Preparation method for composite material antenna cover with thin-wall foam sandwich structure

A technology of composite materials and sandwich structures, applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as inability to process and difficult processing of thin-walled foam sandwiches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

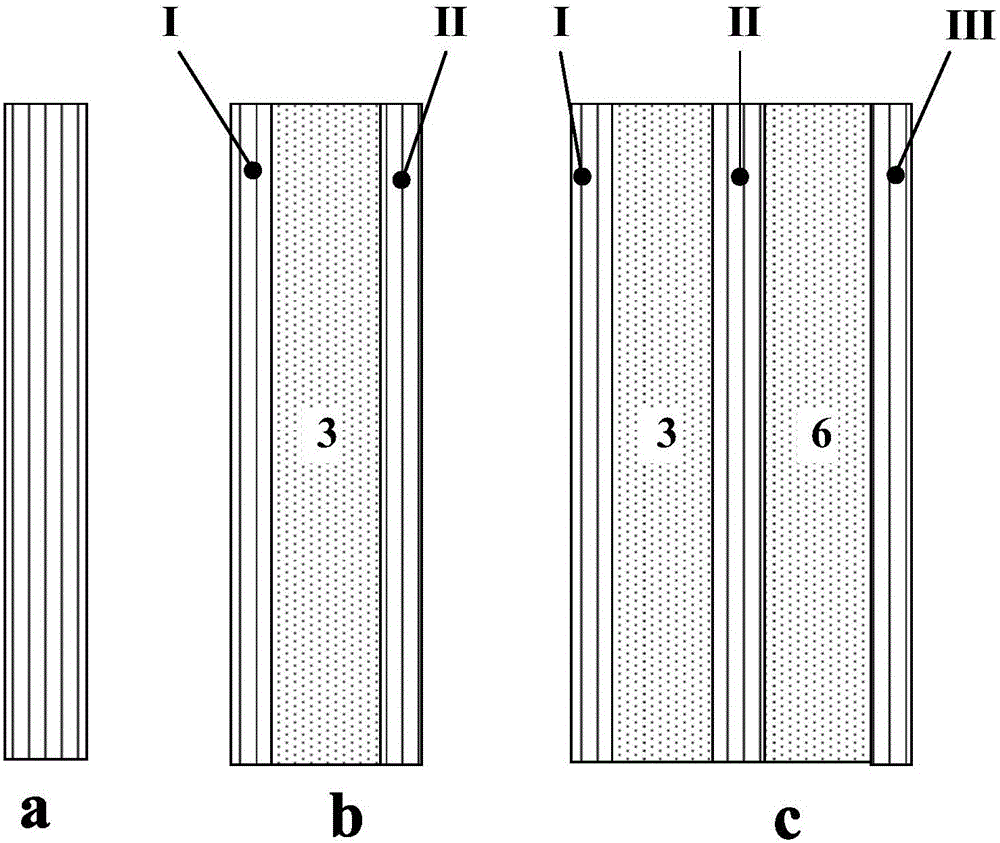

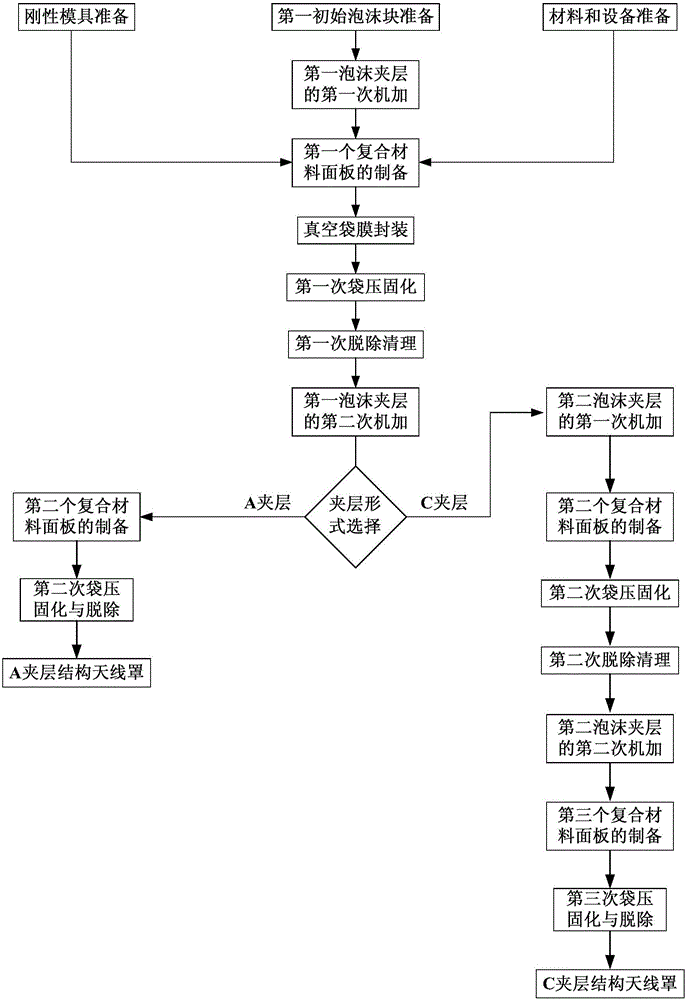

[0071] Example 1 Thin-wall foam A sandwich structure composite material radome with typical thickness 5mm

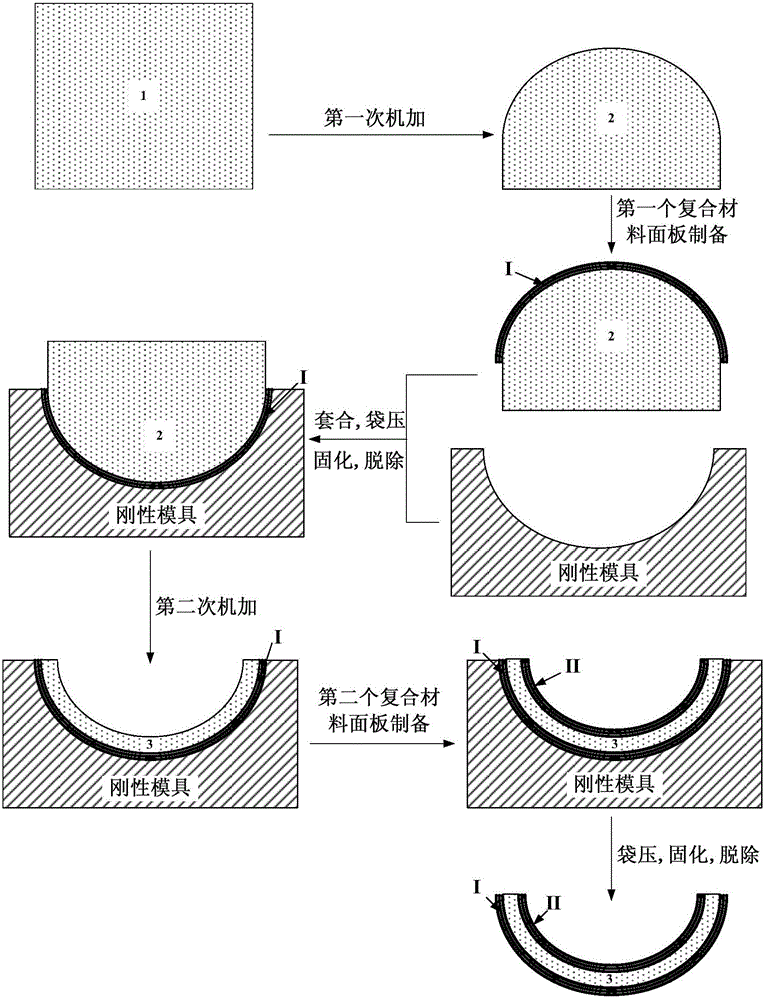

[0072] The first step, rigid mold preparation

[0073] Use 45 # The steel is processed to form the male mold for the radome product. The working surface of the male mold forms the corresponding internal cavity of the radome. The positioning and tool setting benchmarks of the foam interlayer are reserved on the base of the male mold for the second machining overtime.

[0074] Carry out surface grinding, cleaning and coating release agent treatment to male mold, set aside.

[0075] The second step, materials and equipment preparation

[0076] According to the technical requirements of the composite material radome, the S glass fiber fabric (reinforcing material) used for the composite material panel is cut into squares, and dried in an oven for later use; the impregnated liquid epoxy resin and curing agent are vacuum dehydrated and dried, spare. At the same time, pre...

Embodiment 2

[0099] Example 2 A typical thickness of 10mm, a thin-walled foam C sandwich structure radome with locally variable thickness

[0100] The first step, rigid mold preparation

[0101] Use 45 # The steel is processed to form the female mold for the radome product. The working surface of the concave cavity of the female mold corresponds to the outer wall structure of the formed radome. Positioning and tool setting references are reserved on the base of the female mold.

[0102] The molded female mold is surface polished, cleaned and coated with a release agent, and is ready for use.

[0103] The second step, materials and equipment preparation

[0104] According to the technical requirements of the composite radome, the quartz glass fiber fabric (reinforcing material) used for the composite panel is cut into pieces and dried in an oven for later use; the impregnated liquid vinyl resin and curing agent are vacuum dehydrated and dried for later use . At the same time, prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com