Preparation method and product of fiber reinforced fluororesin composite membrane material

A composite membrane material and fiber-reinforced technology, which is applied in the field of fiber-reinforced fluororesin composite membrane products and the field of preparation of fiber-reinforced fluororesin composite membrane materials, can solve the problems of limited production process and performance without clear articles, etc. Achieve broad application prospects, excellent wave-transmitting performance, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

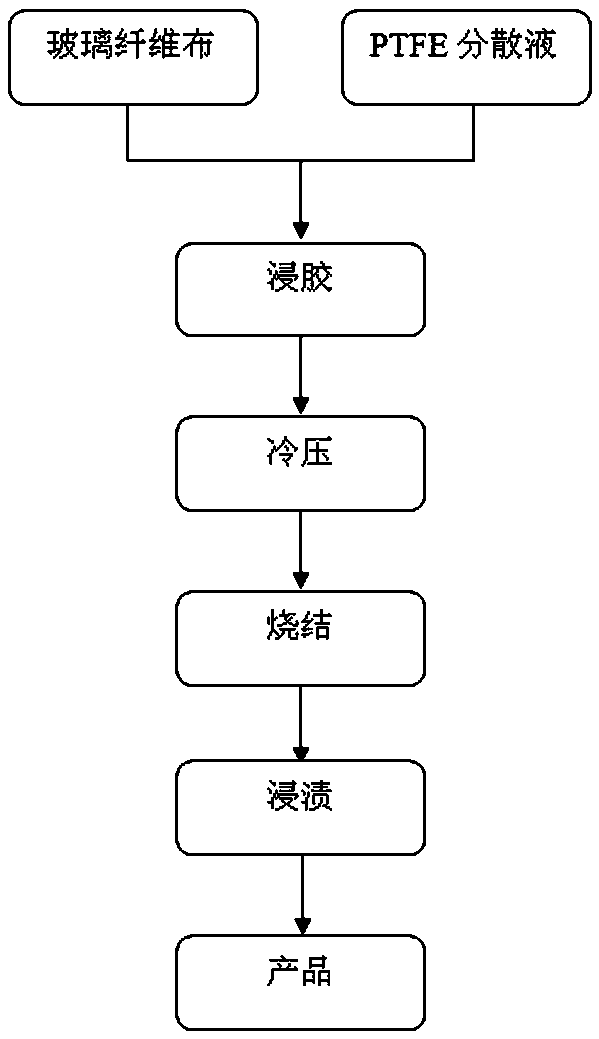

[0028] A preparation method of fiber-reinforced fluororesin composite membrane material, such as figure 1 shown, including the following steps:

[0029] 1) Surface modification of glass fiber cloth: treat the low-dielectric glass fiber cloth at 120° C. for 2 hours at high temperature, and cool to room temperature naturally; then put a silane coupling agent (KH-570 silane coupling agent) with a concentration of 1 wt % ) after soaking in the ethanol solution for 2 hours, take it out and put it into a vacuum oven to dry at 80°C for 4 hours to obtain a surface-modified glass fiber cloth;

[0030] 2) Immerse the surface-modified glass fiber cloth into a polytetrafluoroethylene dispersion water emulsion with a concentration of 40wt%, let it stand for 5 minutes, take out the impregnated glass fiber cloth and put it in an oven to dry at 100°C for 2 hours; The steps of immersion and drying are repeated until the weight content of PTFE resin in the dried film material reaches 50%.

[...

Embodiment 2

[0035] A method for preparing a fiber-reinforced fluororesin composite membrane, comprising the following steps:

[0036] 1) Surface modification of glass fiber cloth: treat the high-silica glass fiber cloth at 180°C for 1 hour, and cool it down to room temperature naturally; then put in 2 wt% silane coupling agent (KH550 silane coupling agent) ethanol After soaking in the solution for 1 hour, take it out and put it in a vacuum oven to dry at 80°C for 2 hours to obtain a surface-modified glass fiber cloth;

[0037] 2) Immerse the surface-modified glass fiber cloth into a polytetrafluoroethylene dispersion water emulsion with a concentration of 60wt%, let it stand for 10 minutes, take out the impregnated glass fiber cloth and put it in an oven and dry it at 200°C for 1 hour . Repeat the steps of immersion and drying until the weight content of PTFE resin reaches 70% in the dried composite film;

[0038]3) Arrange the glass fibers treated in step 3) between the two flat molds ...

Embodiment 3

[0042] A method for preparing a fiber-reinforced fluororesin composite membrane, comprising the following steps:

[0043] 1) Surface modification of glass fiber cloth: treat glass fiber (alkali-free glass fiber cloth) at a temperature of 300° C. for 1 hour, and cool to room temperature naturally; put the treated glass fiber into WD with a concentration of 0.5 wt % After soaking in the ethanol solution of -21 type silane coupling agent for 2 hours, take it out and dry it in a vacuum oven at 80°C for 1 hour to obtain a surface-modified glass fiber cloth;

[0044] 2) Immerse the surface-modified glass fiber cloth into a polytetrafluoroethylene dispersion water emulsion with a concentration of 20wt%, let it stand for 20 minutes, take out the impregnated glass fiber cloth and put it in an oven to dry at 150°C for 2 hours ; Repeat the immersion and drying steps until the weight content of PTFE resin in the dried composite film material reaches 30%;

[0045] 3) Arrange the glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com