal material as a sensitive optical fiber, and comprises an optical fiber core and a cladding material coated outside the optical fiber core; the optical fiber core is simple in preparation process and has excellent absorption characteristics and up-conversion strength, so that the application range of the sapphire optical fiber is greatly expanded; the cladding material is made of multi-component phosphate glass doped with polycrystalline aluminum oxide and Er3+, so that the cost is low, and the requirement of total reflection can be met; and the sensor is high in detection sensitivity and accurate in result.

Owner:NANJING TONGLI CRYSTAL MATERIALS RES INST CO LTD

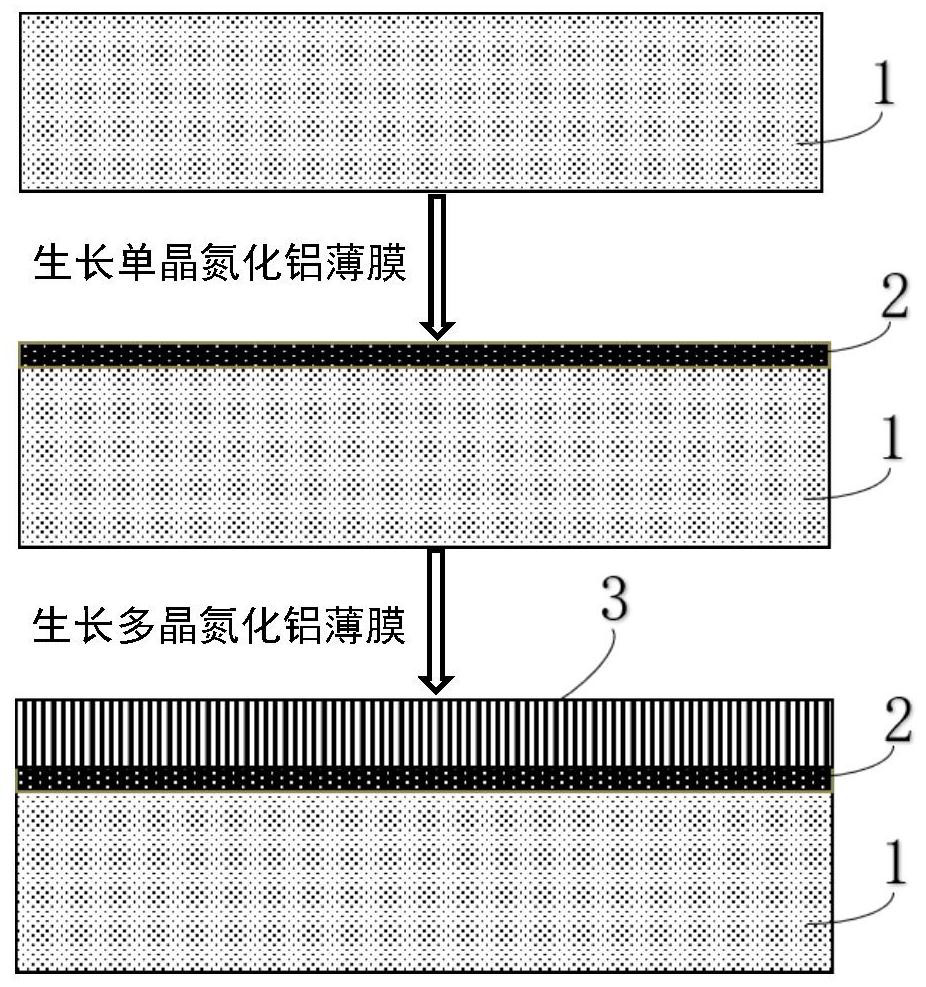

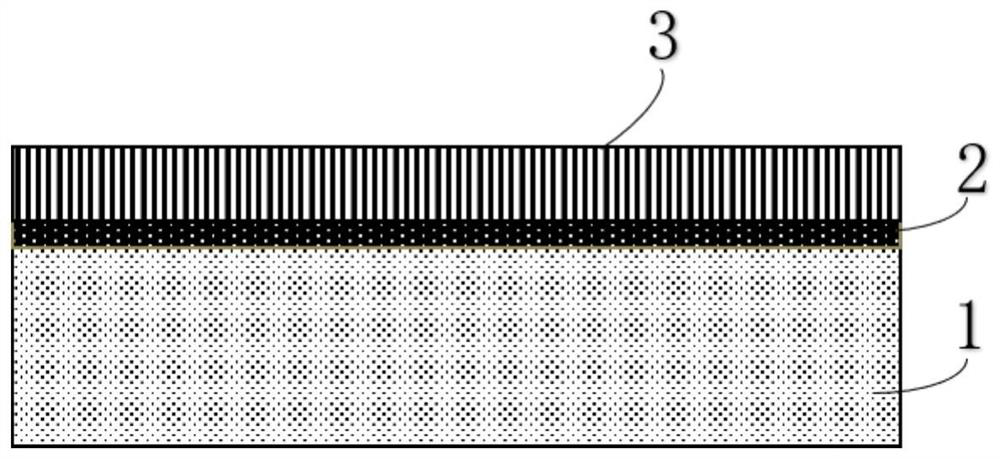

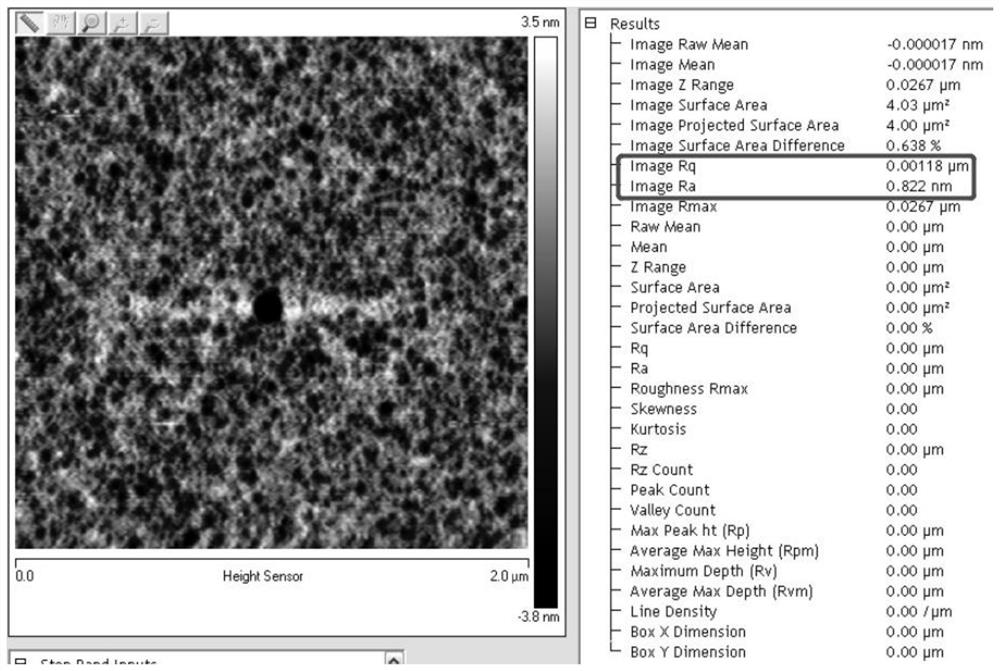

High-quality aluminum nitride piezoelectric film and preparation method thereof

PendingCN111697125AImprove crystal qualitySolve the problem of poor crystal qualityPiezoelectric/electrostrictive device manufacture/assemblyNitrogen compoundsPolycrystalline aluminumSputtering

The invention discloses a preparation method of a high-quality aluminum nitride piezoelectric film, and the method comprises the following steps: (1) taking a substrate, cleaning, spin-drying, and growing a single crystal aluminum nitride film on the substrate by using MOCVD equipment; (2) performing magnetron sputtering on the single crystal aluminum nitride thin film obtained in the step (1) byadopting PVD equipment to generate a polycrystalline aluminum nitride thin film. The method combines MOCVD and PVD two-step growth methods, is simple and easy to operate, significantly improves the crystal quality of the sputtered aluminum nitride film, and realizes the controllability of the thickness and stress of the grown aluminum nitride material. The invention further discloses a high-quality aluminum nitride piezoelectric film which is prepared by the method, the single crystal aluminum nitride film is arranged as a buffer layer, the crystal quality of the aluminum nitride film is high,and the overall performance of the aluminum nitride piezoelectric film is excellent. The invention further discloses an application of the aluminum nitride piezoelectric film to an FBAR filter, and the overall performance of an FBAR filter can be improved.

Owner:广州市艾佛光通科技有限公司

Polycrystalline Aluminum-Containing Grits and Associated Methods

InactiveUS20100024310A1High hardnessImprove toughnessPigmenting treatmentOther chemical processesPolycrystalline aluminumNitride

A method of forming a composite polycrystalline aluminum containing grit can include forming a dispersion of alumina and gelling the dispersion of alumina to form a gel. A nitride abrasive particle can be added to either the dispersion of alumina or the gel. After the nitride abrasive particle has been added, the gel can be processed to form a composite polycrystalline alumina nitride grit.

Owner:SUNG CHIEN MIN

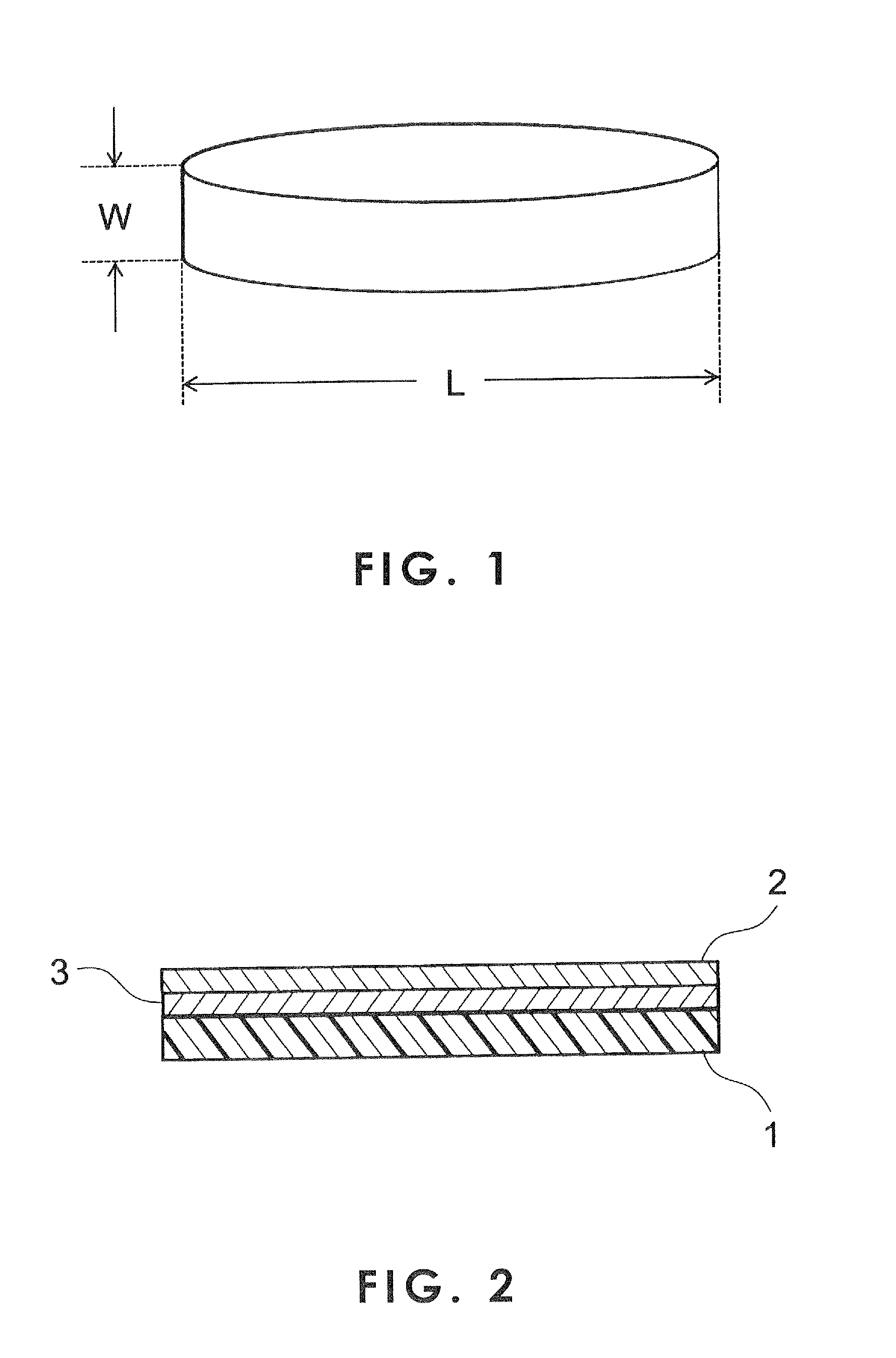

POLYCRYSTALLINE ALUMINUM NITRIDE BASE MATERIAL FOR CRYSTAL GROWTH OF GaN-BASE SEMICONDUCTOR AND METHOD FOR MANUFACTURING GaN-BASE SEMICONDUCTOR USING THE SAME

ActiveUS20130168692A1High yieldSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPolycrystalline aluminumMaximum diameter

There is provided a polycrystalline aluminum nitride substrate that is effective in growing a GaN crystal. The polycrystalline aluminum nitride base material for use as a substrate material for grain growth of GAN-base semiconductors, contains 1 to 10% by weight of a sintering aid component and has a thermal conductivity of not less than 150 W / m·K, the substrate having a surface free from recesses having a maximum diameter of more than 200 μm.

Owner:KK TOSHIBA +1

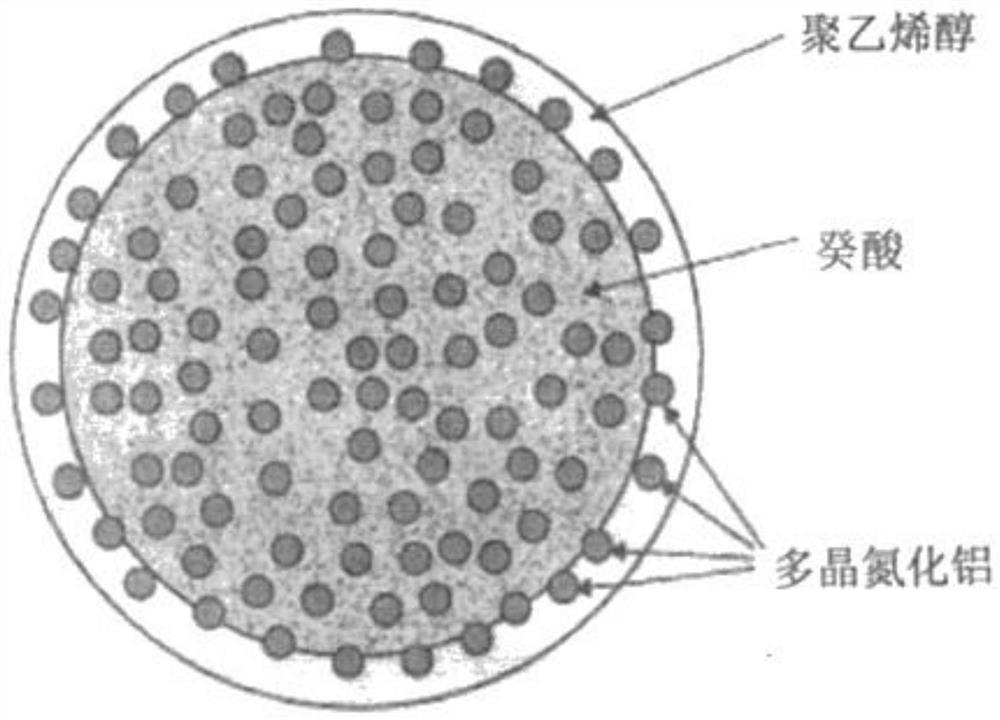

Microencapsulated composite phase change material and production and application thereof

InactiveCN111961445AImprove thermal conductivitySmall coefficient of thermal expansionHeat-exchange elementsMicroballoon preparationPolycrystalline aluminumPolyvinyl alcohol

The invention discloses a microencapsulated composite phase change material as well as production and application thereof. A core material of the microencapsulated composite phase change material is apolycrystalline aluminum nitride-capric acid compound, and a capsule material of the microencapsulated composite phase change material is polyvinyl alcohol. The preparation method comprises the following steps: preparing polycrystalline aluminum nitride-capric acid compound latex particles, coating with polyvinyl alcohol, and carrying out secondary coating. The application method comprises the step of preparing polypropylene fiber cotton by using the microencapsulated composite phase change material. The phase change material has high phase change latent heat and heat exchange capacity, and the phase change temperature of the phase change material is 31.5 DEG C, which is in the most comfortable temperature range of a human body. The prepared intelligent temperature-adjusting polypropylenefiber cotton has a good temperature-adjusting effect and good mechanical properties.

Owner:湖南世东环保节能科技有限公司

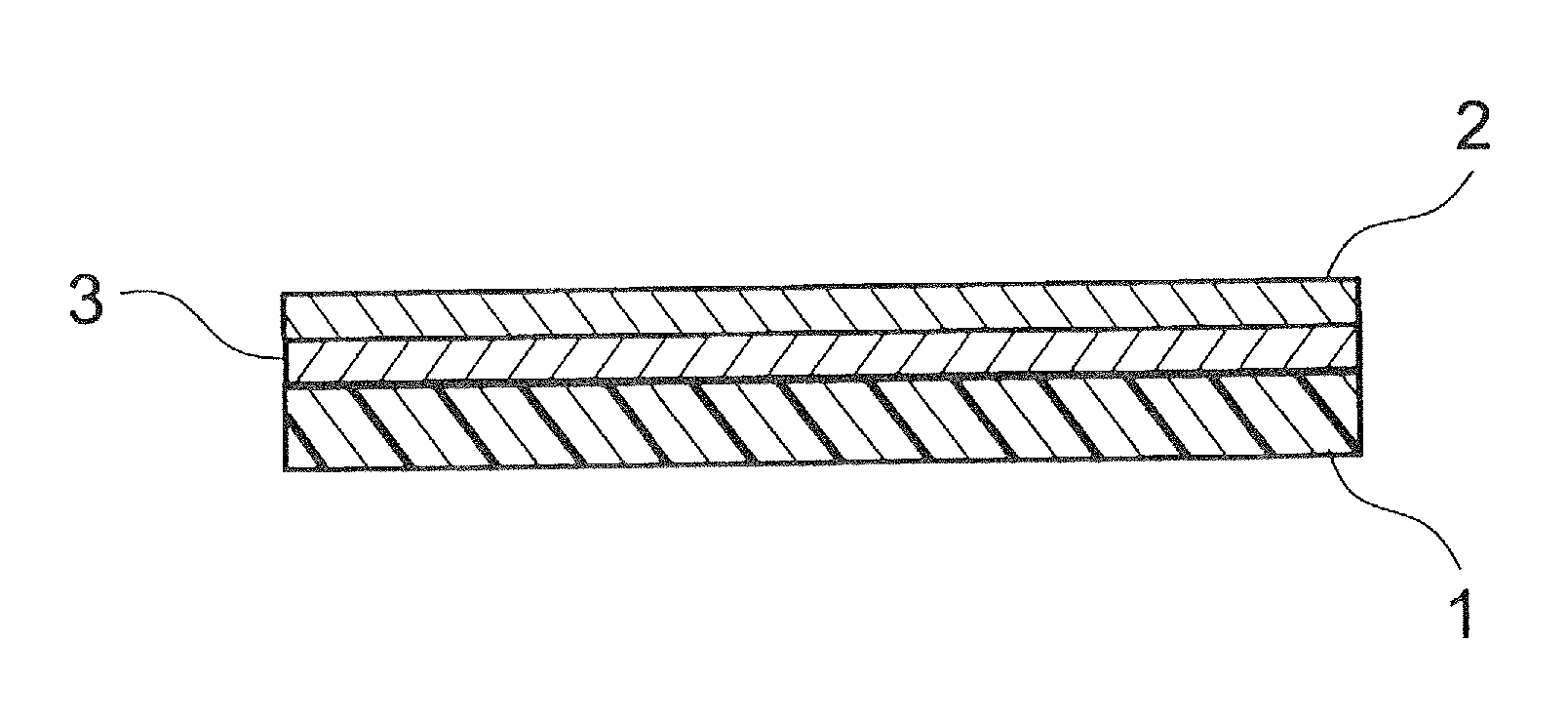

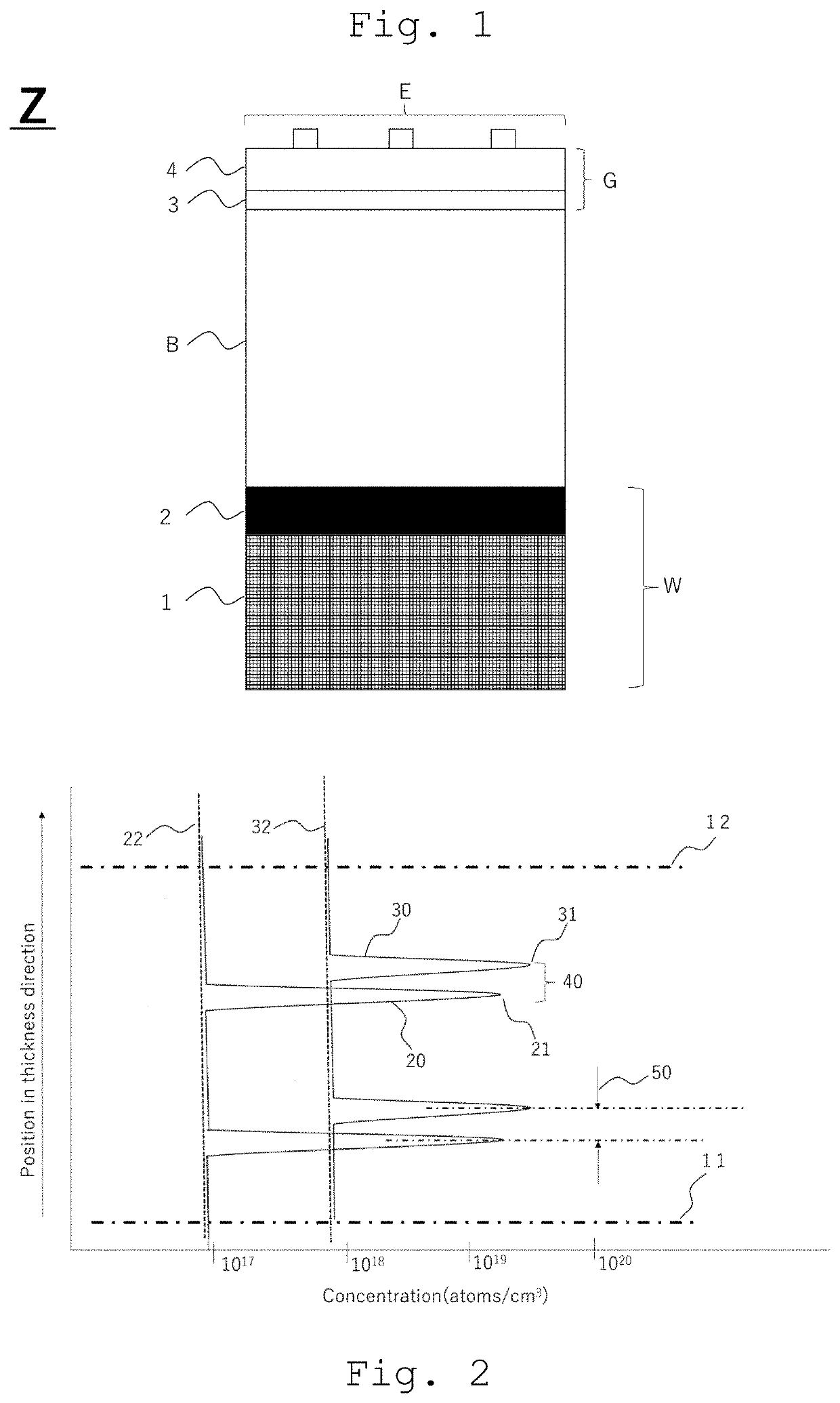

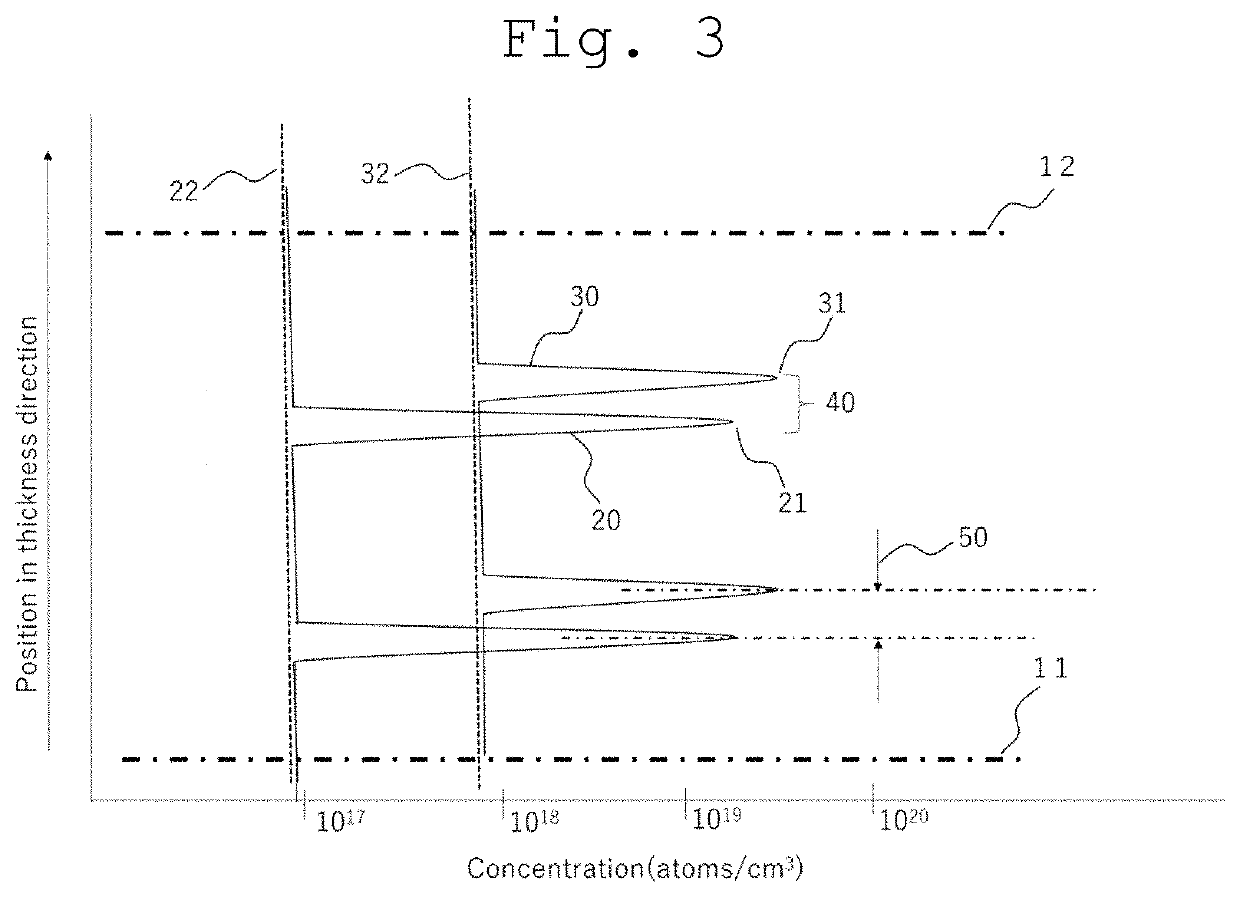

Nitride semiconductor substrate and method of manufacturing the same

ActiveUS20210184004A1Improve pressure resistanceTransistorSemiconductor/solid-state device manufacturingPolycrystalline aluminumPhysical chemistry

The present invention provides a nitride semiconductor substrate suitable for a high frequency device. The nitride semiconductor substrate has a substrate, a buffer layer made of group 13 nitride semiconductors, and an active layer made of group 13 nitride semiconductors in this order, wherein the substrate is composed of a first substrate made of polycrystalline aluminum nitride, and a second substrate made of Si single crystal having a specific resistance of 100 Ω·cm or more, formed on the first substrate, the average particle size of AlN constituting the first substrate is 3 to 9 μm, and preferably, the second substrate grown by the MCZ method has an oxygen concentration of 1E+18 to 9E+18 atoms / cm3 and a specific resistance of 100 to 1000 Ω·cm.

Owner:COORSTEK INC

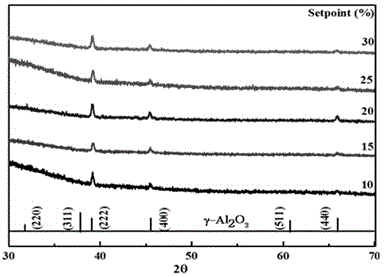

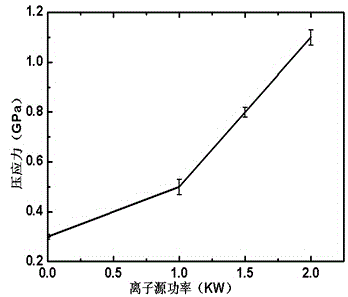

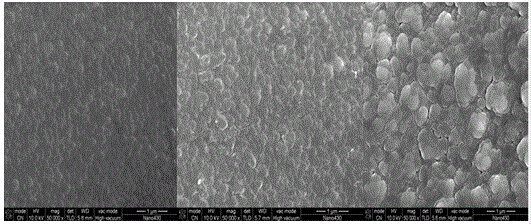

Method for preparing polycrystalline aluminum oxide hard coating

InactiveCN104962873ASimple technical solutionReduce deposition rateVacuum evaporation coatingSputtering coatingLoop controlClosed loop

The invention discloses a method for preparing a polycrystalline aluminum oxide hard coating. According to the method, the polycrystalline aluminum oxide hard coating is prepared by using gas reaction closed-loop control and anode layer ion source assisted magnetron sputtering deposition, gamma-phase Al2O3 in a good crystalline state can be deposited at a relatively low temperature between 200 and 300 DEG C at a speed of 20-30nm / min, and the obtained aluminum oxide coating has relatively high hardness and an ideal stoichiometric ratio; and moreover, the regulation and control of the stress and a microstructure of the coating can be realized by regulating and controlling the energy of the anode layer ion source. The method disclosed by the invention is simple, is strong in process repeatability, and has important application values in the industrial production fields of mechanics, electronics and optics.

Owner:GUANGDONG UNIV OF TECH

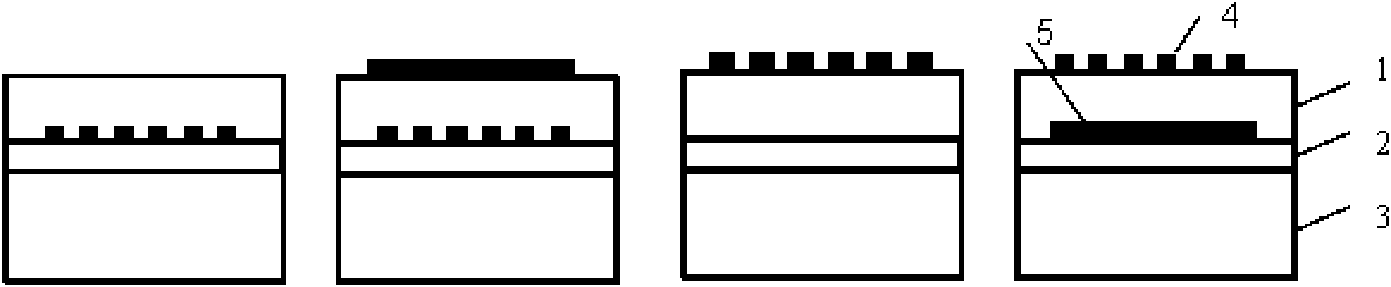

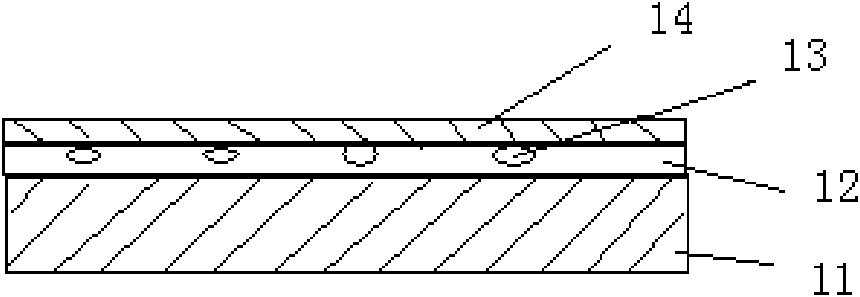

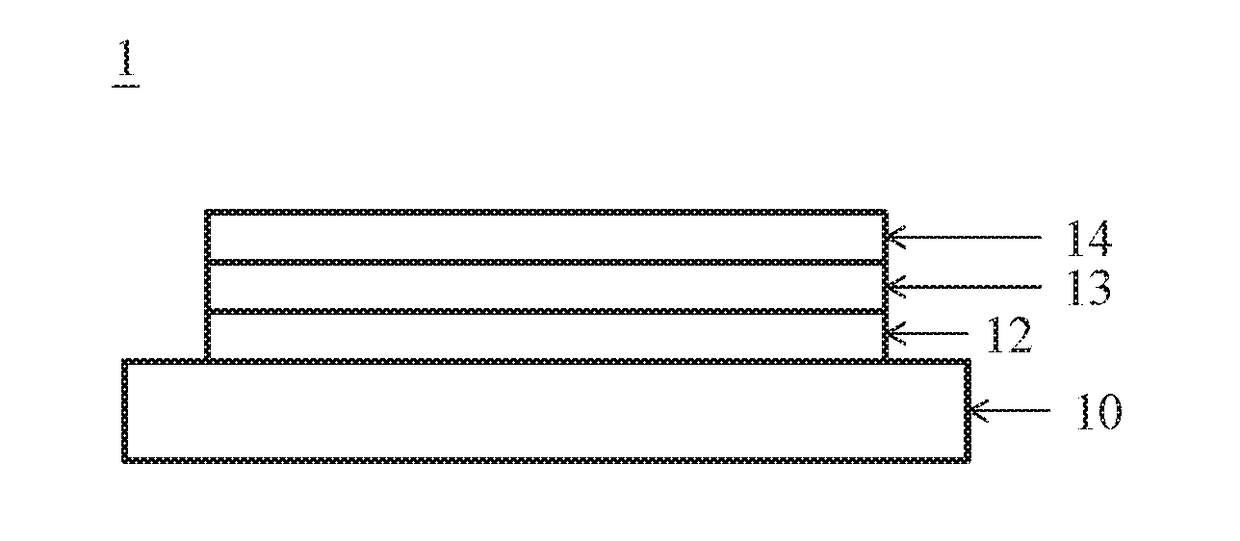

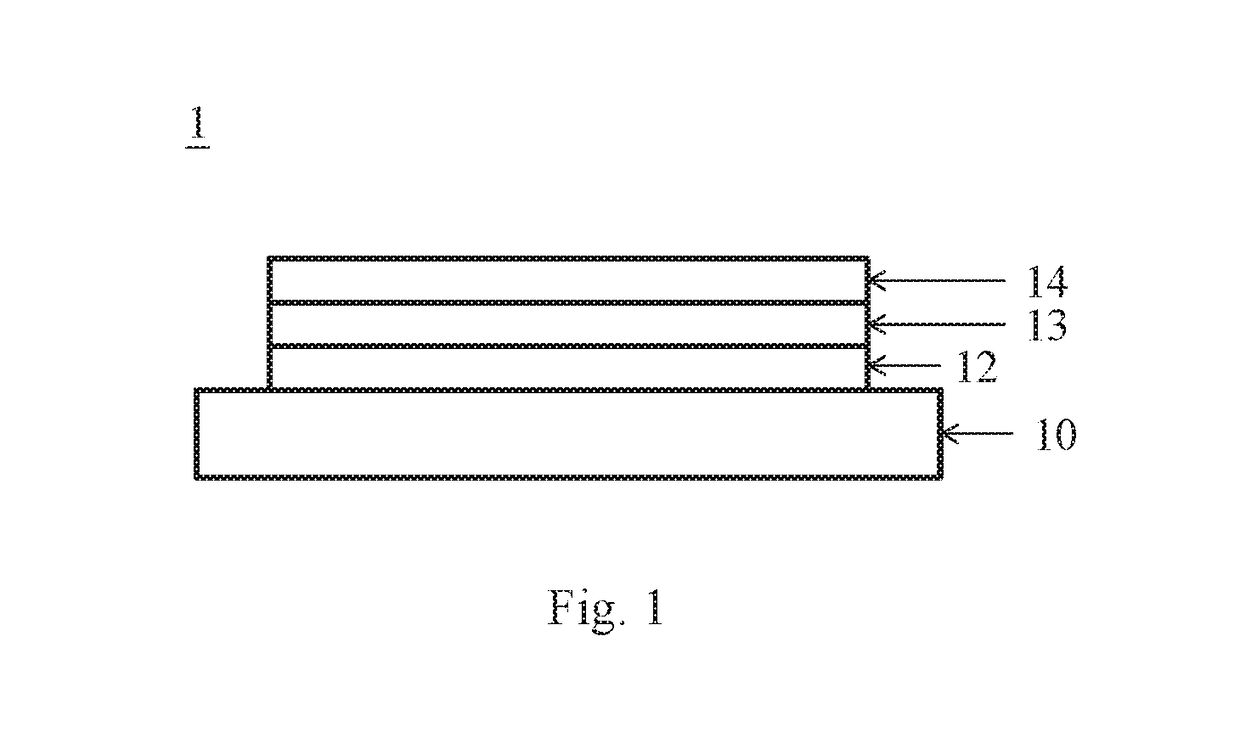

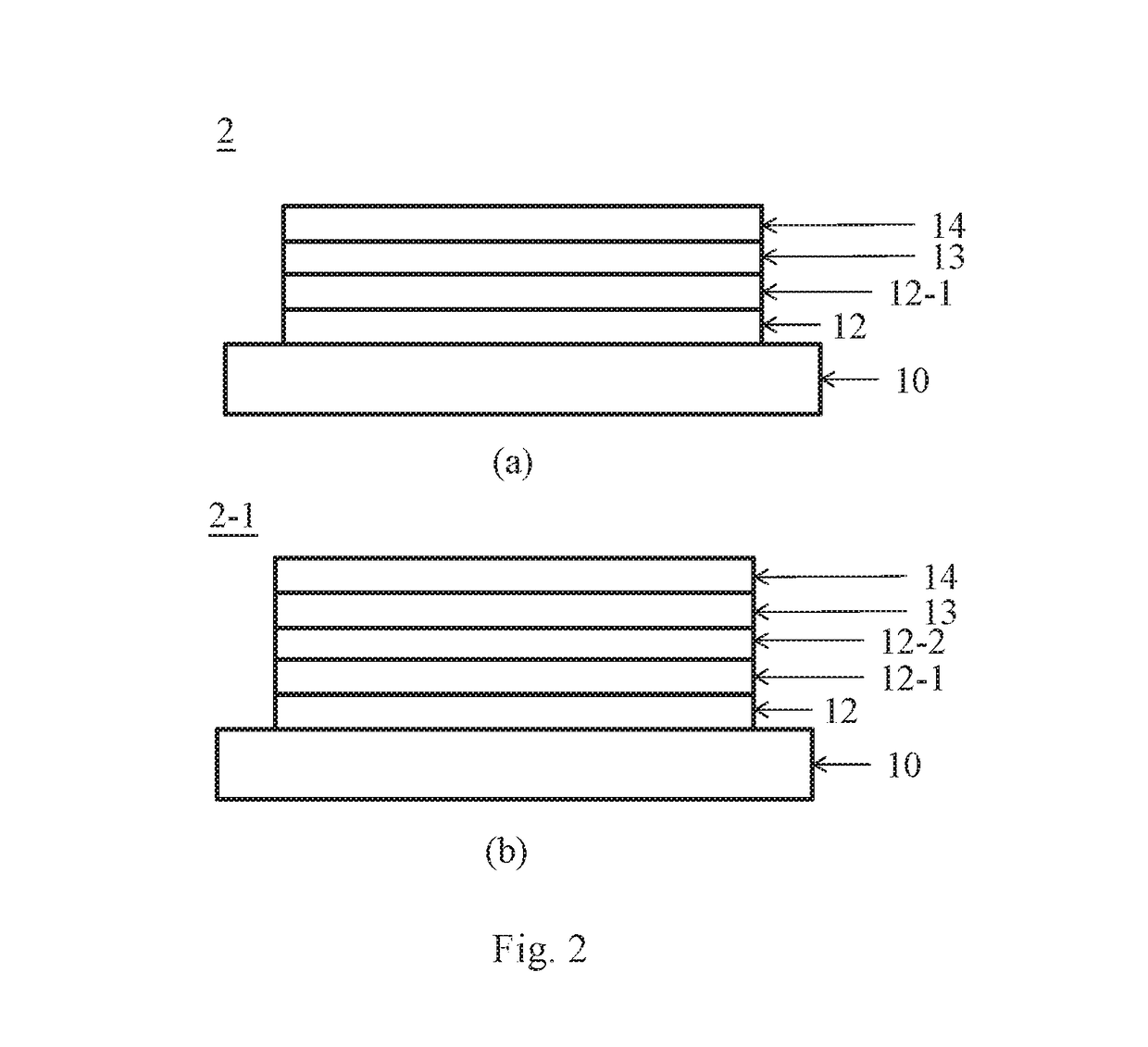

LED epitaxial Structure

InactiveUS20140034948A1Good lattice matchingEasy to optimizeSemiconductor/solid-state device manufacturingSemiconductor devicesPolycrystalline aluminumSingle crystal

An LED epitaxial structure includes the first layer thin film and the second layer thin film. The first layer thin film and the second layer thin film are polycrystalline aluminum nitride and single crystal aluminum nitride respectively, which have good thermal conductivity, insulation, mechanical intensity, and chemistry stability. Based on the substrate mentioned above, growing a single crystal gallium nitride on the second layer thin film as the third layer thin film allows the single crystal aluminum nitride and gallium nitride to have good lattice and thermal expansion match, resulting in the promotion of light emitting and thermal conduction efficiency.

Owner:NAT CHUNG SHAN INST SCI & TECH

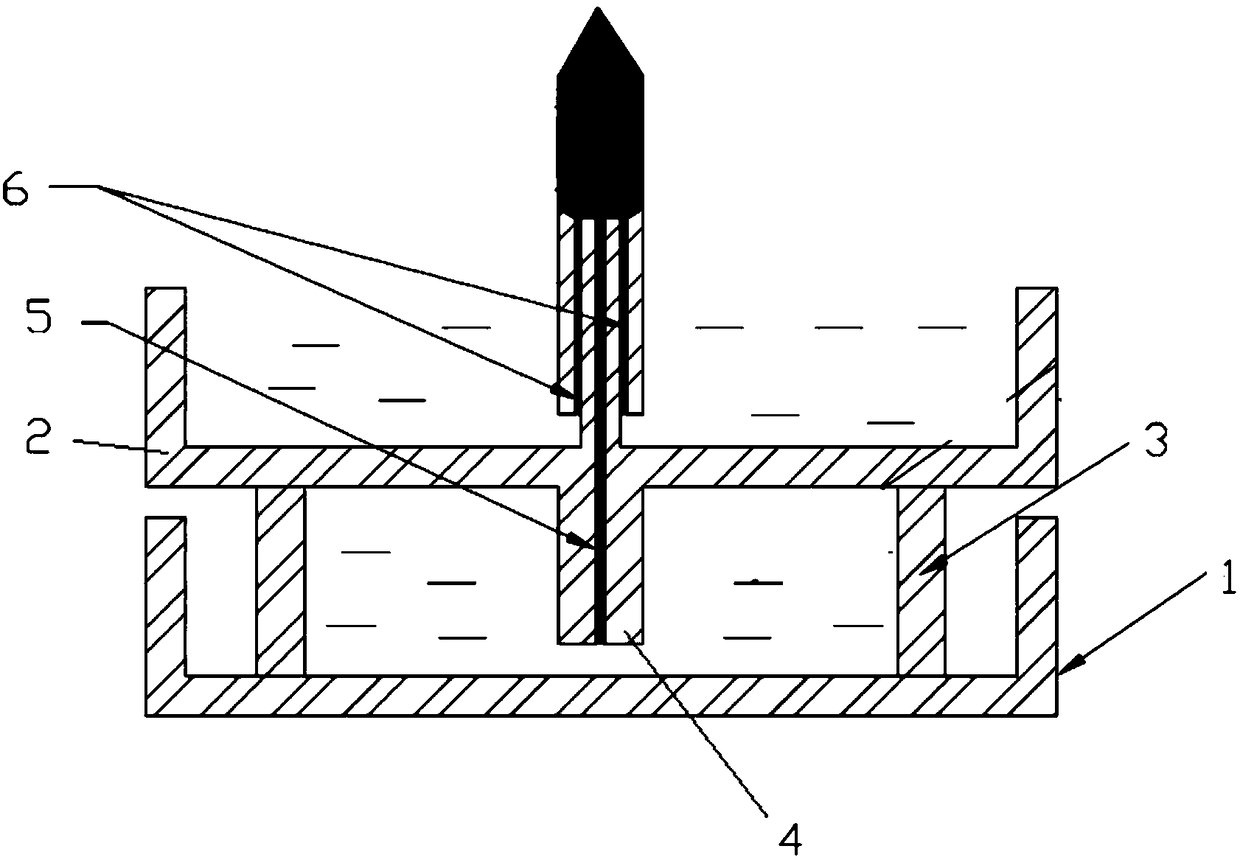

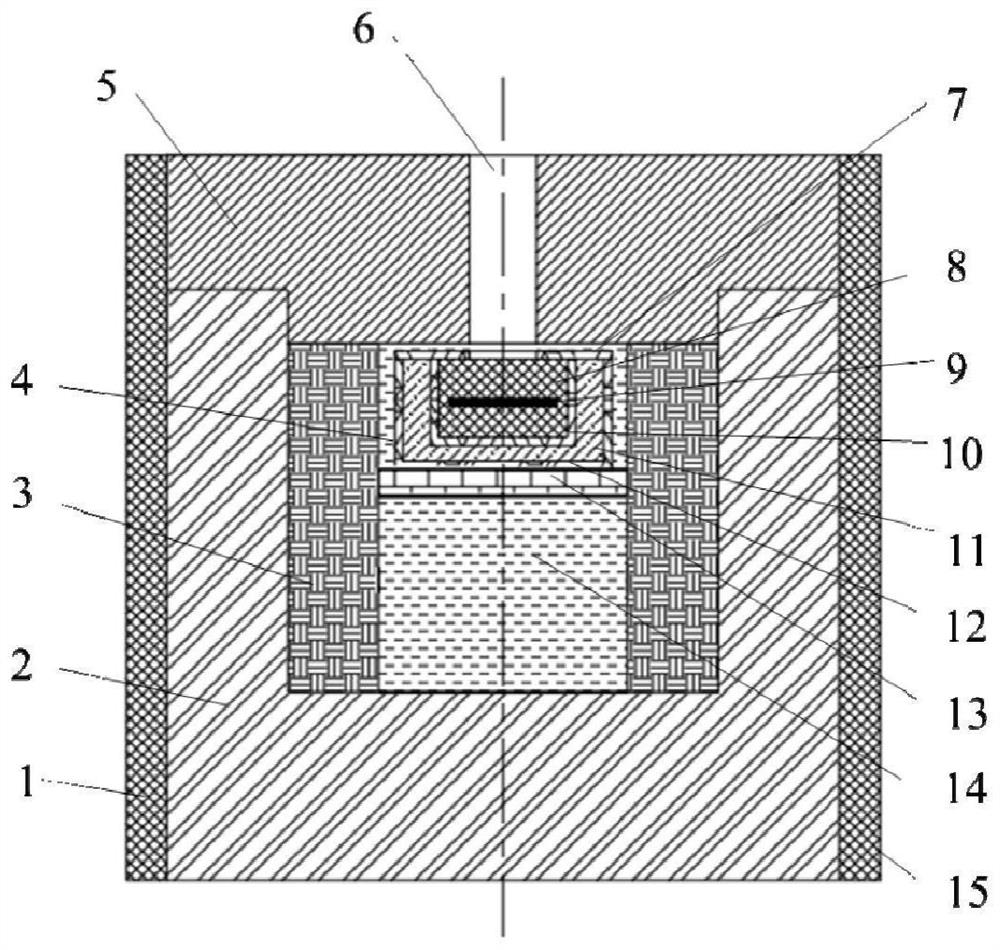

Thermal insulation device for microwave sintering of titanium carbonitride-based metal ceramic material

PendingCN114777474AGood wave permeabilityReduce lossCharge treatment typeCrucible furnacesFiberPolycrystalline aluminum

The invention relates to a heat preservation device for microwave sintering of a titanium carbonitride-based metal ceramic material. The heat preservation device comprises a large-size crucible, a small-size crucible, polycrystalline aluminum oxide high-temperature fibers, first polycrystalline aluminum oxide fiber cotton and a polycrystalline mullite fiber board. The small-size crucible is arranged on the inner side of the large-size crucible, the polycrystalline alumina high-temperature fiber is arranged between the small-size crucible and the large-size crucible, the first polycrystalline alumina fiber cotton is annularly arranged on the outer side of the large-size crucible, and the bottom of the large crucible is arranged on the polycrystalline mullite fiber board. The problems that heat insulation cotton is softened at high temperature, so that the position of a crucible deviates, heat loss is accelerated, and the sintering quality is reduced are solved.

Owner:SHANDONG UNIV

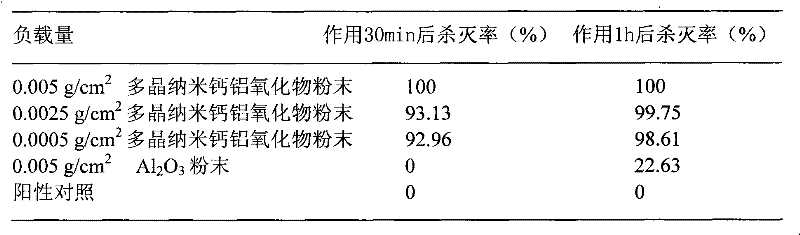

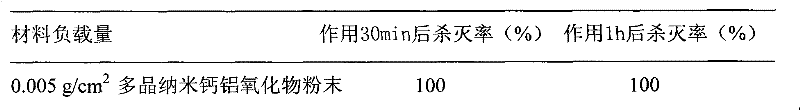

Antimicrobial Application of Polycrystalline Nano Calcium Aluminum Oxide

The invention relates to an inorganic antibacterial material, in particular to the use of a polycrystalline nano-calcium aluminum oxide C12A7-O- material for killing bacteria. The antibacterial material has broad-spectrum antibacterial and bactericidal effects, that is, it has a killing effect on Staphylococcus aureus, Escherichia coli, and Bacillus subtilis var. When the load weight per unit area is greater than or equal to 0.005g / cm2, the killing rate of Staphylococcus aureus and Escherichia coli in one hour is 100%, and the killing rate of Bacillus subtilis varietal spores in one hour is 96%. . Among them, the particle size of polycrystalline nano-calcium aluminum oxide is 10-200nm; the load material is textile or plastic product or ceramic, rubber product, etc., and normal temperature refers to the natural room temperature condition in four seasons. Polycrystalline nano-calcium aluminum oxide has strong antibacterial function, non-toxic, high temperature resistance, strong stability, and can be widely used in antibacterial textiles, antibacterial plastics or ceramics, rubber products and other fields.

Owner:UNIV OF SCI & TECH OF CHINA

Substrate for semiconductor device and semiconductor device using the same

InactiveUS20170373155A1Solve the low heat dissipation efficiencyImprove cooling efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalSilicon oxide

The present invention provides a substrate for a semiconductor device and a semiconductor device using the same. The substrate for a semiconductor device comprises a ceramic supporting base plate formed by a polycrystalline aluminum nitride (AlN) sintered body; at least one silicon oxide layer formed on the base plate by a sol-gel method wherein the at least one silicon oxide layer has an average roughness less than the base plate to block polycrystalline orientation of the base plate and has a total thickness in a range of 10˜5000 nm, the silicon oxide layer is only formed from the sol-gel method and are not single crystalline; a first buffer layer comprising aluminum nitride (AlN) on the at least one silicon oxide layer with a thickness of 0.1˜10 μm; and a gallium nitride layer formed on the first buffer layer and having a single-crystal crystalline structure.

Owner:NATIONAL CHI NAN UNIVERSITY

Energy-saving heat-insulation heat-preserving hot plugging material and preparation method thereof

The invention relates to an energy-saving heat-insulation heat-preserving hot plugging material and a preparation method thereof. The energy-saving heat-insulation heat-preserving hot plugging material is characterized by comprising the following components by weight percent: 0.3 to 0.4 percent of dispersing agent, 0.2 to 0.3 percent of defoaming agent, 0.5 to 0.8 percent of penetrating agent, 0.1 to 0.15 percent of polyacrylamide, 0.3 to 0.6 percent of high-temperature glue, 2.5 to 2.9 percent of closed cell perlite, 0.8 to 1.0 percent of hollow glass microbead, 0.7 to 0.9 percent of nano hollow ceramic microbead, 2.6 to 2.9 percent of bentonite, 2.0 to 3.0 percent of ceramic fibers, 0.5 to 1.0 percent of based-titanium whisker, 0.5 to 1.0 percent of polycrystalline aluminum oxide fibers, 0.1 to 4.0 percent of asbestos and the balance of water; the sum of the weight percentage is 100 percent. The energy-saving heat-insulation heat-preserving hot plugging material has the characteristics of thin coating, light weight, good heat-preserving effect, long service life, environment friendliness, recyclability and the like. The method is mature and reliable in process, and the prepared hot plugging material is stable in performance; convenience in construction is realized, construction by driving a car can be realized, and the difficulty that the heat-preserving material is difficult to pave on the surface of equipment such as a boiler top, a boiler bottom and a steam turbine body can be solved.

Owner:UNIV OF JINAN +1

Method for preparing aluminum oxide micro-sphere

InactiveCN101214984BSimple processShorten the production cycleChemical industryAluminium oxide/hydroxide preparationDecompositionMicrosphere

A process for preparing aluminum oxide microsphere concretely includes the following steps: (1) placing raw materials in a crucible, (2) heat decompositing the raw materials placed in the crucible at the temperature between 1150-1350DEG C by a sintering furnace, (3) heat decompositing and insulating for 0.5-1.5 hours and (4) cooling the furnace to room temperature. Compared with the prior art, the utility model has the advantages that perfect spheroidal structure of the aluminum oxide microsphere is formed by employing the decomposition of polymeric compound pre-substance without any protective atmosphere and catalyst, not only the device and the process are simple, but also the production circle is short, the purity of the product is high, simultaneously, the controllability and the repeatability of the process are extremely fine, the single crystalline or polycrystalline aluminum oxide microsphere can be obtained by controlling the heat decomposition temperature, the grain diameter of the microsphere can be adjusted and controlled by controlling the heat preservation time. The high purity aluminum oxide microsphere, especially a single crystalline alumina microsphere, as a grinding medium, will be widely used in electronics industry, fine process of non-metallic minerals, building and sanitary ceramics and hydrodynamic lubrication and the like, which is a widely used energy-saved material.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com