Energy-saving heat-insulation heat-preserving hot plugging material and preparation method thereof

A material blocking and heating technology, which is applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve the problems of thermal insulation performance being easily affected by climate environment, thermal insulation performance decline, etc., and achieve easy equipment flaw detection. , reduce the extra weight, the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

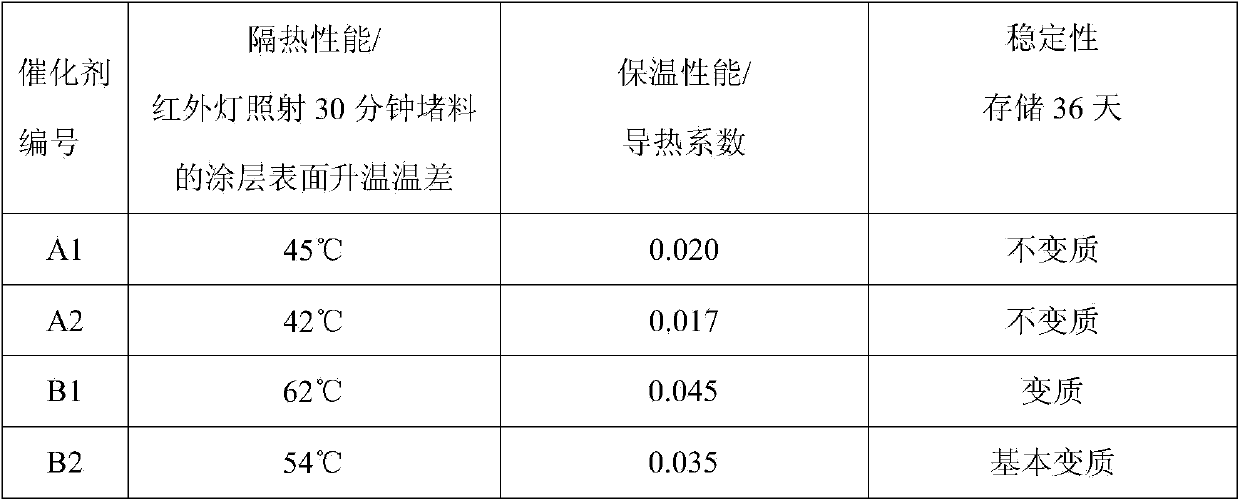

Examples

Embodiment 1

[0020] Prepare various ingredients according to the mixing ratio, add 40g of sodium tripolyphosphate, 20g of ceramic fiber, 10g of potassium hexatitanate whisker, 10g of polycrystalline alumina fiber, and alkylbenzenesulfonate into 9060g of water at a stirring speed of 1000r / min 20g of sodium lauryl alcohol, 50g of polyoxyethylene lauryl alcohol ether, the speed was adjusted to 2000r / min, and stirred for 5 minutes; then 40g of asbestos, 260g of bentonite, 10g of polyacrylamide, 60g of high-temperature glue were added at a speed of 500r / min, and stirred for 10 Minutes; high-temperature glue is to be made up of matrix and binding agent, and the quality of described matrix and binding agent is respectively 55g and 5g, and described matrix is made up of industrial aluminum hydroxide, titanium dioxide micropowder and talcum powder; Said industrial aluminum hydroxide The quality of titanium dioxide micropowder and talcum powder is 16.5g, 27.5g, 11g respectively, and the adhesive is...

Embodiment 2

[0022] Prepare various ingredients according to the mixing ratio, add 8g of sodium tripolyphosphate, 4g of ceramic fiber, 2g of potassium hexatitanate whisker, 2g of polycrystalline alumina fiber, and alkylbenzene sulfonate into 1812g of water at a stirring speed of 1000r / min. 4g of sodium lauryl alcohol, 10g of polyoxyethylene lauryl alcohol, the speed was adjusted to 2000r / min, and stirred for 5 minutes; then 8g of asbestos, 52g of bentonite, 2g of polyacrylamide, 12g of high-temperature glue were added at a speed of 500r / min, and stirred for 10 minutes; the high-temperature glue is made up of matrix and binding agent, and the quality of described matrix and binding agent is respectively 11g and 1g, and described matrix is made up of industrial aluminum hydroxide, titanium dioxide micropowder and talcum powder; Said industrial aluminum hydroxide The quality of titanium dioxide micropowder and talcum powder is 3.3g, 5.5g, 2.2g respectively, and the adhesive is composed of bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com