Antimicrobial Application of Polycrystalline Nano Calcium Aluminum Oxide

A technology of aluminum oxide and nano-calcium, applied in applications, animal repellants, plant growth regulators, etc., can solve the problems of undiscovered, harsh synthesis conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of Polycrystalline Nano Calcium Aluminum Oxide

[0018] In 200ml concentration of 0.2g / ml citric acid aqueous solution, add 2.48g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) (purity: analytically pure) and 4.60g aluminum nitrate (Al(NO 3 ) 3 9H 2 O) (purity: analytically pure) then add 0.5g polyethylene glycol surfactant (purity: analytically pure), control the water bath temperature at 70°C, and continuously stir at a speed of 200r / min until dissolved to obtain a clear solution;

[0019] Add 50ml of ethylene glycol (purity: analytically pure) to the solution, and stir continuously at a speed of 200r / min for 2 hours to form a calcium-aluminum salt sol; stand at 90°C for 24 hours to form a calcium-aluminum salt gel; The glue is heated to 350°C in the air atmosphere and kept for 2 hours to form a blocky solid; grind the blocky solid into particles with a particle size of less than 0.15mm; place the ground particles in an open quartz container Into the...

Embodiment 2

[0020] Example 2 Preparation of Polycrystalline Nano Calcium Aluminum Oxide

[0021] In 200ml concentration of 0.2g / ml citric acid aqueous solution, add 24.80g calcium nitrate (Ca(NO 3 ) 2 4H 2 O) (purity: analytically pure) and 45.95g aluminum nitrate (Al(NO 3 ) 3 9H 2 (0) (purity: analytically pure) then add 0.5g polyethylene glycol surfactant (purity: analytically pure), control the water bath temperature at 80°C, and continuously stir at a speed of 500r / min until it dissolves to obtain a clear solution; Add 120ml of ethylene glycol (purity: analytically pure) to the solution, and stir continuously at a speed of 500r / min for 2 hours to form a calcium-aluminum salt sol; stand at 90°C for 24 hours to form a calcium-aluminum salt gel; Heating to 400°C in an air atmosphere and keeping it warm for 1 hour to form a blocky solid; grind the blocky solid into particles with a particle size of less than 0.15mm, put the ground particles into an open quartz container and put them ...

Embodiment 3 test Embodiment 2

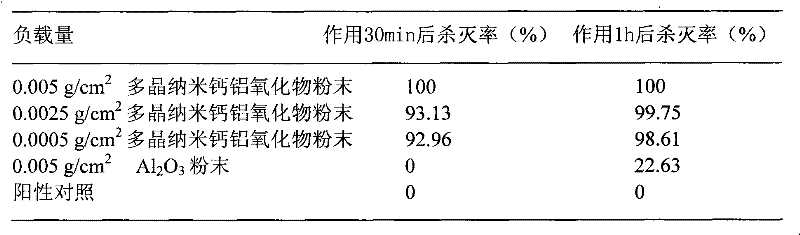

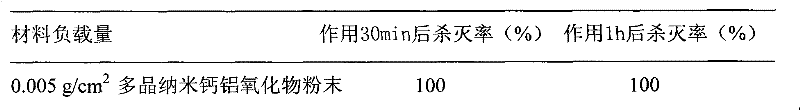

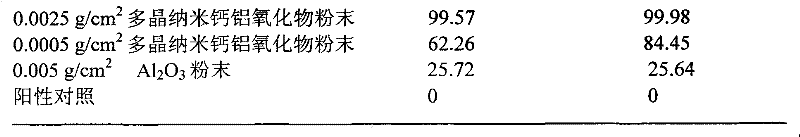

[0022] Embodiment 3 test embodiment 2 sample is to the killing effect of Staphylococcus aureus

[0023] (1) Weigh the 35nm ± 15nm polycrystalline calcium aluminum oxide powder sample prepared in Example 2, and sterilize it at 120° C. for 5 hours for later use;

[0024] (2) Put the mixed cellulose ester microporous filter membrane (Shanghai Xingya Purification Material Factory, specification: φ50mm, pore size: 0.45μm) in a petri dish covered with color-changing silica gel, and sterilize it at 120°C for 5 hours , take 6 pieces of the same area for spare;

[0025] (3) Use a sterile inoculation shovel to gently scratch the Staphylococcus aureus inoculated on the nutrient agar plate (provided by the China Common Microorganism Culture Collection Management Center), add 5ml sterile normal saline, and then use a sterile micropipette The liquid was sucked out and added to the centrifuge tube, then placed in a centrifuge (4000rpm) and centrifuged for 5 minutes to obtain a pure bacteria...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com