Method for manufacturing transparent polycrystalline aluminum oxynitride

An aluminum nitride oxide, transparent technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high production cost and complex process, and achieve the effect of improving the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

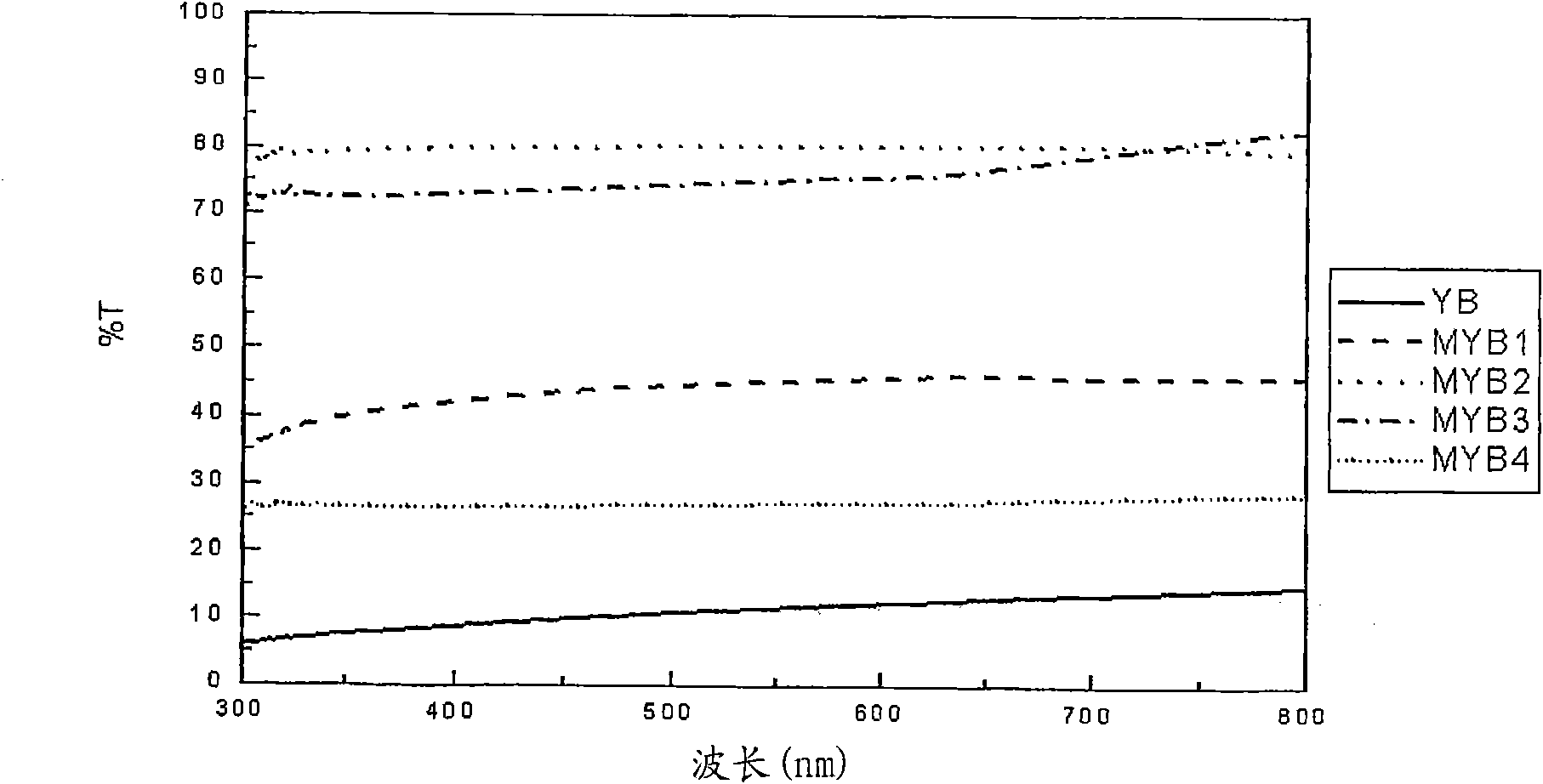

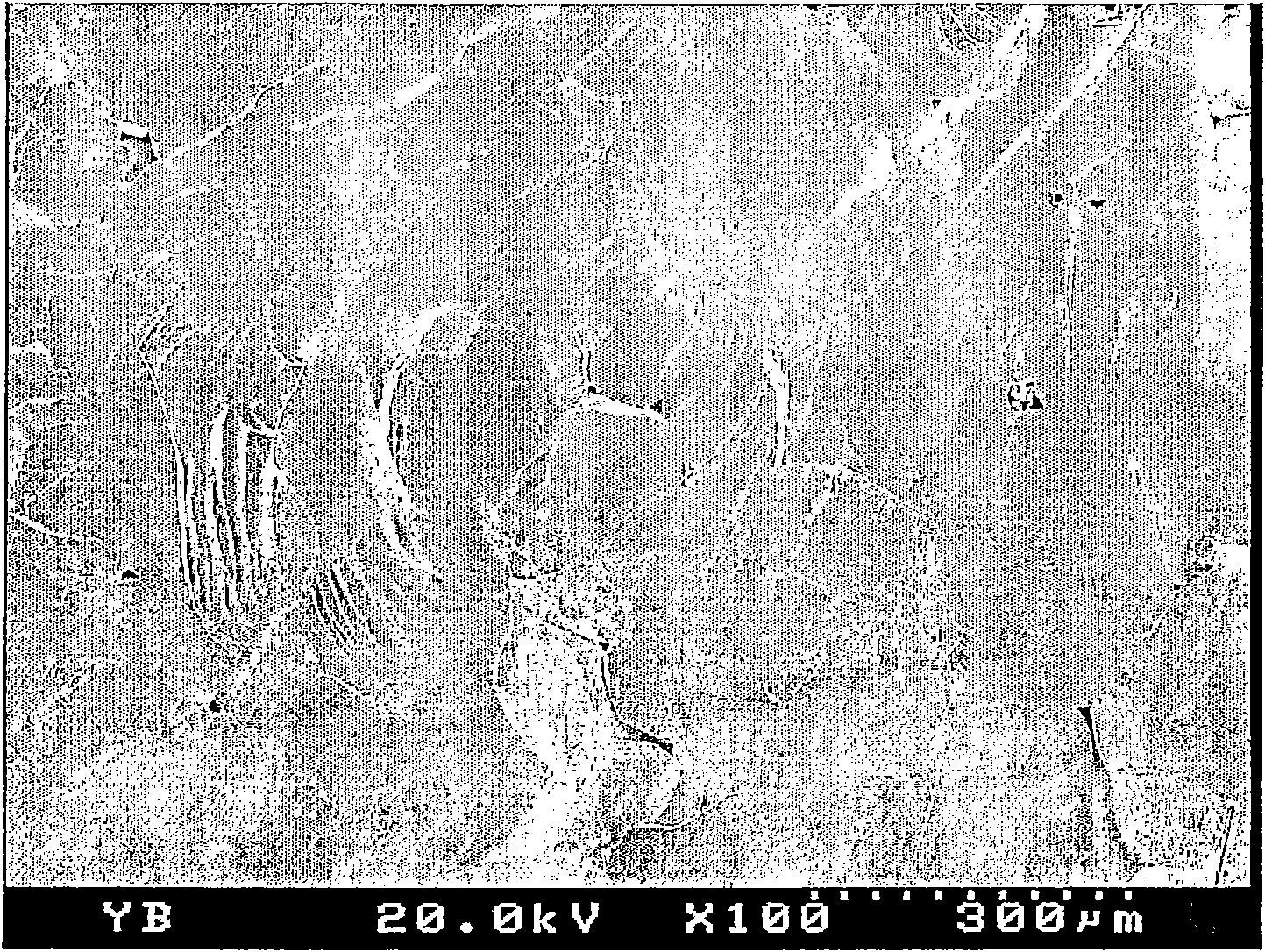

[0044] Five aluminum oxynitride ceramic samples were fabricated under the following conditions, where Y 2 o 3 and BN (whose amounts were set at 0.08wt% and 0.02wt%, respectively) and MgO (whose amounts varied at 0, 0.05, 0.1, 0.2, and 0.3wt%) were added to Al as sintering aids 2 o 3 And AlN (65:35 molar ratio) raw material powder. The mixed raw material powder and sintering aid are passed through high-purity Al in a polyurethane container together with ethanol solvent 2 o 3 The pellets were milled for 48 hours and then dried using a rotary evaporator. The dried powder was formed into a disc of 20 mm diameter and 3 mm width using uniaxial dry pressing, and it was subsequently cold isostatically pressed. The disk-shaped sample was placed in a graphite crucible and sintered in a high-temperature electric furnace with graphite heating elements in a nitrogen atmosphere at 1 atmosphere pressure. Subsequently, it was kept at 1675°C for 10 hours and at 2000°C for 5 hours. The t...

Embodiment 2

[0053] The aluminum oxynitride ceramic sample is made using the same method as in Example 1, but the difference is that the sintering aids are 0.2wt% MgO, 0.08wt% Y 2 o 3 and 0.02wt% BN were added to each sample in the following different ways: (1) no addition; (2) addition of MgO and Y 2 o 3 ; (3) add MgO and BN; (4) add Y 2 o 3 and BN; and (5) add MgO, Y 2 o 3 and BN.

[0054] Figure 7 This is a photograph taken to compare the light transmittance of the aluminum oxynitride ceramic samples produced in this way. In the pictures from left to right you can see: (1) No sintering aid was added to this sample, (2) MgO and Y were added to this sample 2 o 3 , (3) MgO and BN are added to the sample, (4) Y is added to the sample 2 o 3 and BN, and (5) the sample is added with MgO, Y 2 o 3 and BN. In the case where MgO is not added, the transmittance is very low. Added with MgO and Y 2 o 3 Or added with MgO, Y 2 o 3 And in the case of BN, the transmittance is very hig...

Embodiment 3

[0059] Aluminum oxynitride ceramic samples were fabricated using the same method as in Example 1, but the difference was that these samples were sintered at 2000°C for 5 hours without pre-sintering. MgO was added to each sample at addition amounts of 0, 0.05, 0.1, 0.2 and 0.3 wt%, respectively.

[0060] FIG. 11 is a photograph taken to compare the light transmittance of the aluminum oxynitride ceramic samples produced in this way. In FIG. 11 , samples with MgO added in amounts of 0, 0.05, 0.1, 0.2 and 0.3 wt % are respectively from left to right.

[0061] Fig. 12 is a graph showing measured values of linear light transmittance of each sample, which is measured according to wavelength. Table 3 shows the weight ratio of MgO and the average linear transmittance of these samples.

[0062] table 3

[0063] YB-b

[0064] Similar to Example 1, the light transmittance is the highest when 0.1 wt% of MgO is added. However, the light transmittance decreased by about 20%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com