Thermal insulation device for microwave sintering of titanium carbonitride-based metal ceramic material

A ceramic material, microwave sintering technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of reducing the density and mechanical properties of the sintered body, affecting the sintering quality, unreasonable, etc., and achieves good thermal insulation effect. Guarantee the quality of sintering and increase the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

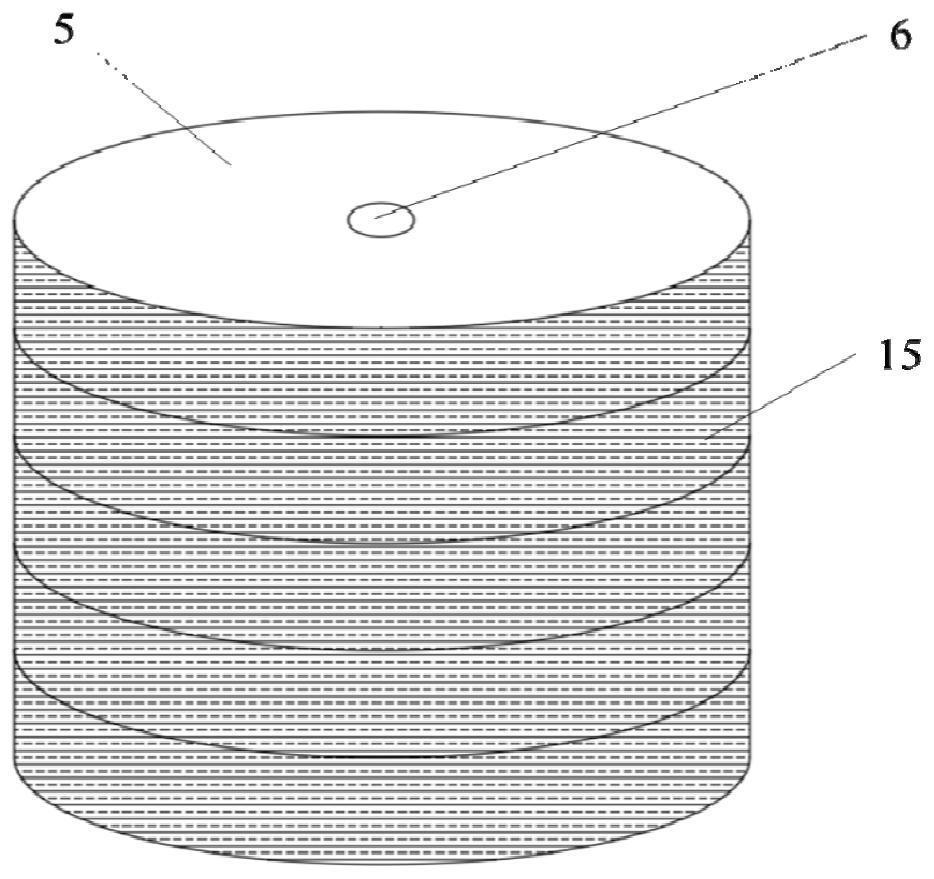

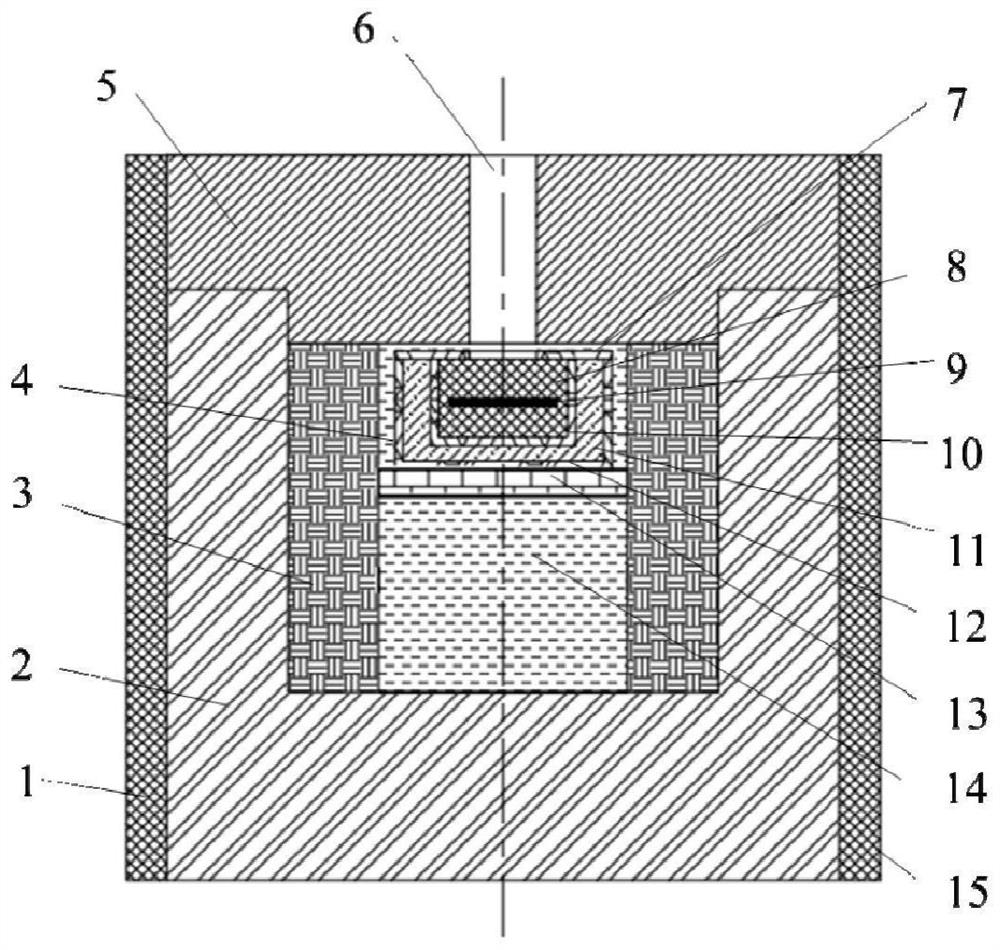

[0042] see figure 2 The thermal insulation device for microwave sintering of ceramic materials in the present invention mainly includes a polycrystalline mullite fiber barrel 2, an aluminum silicate ceramic fiber blanket 3 with a temperature resistance of 1600 °C, and a first polycrystalline alumina fiber cotton with a temperature resistance of 1700 °C 4 , polycrystalline mullite fiber barrel cover 5, small size crucible 10, polycrystalline alumina high temperature fiber 11, large size crucible 12, polycrystalline mullite fiber board 13, second polycrystalline alumina fiber with temperature resistance of 1700 ° C Cotton 14.

[0043] In the device, the polycrystalline mullite fiber barrel 2 and the polycrystalline mullite fiber barrel cover plate 5 constitute a thermal insulation barrel body, and an infrared temperature measuring hole 6 is opened at the center of the mullite fiber barrel cover plate, which is convenient for passing the infrared temperature measurement. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com