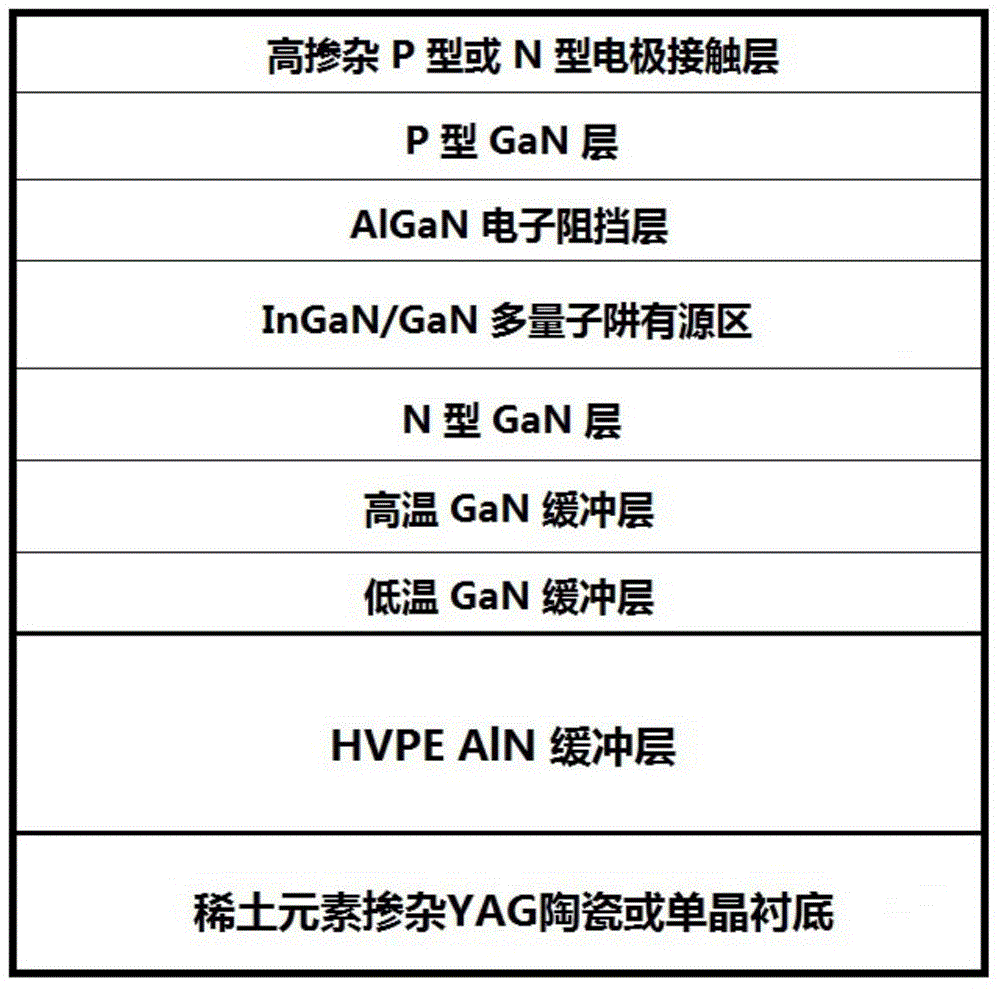

Production method of GaN-based white LED epitaxial structure

An epitaxial structure, white light technology, applied in the direction of chemical instruments and methods, crystal growth, electrical components, etc., can solve the problems of uneven phosphor material, device color shift, thermal degradation, etc., to achieve simplified manufacturing process and good color temperature control , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a Ce:YAG single crystal substrate with a doping concentration of 0.3 at%, a thickness of 500 μm, and a surface roughness of less than 0.5 nm, and put it into the reaction chamber of a hydride vapor phase epitaxy (HVPE) equipment after cleaning. Introduce hydrogen (H 2 ) high temperature baking for 10 minutes, the baking temperature is 1200 ℃, and then ammonia gas (NH 3 ) Nitriding the substrate surface at 1300° C. for 20 minutes.

[0033] Ammonia gas (NH 3 ) and carrier gas nitrogen, the hydrogen chloride (HCl) with a flow rate of 100 sccm is passed into the aluminum source area, the reaction generates a hydride source and is passed into the reaction chamber, the temperature of the aluminum source area is 550 ° C, and the carrier gas of hydrogen chloride (HCl) is Nitrogen, flow 2000sccm. In the reaction chamber, the hydride source and ammonia gas (NH 3 ) and grow a 100nm height (002) oriented polycrystalline AlN buffer layer on the substrate. Wherein, the temp...

Embodiment 2

[0036] Take a piece of Eu:YAG ceramic substrate with a doping concentration of 0.5 at%, a thickness of 100 μm, and a surface roughness of less than 0.5 nm, and put it into the reaction chamber of a hydride vapor phase epitaxy (HVPE) equipment after cleaning. Introduce hydrogen (H 2 ), baked at 800°C for 20 minutes, and then passed ammonia gas (NH 3) for 60 minutes of substrate surface nitriding treatment, and the nitriding temperature is 1300°C. Ammonia gas (NH 3 ) and carrier gas nitrogen, the hydrogen chloride (HCl) with a flow rate of 50 sccm is passed into the aluminum source area, the reaction generates a hydride source and is passed into the reaction chamber, the temperature of the aluminum source area is 450 ° C, and the carrier gas of hydrogen chloride (HCl) is Nitrogen, flow rate 1000sccm. In the reaction chamber, the hydride source and ammonia gas (NH 3 ) and grow a 5nm (002) single crystal AlN buffer layer on the substrate. Wherein, the temperature of the react...

Embodiment 3

[0038] Take a Nd:YAG ceramic substrate with a doping concentration of 0.05at%, a thickness of 1000 μm, and a surface roughness of less than 0.5 nm, and put it into a reaction chamber of a hydride vapor phase epitaxy (HVPE) equipment after cleaning. Introduce hydrogen (H 2 ), baked at 1400°C for 5 minutes, and then passed ammonia gas (NH 3 ) for 3 minutes of substrate surface nitriding treatment, and the nitriding temperature is 1500°C. Ammonia gas (NH 3 ) and carrier gas hydrogen, the hydrogen chloride (HCl) with a flow rate of 300 sccm is passed into the aluminum source area, the reaction generates a hydride source and is passed into the reaction chamber, the temperature of the aluminum source area is 600 ° C, and the carrier gas of hydrogen chloride (HCl) is Hydrogen, flow 2000sccm. In the reaction chamber, the hydride source and ammonia gas (NH 3 ) and grow a 20nm (002) oriented polycrystalline AlN buffer layer on the substrate. Wherein, the temperature of the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com