High-temperature-resistant cladding optical fiber temperature sensor

An optical fiber temperature and sensor technology, used in cladding optical fibers, thermometers, thermometers with physical/chemical changes, etc. Excellent up-conversion strength, improved application range, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sapphire laser crystal material Sm 3+ / Rh 3+ / Mn 2+ / Ti 3+ :Al 2 O 3 .

[0026] Among the sapphire laser crystal materials, Sm 3+ , Rh 3+ , Mn 2+ The molar ratio is 3:2:1; the Sm 3+ , Rh 3+ , Mn 2+ The total moles with Ti 3+ :Al 2 O 3 The molar ratio is 3:100.

[0027] The preparation method of the sapphire laser crystal material comprises the following steps:

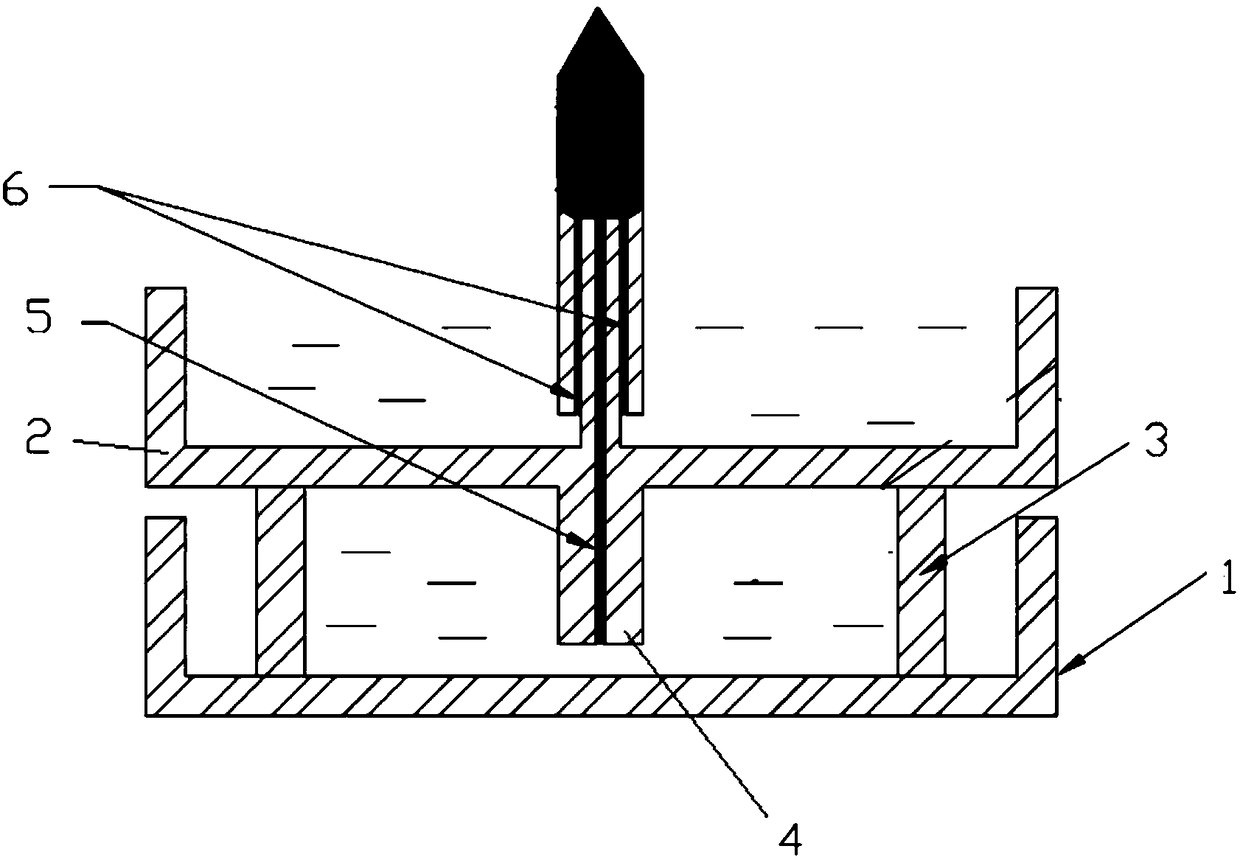

[0028] (1) A crystal growth mold with a capillary tube is placed in the middle of the crucible, and the raw material Al 2 O 3 , Ti 2 O 3 , Sm 2 O 3 , Rh 2 O 3 , MnO is placed in a crucible, and the crucible is heated to melt the raw material to form a melt;

[0029] (2) Connect the seed crystal to the top of the mold to pull the melt, so that the seed crystal continuously undergoes atomic or molecular rearrangement on the interface of the melt, and gradually solidifies with the cooling to grow a single crystal with the same shape as the edge of the mold.

Embodiment 2

[0031] Sapphire laser crystal material Sm 3+ / Rh 3+ / Mn 2+ / Ti 3+ :Al 2 O 3 .

[0032] Among the sapphire laser crystal materials, Sm 3+ , Rh 3+ , Mn 2+ The molar ratio is 2:3:1; the Sm 3+ , Rh 3+ , Mn 2+ The total moles with Ti 3+ :Al 2 O 3 The ratio of moles is 1:100.

[0033] The preparation method of the sapphire laser crystal material comprises the following steps:

[0034] (1) A crystal growth mold with a capillary tube is placed in the middle of the crucible, and the raw material Al 2 O 3、Ti 2 o 3 、Sm 2 o 3 、Rh 2 o 3 , MnO is placed in a crucible, and the crucible is heated to melt the raw materials to form a melt;

[0035] (2) Connect the seed crystal to the top of the mold to pull the melt, so that the seed crystal continuously rearranges atoms or molecules at the interface of the melt, and gradually solidifies as the temperature drops to grow a single crystal with the same shape as the edge of the mold.

Embodiment 3

[0037] Sapphire laser crystal material Sm 3+ / Rh 3+ / Mn 2+ / Ti 3+ :Al 2 o 3 .

[0038] Among sapphire laser crystal materials, Sm 3+ 、Rh 3+ , Mn 2+ The molar ratio is 4:1:1; the Sm 3+ 、Rh 3+ , Mn 2+ The total number of moles and Ti 3+ :Al 2 o 3 The molar ratio is 5:100.

[0039] The preparation method of described sapphire laser crystal material, comprises the following steps:

[0040] (1) place the crystal growth mold that the middle part is provided with capillary in the crucible middle part, the raw material Al 2 o 3 、Ti 2 o 3 、Sm 2 o 3 、Rh 2 o 3 , MnO is placed in a crucible, and the crucible is heated to melt the raw materials to form a melt;

[0041] (2) Connect the seed crystal to the top of the mold to pull the melt, so that the seed crystal continuously rearranges atoms or molecules at the interface of the melt, and gradually solidifies as the temperature drops to grow a single crystal with the same shape as the edge of the mold.

[0042] Test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com