Patents

Literature

222results about How to "Good wave permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

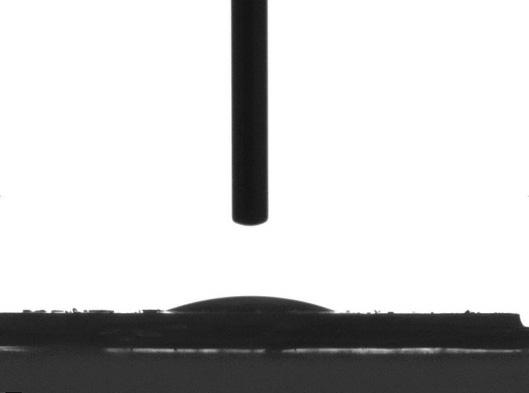

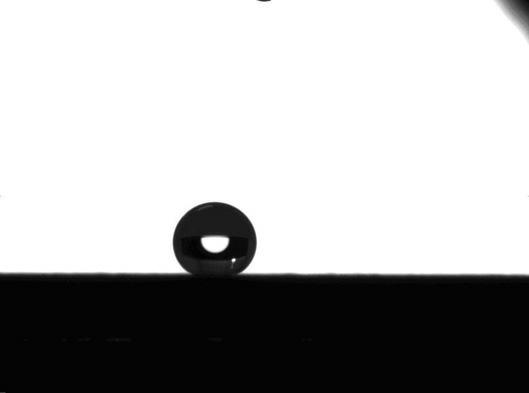

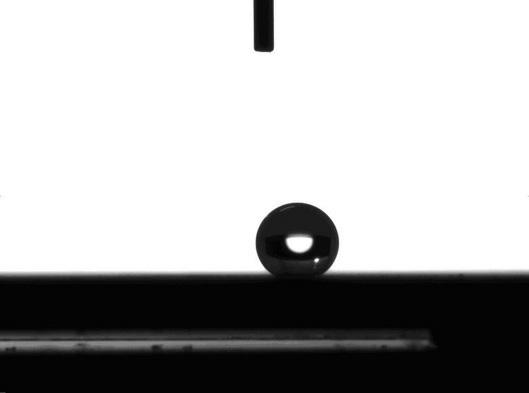

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

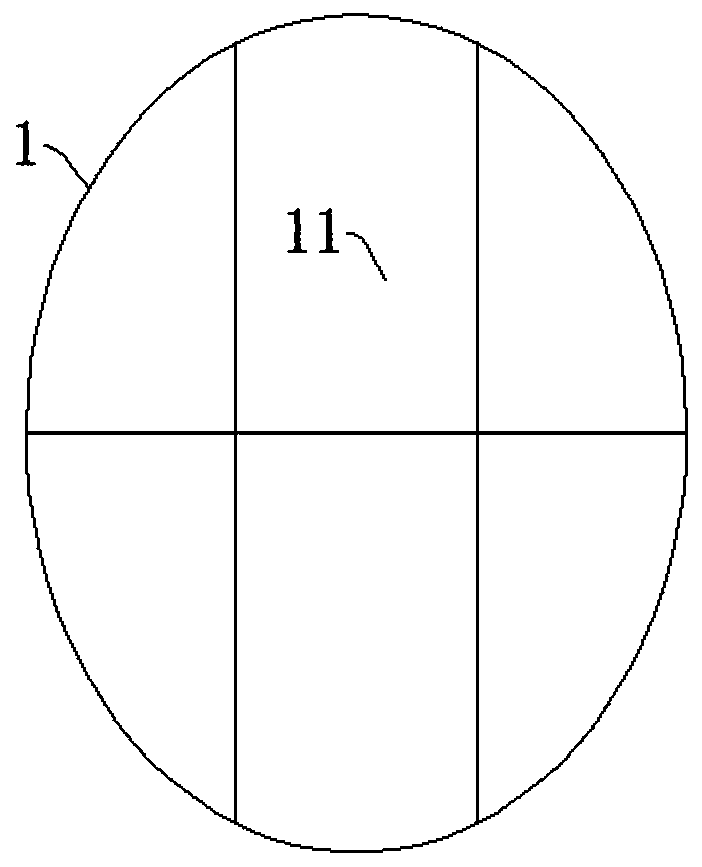

Glass steel radar cover single element and forming method thereof

InactiveCN101630774AAdjust and control thicknessFlat surfaceRadiating element housingsRadarSingle element

The invention relates to a glass steel radar cover single element and a forming method thereof. The radar cover single element is a spherical body, the periphery of which is provided with a sewing structure, wherein the spherical body is formed by assembling the inner skin and the outer skin of the glass steel with a foam core layer and the foam core layer is formed by solidifying injected polyurenthane foam glue material. The forming method comprises the following steps of: presetting a fundamental mould, and copying the female mould and the male mould of the glass steel with the same curvature based on the fundamental mould; respectively manufacturing the inner skin and the outer skin of the radar cover single element on the inner surfaces of the female mould and the male mould of the glass steel; and merging the moulds, and forming an inner cavity between the inner skin and the outer skin. The invention is characterized in that the inner skin is provided with a plurality of through holes which enter into the inner cavity; and the inner cavity is filled with polyurenthane foam glue material from the outside to the inside by the through holes and is solidified to be a foam core layer. The method has simple operation, effectively reduces the use waste of polyurenthane foam, has low cost, guarantees the consilient thickness of the inner skin and the outer skin, and can assemble the radar cover with good safety, reliability and wave permeability.

Owner:北京玻钢院复合材料有限公司

New corrosion resistant composite wave absorbing material

InactiveCN104371271AImprove corrosion resistanceImprove absorbing performanceOther chemical processesPolymerCarbonyl iron

The invention discloses a novel corrosion resistant composite wave absorbing material and a preparation method thereof, and belongs to the field of electromagnetic wave absorbing materials. The wave absorbing material includes 60-100 parts of resin polymer matrix, 50-100 parts of a curing agent, 20-30 parts of ferrite, 20-30 parts of carbonyl iron powder and 5-10 parts of a hollow granular material. The preparation method is as follows: adding a magnetic filler, a conductive filler and a semi conductive filler into resin solution for evenly mixing, and adding the curing agent. The electromagnetic wave absorbing material prepared by the method has the coating thickness of less than or equal to 3mm; in the 2-18GHz, the absorption reflectivity is less than or equal to-10dB; and the electromagnetic wave absorbing material is stealth material with good corrosion resistance, strong wave absorbing performance and wide wave absorbing band.

Owner:BEIJING GUOHAO SENSOR TECH RES INST GENERAL PARTNERSHIP

Fiberglass radome modified by glass beads and preparation method thereof

The invention discloses a fiberglass radome modified by glass beads, which reduces the DK value thereof, and improves the wave penetration performance of the products. The fiberglass radome modified by glass beads is prepared by the following raw materials in weight portion: 100 portions of unsaturated polyester, 2-10 portions of glass beads, 0.5-2 portions of mold release agent, 0.5-2 portions of curing agent and 0.5-2 portions of accelerator.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

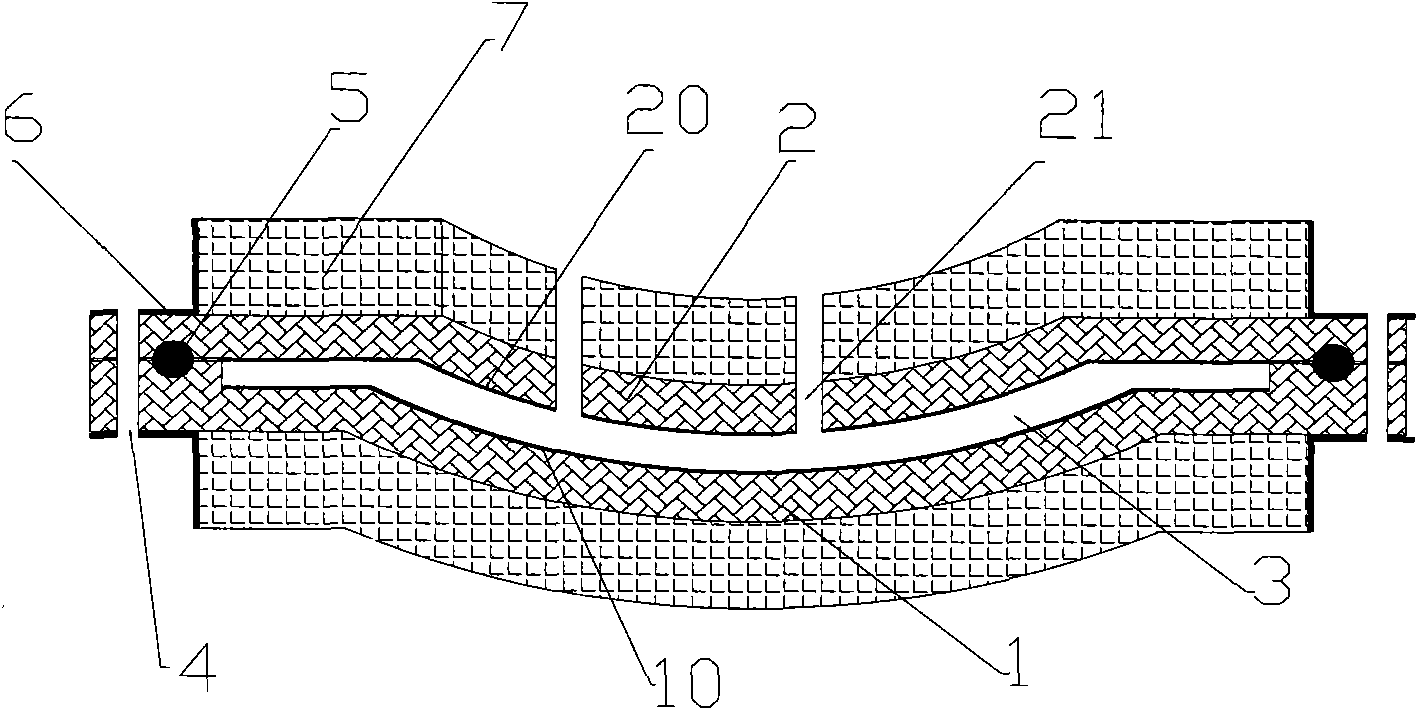

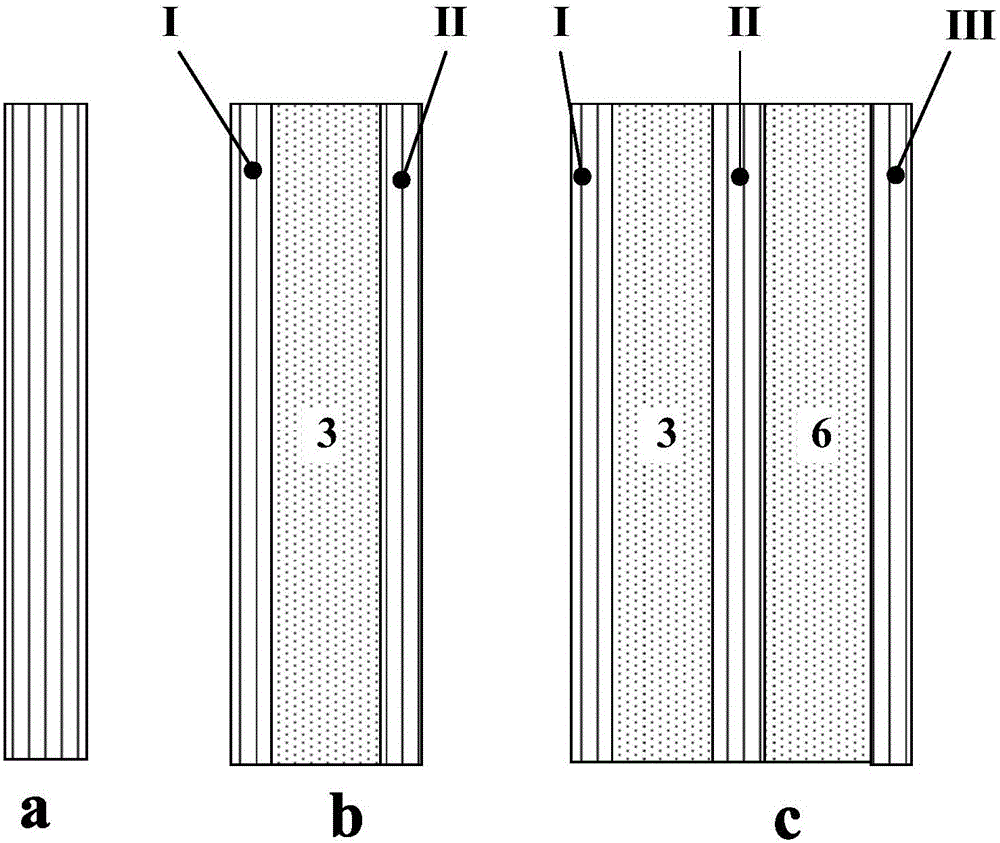

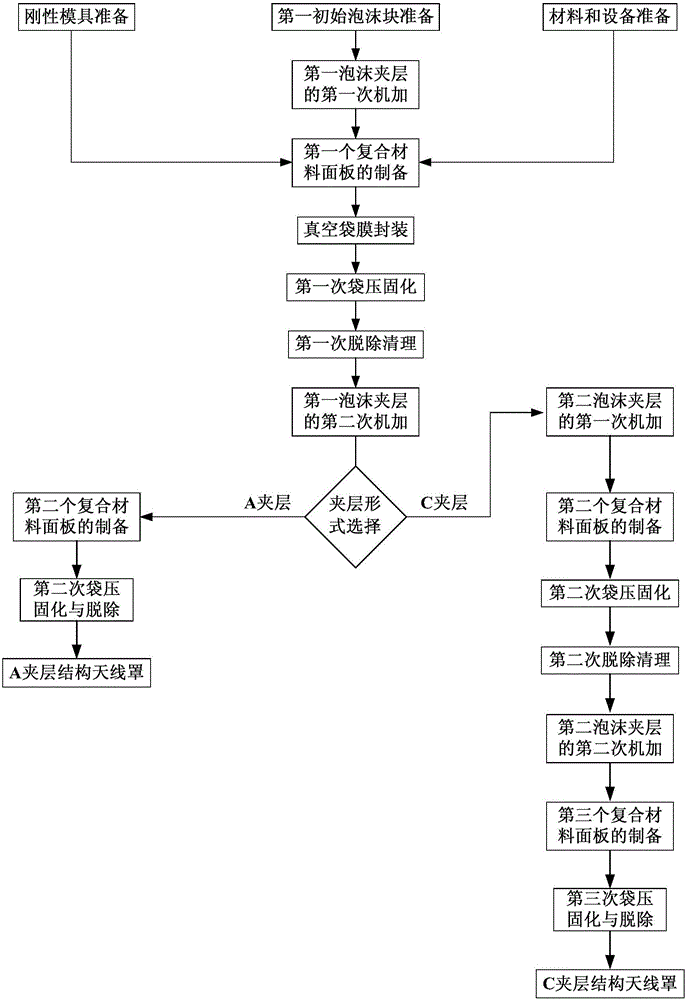

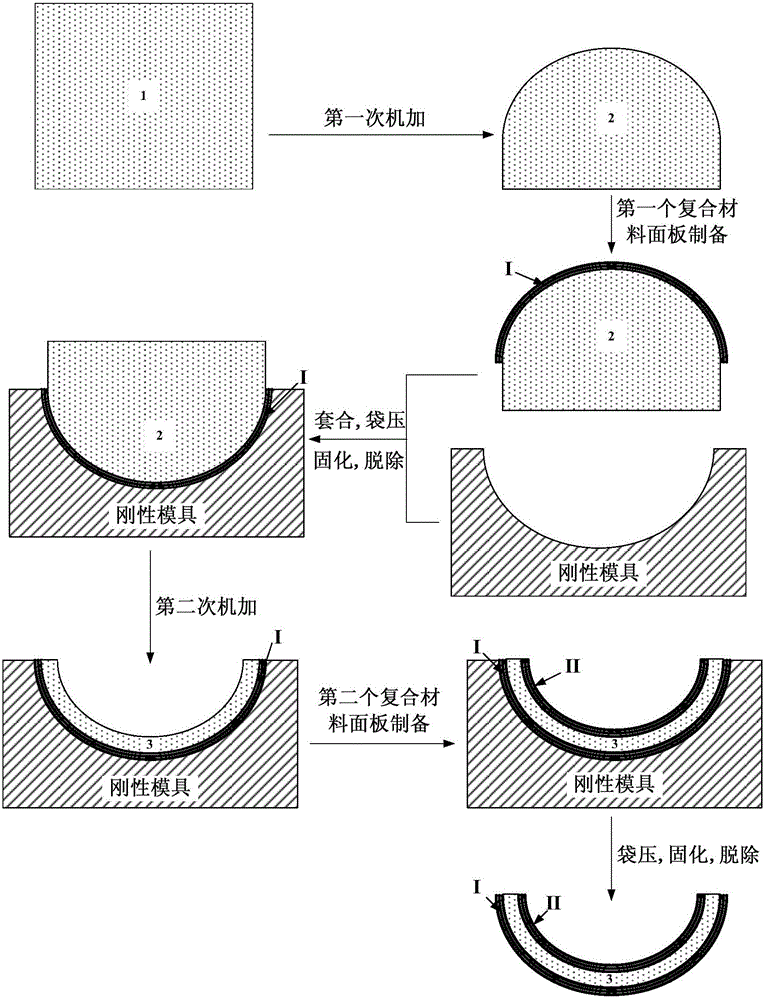

Preparation method for composite material antenna cover with thin-wall foam sandwich structure

ActiveCN105922703AGood wave permeabilityAvoid Bonding InsufficiencyLamination ancillary operationsLaminationThin walledSurface plate

The invention discloses a preparation method for a composite material antenna cover with a thin-wall foam sandwich structure. The invention aims to solve the problem of difficult processing or incapable processing for a thin-wall foam sandwich layer in the process of preparation of an antenna cover with a sandwich structure. According to a technical scheme of the invention, processing of the entire body of the thin-wall foam sandwich layer comprises two steps: performing primary processing, namely subjecting an initial foam block to single-face mechanical processing; and performing secondary processing after subjecting the single-face mechanically processed foam block to reinforcing and rigidity increasing, i.e., subjecting the rest of faces of the thin-wall sandwich layer to processing on a combination of a rigid mold, a composite material panel and the single-face mechanically processed foam block so as to prepare the thin-wall foam sandwich layer meeting the technical requirements of a target antenna cover. In addition, through resin impregnation with fabrics and a vacuum bag molding technique, preparation of the composite material panel and bonding of the panel with the foam sandwich layer in the target antenna cover are realized. By adopting the preparation method provided by the invention, the difficulty of preparation of the thin-wall foam sandwich layer through processing of the entire body of the initial foam block is overcome; the molding process of the antenna cover is simple; and the prepared antenna cover has the advantages of few defects, light weight and good wave permeability.

Owner:NAT UNIV OF DEFENSE TECH

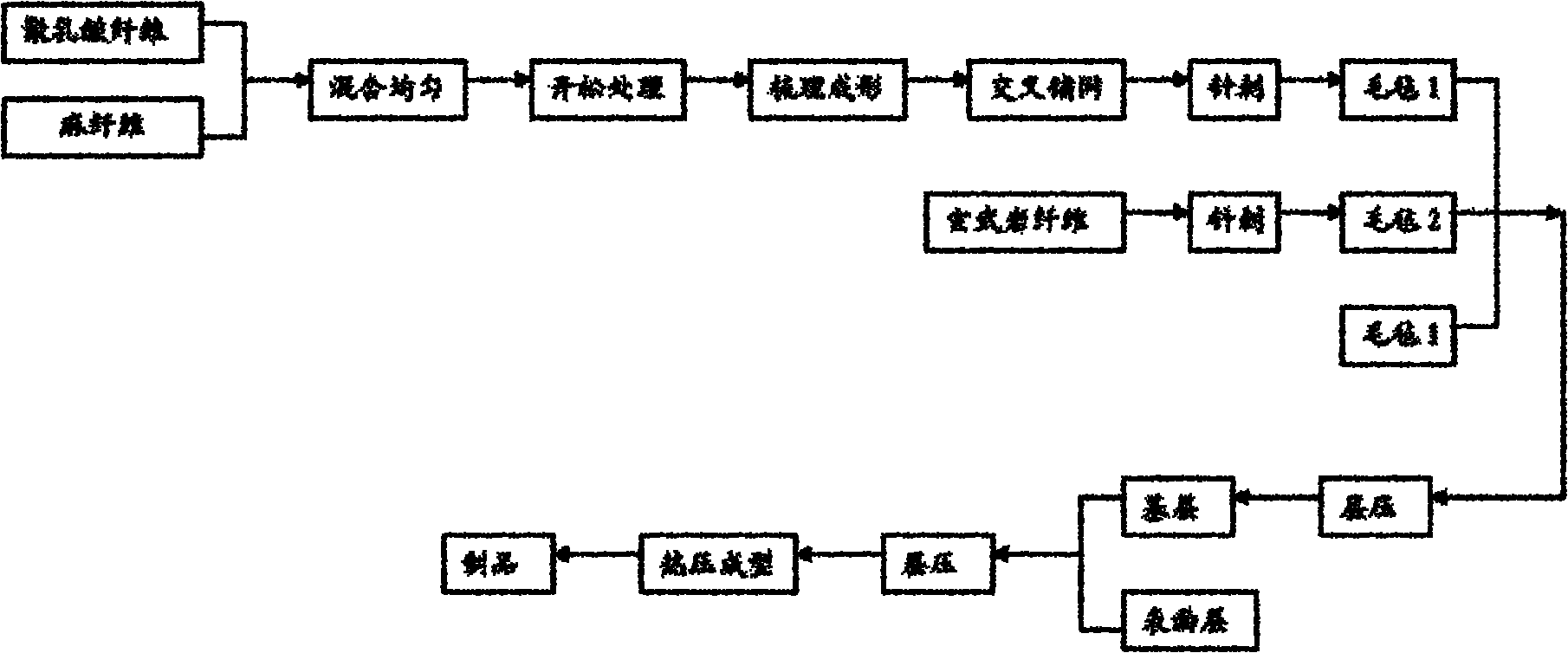

Composite fiber automobile interior board and production method thereof

InactiveCN102166842AImprove tensile propertiesGood filterability at high temperatureLaminationLamination apparatusSurface layerSisal fiber

The invention relates to a composite fiber automobile interior board and a production method thereof. The automobile interior board comprises a base layer and a non-woven or woven surface layer which is laminated on the at least one surface of the base layer, wherein the base layer consists of the following composite fibers: first fibers, namely polylactic acid fibers, second fibers, namely bastose selected from at least one of jute fibers, sisal fibers, ramie fibers, linen fibers, hemp fibers and kenaf fibers, and third fibers, namely basalt fibers in a weight percentage ratio of (20-70):(10-60):(10-60); and the surface layer consists of polylactic acid fibers. The composite fiber automobile interior board can be made into a three-dimensional deep drawing high-strength automobile interior board, and is safe, firm and environment-friendly when used as the base material of an automobile door inner board and a ceiling.

Owner:DALIAN UNIV OF TECH

Conformal ceramic metamaterial and preparation method thereof

InactiveCN102757229AGood wave permeabilityHigh strengthCeramic layered productsAntennasScreen printingMetallurgy

The invention provides a conformal ceramic metamaterial and a preparation method of the conformal ceramic metamaterial. The method comprises the following steps of: degassing and pre-polymerizing suspension comprising ceramic powder and an organic system to obtain slurry, pouring the slurry into a first mold, and curing to obtain a green body; preparing the ceramic powder into ceramic slurry and casting into a green ceramic chip, and preparing a metal microstructure on the green ceramic chip through a screen printing technology; attaching the prepared green ceramic chip comprising the metal microstructure to the outer surface of the green body, and obtaining the green body with the metal microstructure; pouring the slurry into a second mold, inserting the green body with the metal microstructure, and curing to obtain a blank with a conformal structure comprising the metal microstructure; and performing degluing and sintering the blank with the conformal structure comprising the metal microstructure, thus obtaining the conformal ceramic metamaterial. The curved conformal ceramic metamaterial is prepared by organically combining a gel-casting molding method and a low temperature co-fired ceramic (LTCC) or high temperature co-fired ceramic (HTCC) technology, so that the conformal ceramic metamaterial has high wave-penetrating performance and high-temperature resistance; and because the inner and outer ceramic chip layers are combined in a conformal mode, the strength of the conformal ceramic metamaterial is improved.

Owner:KUANG CHI INNOVATIVE TECH

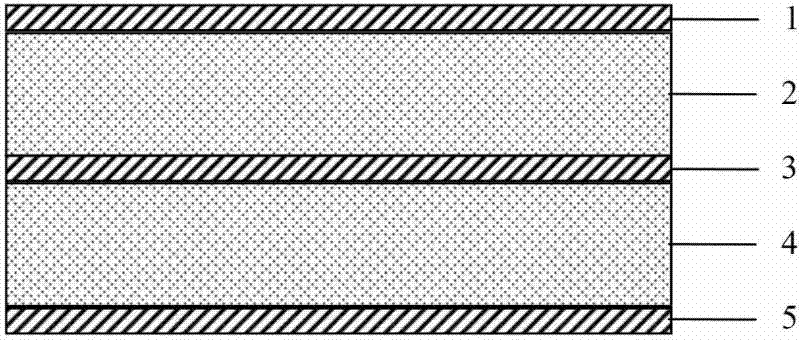

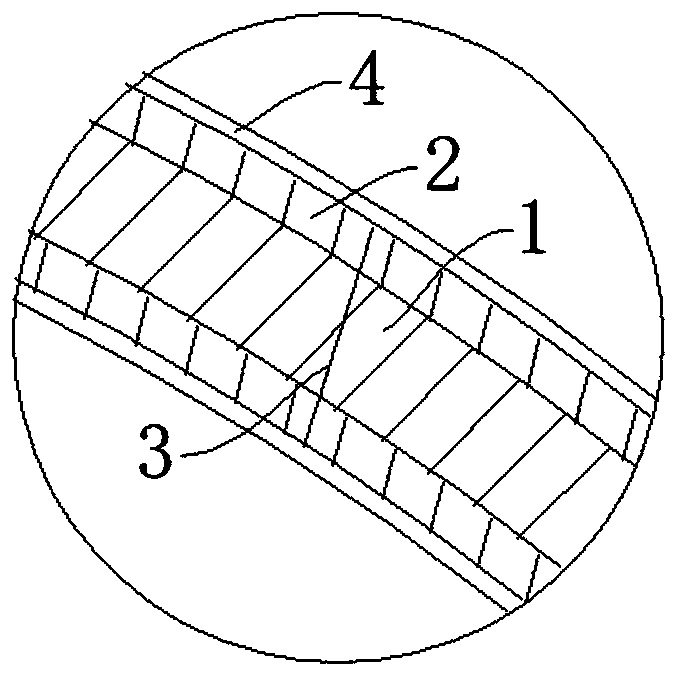

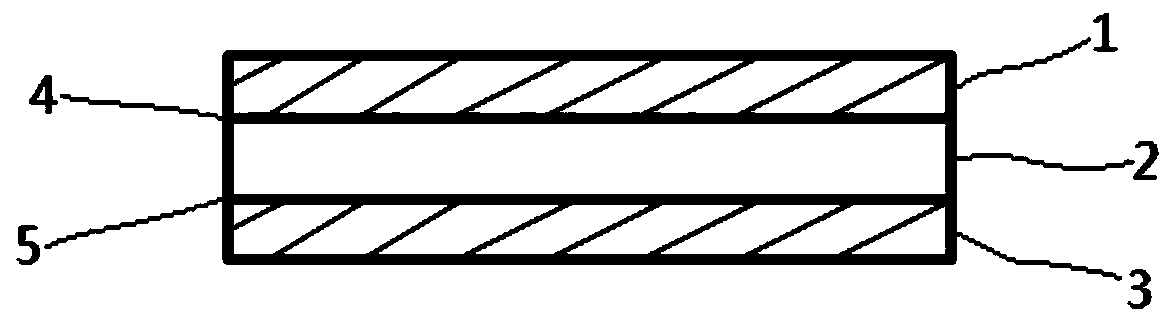

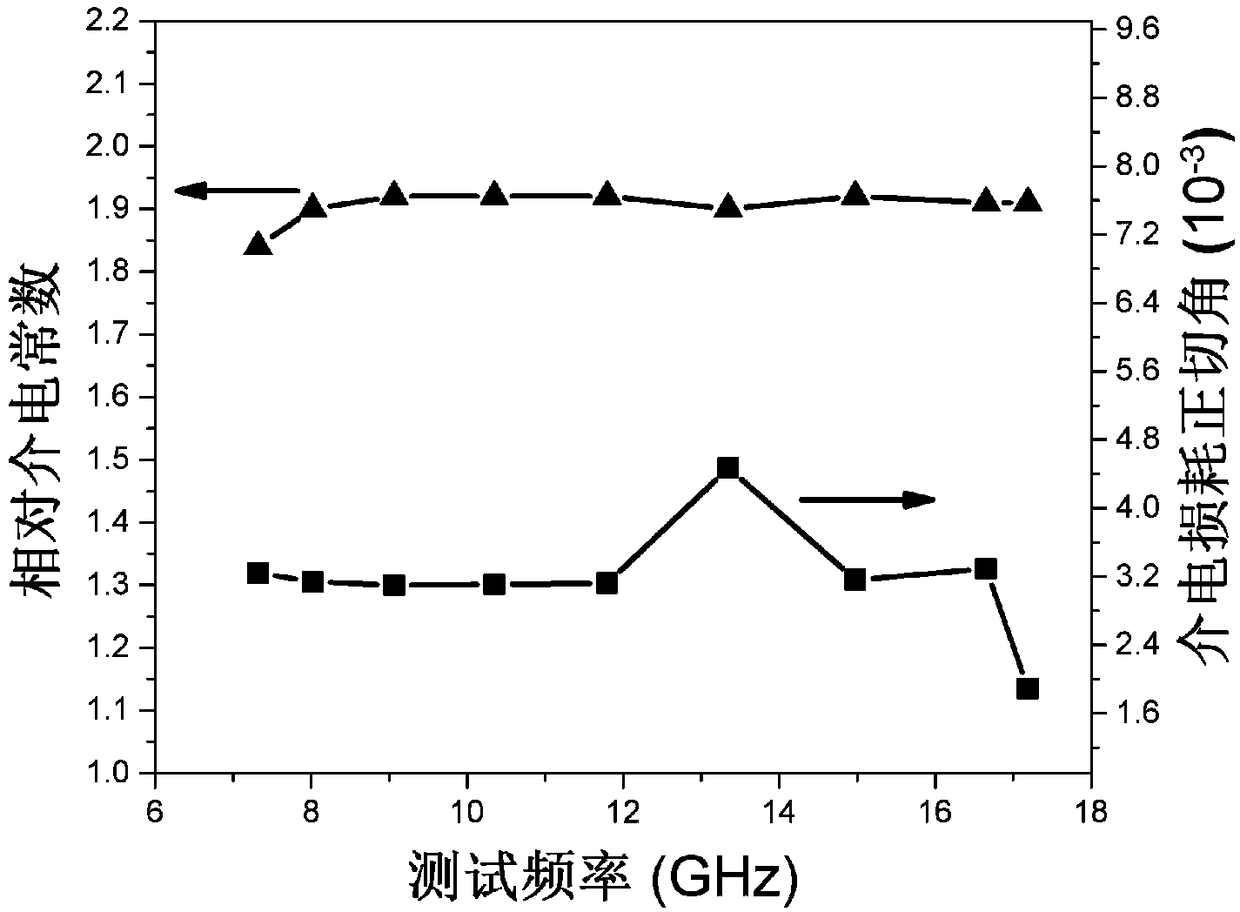

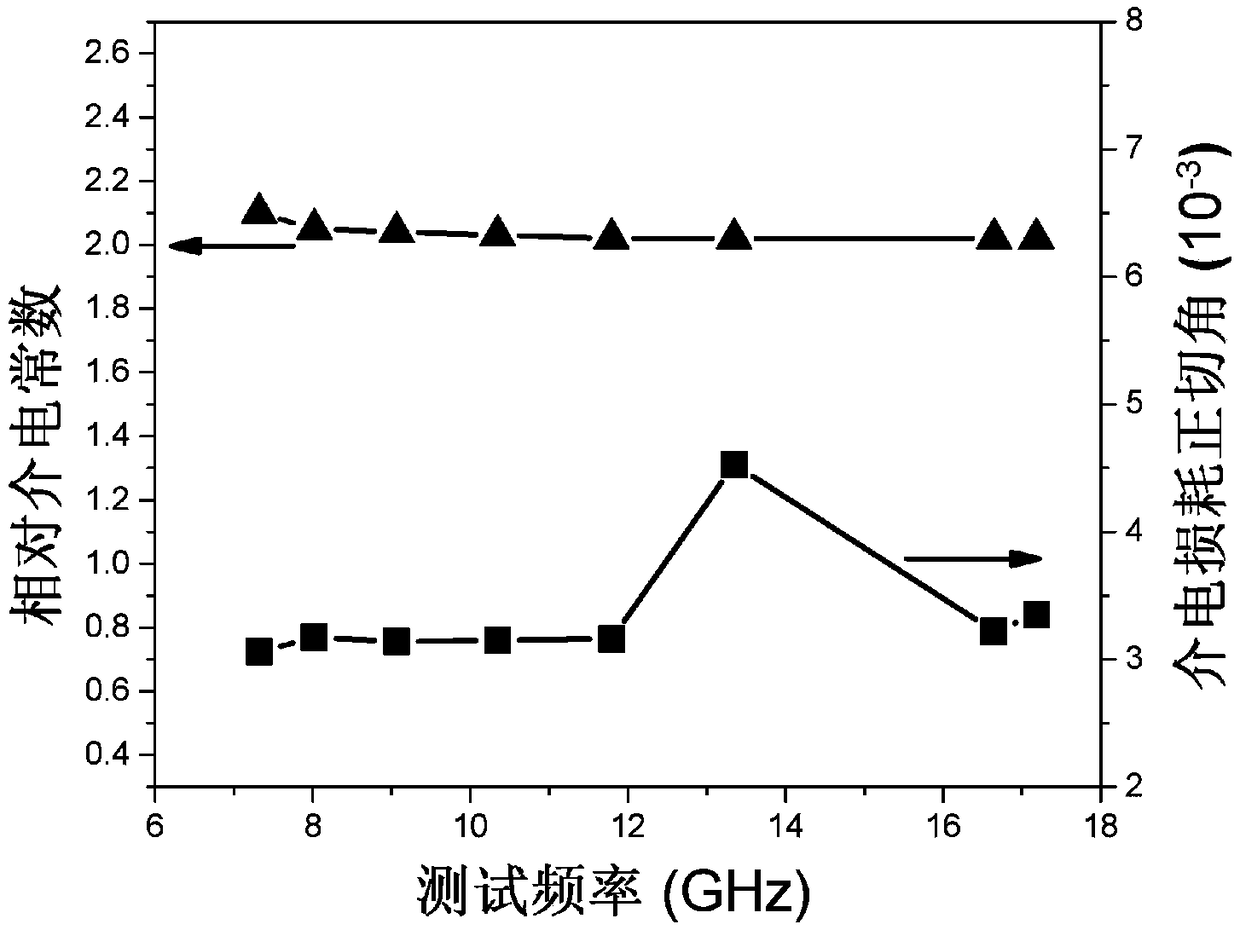

Wave-transmitting material with broadband resin matrix interlayer structure and preparation method of wave-transmitting material

ActiveCN102303441AImprove toughnessHigh strengthSynthetic resin layered productsPolymer scienceResin matrix

The invention discloses a wave-transmitting material with a broadband resin matrix interlayer structure and a preparation method of the wave-transmitting material. The wave-transmitting material comprises an outer skin layer, a first foam sandwich layer, a middle skin layer, a second foam sandwich layer and an inner skin layer which are sequentially overlapped and tightly combined, wherein the outer skin layer, the middle skin layer and the inner skin layer are made of continuous quartz fibre reinforced resin-base composite materials; the first foam sandwich layer and the second foam sandwich layer are made of polyurethane foams, the outer skin layer, the middle skin layer and the inner skin layer have dielectric constants of 3.1-3.2 and loss angle tangent values of 0.009-0.01; and the first foam sandwich layer and the second foam sandwich layer have dielectric constants of 1.10-1.15 and loss angle tangent values of 0.005-0.006. The preparation method comprises the steps of: preparing reinforced materials, and laying the reinforced materials according to the layering order and the thickness of each layer, pre-forming and curing to obtain the wave-transmitting material. The wave-transmitting material has the advantages of simple structure and high cost performance.

Owner:NAT UNIV OF DEFENSE TECH

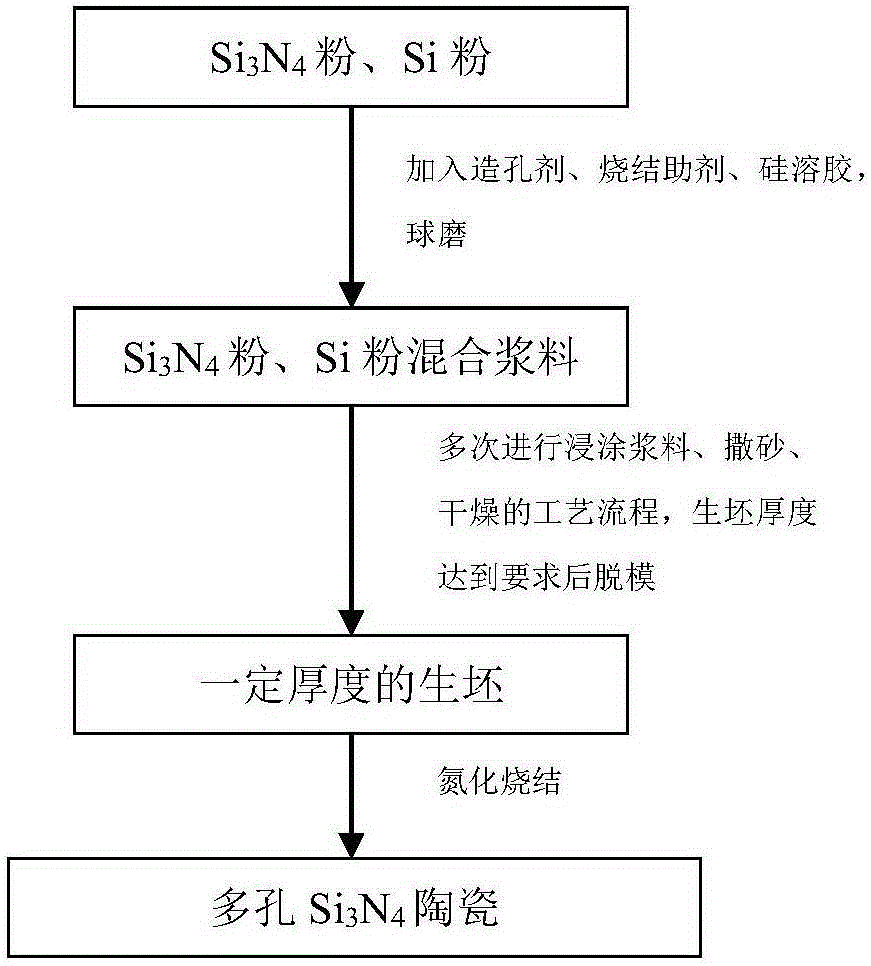

Method for producing complex-shaped porous silicon nitride ceramic product

InactiveCN105198475AImprove mechanical propertiesGood wave permeabilityCeramicwareParaffin oilsSlurry

The invention relates to a method for producing a complex-shaped porous silicon nitride ceramic product. The method includes: using Si3N4 powder, Si powder, sintering auxiliaries, pore forming agent and silica sol to prepare mixed slurry; producing a male die with an outer surface identical with the appearance and size of the inner cavity of the product, and coating paraffin on the surface of the die; soaking the die into the slurry to allow the slurry to be adhered to the surface of the die, and then spraying Si3N4 coarse powder to the surface of the die to allow a layer of Si3N4 coarse powder to be evenly adhered to the slurry adhered to the surface of the die; drying the die in a ventilated environment for 1-3 hours to consolidate and harden the slurry on the surface of the die; repeating the soaking, spraying and drying process for multiple times until the thickness of the outer powder layer of the die meets the requirement; placing the die into an oven to melt the paraffin so as to separate a ceramic green body from the die; performing nitridation sintering on the green body to obtain the porous silicon nitride ceramic product. The bending strength of the porous silicon nitride ceramic product produced by the method is not lower than 50MPa, and the porous silicon nitride ceramic product is good in wave transmission performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Synthetic fiber paper containing basalt fiber and chemical fiber and its preparation method

ActiveCN1948615AImprove high temperature resistanceImprove mechanical propertiesInorganic fibres/flakesTemperature resistanceBasalt fiber

The invention belongs to the field of composing fiber paper. It relates to composing non-woven paper, especially relates to a kind of fiber paper made by wet method with basaltic fiber, aramid fiber and polyphenylene sulfide fiber. The composing fiber paper has much strongpoint including well mechanical property, good high-temperature resistance, acid resistance, alkali resistance, strength uvioresistant property, low hygroscopic, better environment bearing property, good insulativity, good high-temperature filterability, radio resistance and good wave-passing property. Therefore, the composing fiber paper is applicable for military engineering and civil fields including aerospace, military engineering, vehicle and ship building and architecture.

Owner:LONGPONT

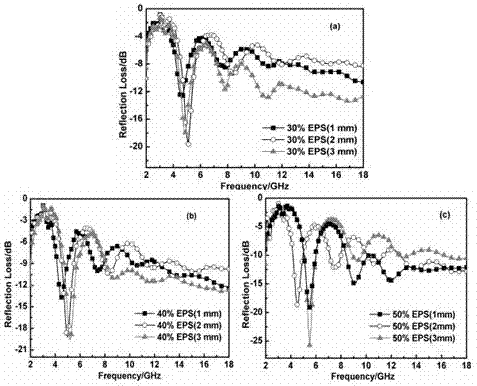

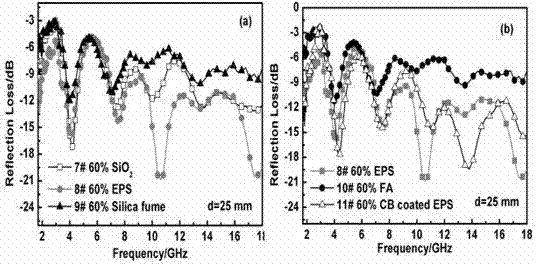

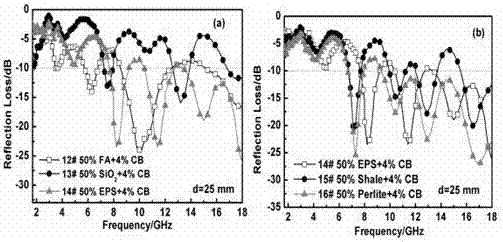

Double-layer allotype surface cement-based absorption material and preparation method thereof

InactiveCN107056325ASmall thickness and densityImprove absorption performanceCeramicwareReflectivityAbsorption bandwidth

The invention provides a double-layer allotype surface cement-based absorption material and a preparation method thereof, which relate to the cross technology field of electromagnetism and material science. Cement is adopted as a matrix, polystyrene foam and pulverized fuel ash are adopted as admixtures, an appropriate microwave absorption agent is compounded, and the obtained double-layer allotype surface cement-based absorption material is low in cost, energy saving and environmentally-friendly; a traditional panel material is subjected to surface shape designs such as a double-layer shape, a triangular shape, a sinusoidal shape, a semicircular shape and a right-angle groove shape, so that a series of double-layer allotype surface cement-based absorption material with a favorable electromagnetic absorption performance is prepared, the density and the thickness are small, the effective absorption bandwidth smaller than -10dB within the range of 1.7 to 18GHz is 13GHz or more, and the minimum reflectance is less than -30dB.

Owner:HAINAN UNIVERSITY

Preparation method of high-temperature wave-transparent composite material toughened by hybrid-woven fibers

ActiveCN103664213AImprove high temperature resistanceGood wave permeabilityO-Phosphoric AcidALUMINUM PHOSPHATE

The invention provides a preparation method of a high-temperature wave-transparent composite material toughened by hybrid-woven fibers. The preparation method comprises the following steps: (1), weaving boron nitride fibers, high silica fibers and quartz fibers into prefab forms in a hybrid manner by virtue of a weaving method or a knitting method, wherein the prefab types are 2.5-dimensional or 3-dimensional forms; (2), mixing phosphoric acid in a certain mass fraction with aluminum hydroxide, adding deionized water and sufficiently stirring until mixing uniformly, and standing for 2 hours-4 hours to prepare aluminum phosphate sol; (3), placing fiber prefabs in the prepared aluminum phosphate sol, and sufficiently impregnating; (4), placing the fiber prefabs impregnated by the aluminum phosphate sol into an oven for carrying out a thermal-treatment drying process; (5), placing a dried composite material at 700 DEG C-900 DEG C for sintering and treating for 1 hour-2 hours; and (6), repeating the processes in step (3) to step (5) for 5-7 times to prepare the compact composite material. According to the invention, the technical process is relatively simple, easy to operate and low in cost; and the prepared composite material has very good high temperature resistance and wave-transparent performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

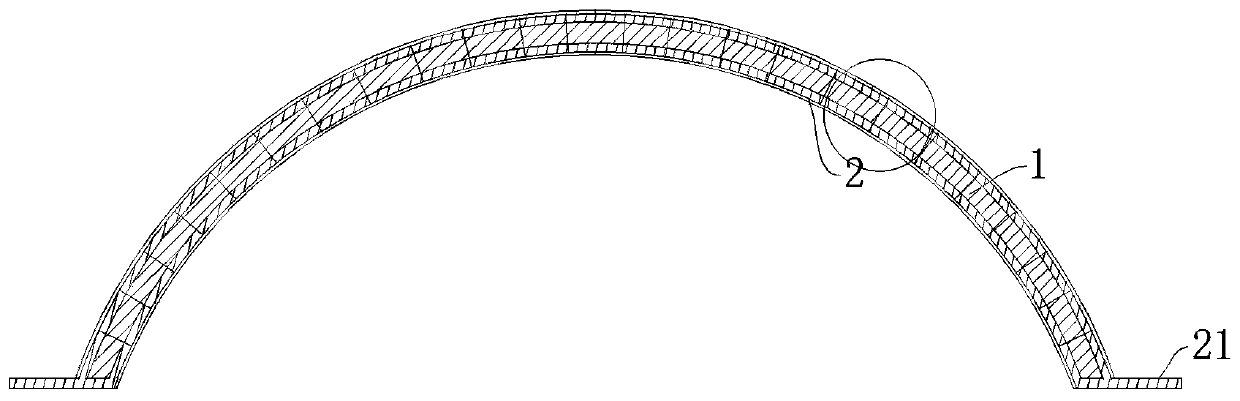

Wave-transparent radome

PendingCN110867659AQuality assuranceGood wave permeabilityRadiating element housingsFiberElectrical performance

The invention discloses a wave-transparent radome, which comprises a radome prefabricated body. The inner surface and the outer surface of the radome prefabricated body are connected with a pluralityof layers of first fiber cloth; the radome prefabricated body is formed by splicing a plurality of foam prefabricated bodies in polygonal curved surface structures; and the adjacent prefabricated bodies in the radome prefabricated body and the prefabricated bodies and the first fiber cloth are subjected to vacuum bonding through resin and are cured into a whole. The preparation of the foam prefabricated body ensures the conformability of the radome sandwich foam in complex curvature surface; all layers of radome bodies are cured layer by layer in the curing process, so that the interlayer defects of the radome bodies are reduced; the state of each layer of the radome body can be inspected layer by layer, so that the overall quality of the radome is ensured; due to the design of the multiple layers of sandwich foam, the radome has excellent wave-transparent performance under wide-band and high-frequency working frequencies, and the electrical performance of the radome is improved; and the sandwich foam radome body structure sewed between the layers effectively increases the overall strength and rigidity of the radome, and the bearing capacity of the radome is improved.

Owner:SHAANXI AIRCRAFT CORPORATION

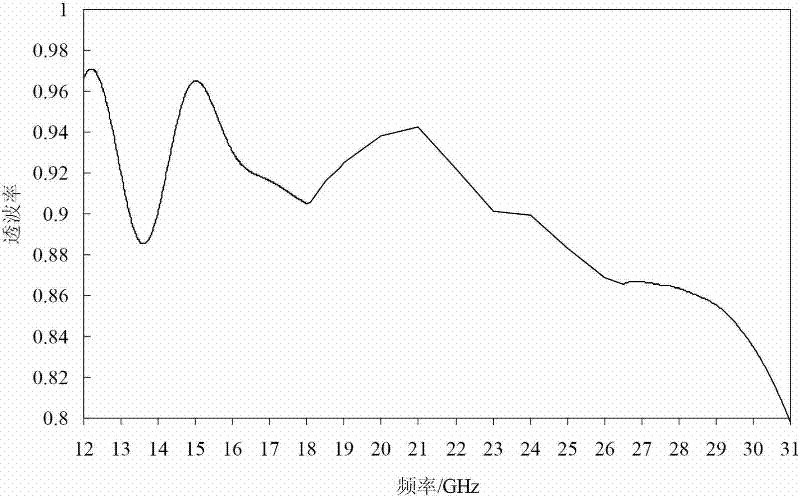

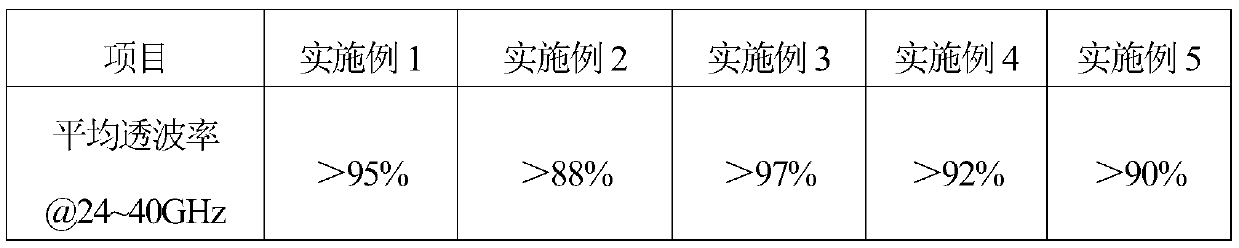

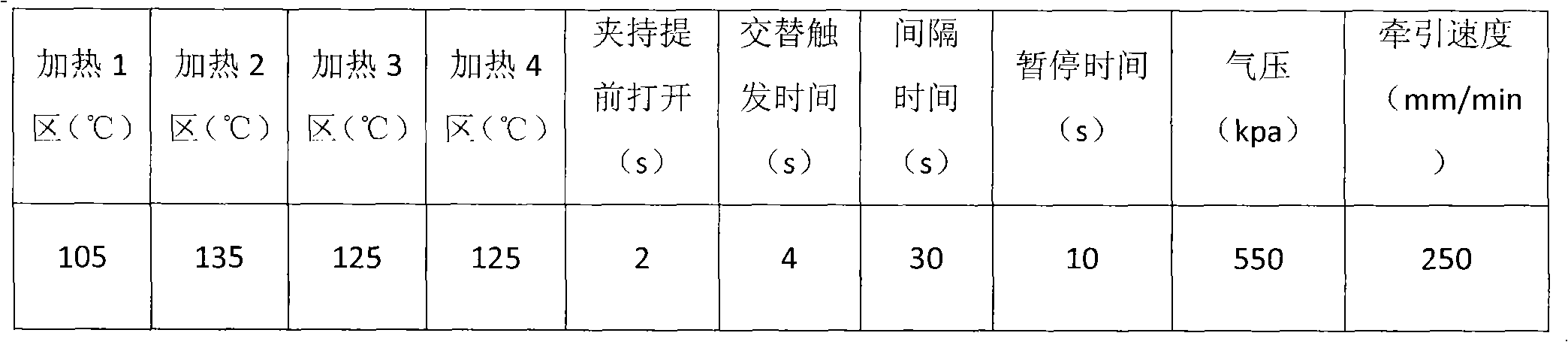

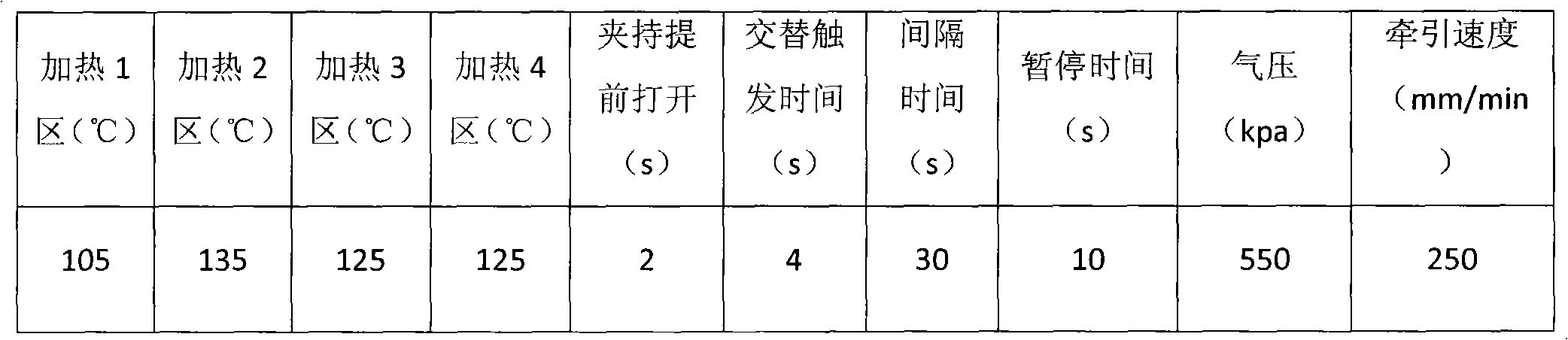

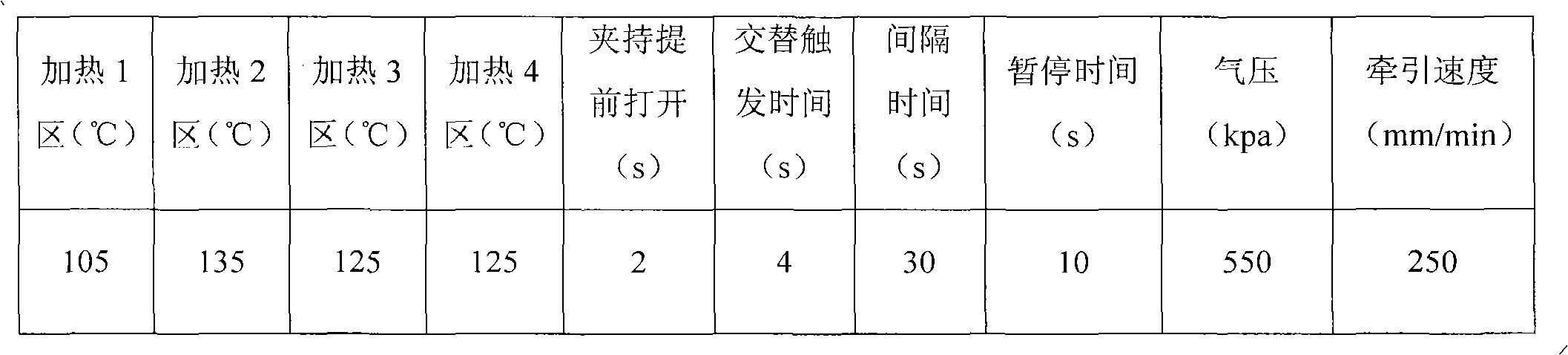

Wave-transmitting material for millimeter-wave radome and forming method thereof

ActiveCN110539539AImprove flame retardant performanceEasy to processSynthetic resin layered productsRadiating element housingsPolymer scienceFire retardant

The invention belongs to the technical field of manufacturing of communication radome materials, and particularly relates to a wave-transmitting material for a millimeter wave radome and a forming method thereof. A polyethersulfone resin material is adopted as a skin layer, a polyether sulfone foam material is adopted as a core layer, and the skin layer and the core layer are both made of the samethermoplastic material which is easy for machine shaping; and the polyethersulfone material has excellent flame retardant properties, and the flame retardant grade of the polyethersulfone material can reach the UL94-V0 grade. When a thermosetting material or a conventional thermoplastic material is used as a wave-transmitting material in the prior art, a flame retardant is added to improve the flame retardant property of the material, but the addition of the flame retardant seriously influences the dielectric properties of the material, so the problem of reduction in wave-transmitting rate ofthe material occurs; and the wave-transmitting material provided by the invention overcomes the above-mentioned problem and can maintain excellent wave-transmitting performance on the premise of meeting flame-retardant requirements.

Owner:SHANGHAI ALLIED PLASTIC IND

Method for preparing double-layer wave-permeable heat proofing and insulating composite structural part

The invention discloses a method for preparing a double-layer wave-permeable heat proofing and insulating composite structural part. The structural part comprises an inner heat insulation material and an outer heat-proof +material. The method includes steps of preparation of the outer heat-proof material, preparation of silicon oxide hollow microspheres, preparation of chopped fiber reinforced silicon oxide hollow microsphere slurry, casting of the chopped fiber reinforced silicon oxide hollow microsphere slurry and thermal treatment of a structural part blank material. Quartz fiber reinforced quartz composite ceramic serves as the outer heat-proof material, chopped fiber reinforced silicon oxide hollow microsphere ceramic serves as the inner heat insulation material, compact combination of the inner and outer materials is realized by means of slurry casting and high-temperature sintering moulding, and integration of advantageous performances of high temperature resistance, heat proofing, heat insulation, wave permeability and the like is realized.

Owner:湖北三江航天江北机械工程有限公司

Glass fiber reinforced plastic antenna housing modified by aluminum hydroxide and preparation method thereof

InactiveCN101942185AHigh hardnessIncrease reaction rateRadiating element housingsPolyesterGlass fiber

The invention discloses a glass fiber reinforced plastic antenna housing modified by aluminum hydroxide, which has the advantages of reducing DK value thereof and improving the wave penetrating property of the product. The glass fiber reinforced plastic antenna housing modified by aluminum hydroxide is prepared from the following raw materials in part by weight: 100 parts of unsaturated polyester, 5 to 30 parts of aluminum hydroxide, 0.5 to 2 parts of releasing agent, 0.5 to 2 parts of curing agent and 0.5 to 2 parts of accelerant.

Owner:NANJING HUAGE ELECTRONICS & AUTOMOBILE PLASTIC IND

High temperature-resistant, heat-insulation and wave-permeable ceramic-based composite material and preparation method thereof

The invention provides a high temperature-resistant, heat-insulation and wave-permeable ceramic-based composite material and a preparation method thereof. The preparation method comprises the following steps of using kaolin, aluminum oxide and industrial aluminum sol as the raw materials, using a mineralizing agent and a sintering additive as the auxiliary materials, adding a perforating agent, and performing glue discharge and sintering technology, so as to prepare a mullite porous ceramic with high porosity; using ethyl silicate and siloxane monomer as the raw materials to prepare a siliconoxide sol, enabling the silicon oxide sol to permeate into the mullite porous ceramic, drying at normal temperature, cracking under the inert atmosphere, then permeating into the aluminum sol, drying,and decarbonizing in the high-temperature air, so as to obtain the high temperature-resistant, heat-insulation and wave-permeable ceramic-based composite material. The high temperature-resistant, heat-insulation and wave-permeable ceramic-based composite material has the beneficial effects that the raw materials are reasonably selected, so as to complete the low-temperature preparation of the porous mullite, and decrease the production energy consumption while the cost of the raw material is reduced; the drying technology of the aerogel is simplified, and the preparation cycle is shortened; the characteristics of low density, high temperature-resistant property and low heat conductivity are realized; the excellent wave-permeable property is realized.

Owner:HARBIN INST OF TECH

Making method of amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on metal surface

The invention relates to a making method of a high temperature-resistant wave transmitting ceramic coat on a metal surface, and concretely relates to a making method of an amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on the metal surface. The purpose of the invention is solving the problems of low high temperature resistance temperature and low wave transmittance of present organic coat systems. The method comprises the following steps: 1, weighing a raw material; 2, preparing an amorphous AlPO4 adhesive solution; 3, preparing a wave transmitting ceramic coating; and 4, preparing the amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat on the metal surface. The coat obtained in the invention has good dielectric properties, and the dielectric constant is small, so the dielectric loss angle is small, thereby the electromagnetic wave transmittance is improved, and the wave transmittance is greater than 80% in 1-18GHz; and the high temperature resistance is good, the high temperature resistance temperature is 500-1300DEG C, and the amorphous aluminum phosphate-based high temperature-resistant wave transmitting ceramic coat has the advantages of environmentally-friendly and nontoxic raw material, good film forming property, low cost, simple preparation method and short period.

Owner:HARBIN INST OF TECH

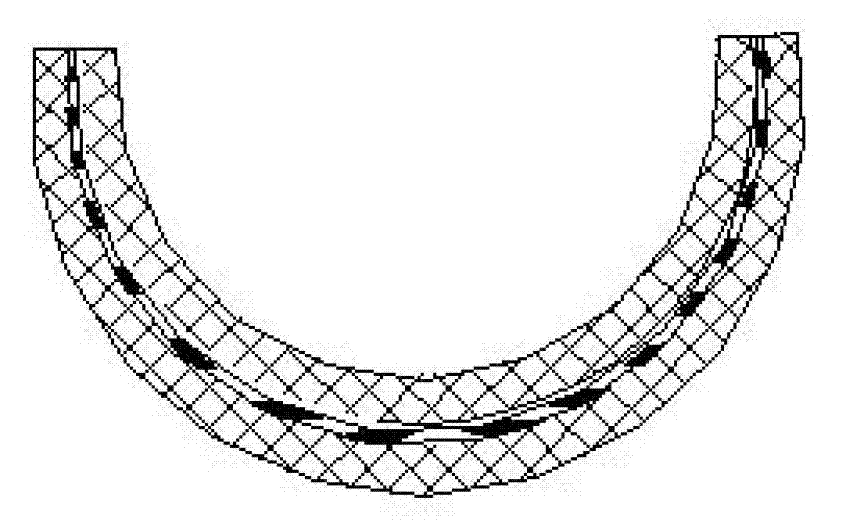

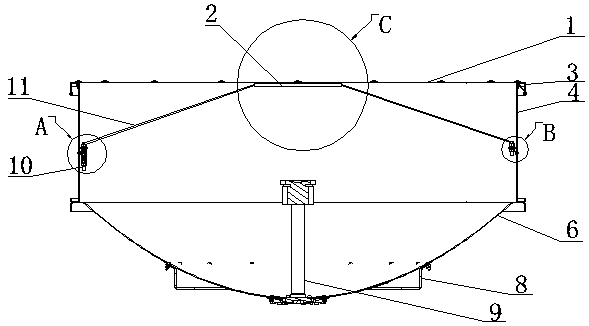

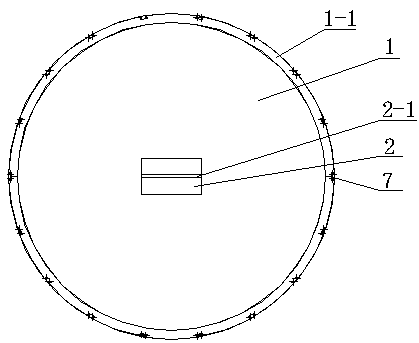

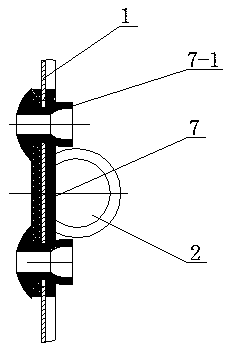

Microwave antenna wide-frequency flexible antenna cover

ActiveCN108461916AImprove electrical performanceLow insertion lossRadiating element housingsCompound aFiber

Provided is a microwave antenna wide-frequency flexible antenna cover having the periphery fixed on a fence surrounding the antenna and opposite to the reflection surface of the antenna, the antenna cover is formed by compounding a high-molecular polymer outer layer and a composite fiber textile structure layer mixed with a shielding wave-absorbing filament, a tensioning element used for being connected with a traction mechanism is arranged on one surface, facing the antenna reflection surface, of the antenna cover, the traction mechanism is connected to the inner wall of the fence, and a traction force which enables the antenna cover to change to form a concave surface acts on the antenna cover via the tensioning element. The antenna cover of the structure is good in wave permeability, and the thickness of the antenna cover does not need to be selected according to the working wavelength of the antenna. The antenna cover with a uniform thickness can obtain lower antenna insertion lossin multiple frequency bands, the use of a multi-frequency-band microwave antenna can be met, and the universality of the antenna cover is realized in a relatively wide frequency range, and the defectthat traditional antenna covers made of ABS and other materials have different frequency bands and have poor specificity is overcome.

Owner:TONGYU COMM INC

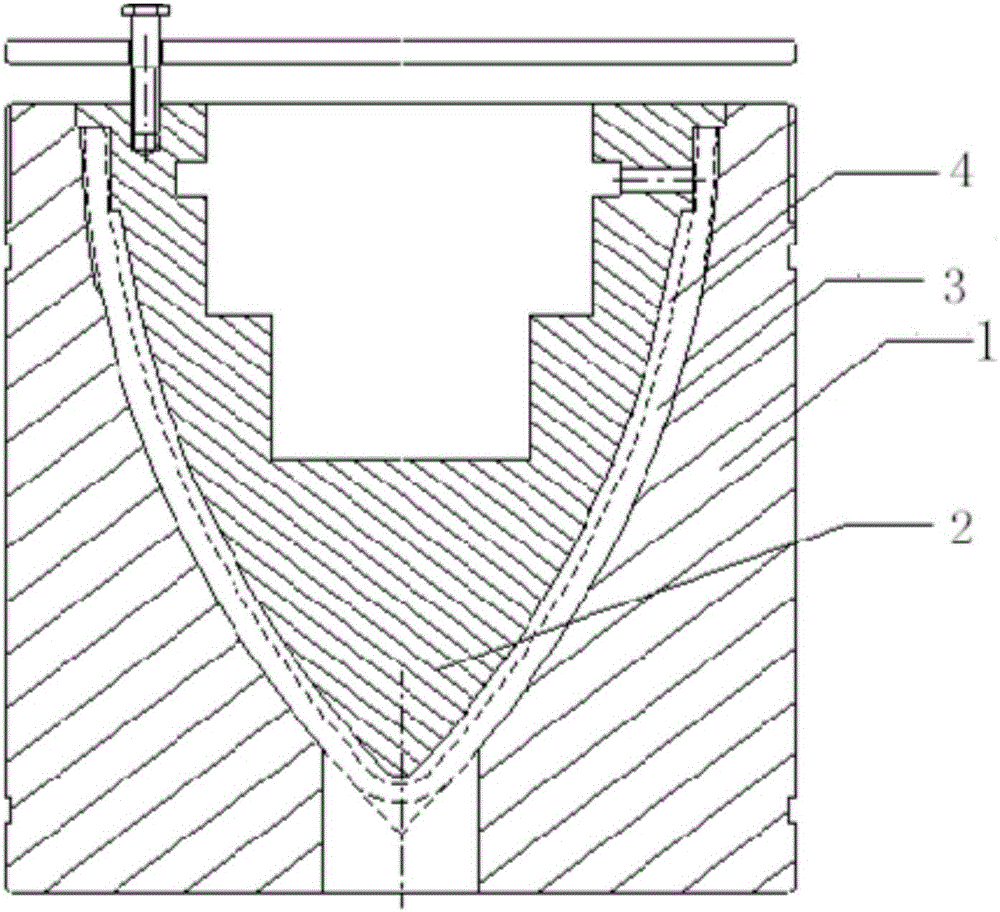

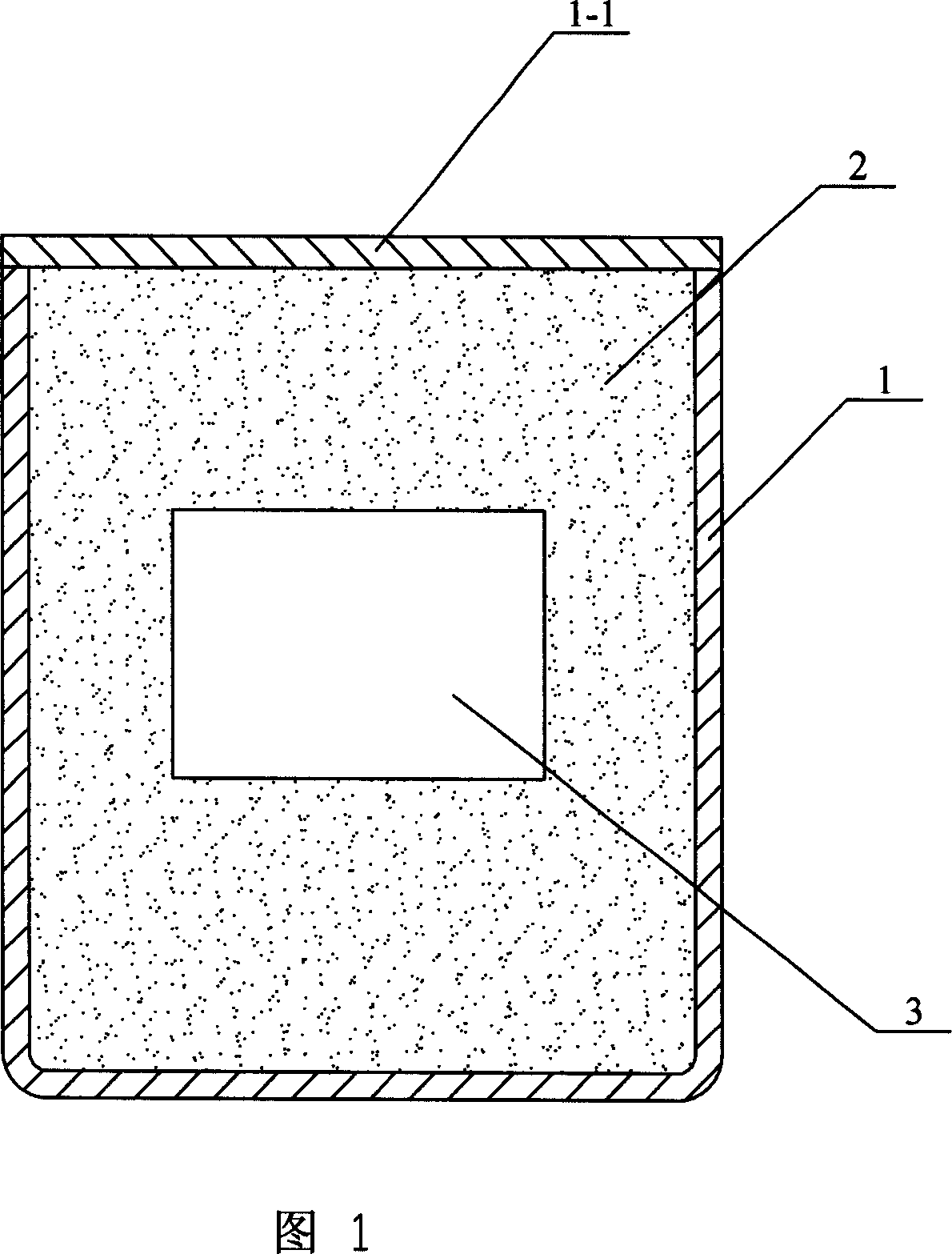

Microwave sintering material placing device

InactiveCN101017058AGood wave permeabilityLow absorption rateCrucible furnacesCrucibleMicrowave sintering

A microwave sinter material container is formed by a glass container 1 with a cover, a flameproof material 2 and a diamond pot 3, for resolving the problems as non-uniform heating and acute temperature change. The glass container 1 contains the flameproof material 2, the diamond pot 3 is embedded in the material 2, and the thickness of the material 2 is not lower than 2cm, therefore, the invention can quickly heat and save energy, and heat uniformly to prolong the service life of diamond pot.

Owner:HARBIN INST OF TECH

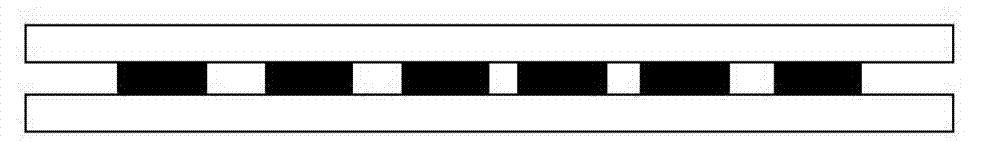

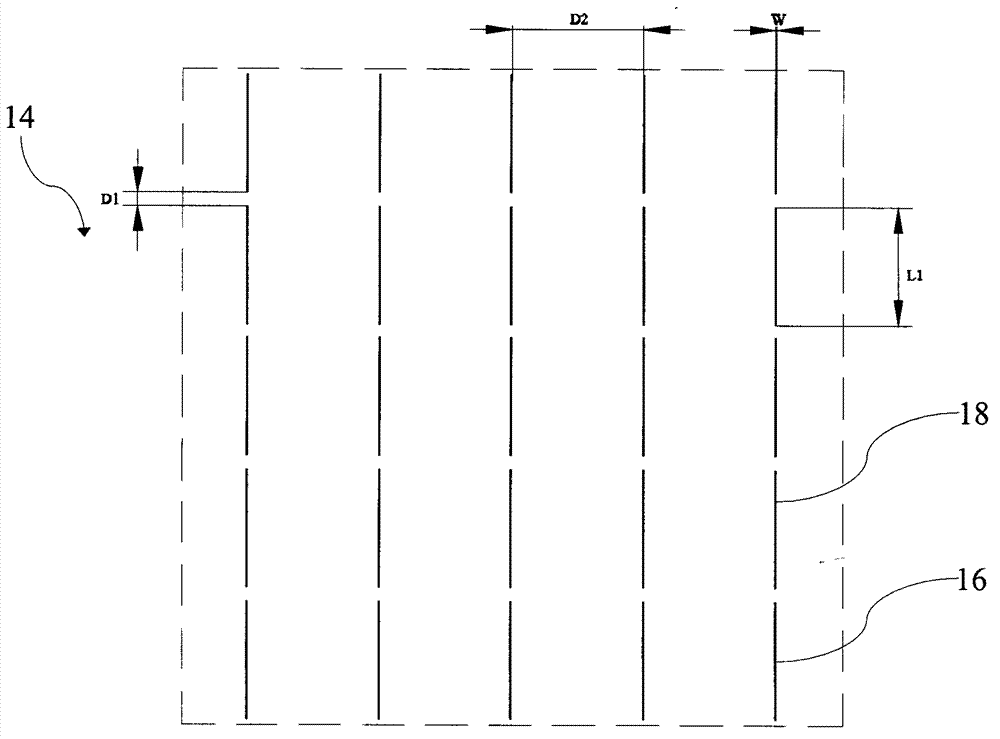

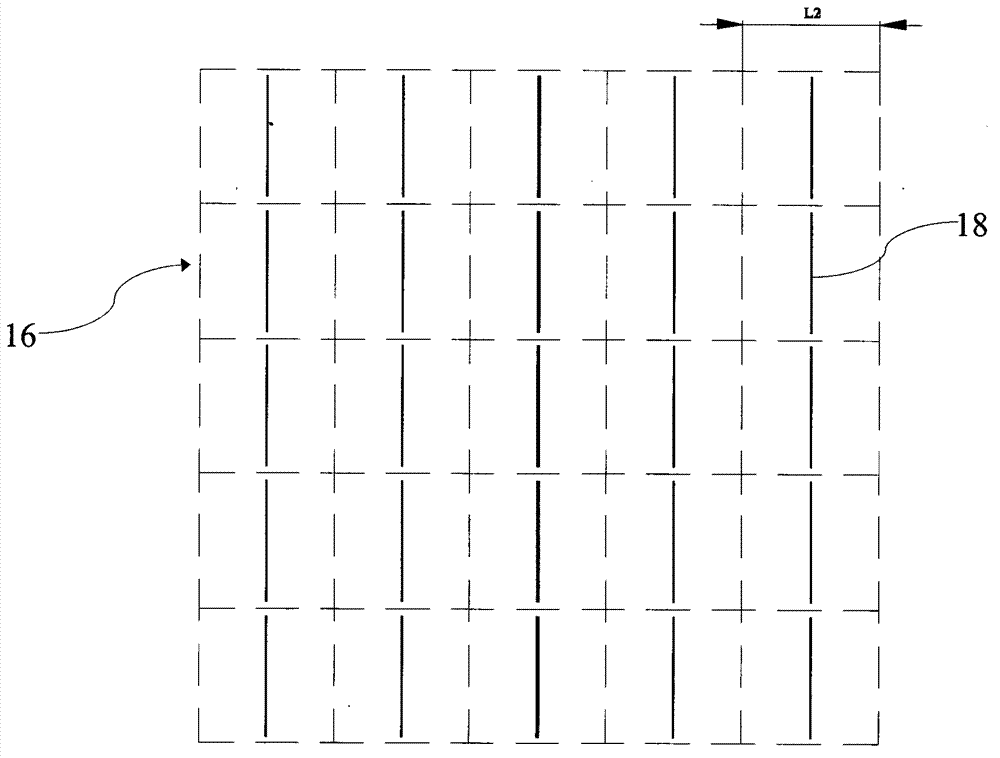

Frequency selection composite material and frequency selection antenna housing and antenna system made of frequency selection composite material

ActiveCN102856653AReflection becomes smallerImproved wave transparencyRadiating element housingsWaveguide type devicesHigh resistanceEngineering

The invention relates to a frequency selection composite material. The material comprises a composite sheet layer, wherein the composite sheet layer comprises two medium base plates and a structure layer which is arranged between the two medium base plates, the structure layer comprises a plurality of first discontinuous metal wires which are parallel to one another, each of the discontinuous metal wires comprises a plurality of wire segments which are arranged at intervals, the lengths of the first discontinuous metal wires are equal, the widths of the first discontinuous metal wires are equal, and the distances between any two adjacent ends of any two adjacent wire segments are equal; the distances between any first discontinuous metal wires and adjacent first discontinuous metal wires are equal, two corresponding ends of wire segments of corresponding positions of any two adjacent first discontinuous metal wires are flush with each other, the composite material is low in reflection and high in wave transmission rate for low-frequency range electromagnetic waves, so that the material has good wave transmission performance, and at the same time, the material can inhibit high-frequency stage electromagnetic waves and has a band elimination function, so that the material has low-pass high-resistance frequency-selection selection characteristics. The invention also relates to a frequency selection antenna housing and an antenna system made of the frequency selection composite material.

Owner:KUANG CHI INST OF ADVANCED TECH

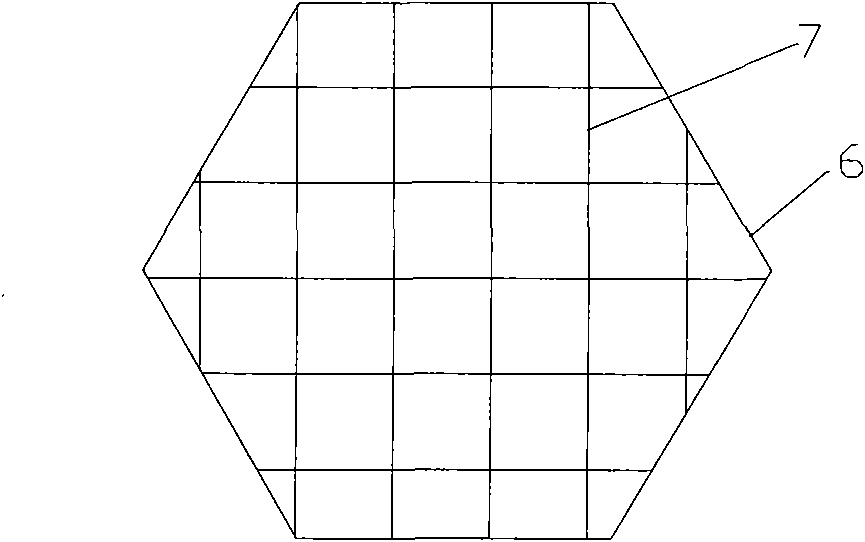

Wideband-elimination metamaterial and wideband-elimination metamaterial antenna housing and antenna system

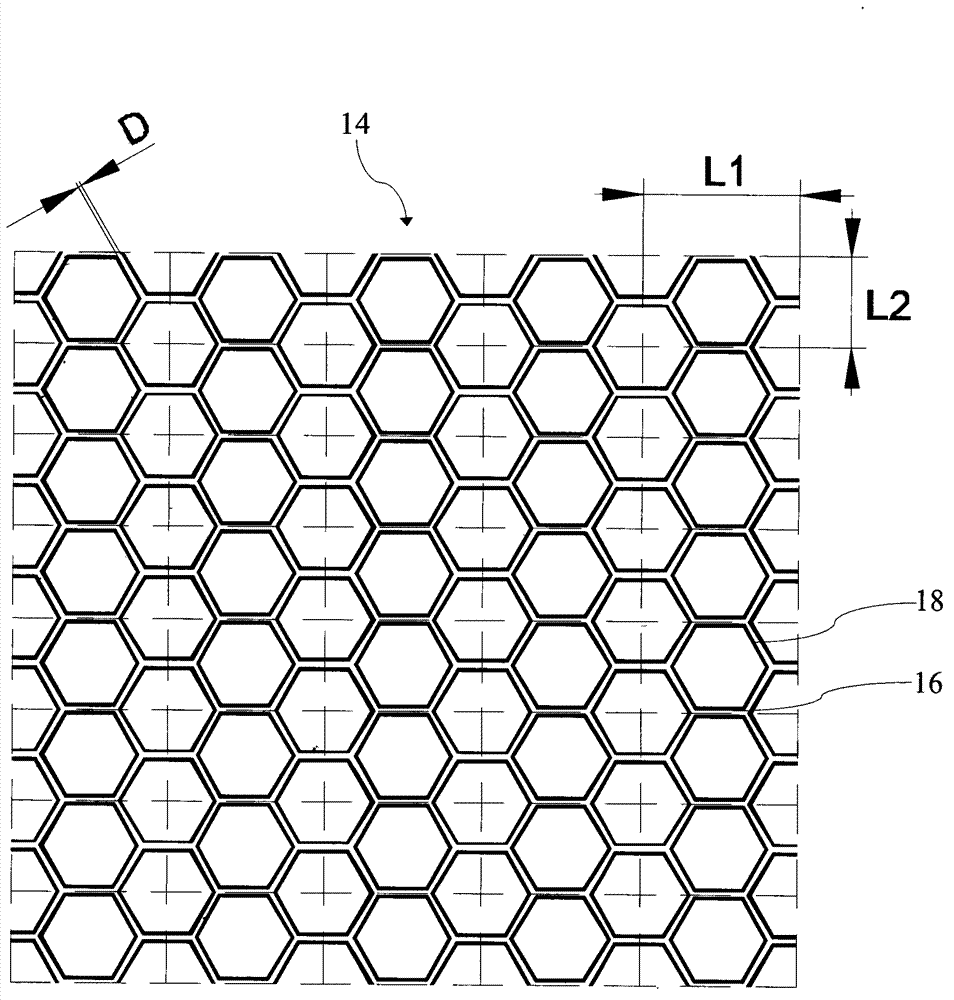

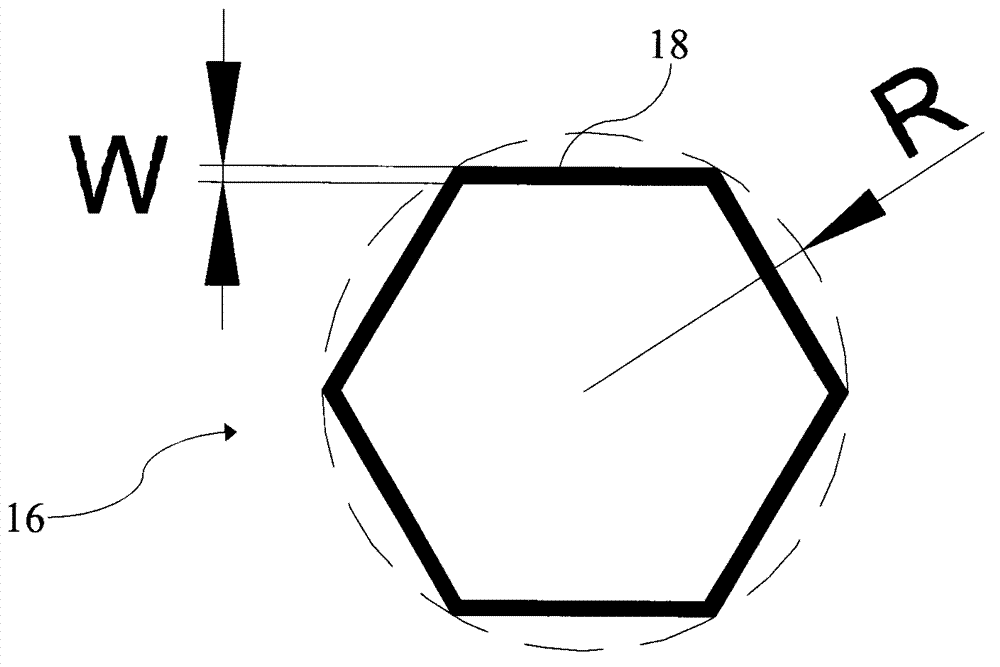

ActiveCN102856654AWith broadband band rejection functionReduce spacingRadiating element housingsMetal microstructureMetamaterial

The invention relates to a wideband-elimination metamaterial which comprises a metamaterial slice, the metamaterial slice comprises a media substrate and two structure layers which are attached to two opposite surfaces of the media substrate respectively, each structure layer comprises a plurality of regularly hexagonal metal micro-structures, the two metal micro-structures in the two structure layers, positioned at corresponding positions of the media substrate, form a pair, two adjacent sides of any two adjacent metal micro-structures in each structure layer are parallel to each other, so that the central interval of any two adjacent metal micro-structures is reduced, thus being capable of restraining electromagnetic wave in an ultrawide high frequency range so as to enable the metamaterials to have a wideband-elimination function; and the electromagnetic wave in low frequency range has the advantages of high wave transmittance and small reflection as well as good wave transmitting property. The invention further relates to a wideband-elimination metamaterial antenna housing and an antenna system which are produced by the wideband-elimination metamaterials.

Owner:KUANG CHI CUTTING EDGE TECH LTD

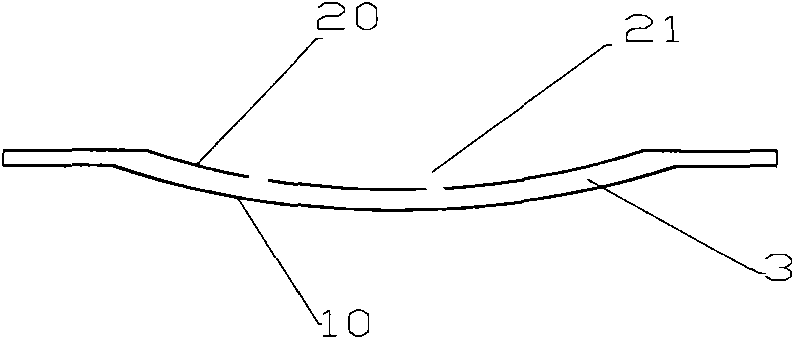

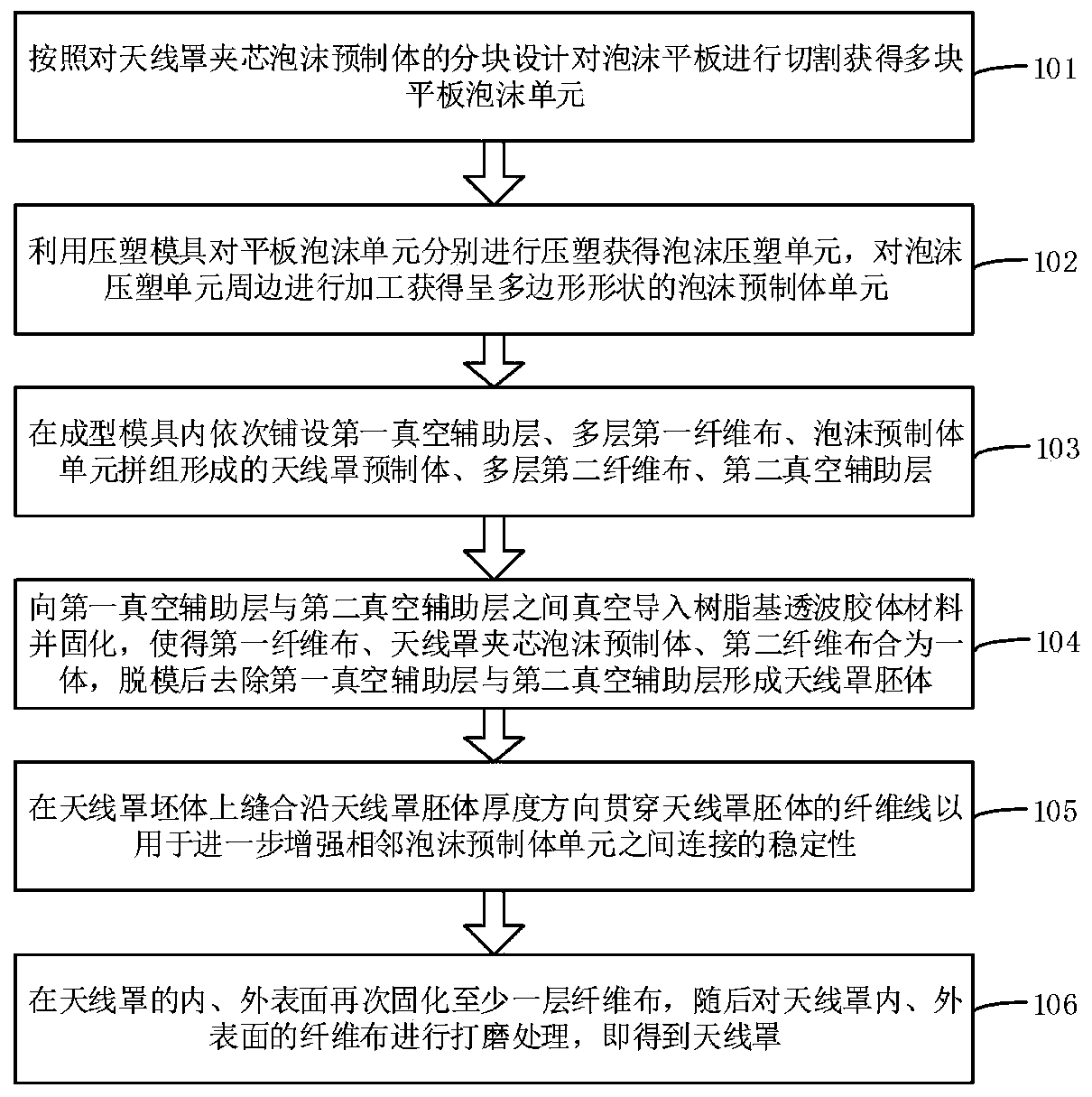

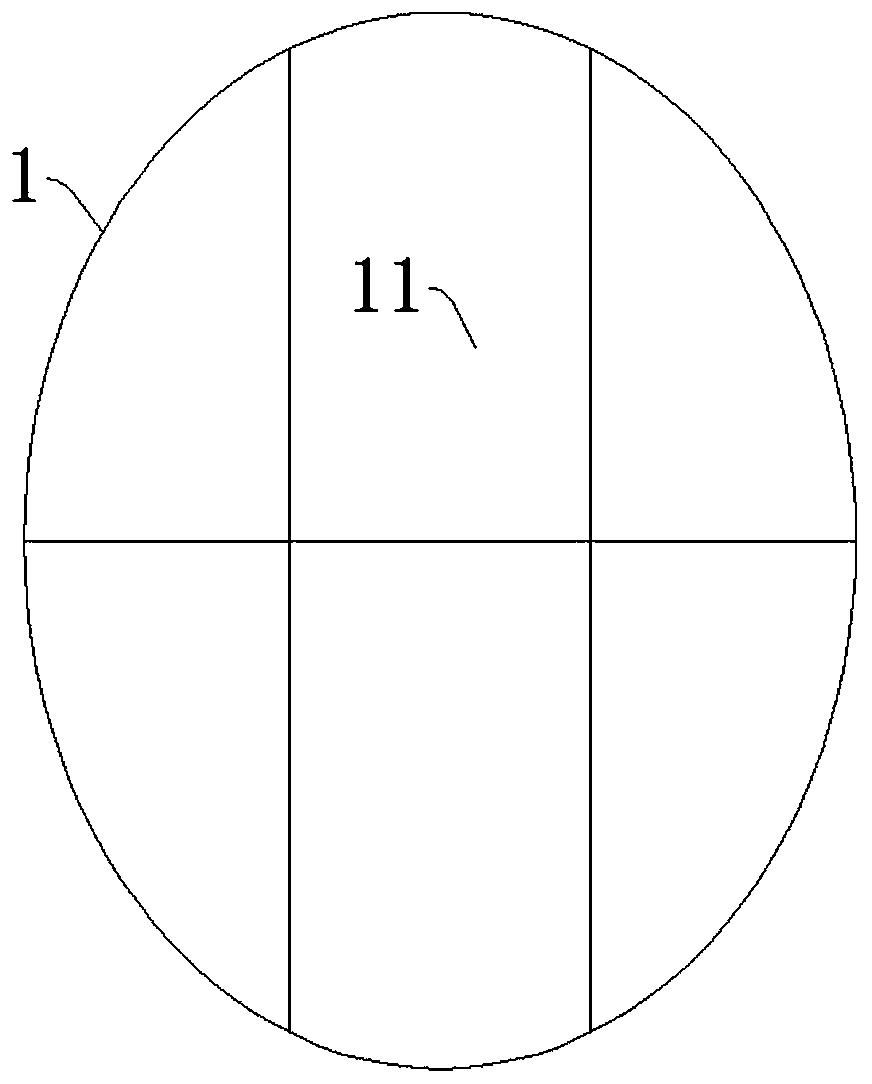

Forming method for antenna housing based on single layer sandwich foam prefabricated body resin

InactiveCN110948908AQuality assuranceGood wave permeabilityDomestic articlesCompression moldingFiber

The invention discloses a forming method for an antenna housing based on single layer sandwich foam prefabricated body resin. The forming method comprises the following steps of cutting a foam flat plate to obtain a plurality of flat plate foam units; respectively performing compression molding and peripheral processing on the flat plate foam units to obtain polygon-shaped foam prefabricated bodyunits; paving a first vacuum auxiliary layer, a plurality of layers of fiber cloth, an antenna housing sandwich foam prefabricated body formed by splicing foam prefabricated body units, a plurality oflayers of second fiber cloth and a second vacuum auxiliary layer in a forming mould in sequence; and introducing a resin-based permeable colloidal material between the first vacuum auxiliary layer and the second vacuum auxiliary layer and curing to form an antenna housing blank. The preparation of a foam prefabricated body ensures the configuration of antenna housing sandwich foam with complex curvature molded surfaces; various layers of housing body are cured layer by layer in a curing process, so that the interlayer defects of the housing body are reduced; the state of various layers of thehousing body can also be detected layer by layer; the overall quality of the antenna housing is ensured; the overall strength and rigidity of the antenna housing are improved; and the bearing capacity of the antenna housing is improved.

Owner:NINGBO SHUXIANG NEW MATERIAL

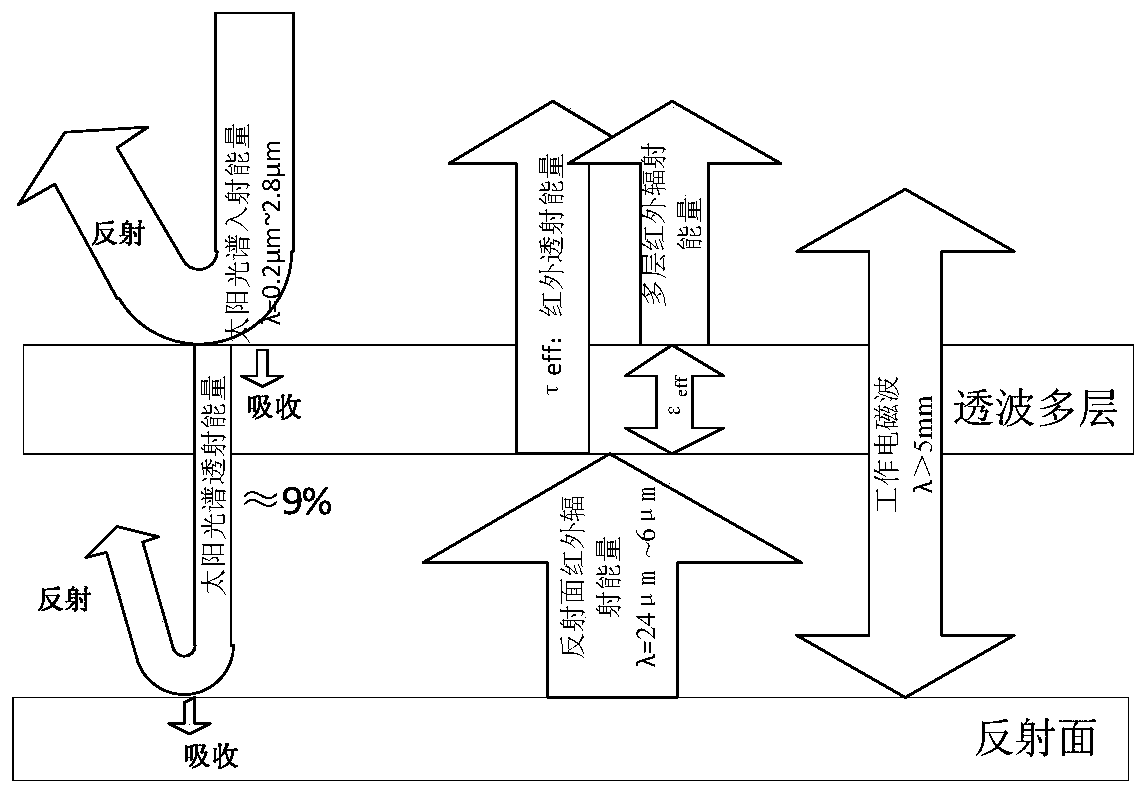

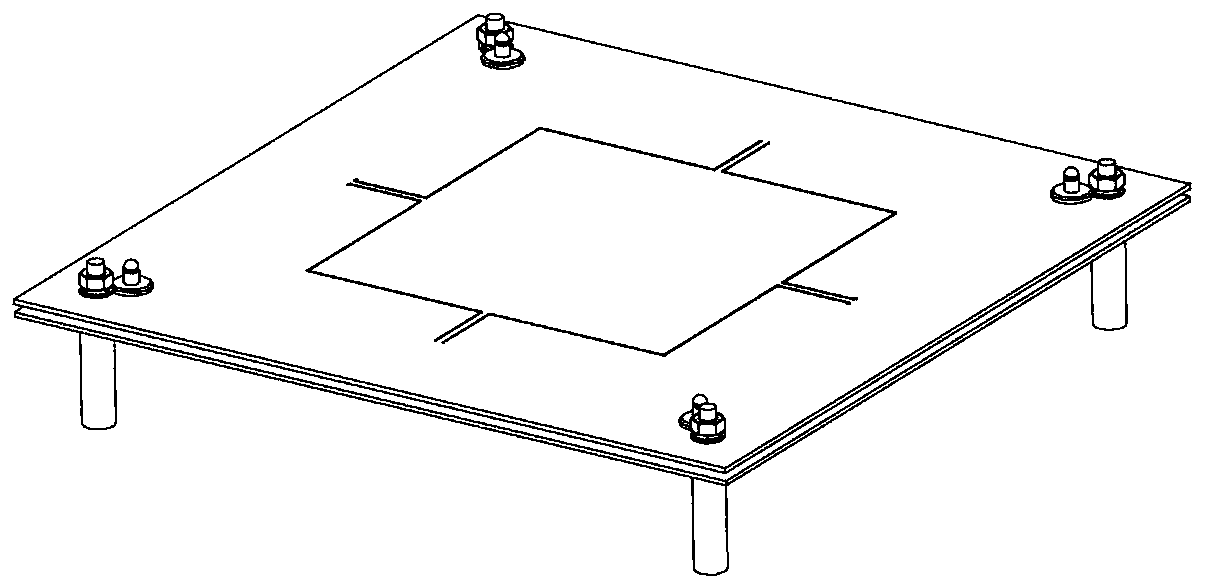

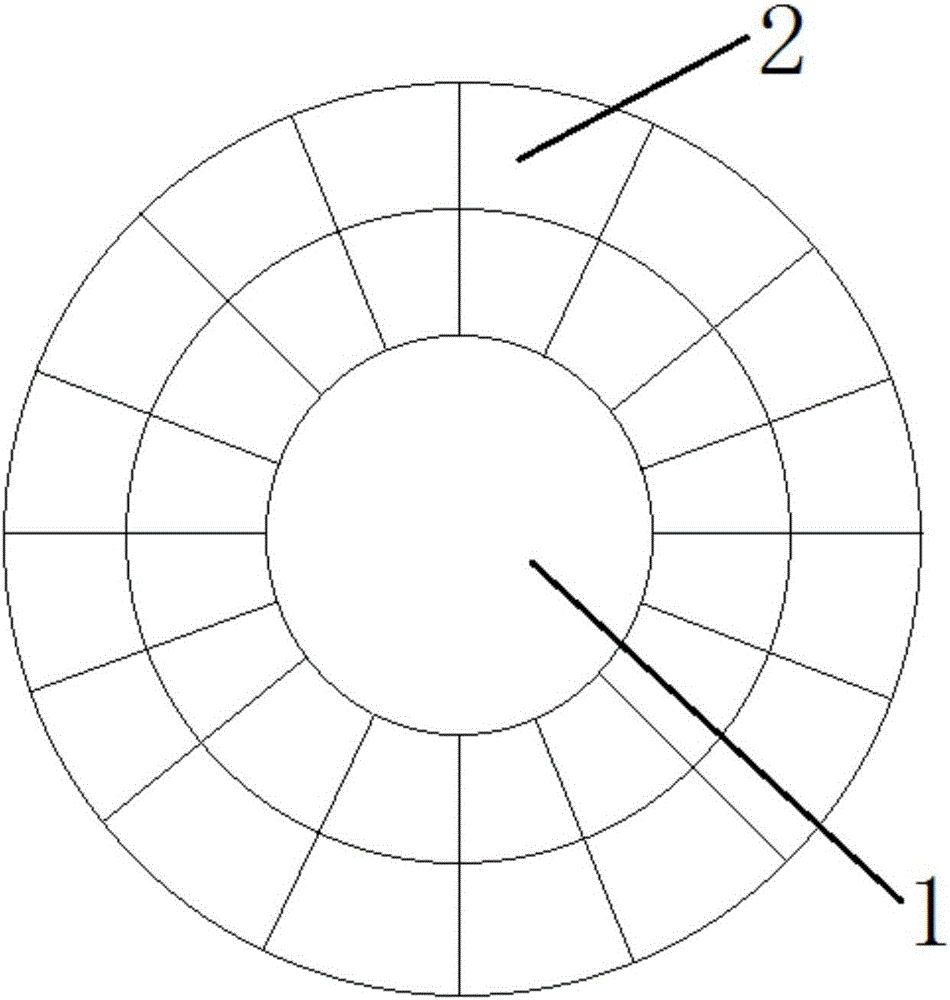

Wave-transparent multilayer heat insulation structure for realizing thermal control of spacecraft antenna

InactiveCN111063977AImprove isolation efficiencySolve the problem of high temperature caused by absorbing the sun's heat flowDe-icing/drying-out arrangementsMechanical engineeringThermal control

The invention discloses a wave-transparent multilayer heat insulation structure for realizing thermal control of a spacecraft antenna. The wave-transparent multilayer heat insulation structure comprises reflecting screens (1), spacing layers (2), a surface film (3) and an inner side film (5). The laminated structure of the multiple layers of reflecting screens (1) has the effect of increasing infrared radiation thermal resistance. The spacing layers (2) are arranged between every two layers of reflecting screens (1) to isolate the heat conduction between layers of the reflecting screens (1).The surface film (3) has the effect of reflecting solar spectrum heat radiation. A sewing material (4) is used for multilayer sewing of the reflecting screens (1). An inner side film (5) and the reflecting screens (1) are made of the same material, and the inner side film mainly plays a role in protection to avoid damage caused by friction between the multilayer heat insulation structure and a product . According to the invention, the wave-transparent multilayer heat insulation structure has good transmissivity for working electromagnetic waves of the antenna and has high reliability.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

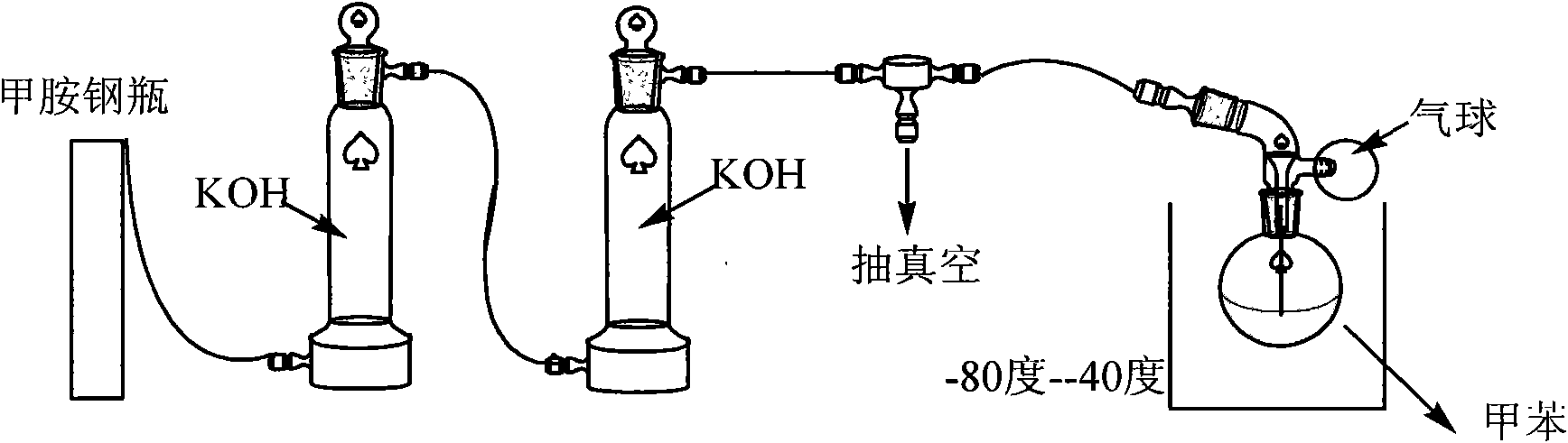

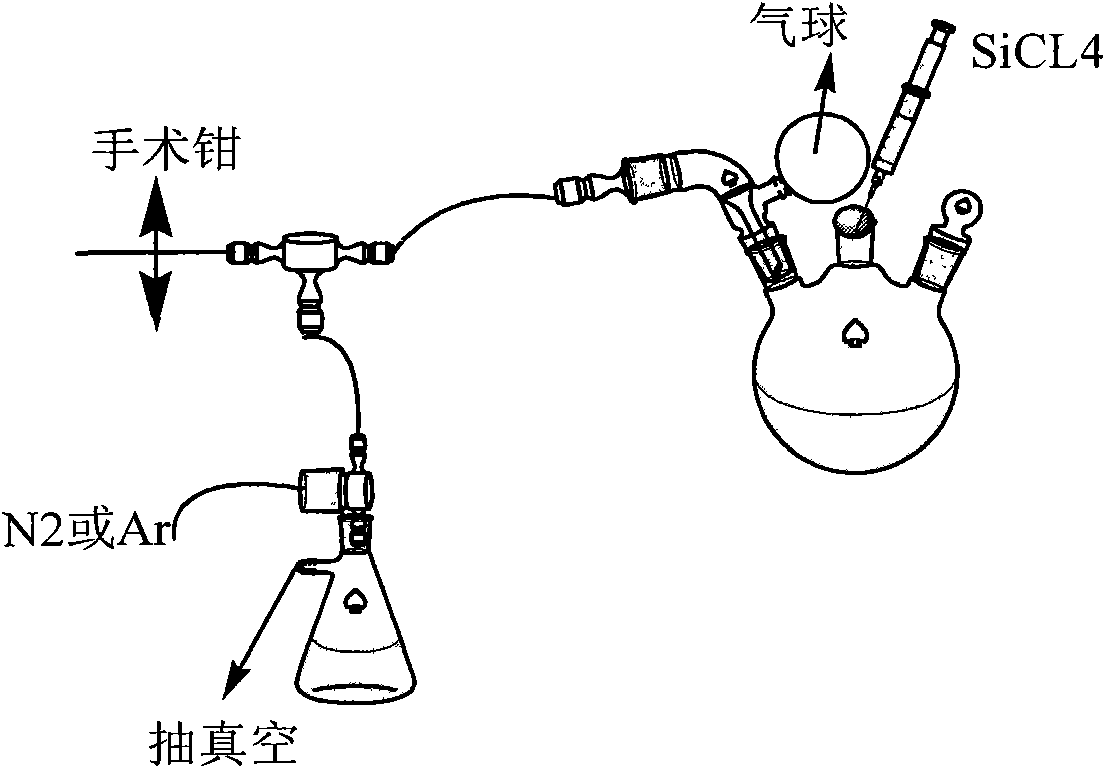

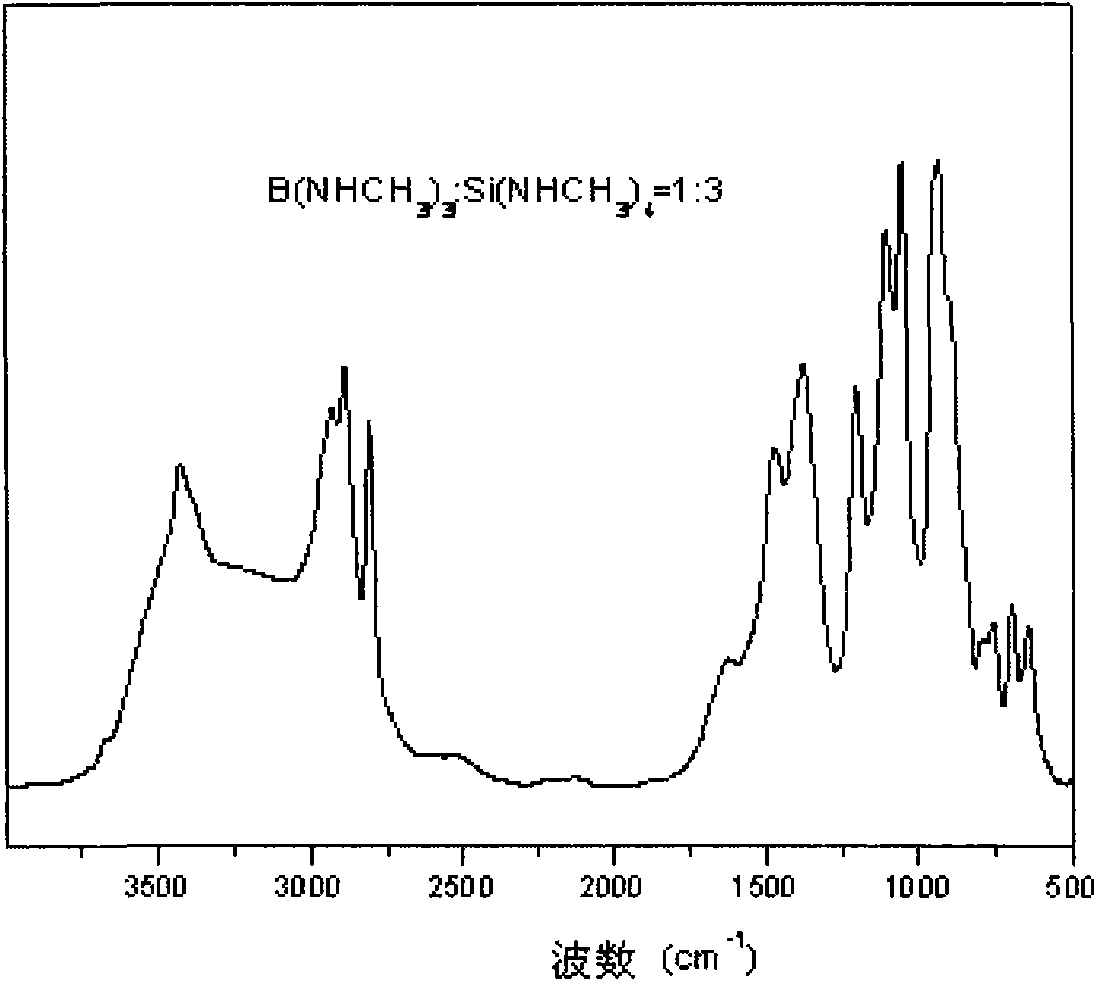

Method for preparing borosilazane ceramic fiber precursor

The invention relates to a method for preparing a borosilazane ceramic fiber precursor, which comprises the following steps of: reacting boron trichloride (BC13) with methylamine (CH3NH2) at -80DEG C for 12 to18 hours, reacting at -40 DEG C for 12 to 18 hours to synthesize B(NHCH3)3 micromolecules, and synthesizing Si(NHCH3)4 micromolecules by silicon tetrachloride (SiCl4) and the methylamine (CH3NH2); and removing excessive methylamine from the two type of micromolecules, filtering, mixing, condensing at the temperature of between 135 and 165 DEG C to obtain the precursor with good filament picking effect. The method has the advantages of low cost of raw materials, pure product, and high synthetic yield; and the prepared ceramic fiber precursor is heated to 1,700 DEG C in the ammonia atmosphere, the obtained product has the carbon content of less than 0.05 percent through element analysis, and has good wave permeability and good application prospect.

Owner:DONGHUA UNIV

Preparation method of carbon fiber/glass fiber hybrid invisible composite material

The invention discloses a preparation method of a carbon fiber / glass fiber hybrid invisible composite material. The preparation method includes the following steps: with carbon fibers as core yarns and glass fibers as weaving yarns, spinning the core yarns and the weaving yarns to form carbon fiber / glass fiber covered yarns through a two-dimensional weaving technology; weaving the core fiber / weaving fiber covered yarns into cloth, and performing composite curing to the cloth and epoxy resin through a resin transfer molding process to prepare the carbon fiber / glass fiber hybrid invisible composite material. Through the carbon fiber / glass fiber covered yarn structure, electromagnetic wave can enter the interior of the covered yarns as most as possible by means of wave transmission performance of the glass fiber, and then the electromagnetic energy is converted into thermal energy or energy in other forms by means of resistive loss of the carbon fibers, thus dissipating the energy. The carbon fibers are employed as core yarns, so that the material is basically in a straight status, thereby effectively achieving the mechanical performance of the material. The hybrid invisible composite material has excellent mechanical performance.

Owner:南通欣丰桥架有限公司

Rapidly synthesized polishing-free cordierite ceramic sheet for microwave oven and production method thereof

Provided are a rapidly synthesized polishing-free cordierite ceramic sheet for a microwave oven and a production method of the rapidly synthesized polishing-free cordierite ceramic sheet. The production method comprises the following steps: basic materials including 35-55% of mullite, 15-35% of attaclay, 10-25% of black soil, 0-10% of cordierite, 0-10% of petalite, 0-5% of kaolin, 0-2% of calcium carbonate, 0-2% of potassium feldspar and 0-10% of Al2O3 are prepared according to weight ratio, the additives are polyvinyl alcohol (PVA) and sodium humate, the above all powdery basic materials are subjected to ball-milling to be crushed, the two additives are added into the basic material and are subjected to proper ball-milling to be fully mixed, then the basic materials and the additives are screened through a screen with 200-400 meshes, the iron in the basic materials and the additives is attracted, then the basic materials and the additives are sprayed with mist, dried to make powder, mechanical pressed, applied with glaze, and rapidly sintered at the intermediate temperature of 1220-1300 DEG C to make the product. According to the invention, the raw ores of mullite and attaclay are used to make the sheet, so that the cost of raw materials is greatly lowered, the glaze can be co-fired at one time, and the cordierite crystalline phase is rapidly synthesized by taking advantages of lattice imperfection of various raw mineral materials. The sheet can be pressed very thin and flat so as to avoid polishing.

Owner:湖南嘉盛电陶新材料股份有限公司

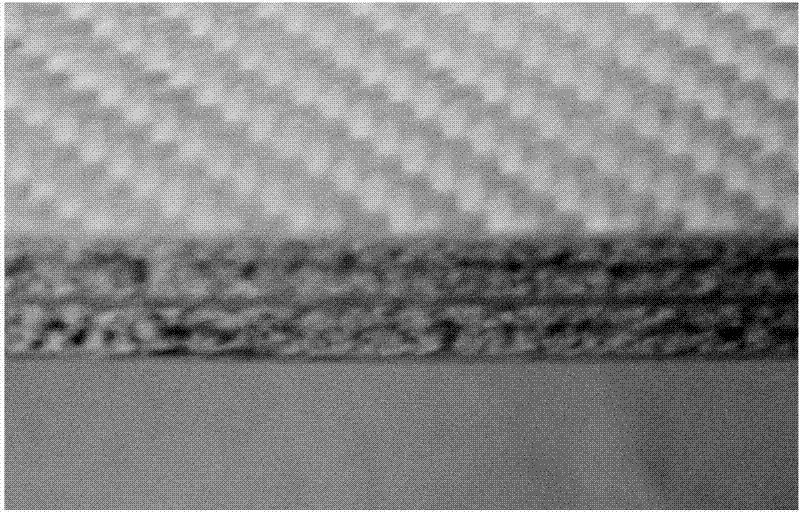

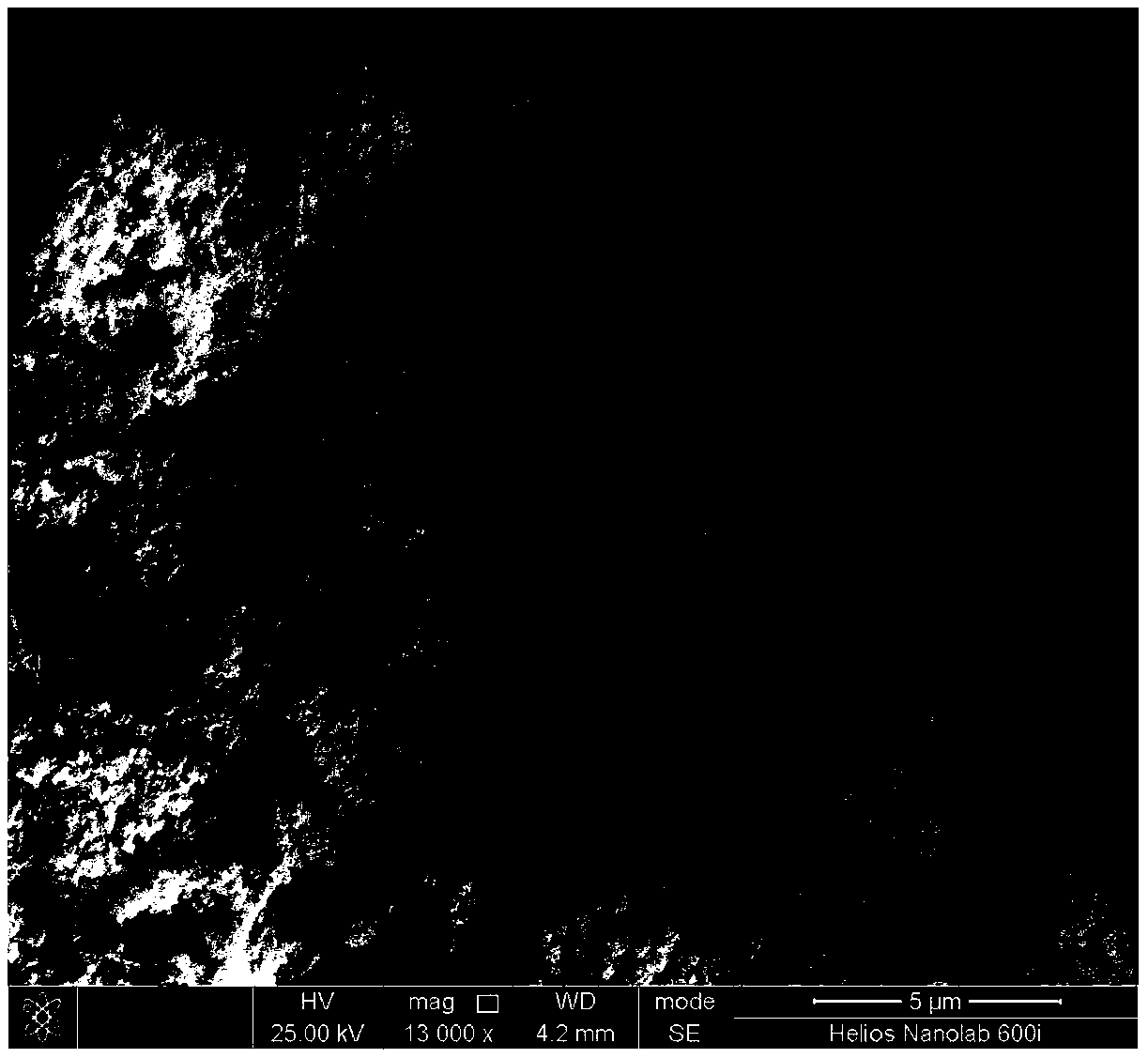

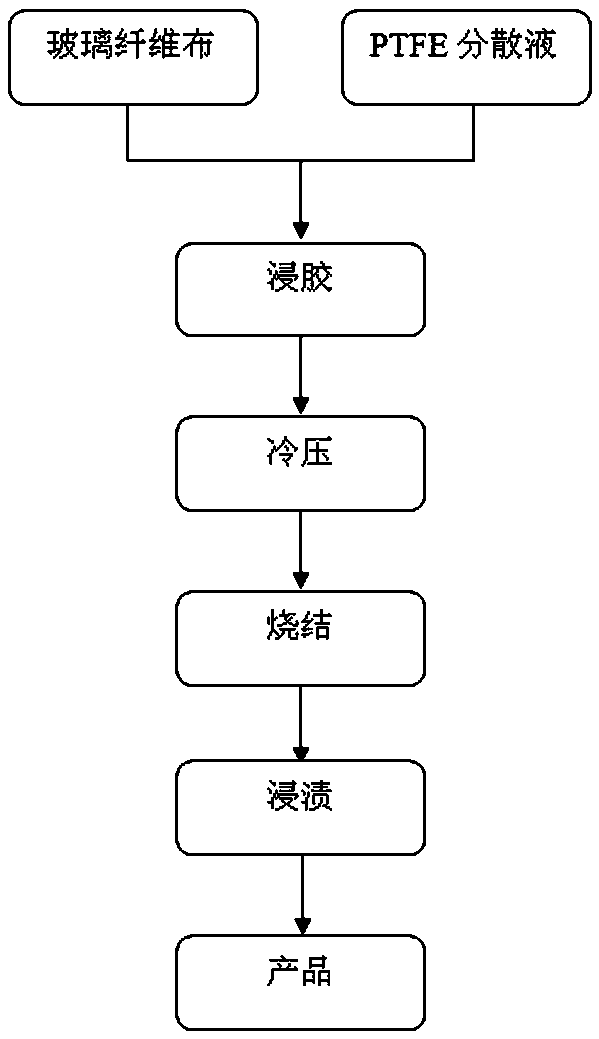

Preparation method and product of fiber reinforced fluororesin composite membrane material

ActiveCN109280302AImprove densification performanceImprove mechanical propertiesGlass fiberElectronic communication

The invention discloses a fiber reinforced fluororesin composite membrane material and a preparation method thereof. Polytetrafluoroethylene resin is selected as a main matrix material of the composite material, and a glass fiber cloth is selected as a reinforcing material. Surface modification is carried out on glass fibers by using a coupling agent, then immersion enhancing modification is carried out, and finally the composite material is obtained, wherein properties such as wear resistance, chemical resistance, tensile strength, water absorption rate, wave-transmitting performance and thelike of the obtained material are far superior to the properties of same-type membrane materials in China. Therefore, the composite membrane material provided by the invention has a wide application prospect in the fields of electronic communication, aerospace, military radars and the like.

Owner:ZHENGZHOU UNIV

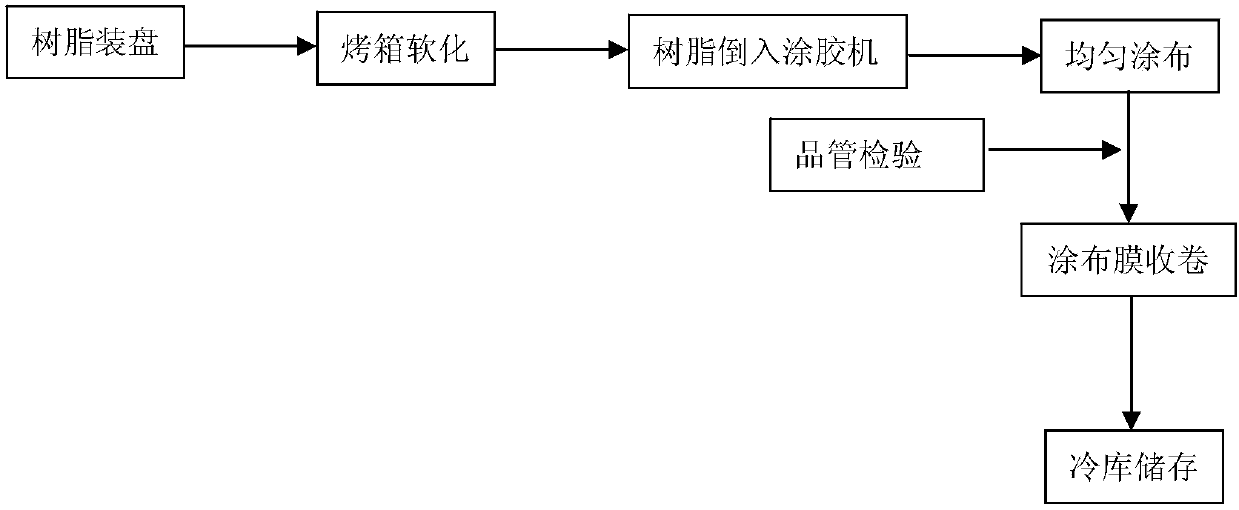

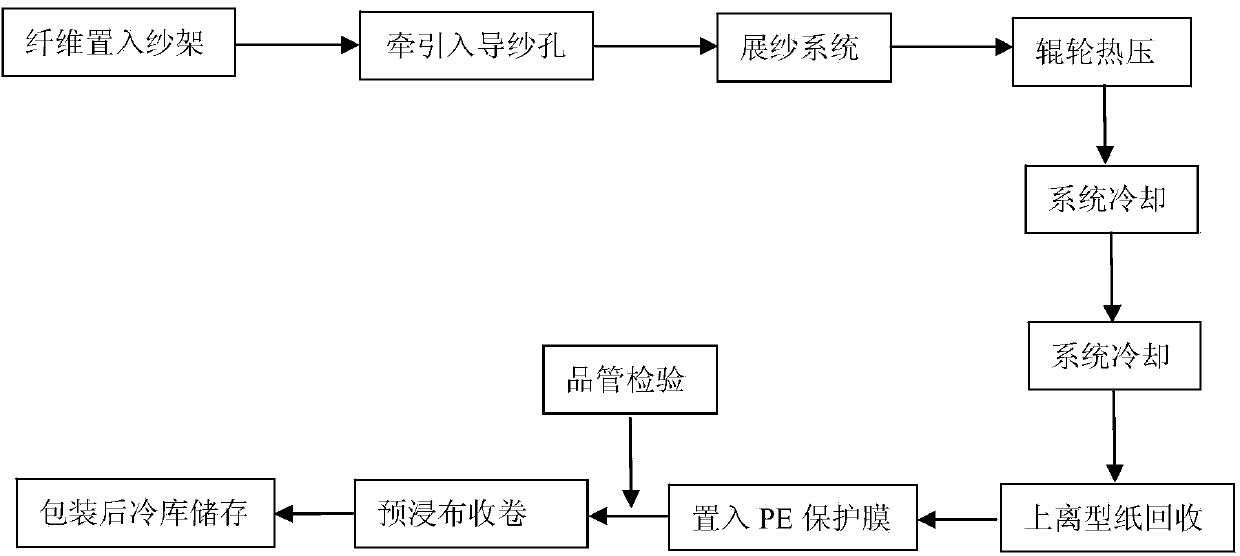

Basalt fiber prepreg and preparation method thereof

The invention discloses a basalt fiber prepreg comprising basalt fiber, epoxy resin and release paper, wherein the epoxy resin is soaked into a basalt fiber layer; and the release paper is directly attached to the outer surface of the basalt fiber layer. In addition, the invention discloses a two-step hot melting preparation method of the basalt fiber prepreg, and the preparation method comprises the steps of film preparation and presoaking. The method disclosed by the invention is simple, and the prepared basalt fiber prepreg is favorably applied to the market field of composite materials such as plates, fishing poles and profiled bars. The basalt fiber and a product thereof have abnormally excellent performances on the following aspects of remarkable high temperature resistance and thermal shock resistance, relatively low heat conduction coefficient, high elasticity modulus and tensile strength, good chemical stability, relatively high sound absorption coefficient, favorable electric insulation and dielectric properties, relatively low moisture absorptivity and natural silicate intermiscibility.

Owner:SUZHOU SUYUE NEW MATERIAL

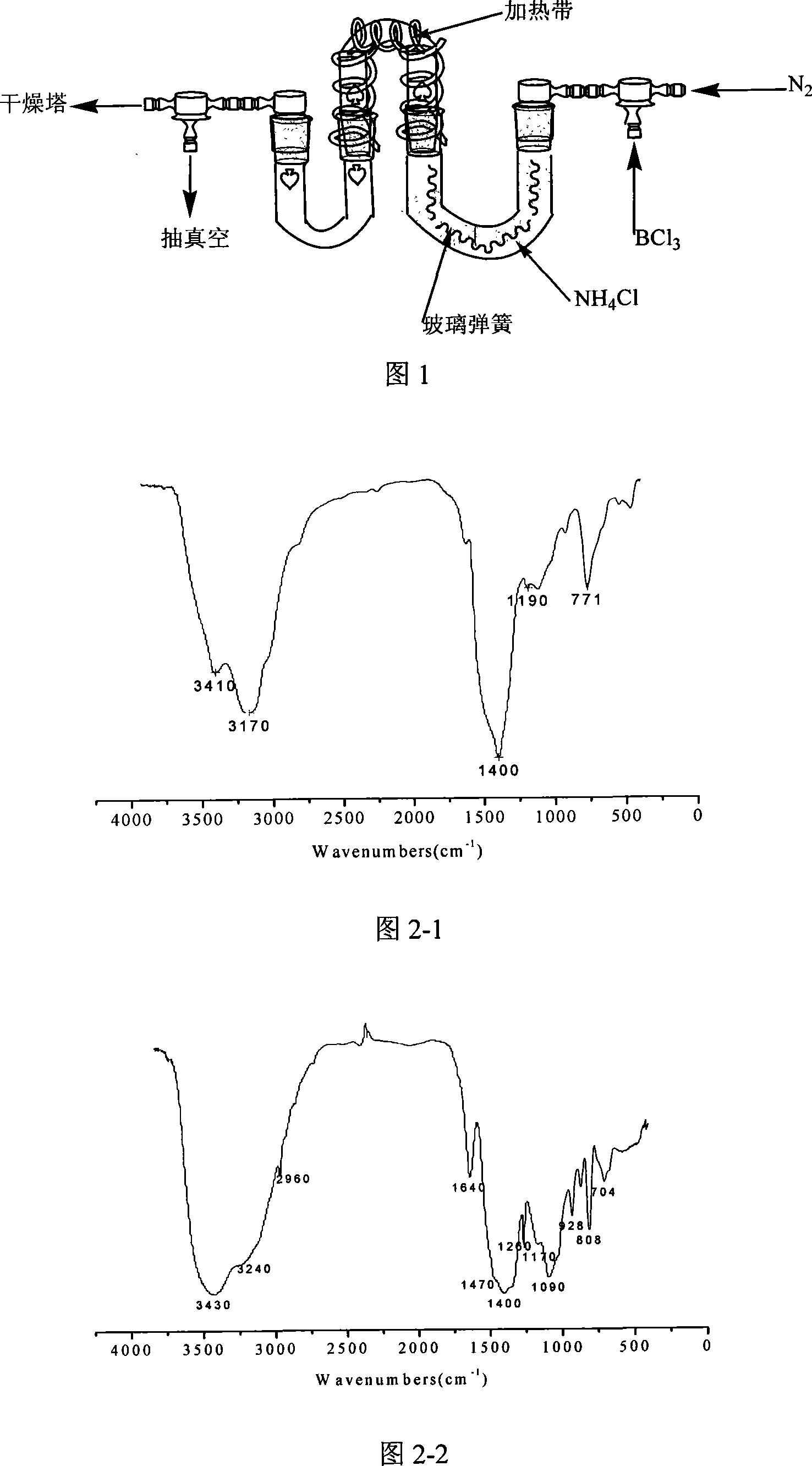

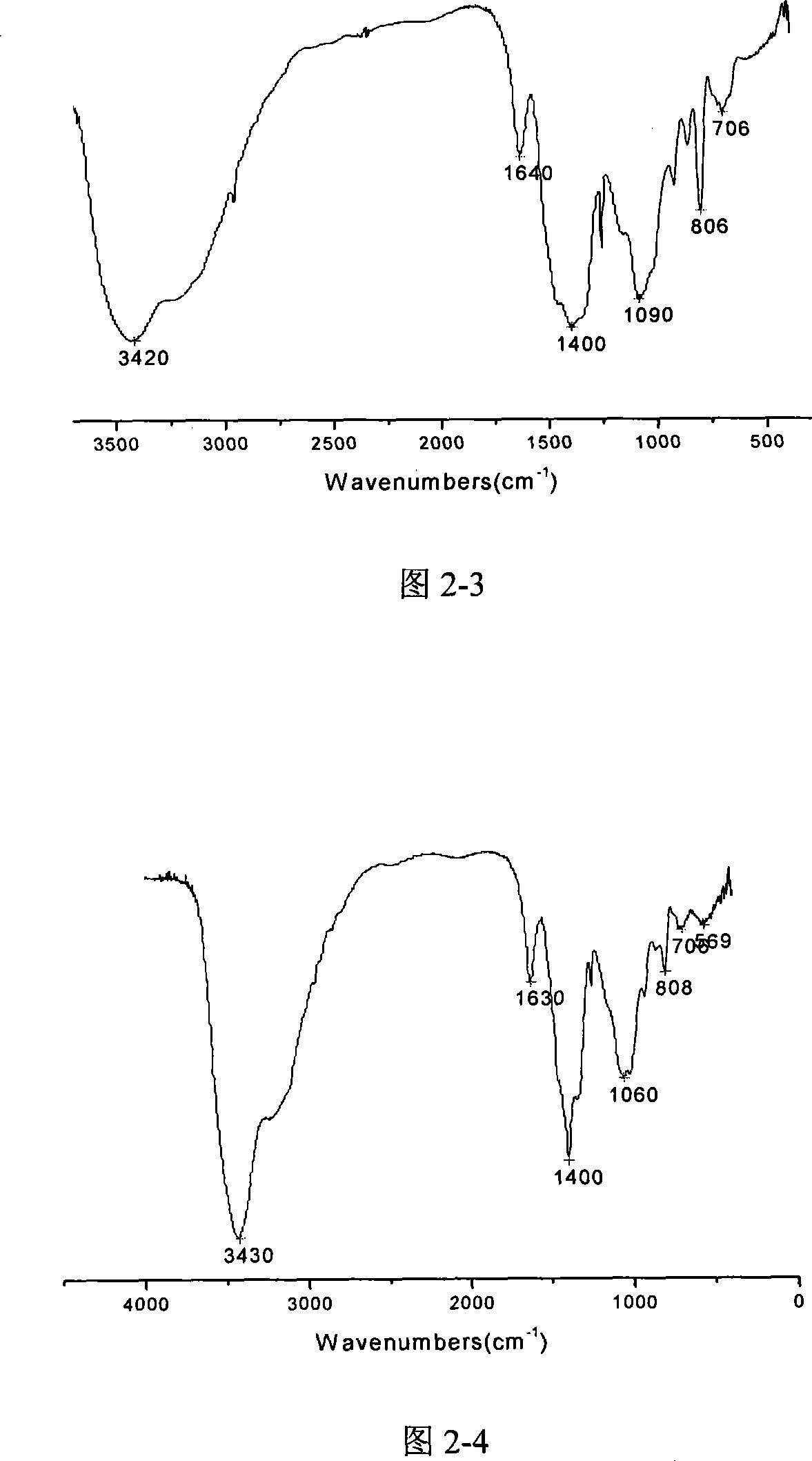

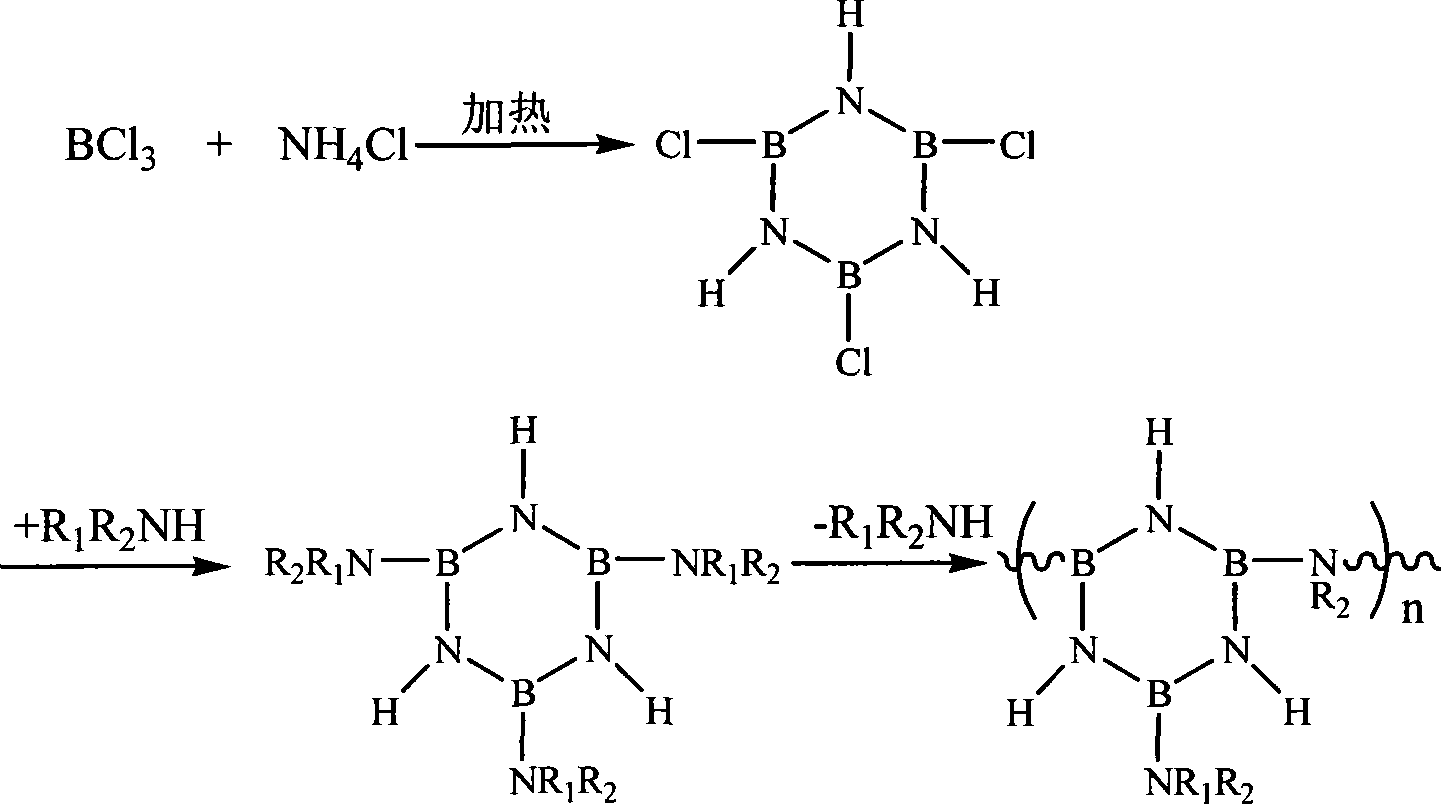

Method for producing boron-nitrogen ceramic fibre fore-runner body

The invention relates to a preparation method of a boron nitrogen ceramic fiber precursor. The method synthesizes a trichloroborazine crystal through a high-temperature reaction of boron trichloride and ammonium chloride, and the product is mixed with an aliphatic compound containing an amino or imine group. The alkylamine is reacted at low temperature, then raised to room temperature for reaction, and then heated to 130°C to 250°C for reaction to obtain a precursor polymer. The precursor has good spinnability, and the pyrolysis product contains very little carbon element, which can make the final boron nitrogen fiber have good wave permeability.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com