Microencapsulated composite phase change material and production and application thereof

A composite phase change material and microencapsulation technology, applied in the field of textile fibers, can solve problems such as the heat exchange effect of formaldehyde-containing phase change materials, and achieve the effects of controllable and intelligent temperature regulation, controllable structure, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

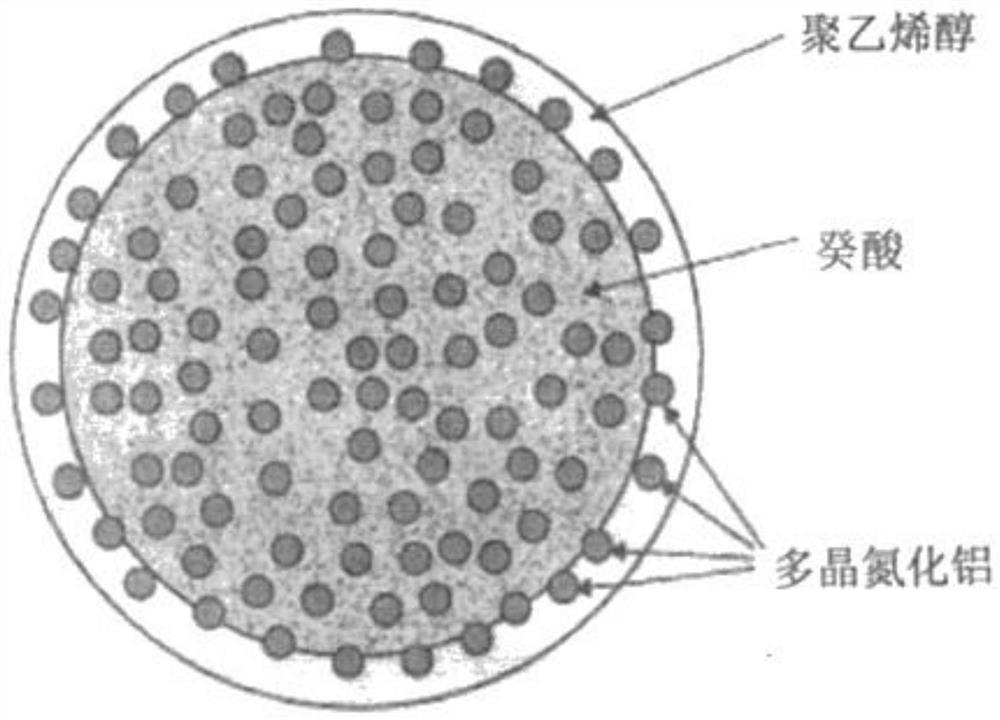

[0028] This embodiment discloses a microencapsulated composite phase change material, which includes a core material made of aluminum nitride-decanoic acid composite and a capsule material made of polyvinyl alcohol.

[0029] The steps of making the microencapsulated composite phase change material in this embodiment are as follows:

[0030] S1. Mix 50g of capric acid, 15g of polycrystalline aluminum nitride and 1g of cetyltrimethylammonium chloride evenly. Under the action of high-speed stirring and shearing, gradually add hot water at 60°C, keep warm and shear at 120°C minutes, and then slowly lower the temperature to 25-30°C to obtain a polycrystalline aluminum nitride-decanoic acid complex emulsion.

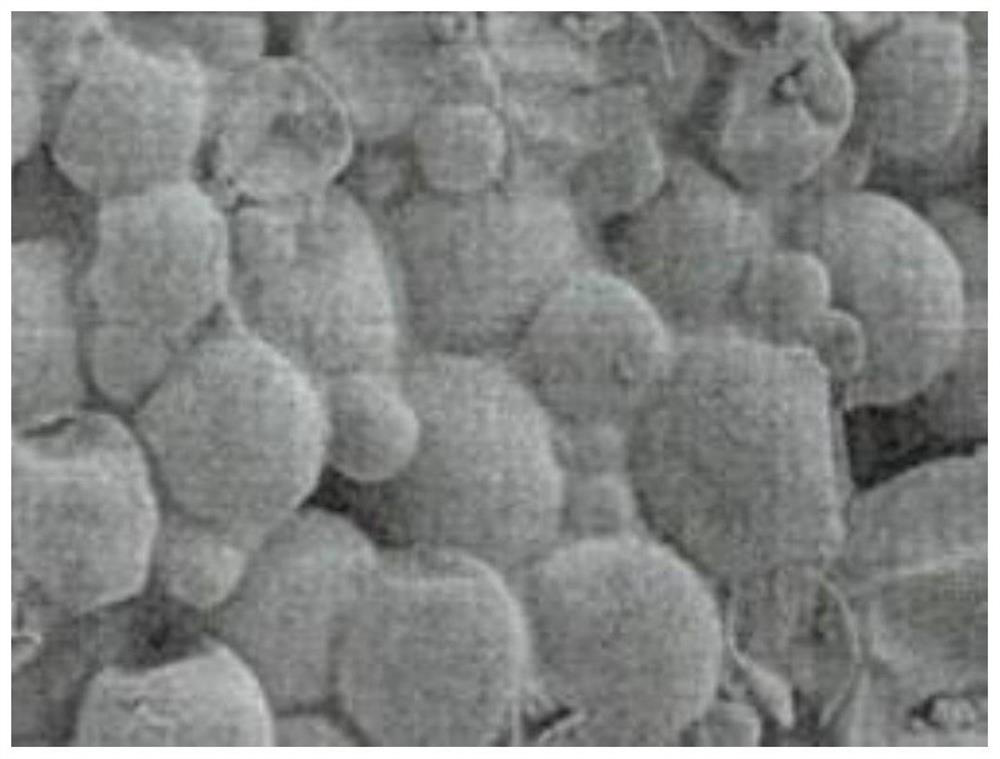

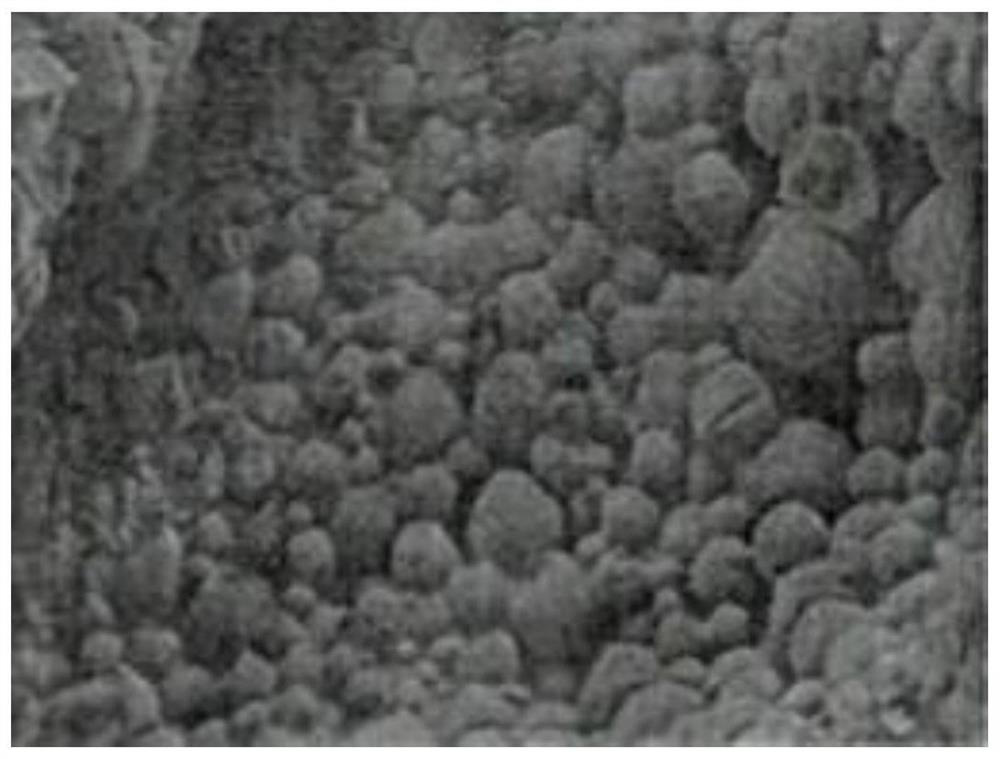

[0031] S2. Detect the particle size, distribution and thermal conductivity of the latex particles in the polycrystalline aluminum nitride-decanoic acid composite emulsion to ensure that the particle size of the latex particles is less than 1um and uniformly distributed in the ...

Embodiment 2

[0039] This embodiment discloses a microencapsulated composite phase change material, which includes a core material made of aluminum nitride-decanoic acid composite and a capsule material made of polyvinyl alcohol.

[0040] The steps of making the microencapsulated composite phase change material in this embodiment are as follows:

[0041] S1. Mix 50g of capric acid, 15g of polycrystalline aluminum nitride and 1g of cetyltrimethylammonium chloride evenly. Under the action of high-speed stirring and shearing, gradually add hot water at 70°C, keep warm and shear at a high speed for 80 minutes, and then slowly lower the temperature to 25-30°C to obtain a polycrystalline aluminum nitride-decanoic acid complex emulsion.

[0042] S2. Detect the particle size, distribution and thermal conductivity of the latex particles in the polycrystalline aluminum nitride-decanoic acid composite emulsion to ensure that the particle size of the latex particles is less than 1um and uniformly distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com