Basalt fiber prepreg and preparation method thereof

A technology of basalt fiber and prepreg, which is applied in the field of basalt fiber prepreg to achieve consistent thermal expansion and contraction coefficients, simple subsequent processing and molding, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

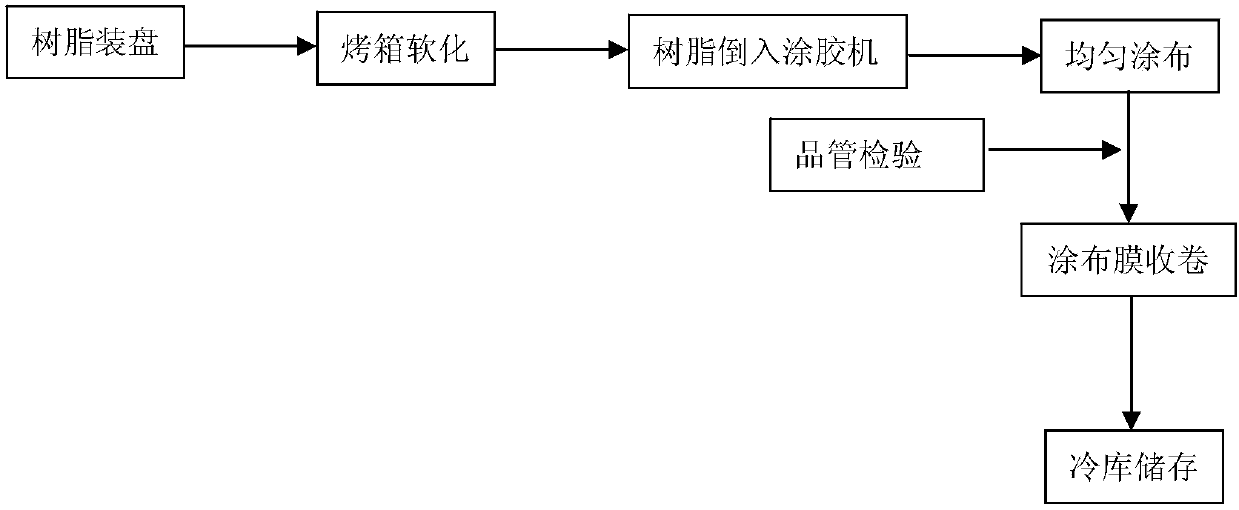

[0037] The basalt fiber prepreg of the present invention is prepared by a two-step hot-melt method, and the preparation method includes film making and prepreg. Film making includes steps: 1) Put the epoxy resin matrix in a mixer and mix thoroughly; 2) After the mixture obtained in step 1) is heated to 80°C, it is transported to the glue rollers, and the distance and distance between the glue rollers are adjusted. The running line speed of the pattern paper is used to prepare the film with different thicknesses; 3) Use an infrared instrument to detect the thickness of the film or the surface density of the film, and reduce the temperature of the film through the cooling plate to reduce its curing degree; 4) Winding , Packed and stored in cold storage for later use.

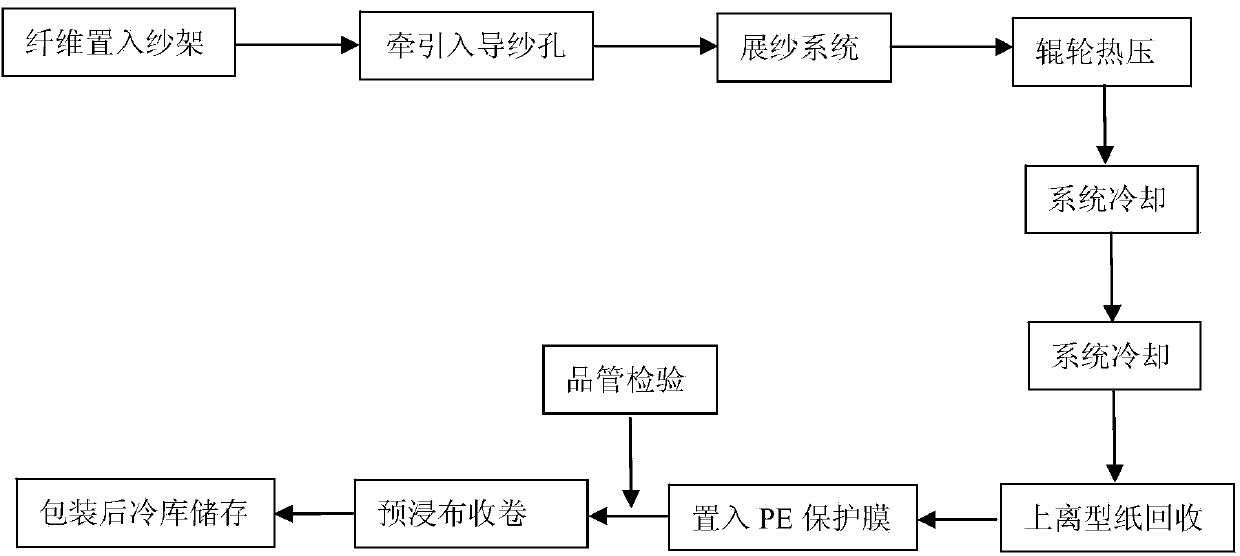

[0038] Prepreg includes steps: 1) Lead out the fibers from the creel, and reach the specified width after adjusting the tension, gathering and flattening the yarn collecting plate; 2) Lead out the pre-fabricated f...

Embodiment 1

[0042] Described epoxy resin is made up of the component of following weight ratio:

[0043] ATN series epoxy resin: 7%; E-51: 23%; E-44: 10%; E-20: 31%; micronized dicyandiamide: 9%; urea accelerator: 2%; hydrated alumina : 17%; white carbon black thickener: 1%.

[0044] 1) Preheat ATN series epoxy resin, E-51, E-44 and E-20 epoxy resin in an oven at 110°C for 7 hours to remove moisture and small volatile substances in the resin;

[0045] 2) Weigh a small amount of liquid epoxy resin and a certain amount of curing agent and accelerator to pre-mix in a dough maker, stir for 25 minutes, and make resin pastes of curing agent and accelerator respectively;

[0046] 3) Grinding the resin paste prepared in step 2 on a three-roll mill for two to three times to obtain a curing agent and accelerator masterbatch with a smaller viscosity and a more uniform powder particle size;

[0047] 4) Put the preheated epoxy resin into the reaction kettle and stir, and vacuum defoaming, while cool...

Embodiment 2

[0051] The resin is composed of components in the following weight ratios:

[0052] ATN series epoxy resin: 5%; E-51: 21%; E-44: 11%; E-20: 34%; micronized dicyandiamide: 8%; urea accelerator: 2.5%; hydrated alumina : 17%; white carbon black thickener: 1.5%.

[0053] 1) Preheat ATN series epoxy resin, E-51, E-44 and E-20 epoxy resin in an oven at 120°C for 8 hours to remove moisture and small volatile substances in the resin;

[0054] 2) Weigh a small amount of liquid epoxy resin and a certain amount of curing agent and accelerator to pre-mix in a dough maker, stir for 30 minutes, and make resin pastes of curing agent and accelerator respectively;

[0055] 3) Grinding the resin paste prepared in step 2 on a three-roll mill for two to three times to obtain a curing agent and accelerator masterbatch with a smaller viscosity and a more uniform powder particle size;

[0056] 4) Put the preheated epoxy resin into the reaction kettle to stir, and vacuum defoaming, while cooling do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com