Patents

Literature

60results about How to "Good surface fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

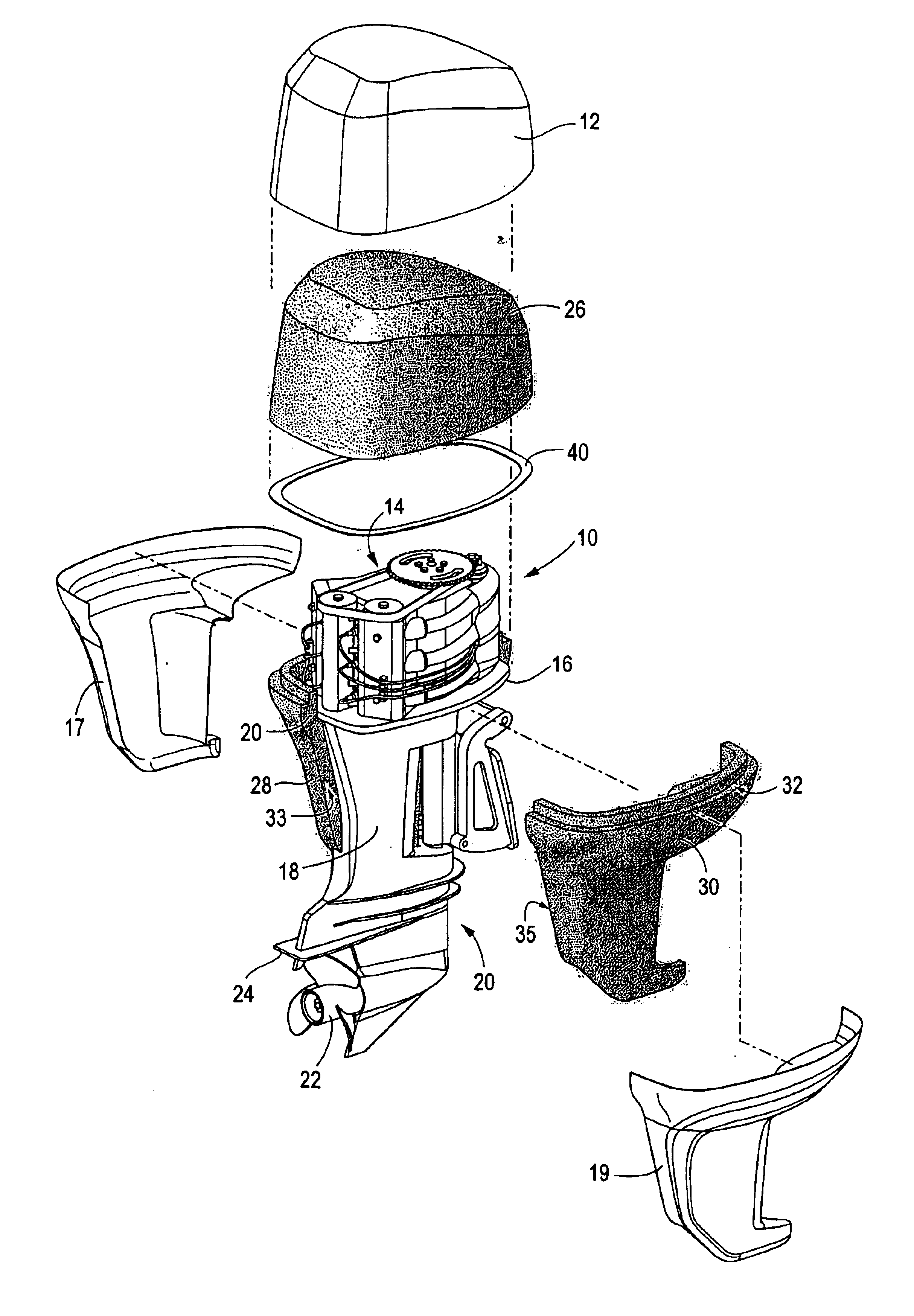

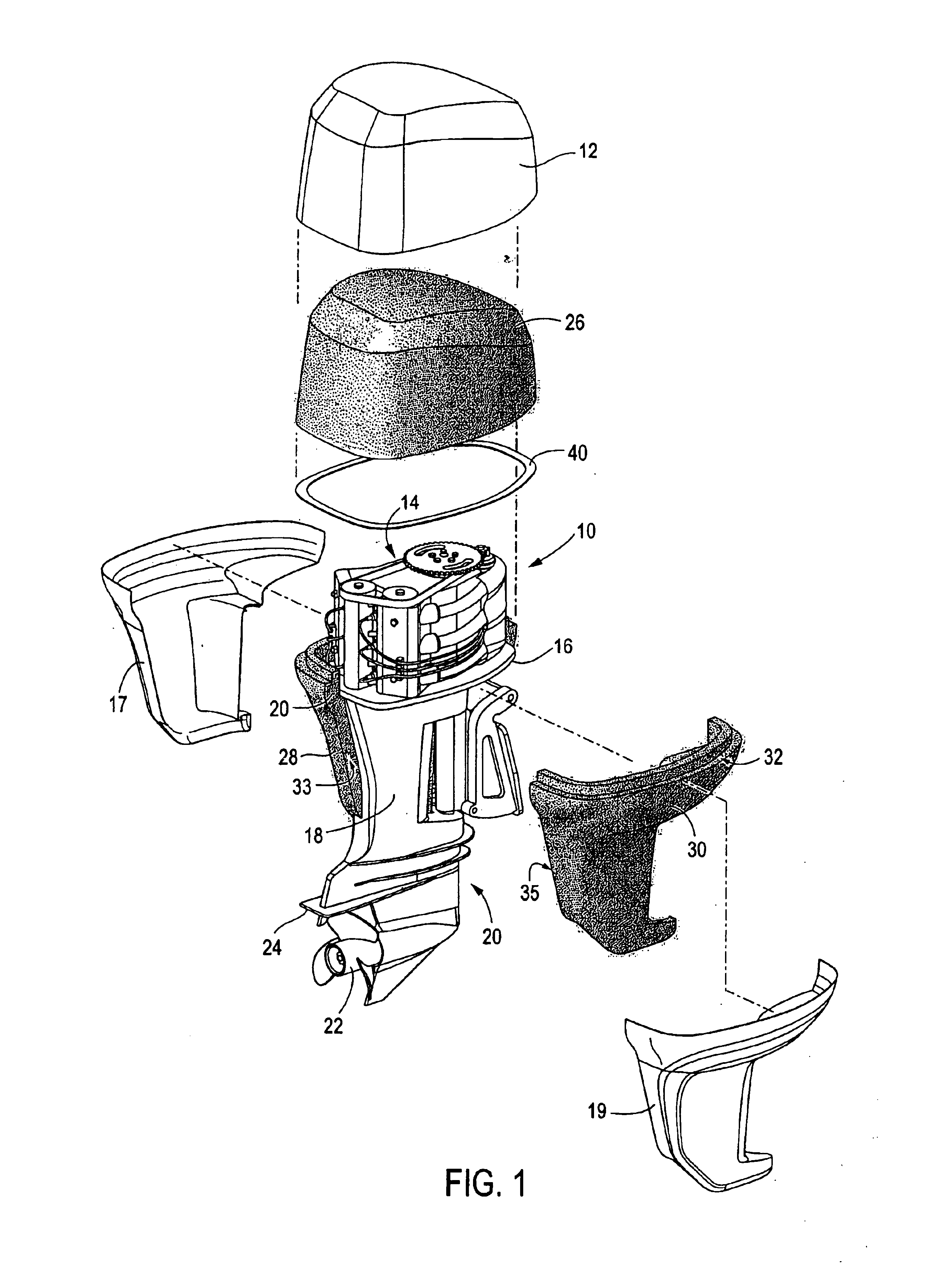

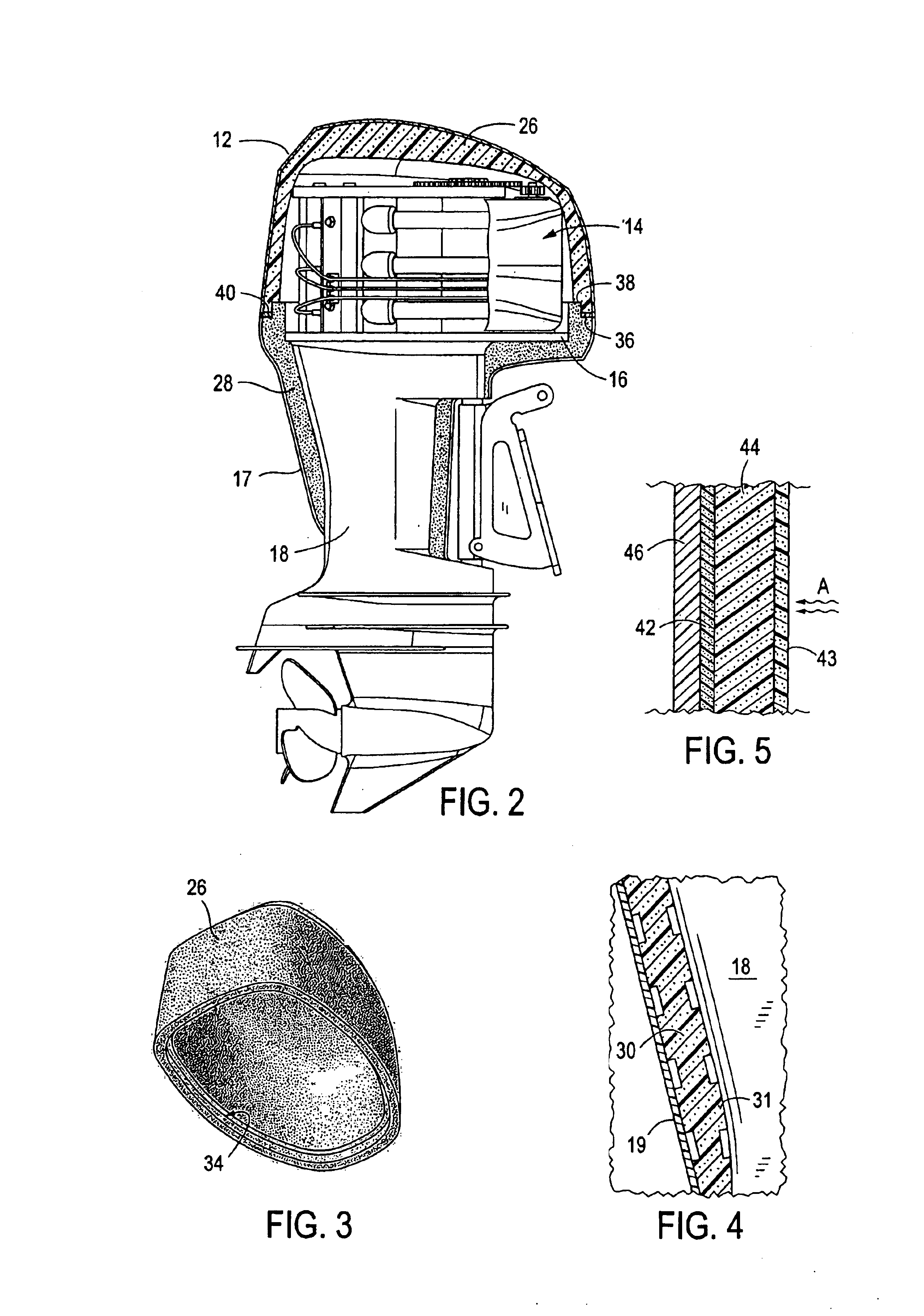

Sound insulation for outboard motors

InactiveUS6875066B2Reduce decreaseGood surface fitExhaust apparatusPropulsion power plantsPulp and paper industrySurface matching

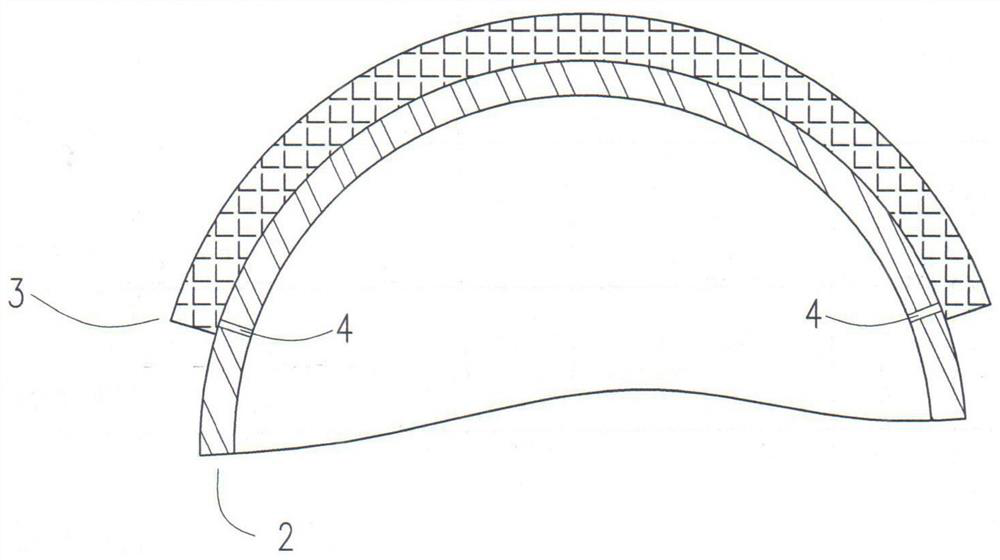

Sound insulation for an engine contained within an outer casing, the insulation made up from a minimal number of interlocking molded foam insulation pieces forming a substantially continuous shroud surrounding the operating parts of the engine and having an outer surface matching the inner shape of the outer casing and in contact therewith. Preferably the outer casing is used to generate the molds used to manufacture the molded sound insulation pieces, thereby providing a good surface fit between the outer insulation surface and the inner casing surface.

Owner:POLYMER TECH CORP

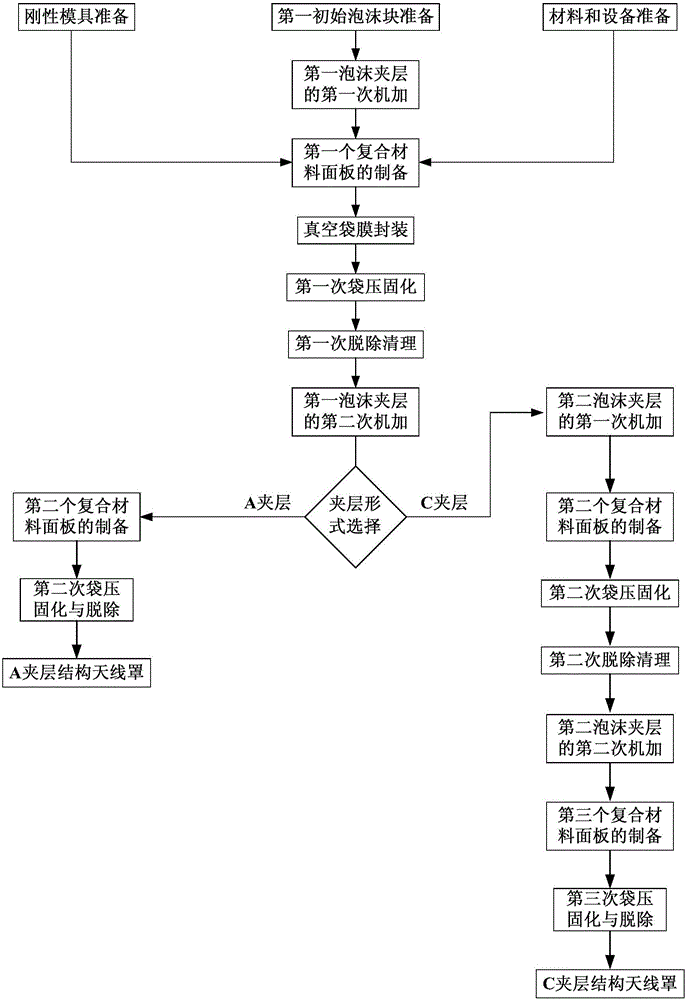

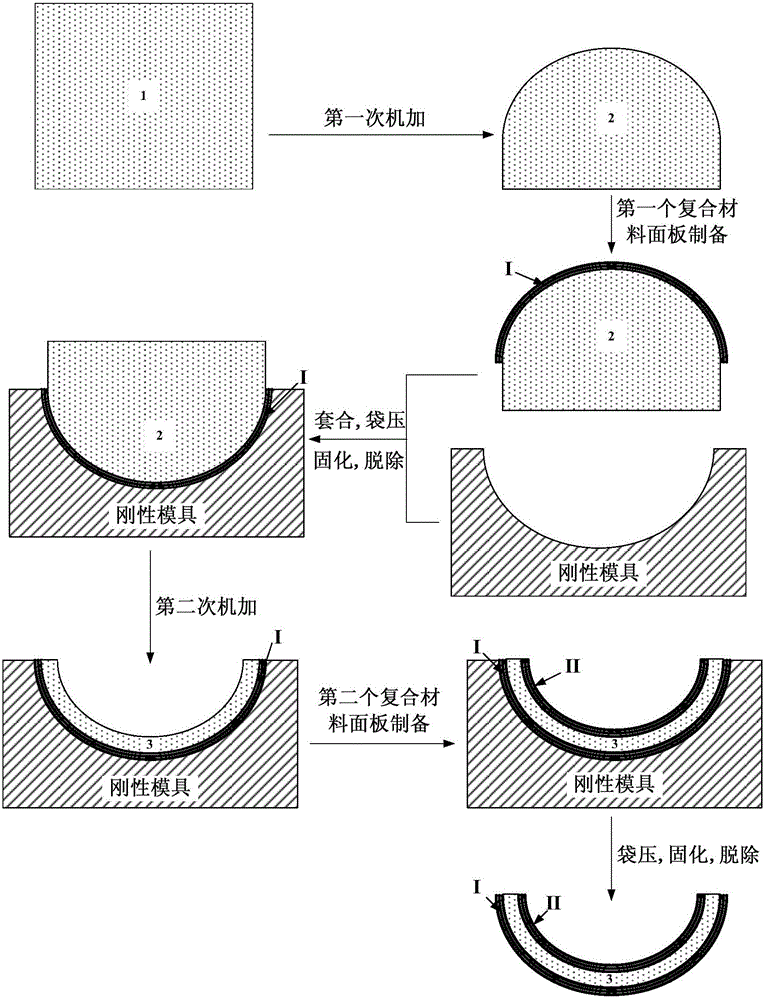

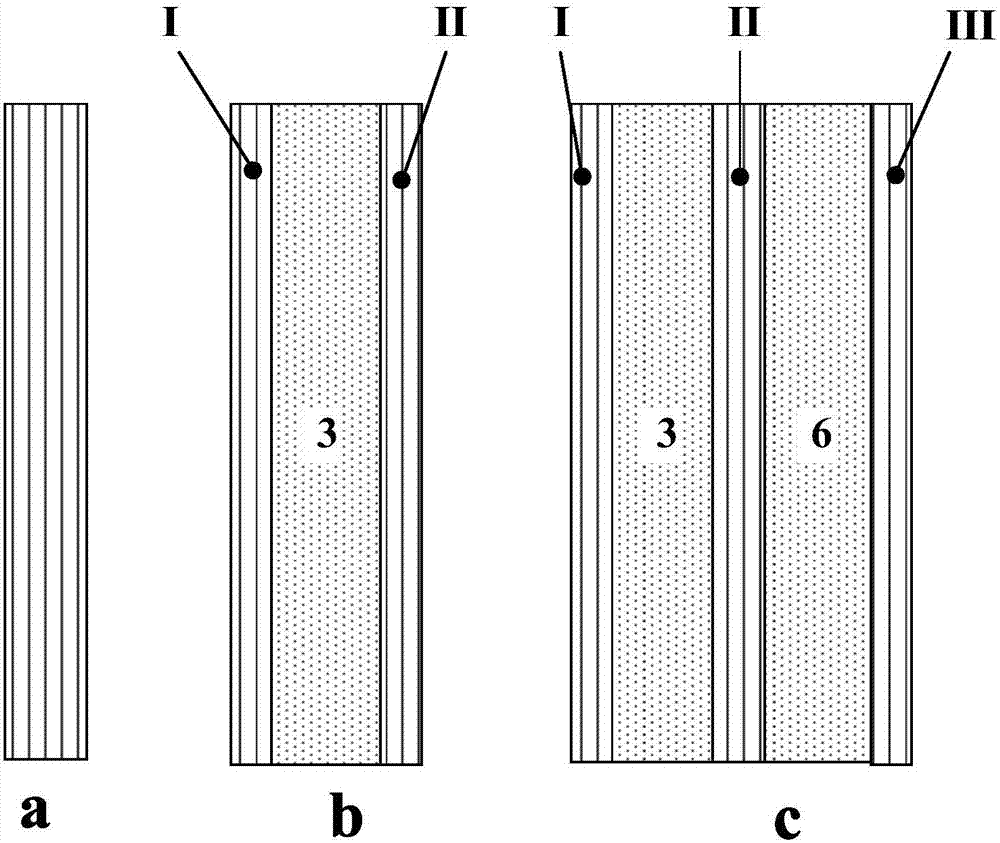

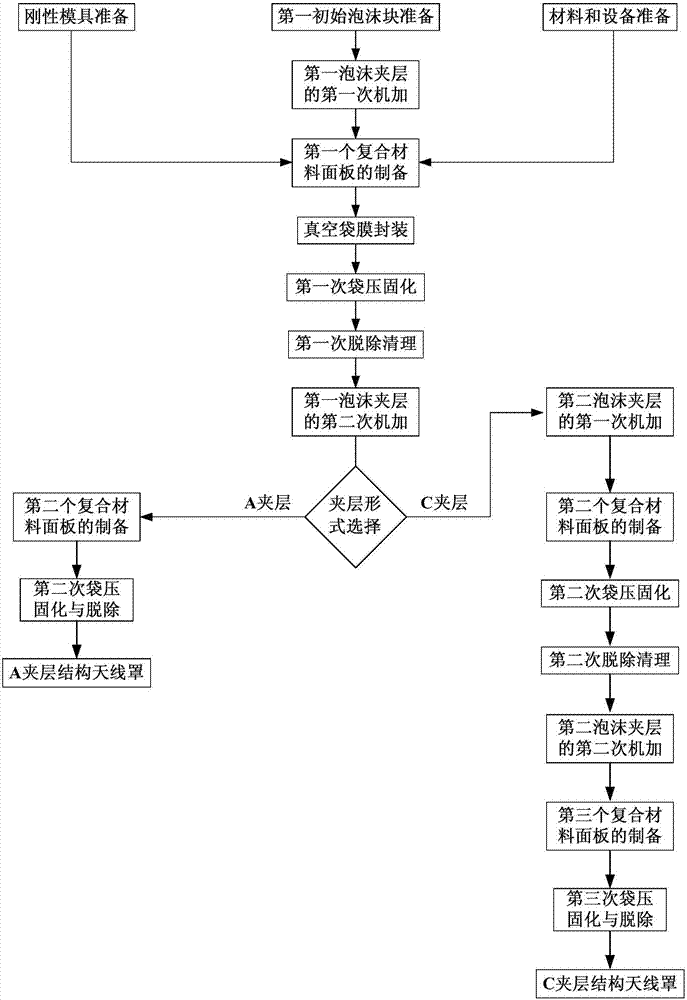

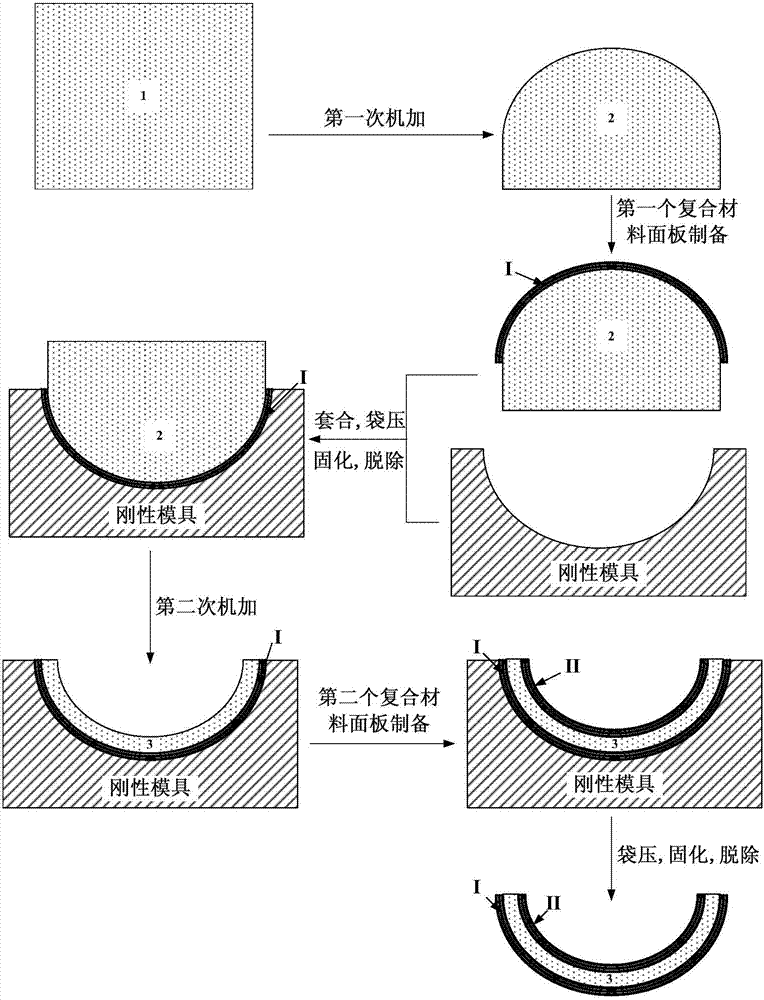

Preparation method for composite material antenna cover with thin-wall foam sandwich structure

ActiveCN105922703AGood wave permeabilityAvoid Bonding InsufficiencyLamination ancillary operationsLaminationThin walledSurface plate

The invention discloses a preparation method for a composite material antenna cover with a thin-wall foam sandwich structure. The invention aims to solve the problem of difficult processing or incapable processing for a thin-wall foam sandwich layer in the process of preparation of an antenna cover with a sandwich structure. According to a technical scheme of the invention, processing of the entire body of the thin-wall foam sandwich layer comprises two steps: performing primary processing, namely subjecting an initial foam block to single-face mechanical processing; and performing secondary processing after subjecting the single-face mechanically processed foam block to reinforcing and rigidity increasing, i.e., subjecting the rest of faces of the thin-wall sandwich layer to processing on a combination of a rigid mold, a composite material panel and the single-face mechanically processed foam block so as to prepare the thin-wall foam sandwich layer meeting the technical requirements of a target antenna cover. In addition, through resin impregnation with fabrics and a vacuum bag molding technique, preparation of the composite material panel and bonding of the panel with the foam sandwich layer in the target antenna cover are realized. By adopting the preparation method provided by the invention, the difficulty of preparation of the thin-wall foam sandwich layer through processing of the entire body of the initial foam block is overcome; the molding process of the antenna cover is simple; and the prepared antenna cover has the advantages of few defects, light weight and good wave permeability.

Owner:NAT UNIV OF DEFENSE TECH

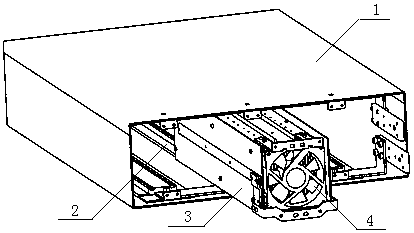

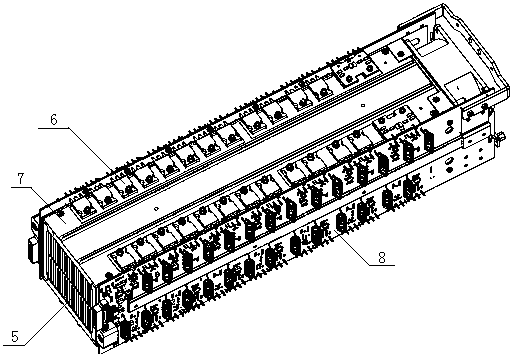

Electronic load testing device

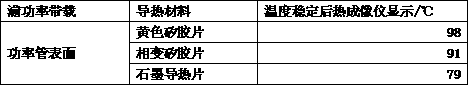

PendingCN108387803AReduce volumeImprove thermal conductivityElectrical testingElectricityElectronic load

The invention provides an electronic load testing device. The device includes a housing and one or more power modules, one or more parallelly arranged electric insulation guide rails, the power modules are arranged in the housing through the electric insulation guide rails in electric insulation from the housing in a drawing and inserting mode, each power module includes a PCB, power devices, a graphite flake and a radiator, the radiator arranged to be a positive electrode and a negative electrode on the PCB are connected to a test input end of the electronic load testing device separately, the power devices and the graphite flake are mounted on the radiator in an attached mode, negative ends of the power devices are electrically connected to the PCB, and positive ends of the power devicesare electrically connected to the radiator through the graphite flake. Electrical connection is realized, power density is increased, heat emission is reduced, heat dissipation is enhanced and the volume of the radiator is reduced; and at the same time, relatively good adhesion property is achieved, electrical conductivity is improved, large-area electrical connection between power tubes and theradiator can be realized, the welding of a pin is omitted, and the large-cross section radiator is used as a lead, thereby reducing conventional lead heat emission of whole machine heat emission.

Owner:ILD ELECTRONICS CO LTD

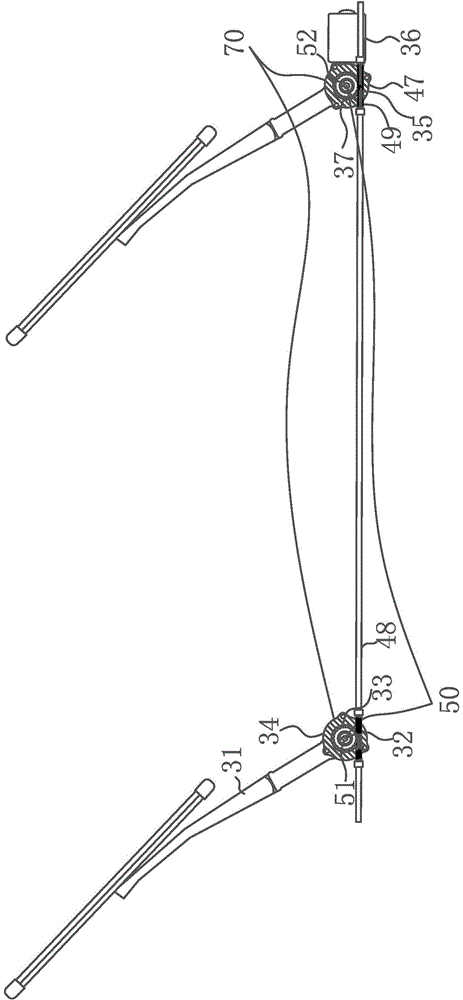

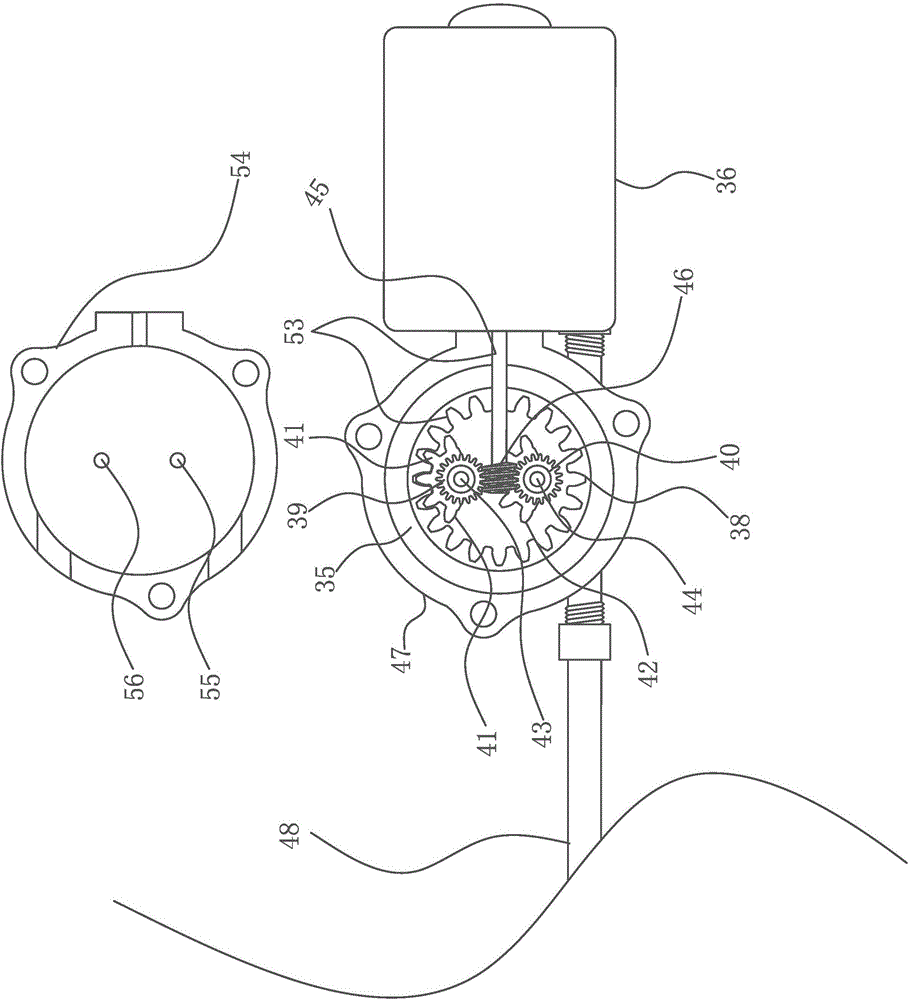

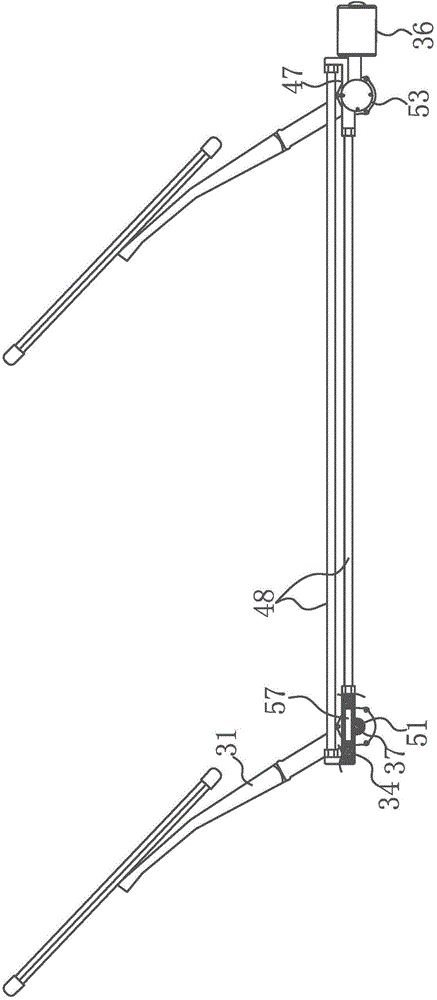

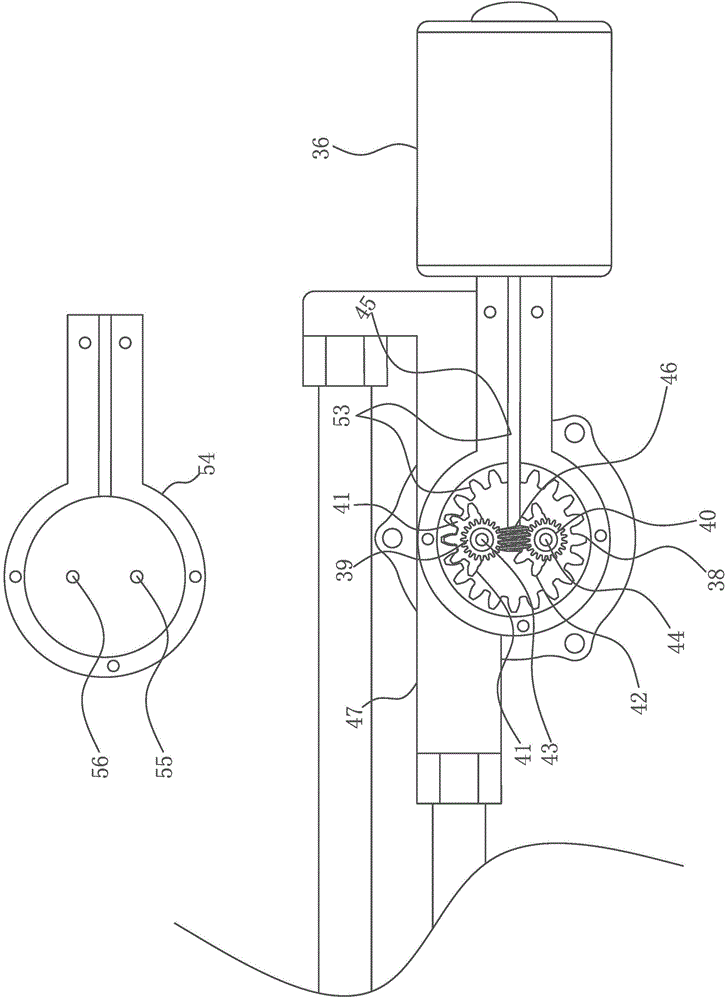

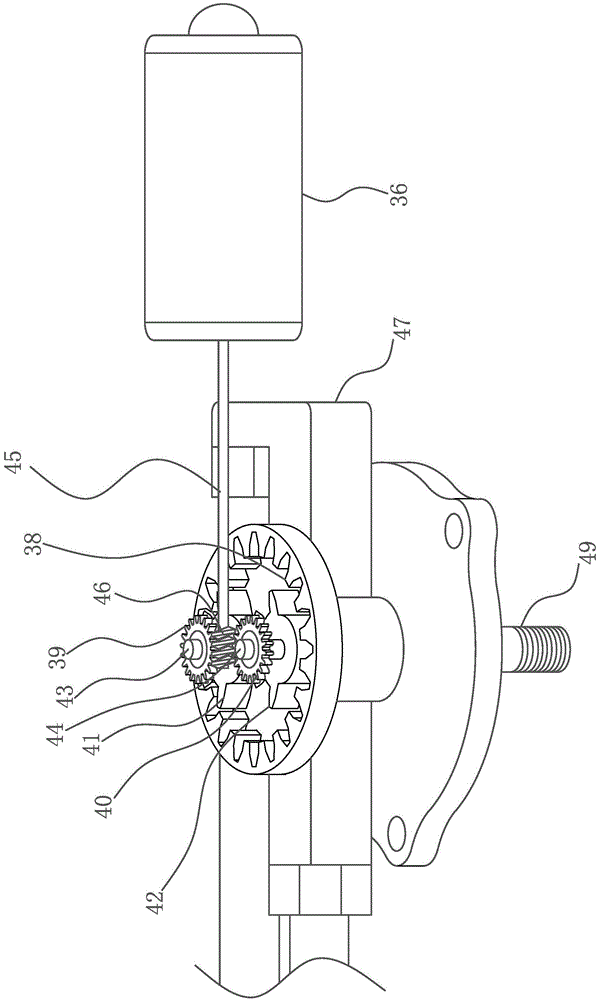

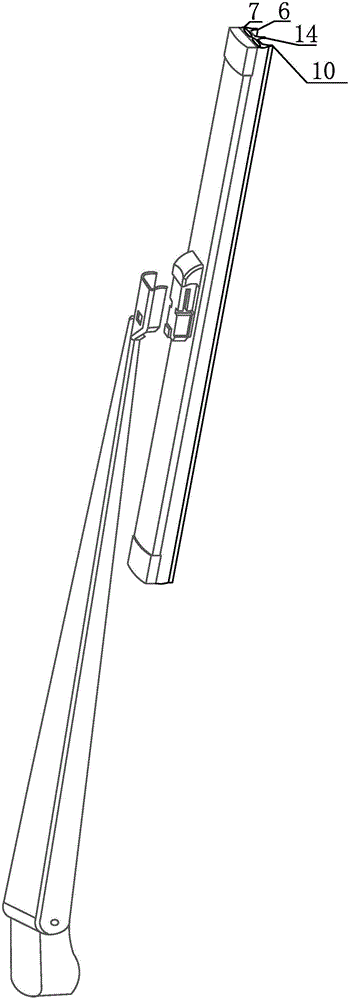

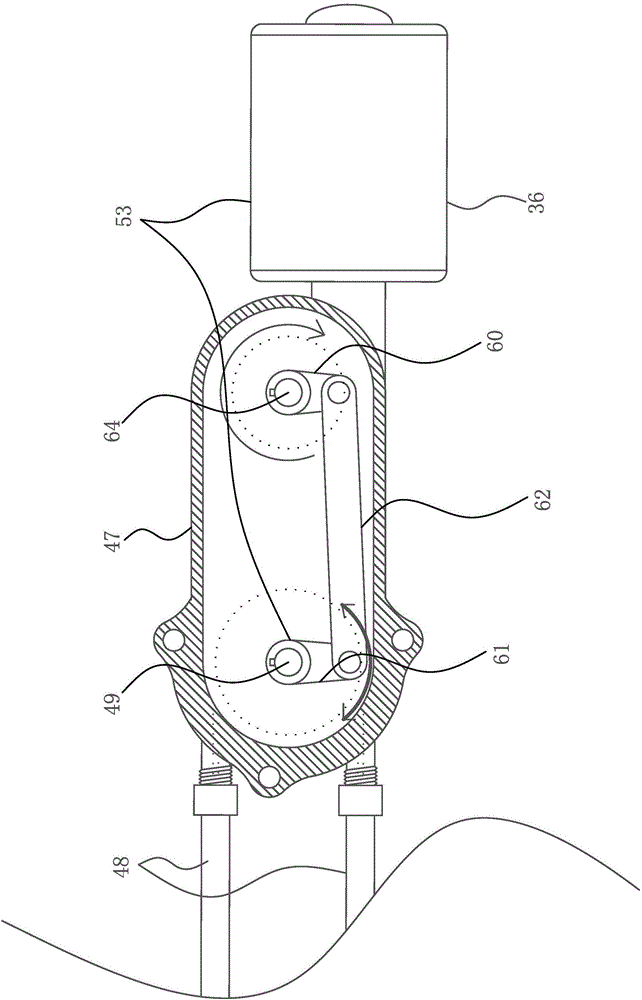

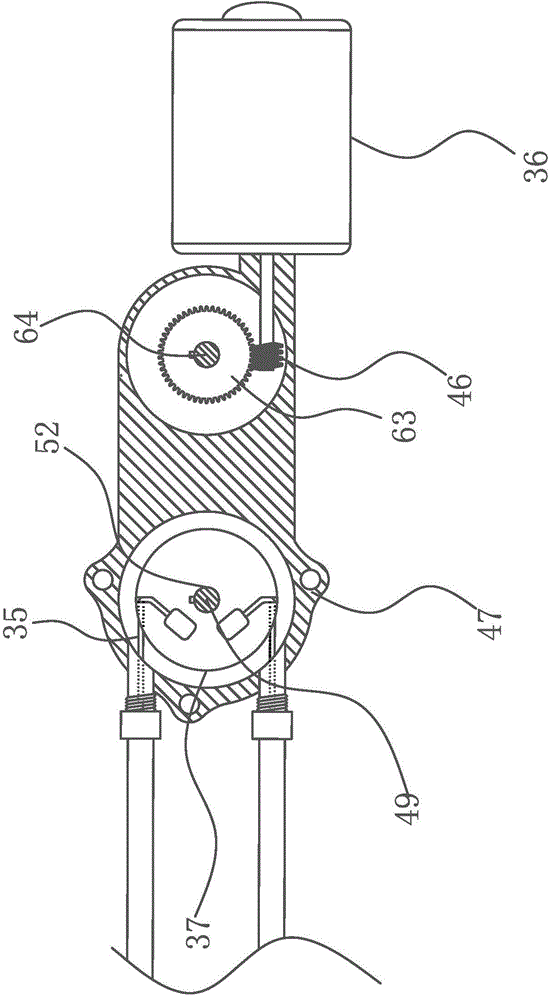

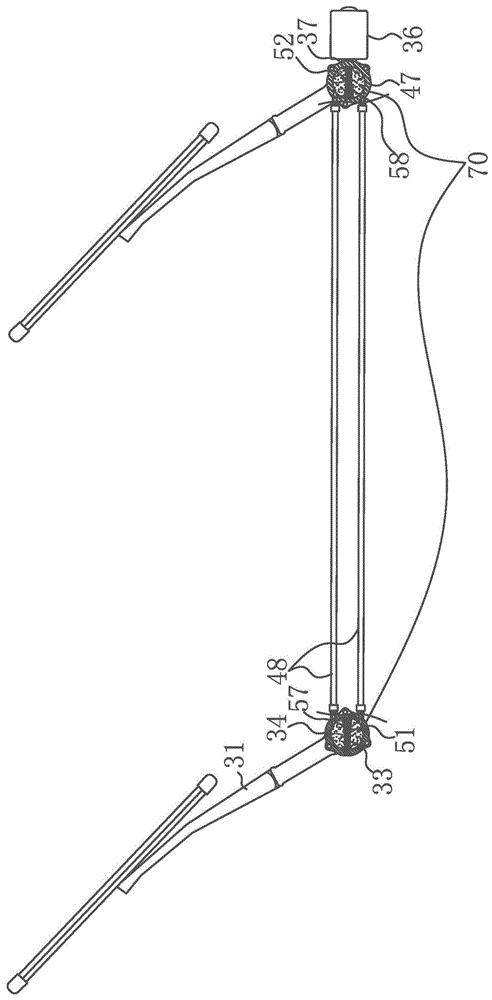

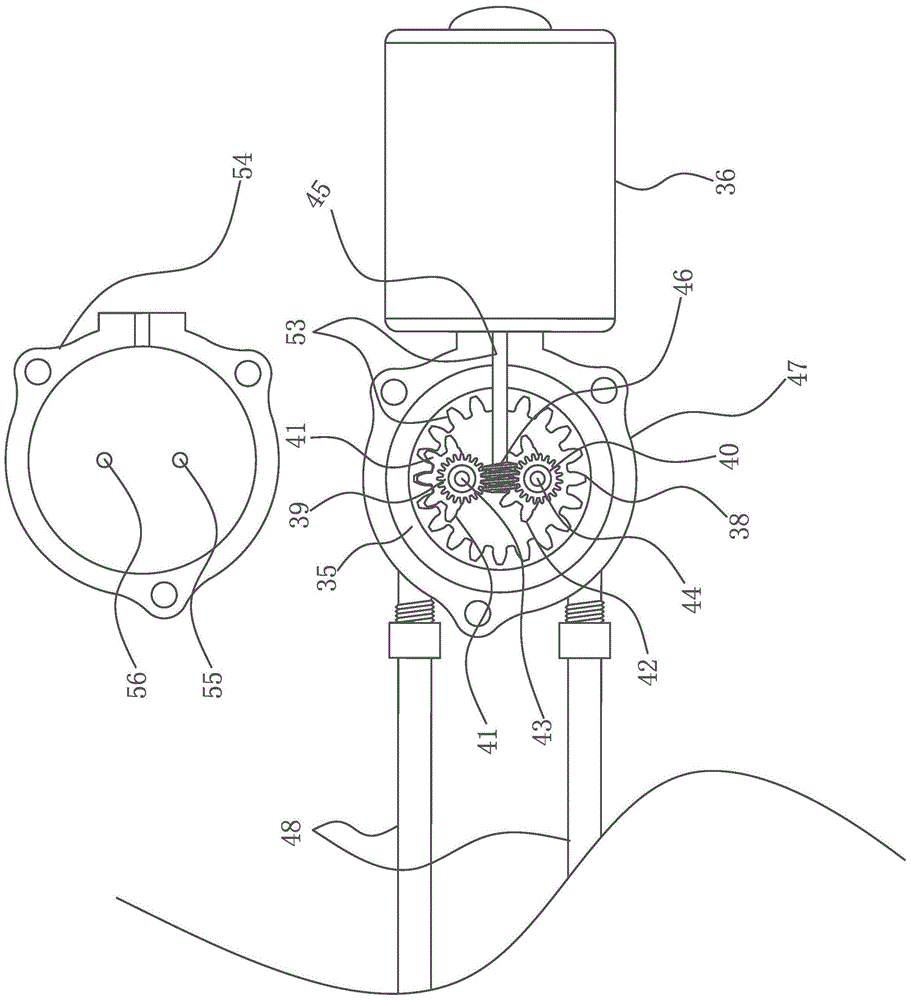

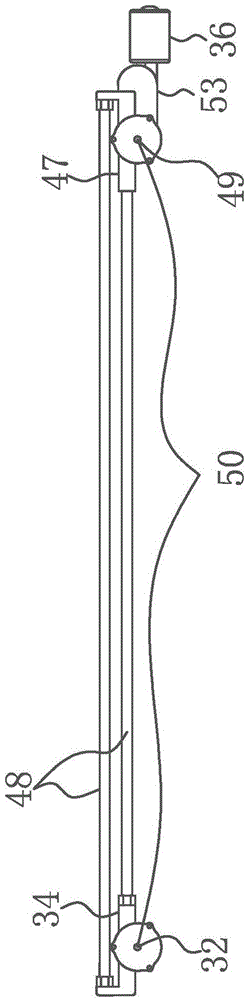

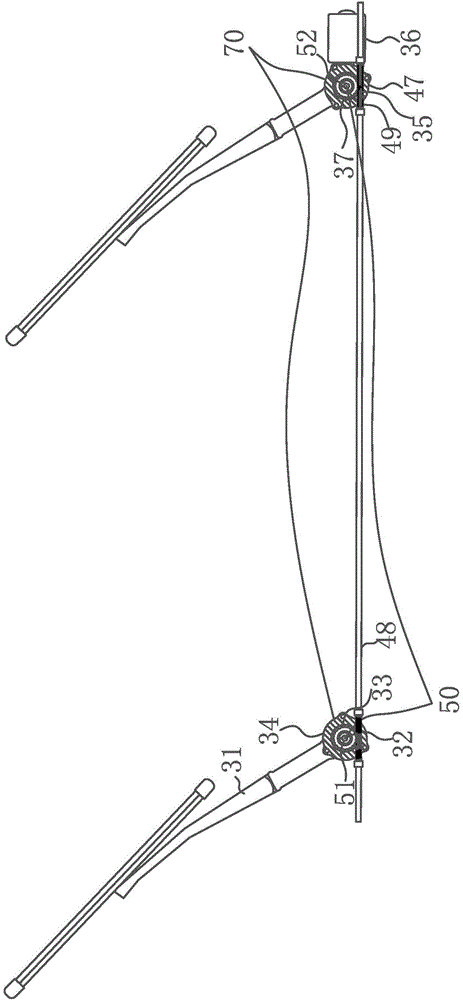

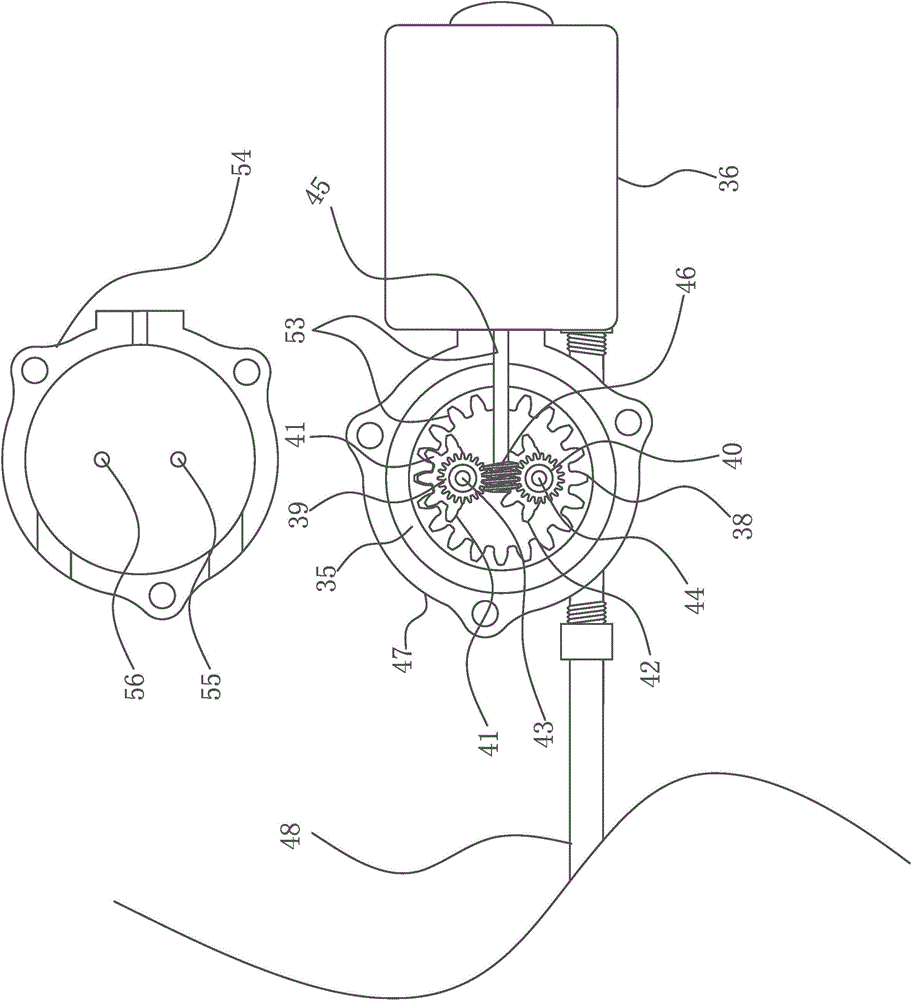

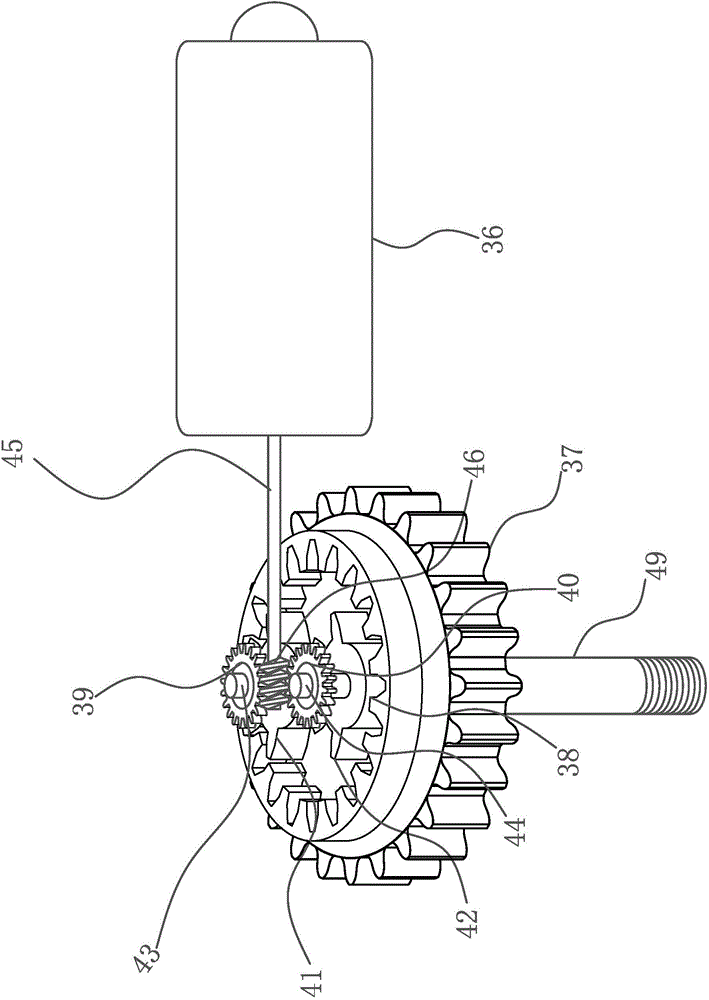

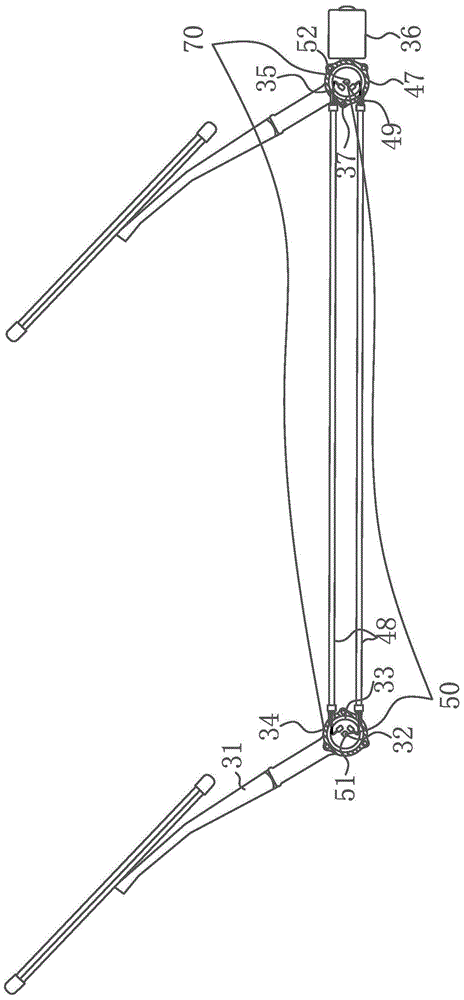

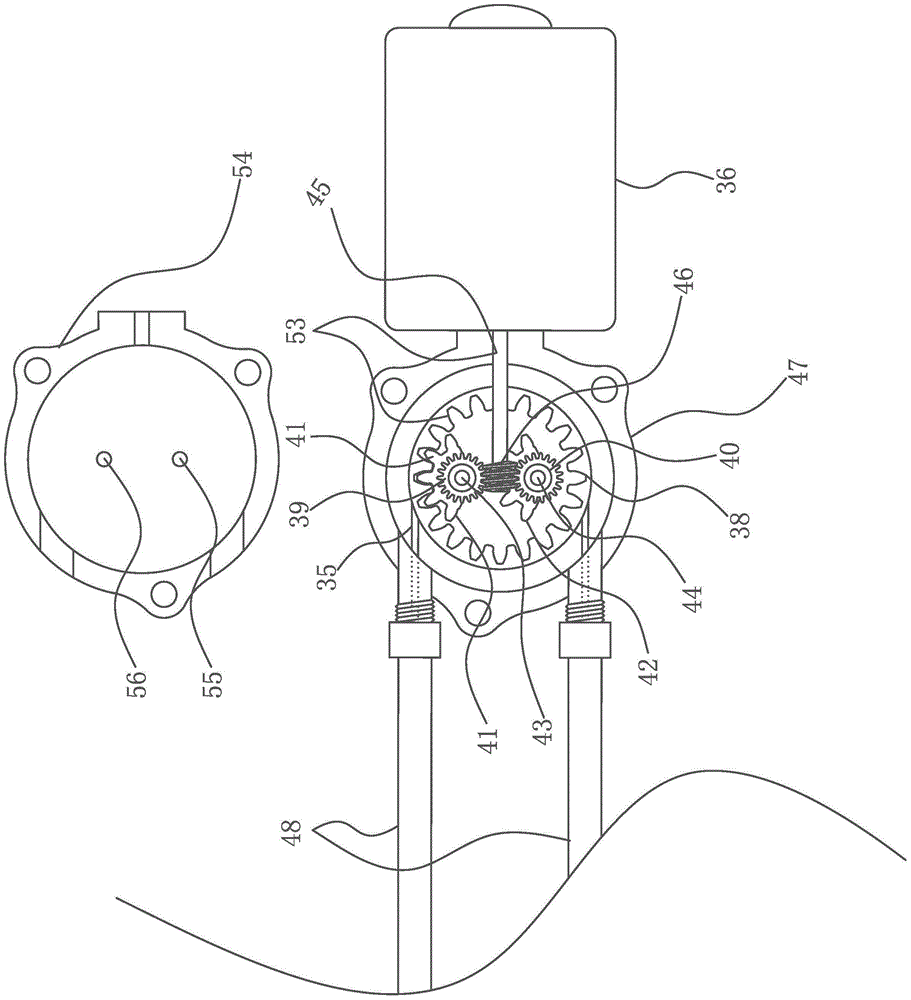

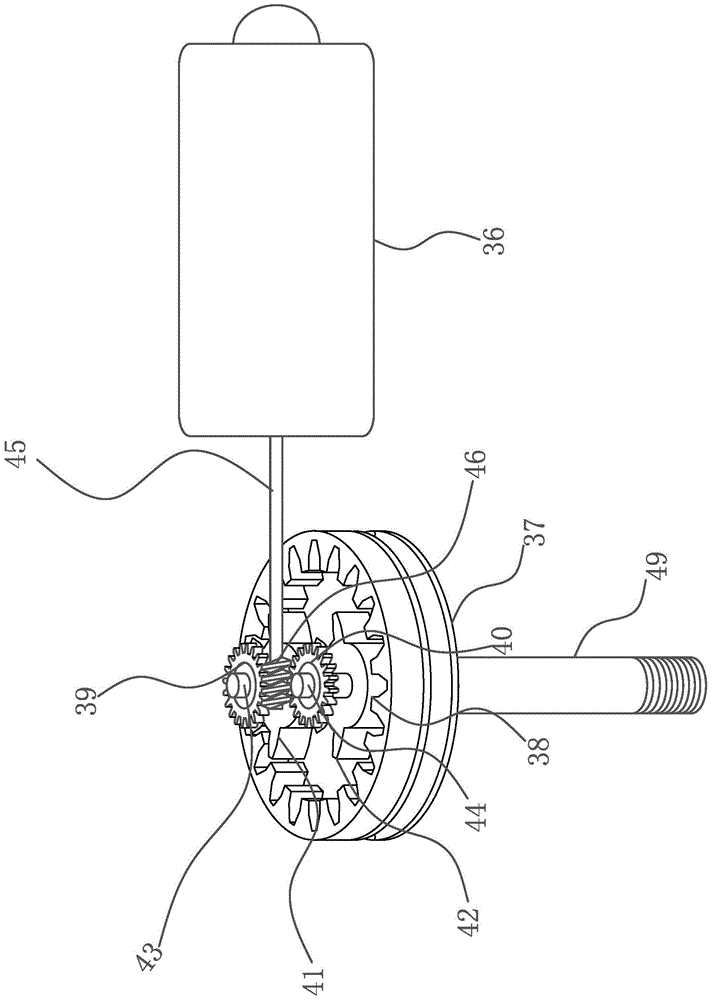

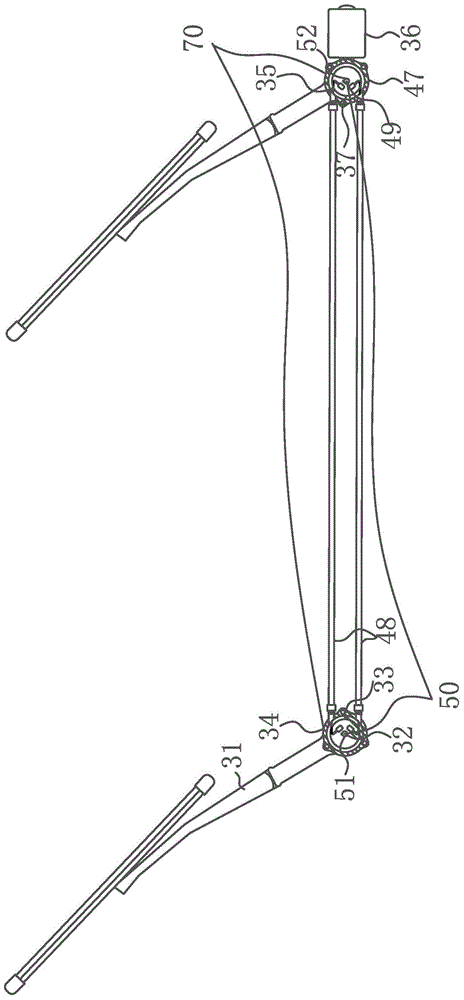

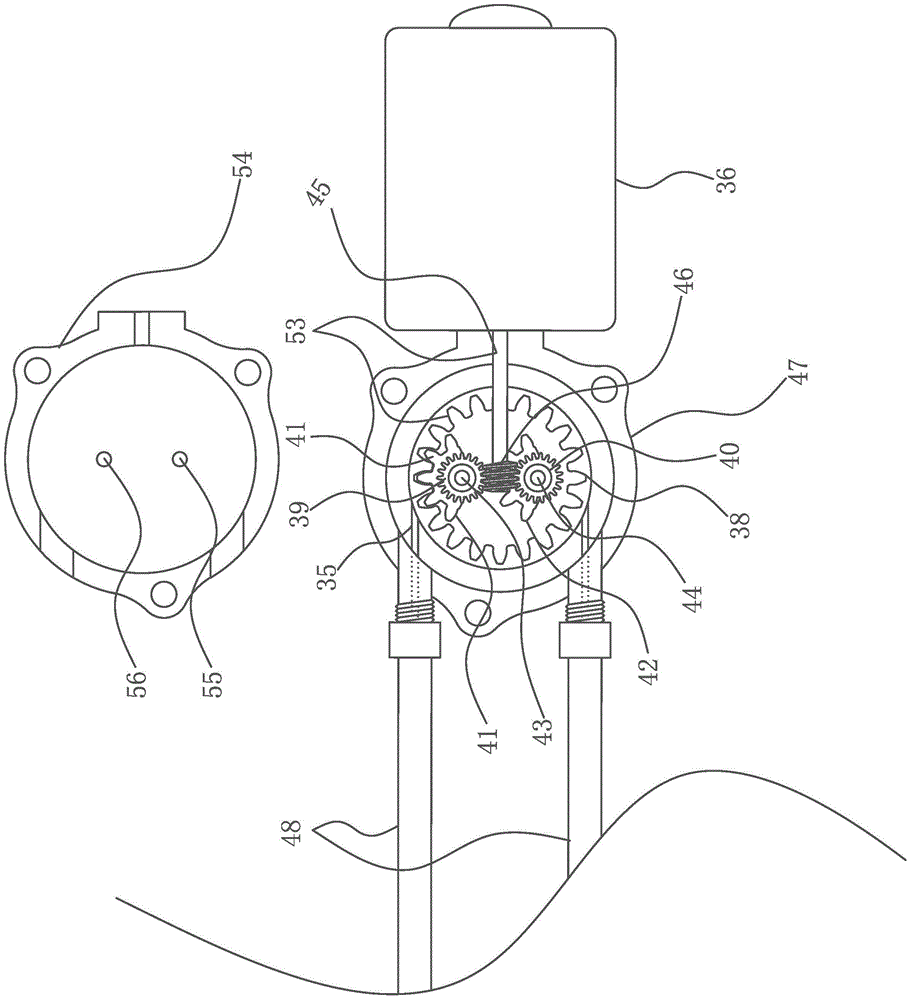

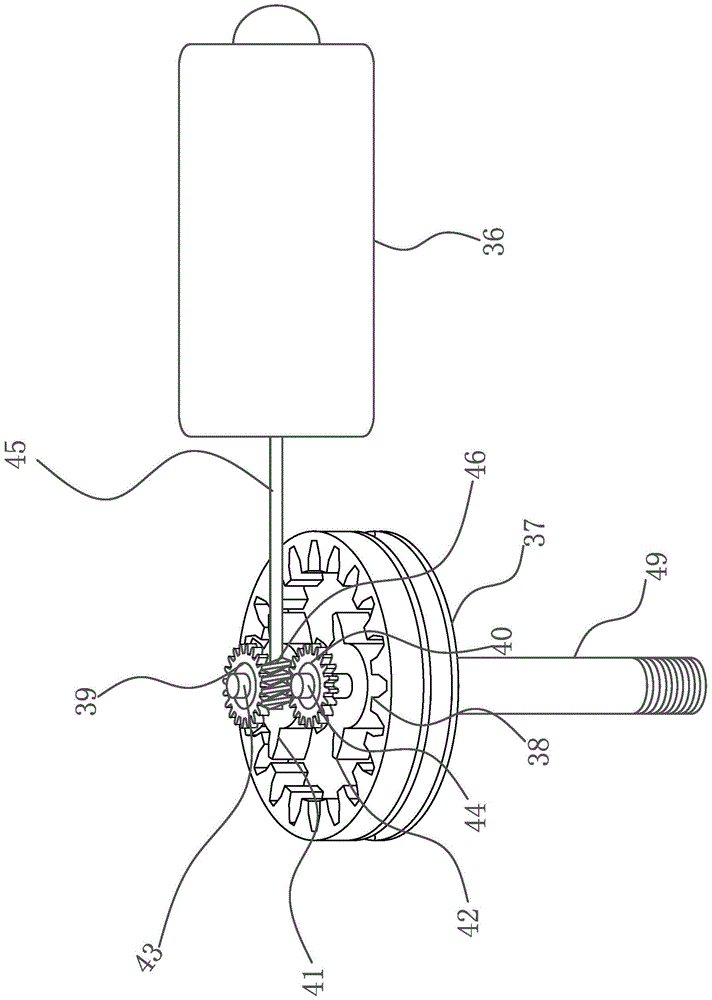

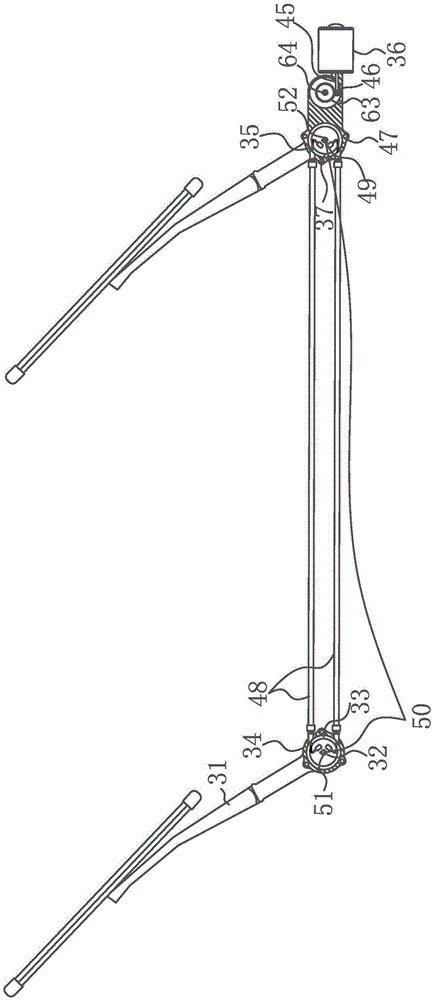

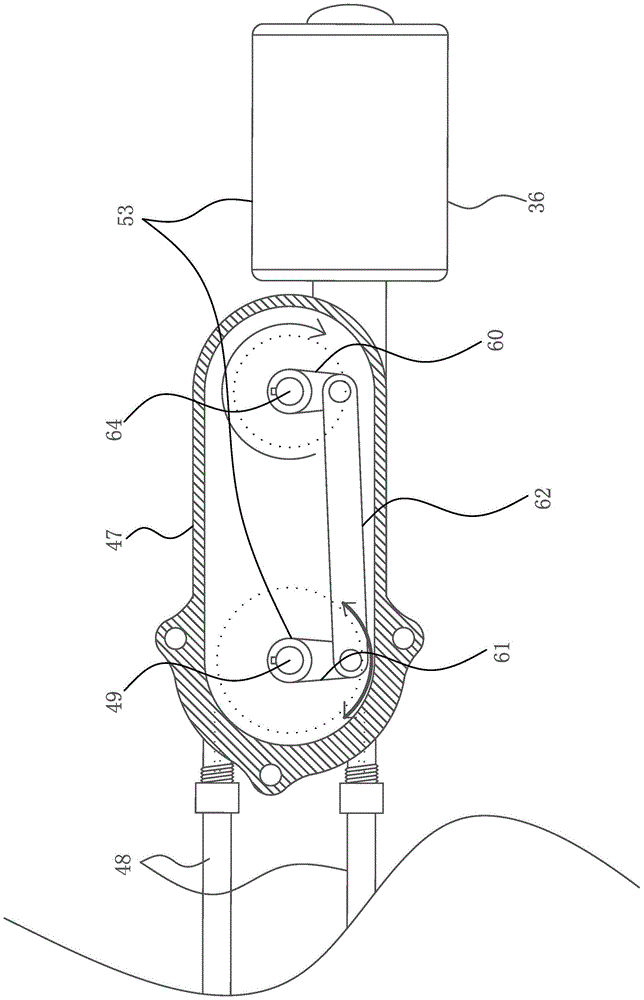

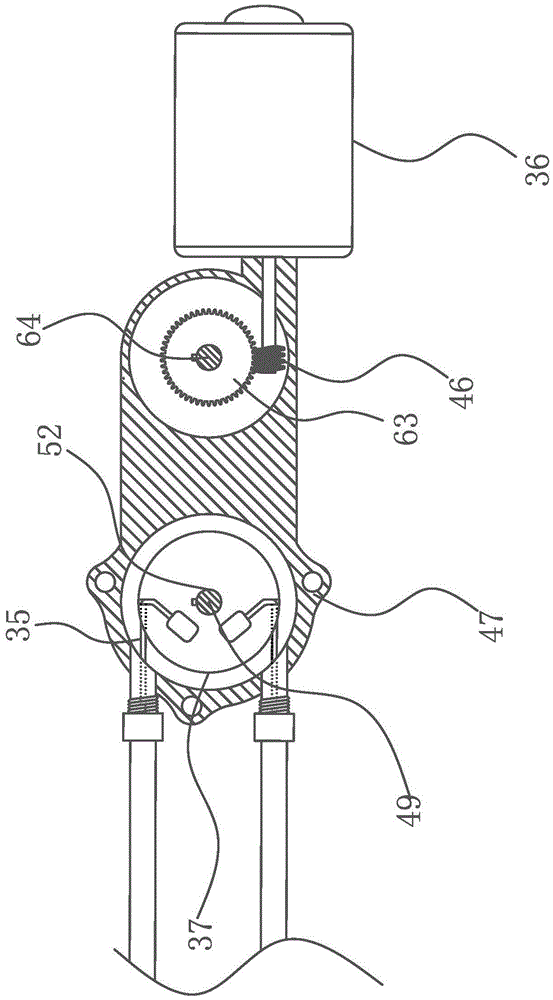

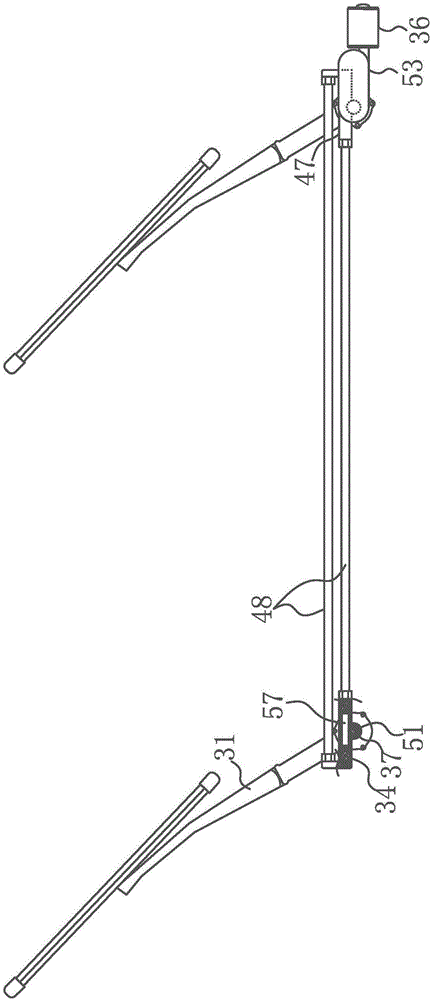

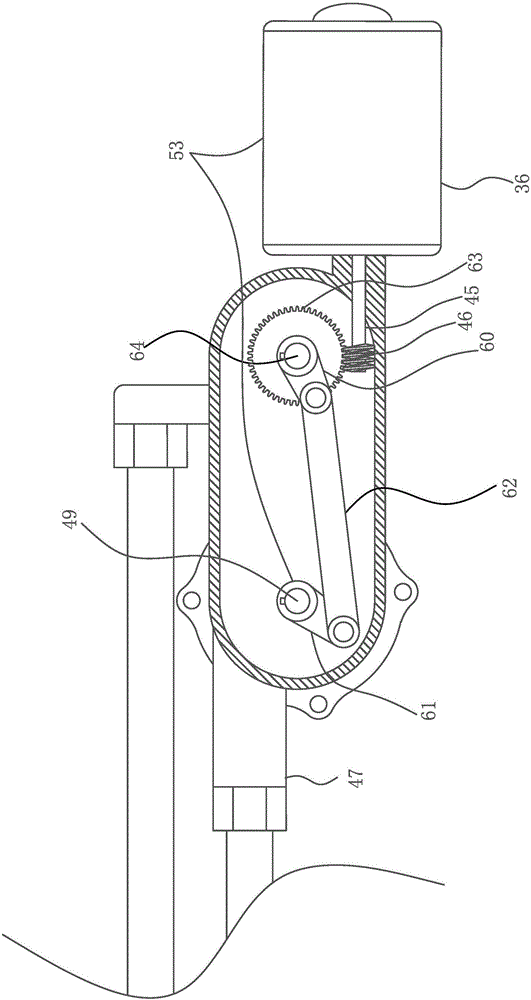

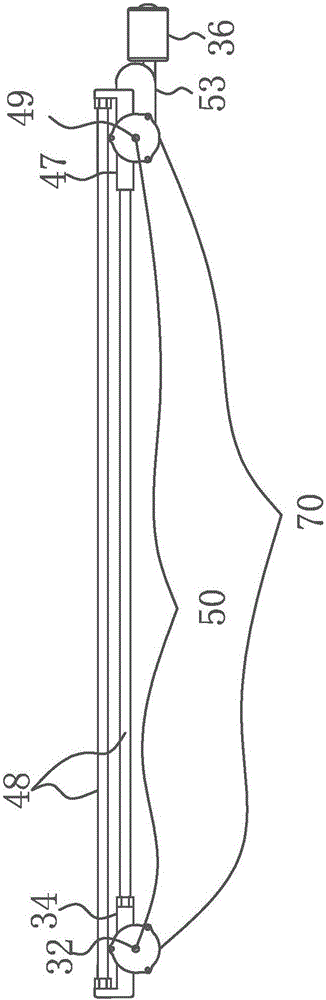

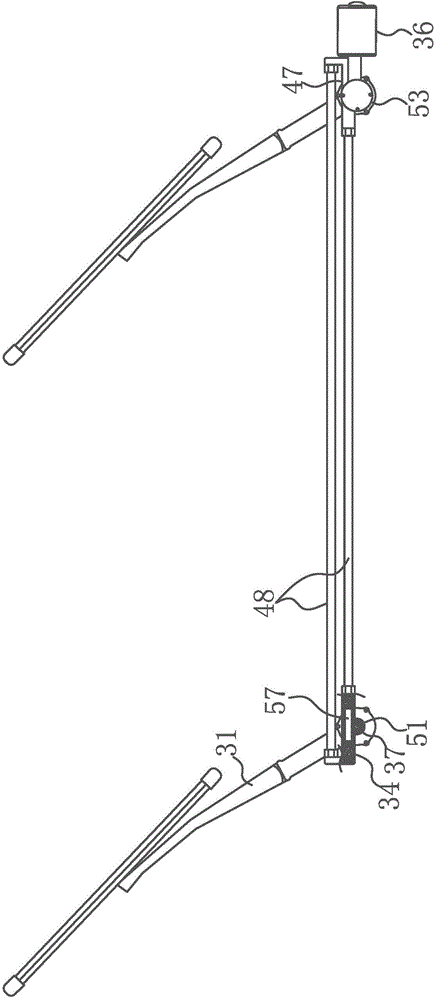

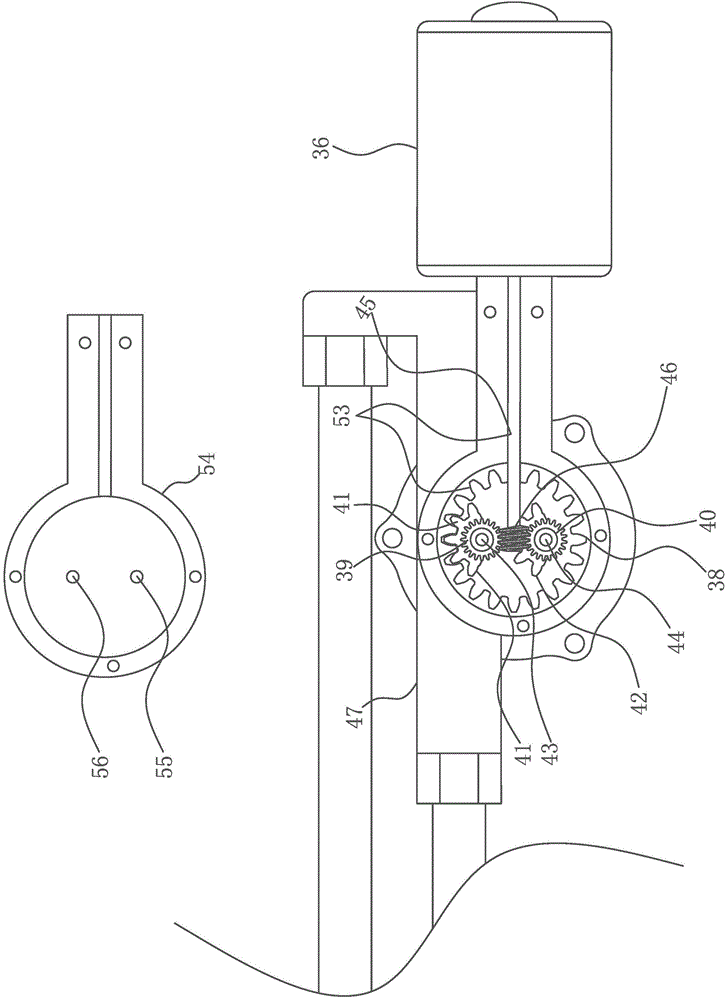

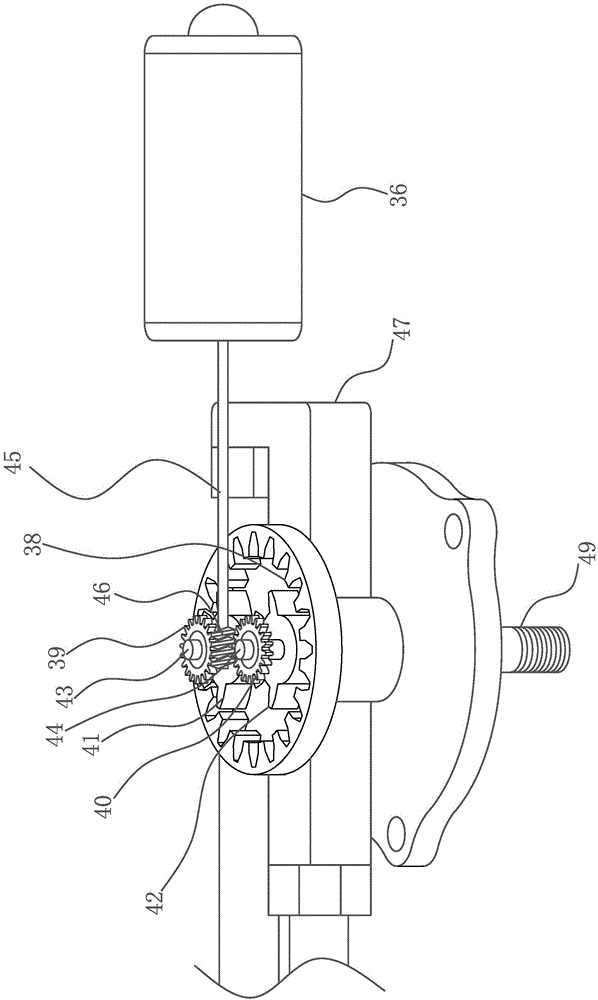

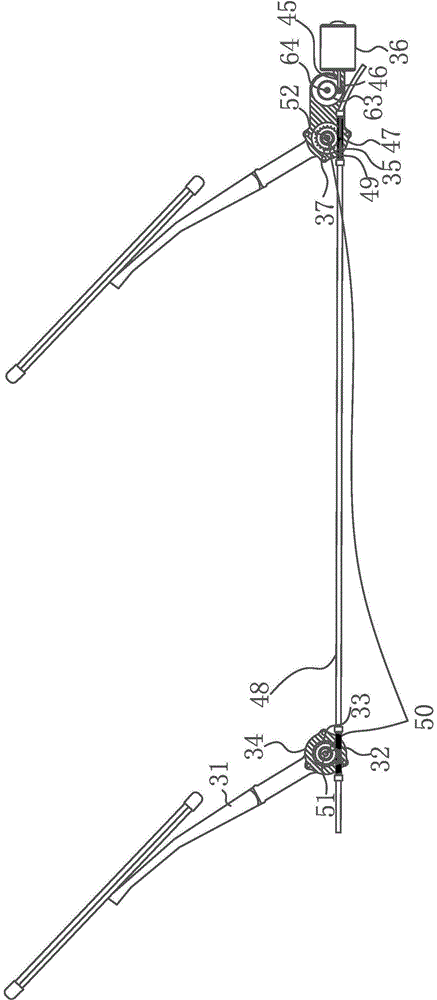

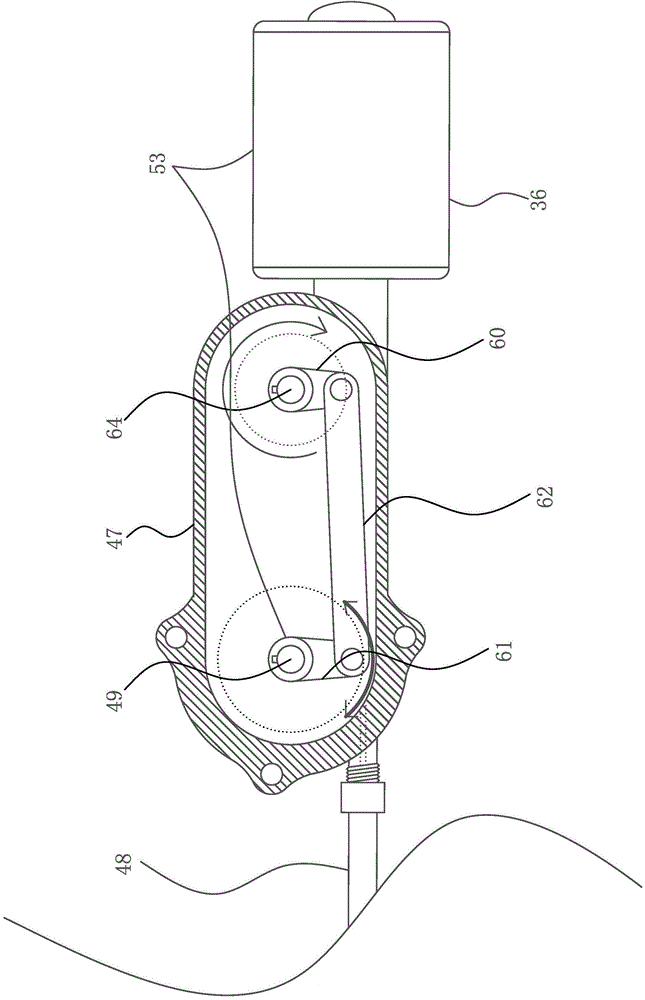

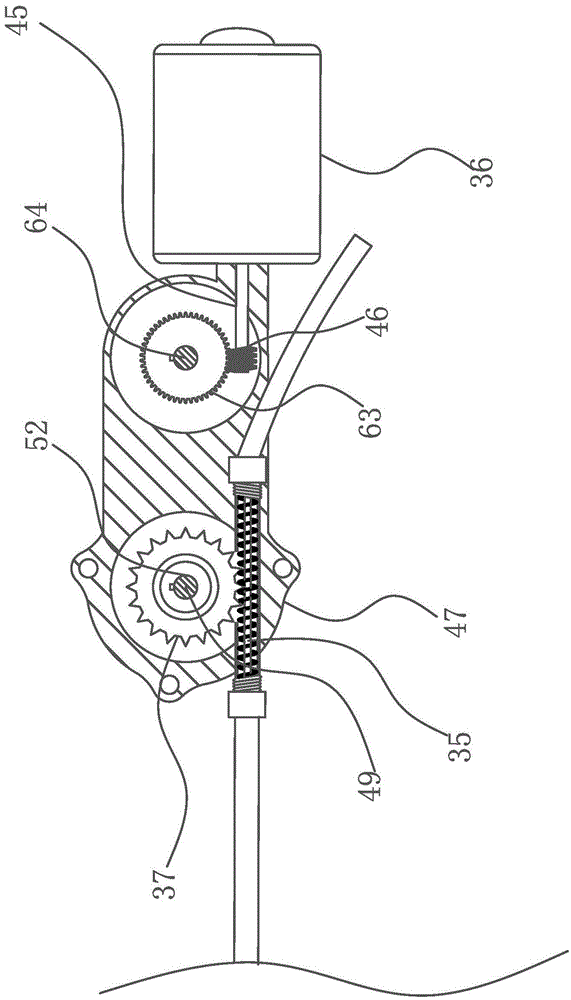

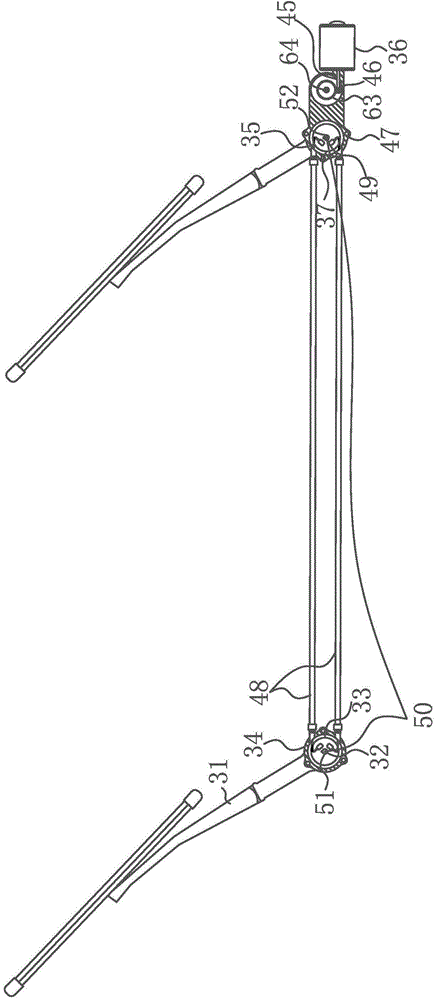

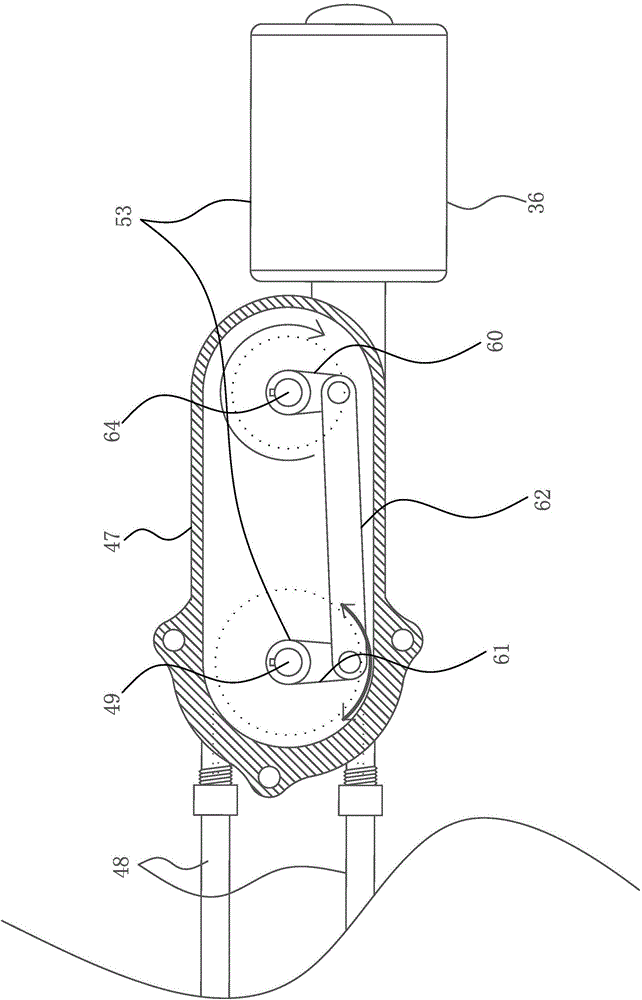

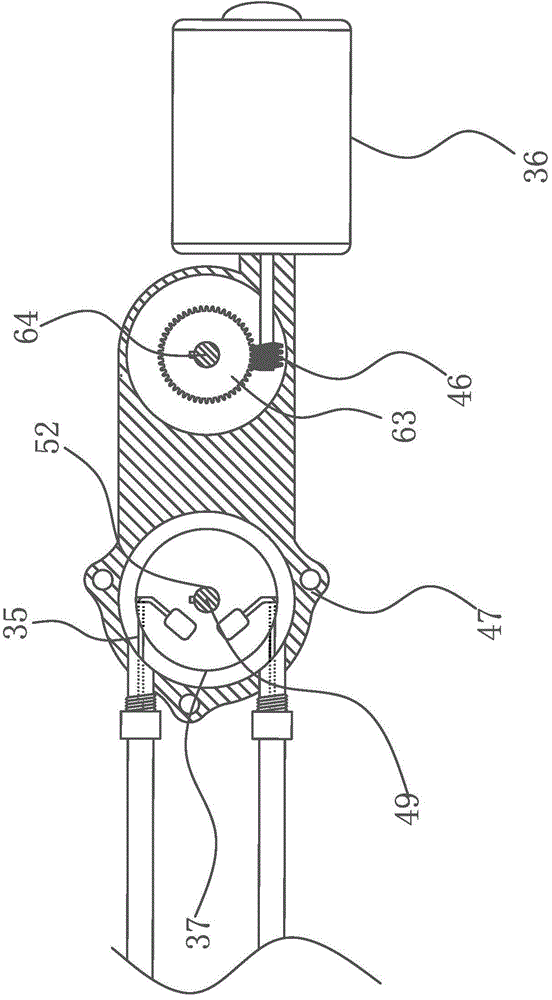

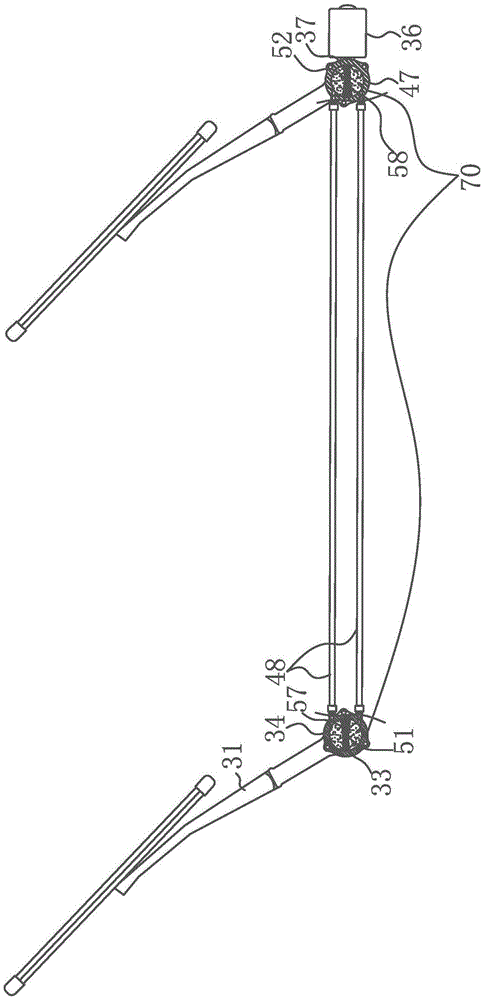

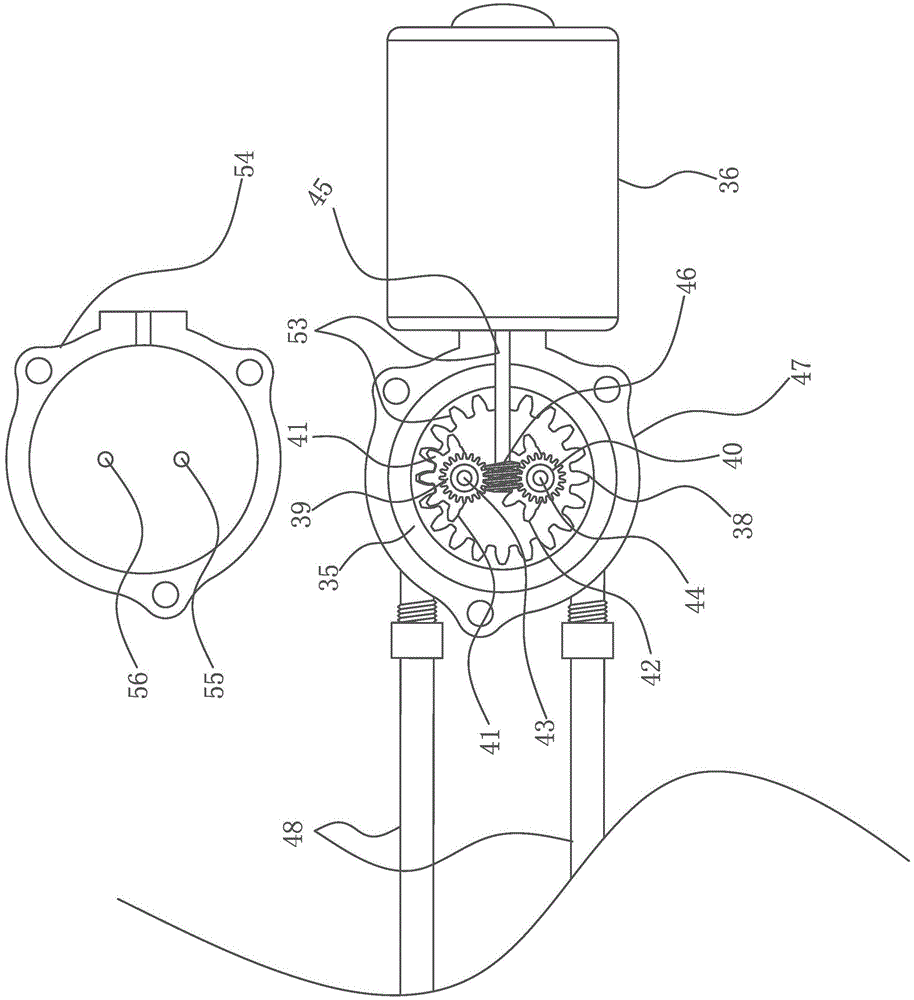

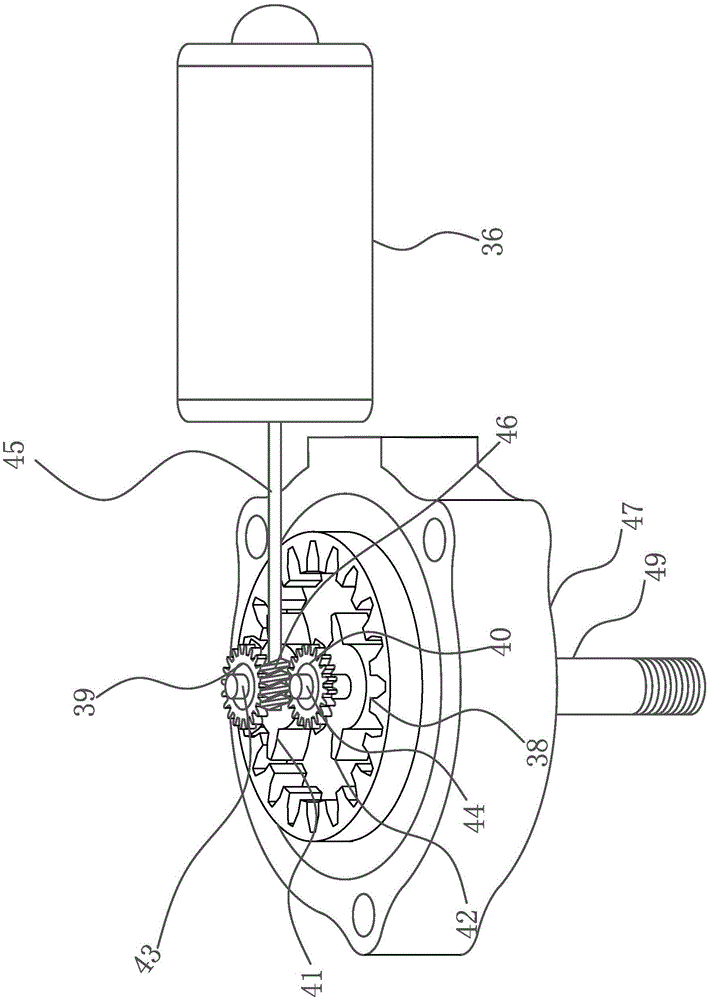

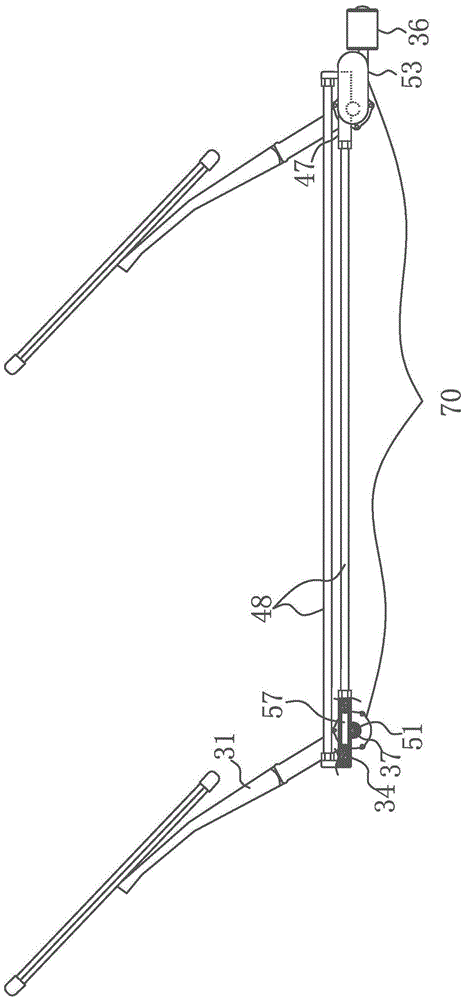

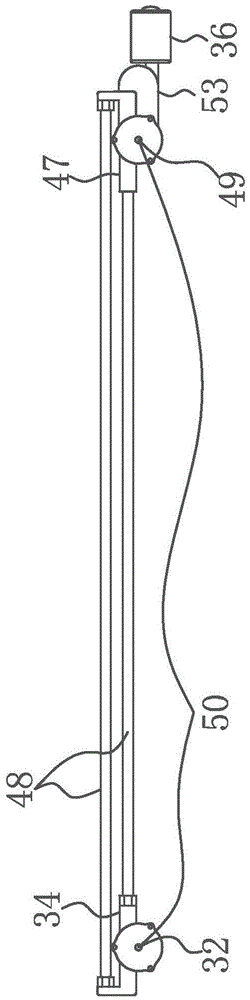

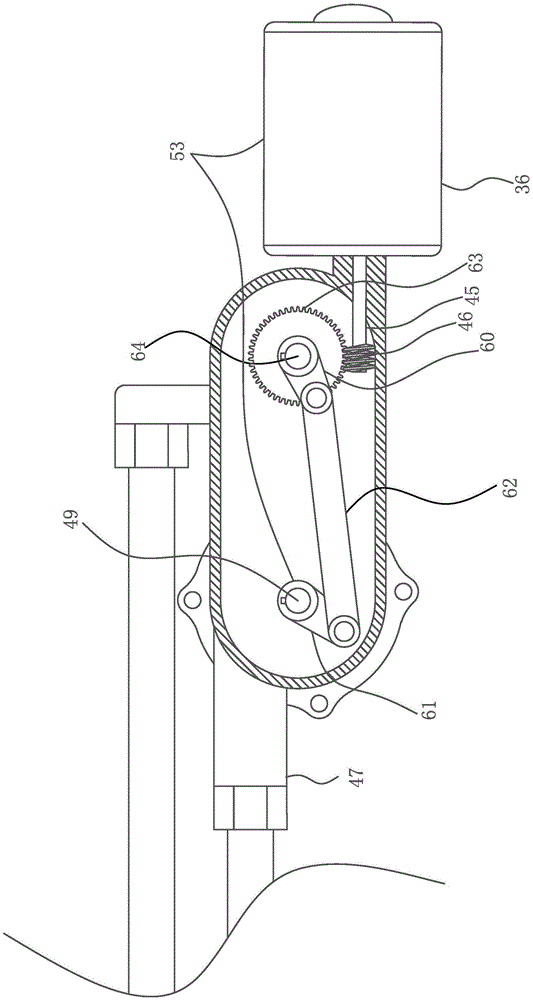

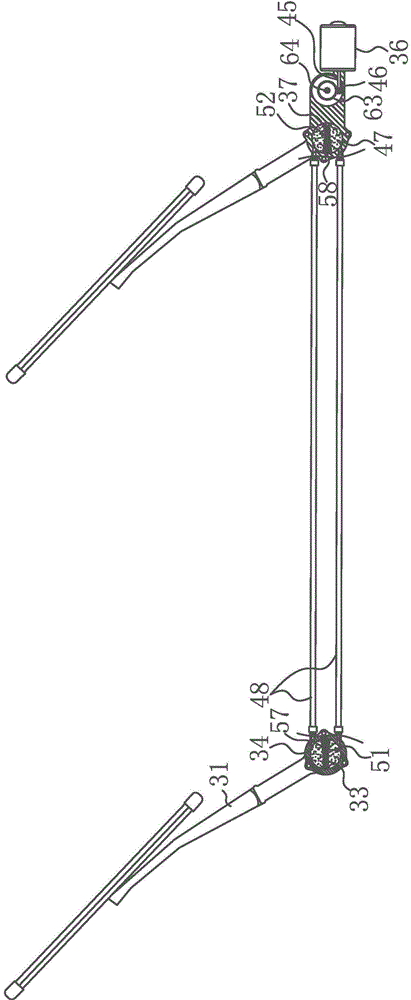

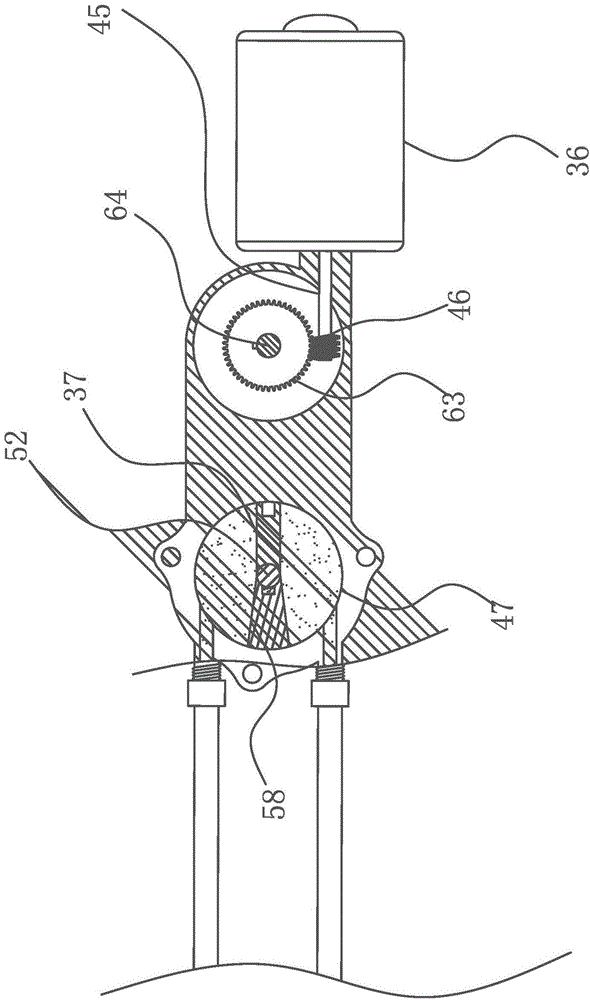

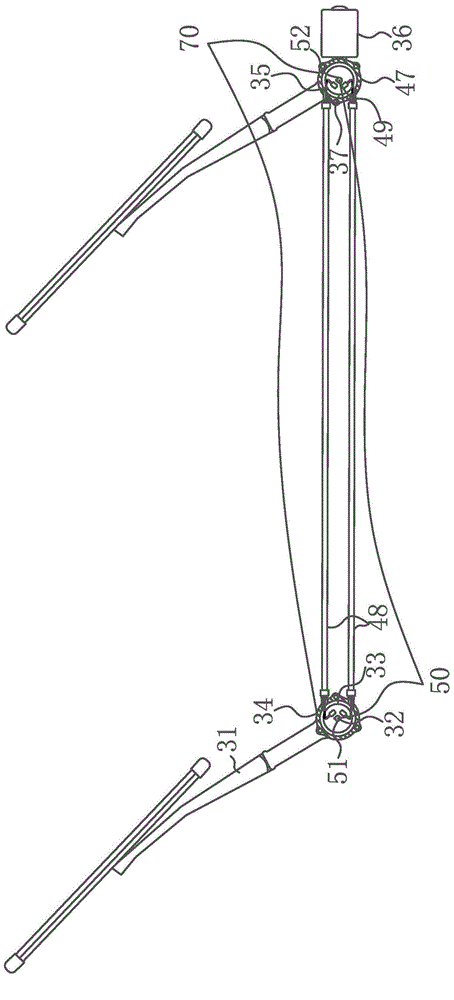

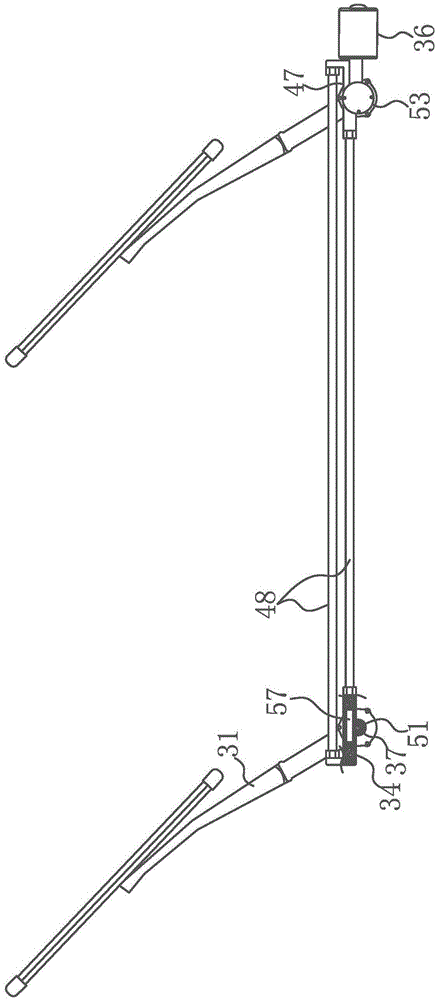

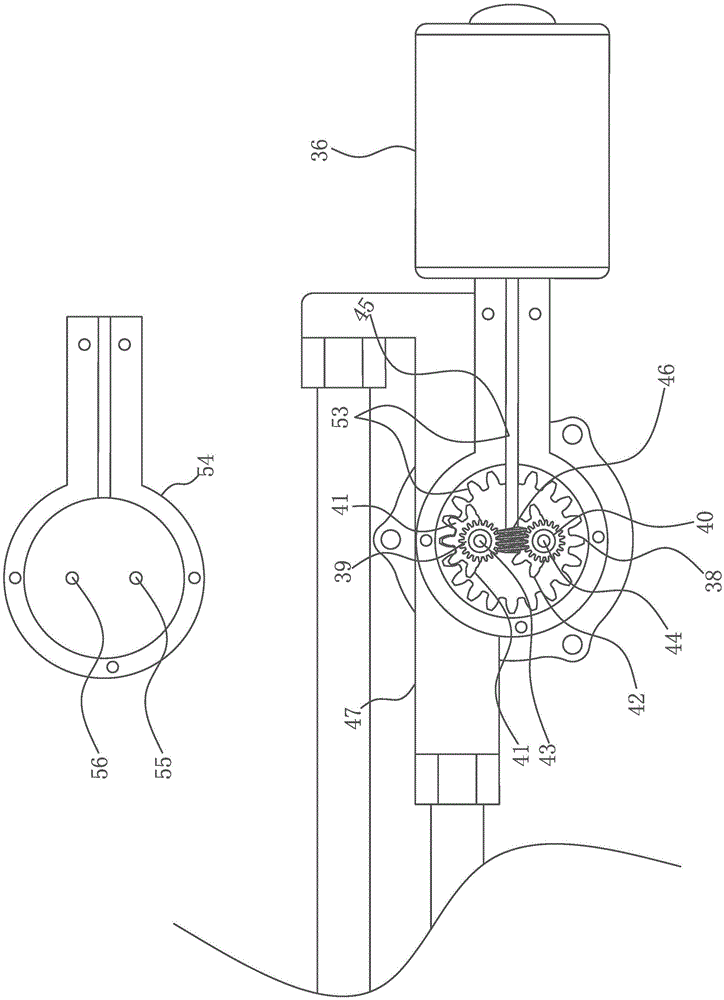

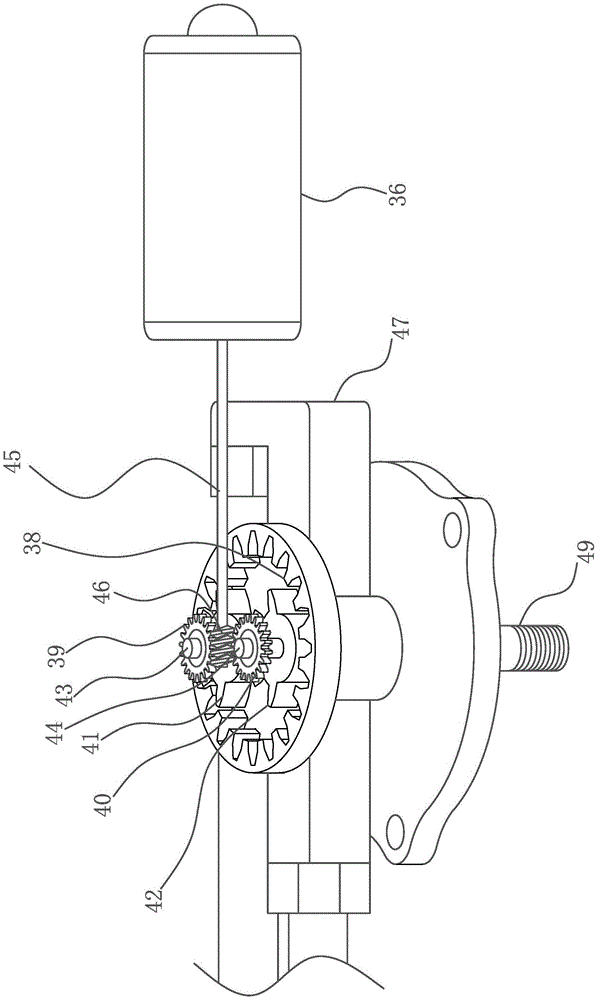

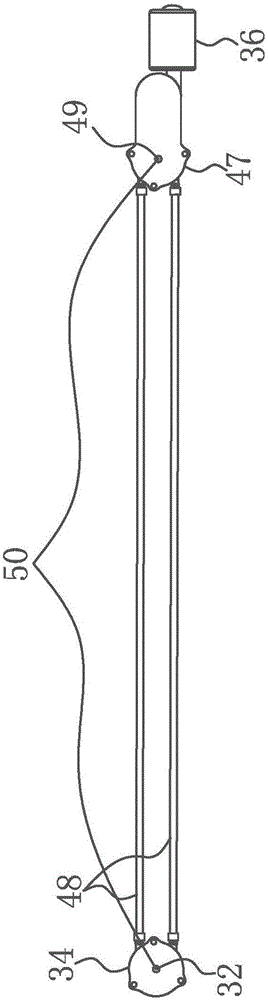

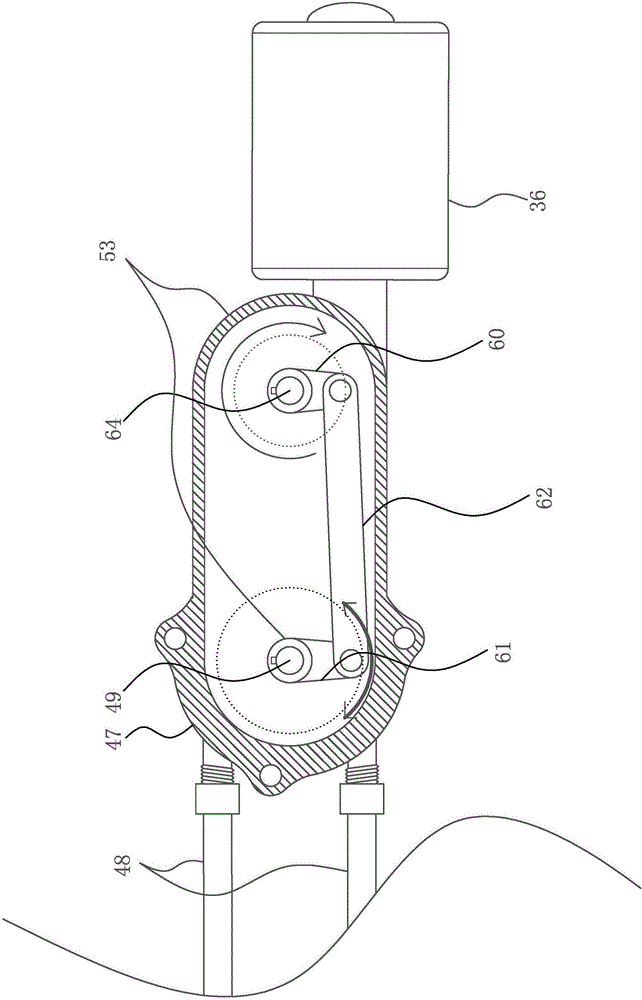

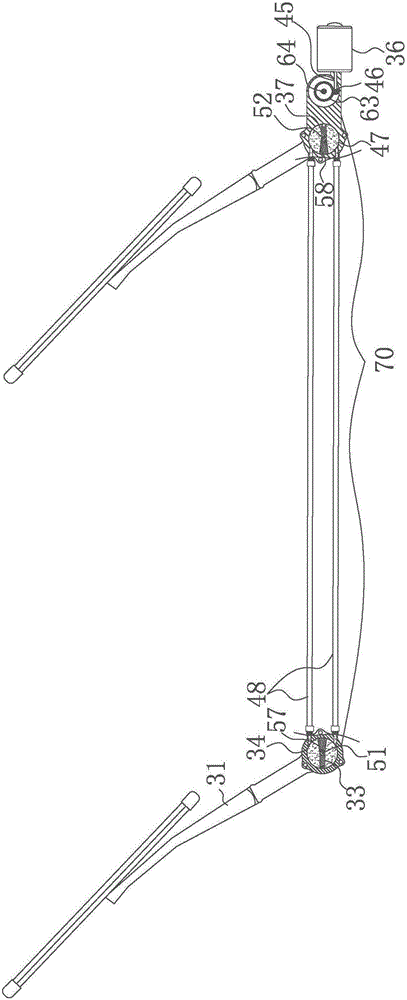

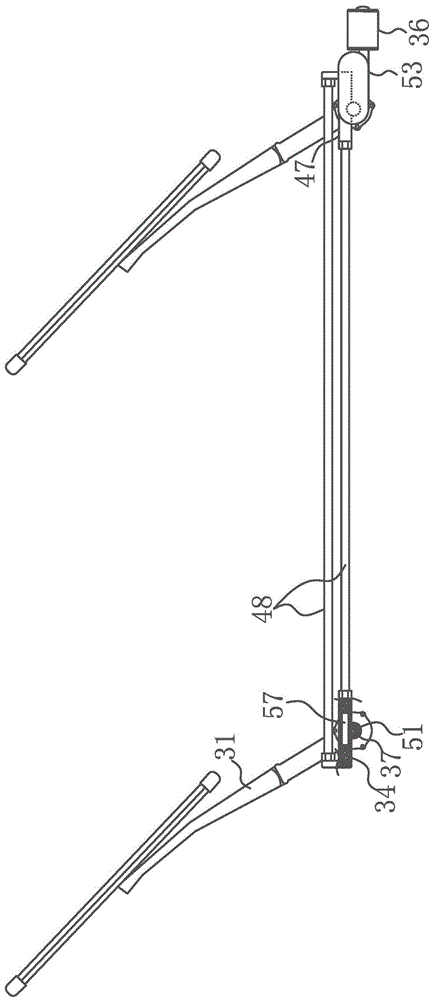

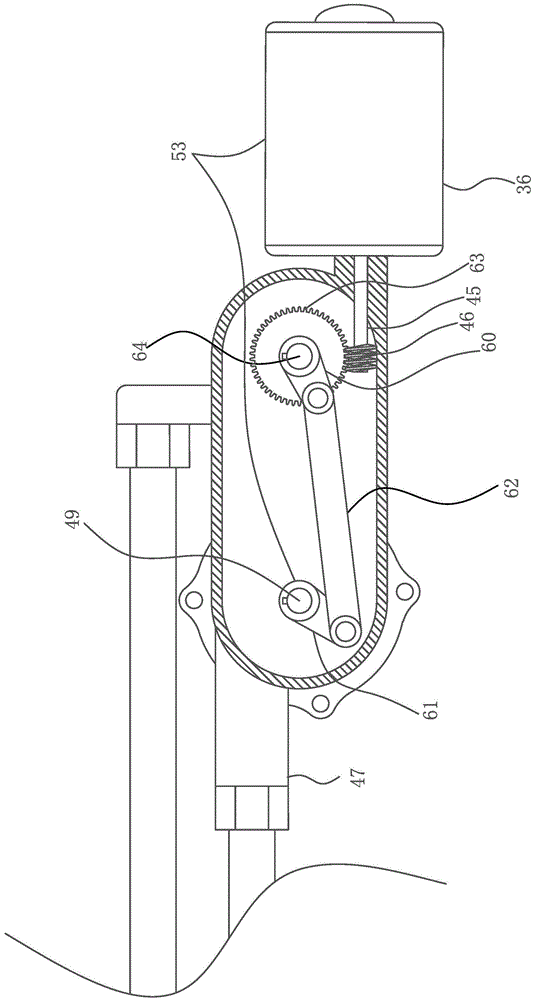

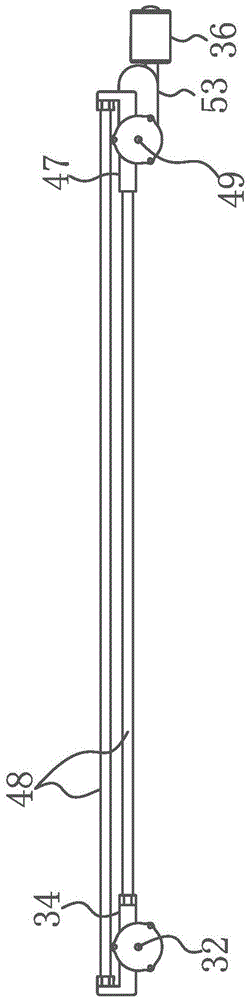

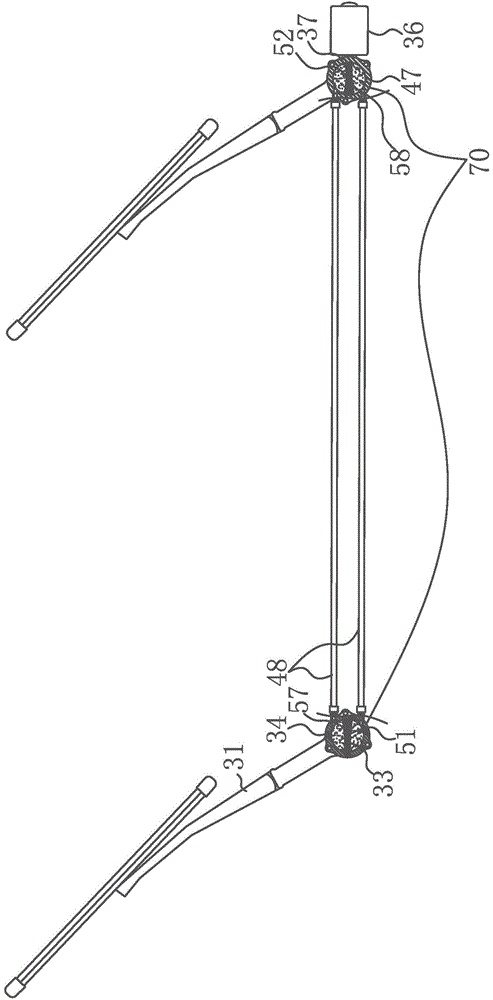

Three-scraping-plate flexible wall round hole inner support windshield wiper flexible shaft type windshield scraper

Provided is a three-scraping-plate flexible wall round hole inner support windshield wiper flexible shaft type windshield scraper. The windshield scraper comprises a windshield scraper motor, a windshield wiper drive mechanism and a windshield wiper, and is characterized in that a windshield wiper drive shaft comprises a driven windshield wiper drive shaft and a driving windshield wiper drive shaft, the driven windshield wiper drive shaft and the driving windshield wiper drive shaft are provided with a driven gear and a driving gear respectively, the driven gear and the driving gear are connected through a flexible shaft and transmit torque, and the driving gear is provided with a forward and backward rotation gear intermittent transmission mechanism. The windshield scraper drive mechanism is of a closed structure, low in operating noise, especially suitable for transmission in complex structures of external environments and long-distance transmission, capable of adapting to different vehicle types and free of external influences, avoids the defect that the windshield scraper motor is burnt out due to external barriers, effectively lowers noise in a vehicle and improves the interior comfort in running of the vehicle, a windshield scraper rubber strip is supported by flexible walls and can be better attached to windshield glass, and the scraping efficiency of the three-scraping-plate structure is three times that of a single common scraping plate.

Owner:ZHEJIANG XINYUANHONG MACROMOLECULE MATERIAL

Flexible wall supported wiper hydraulic swing windscreen wiper

ActiveCN104554159AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEngineeringInterior noise

A flexible wall supported wiper hydraulic swing windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear rack swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a forward and reverse rotating gear intermittent drive mechanism is arranged on the driving gear rack swing oil cylinder. The flexible wall supported wiper hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicle of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:TONGLING HUIYU IND CO LTD

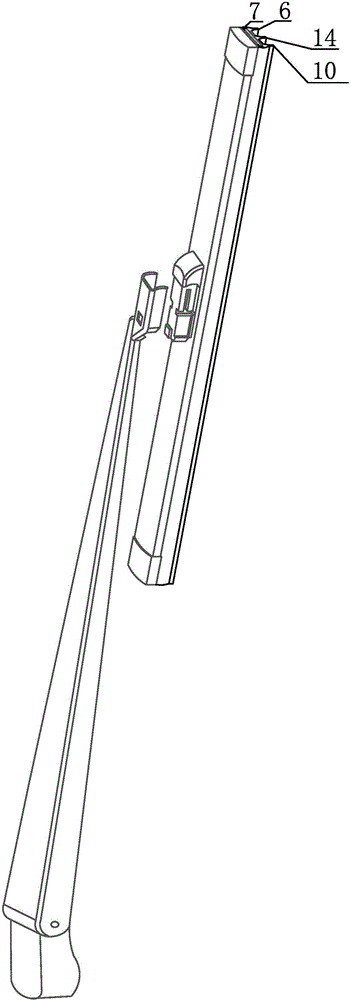

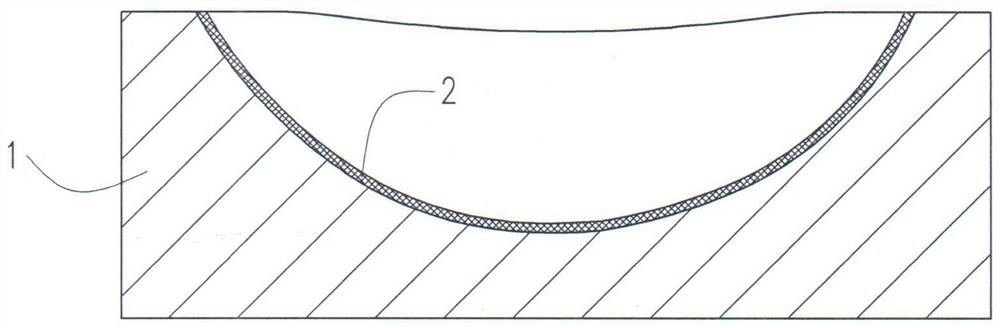

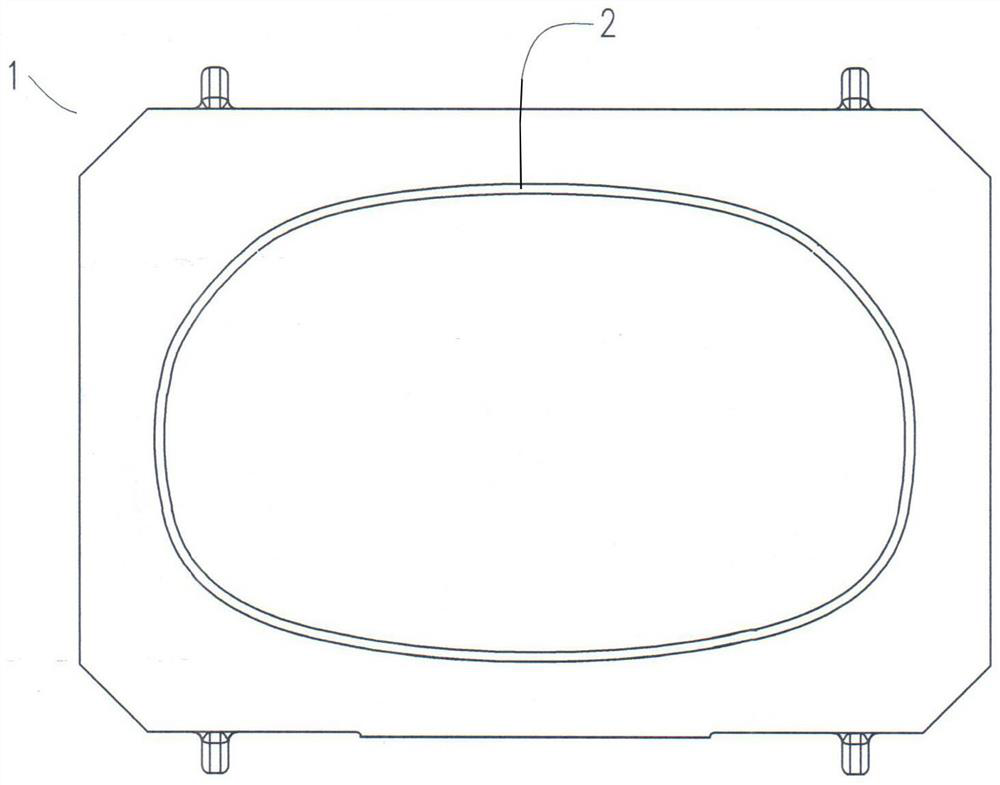

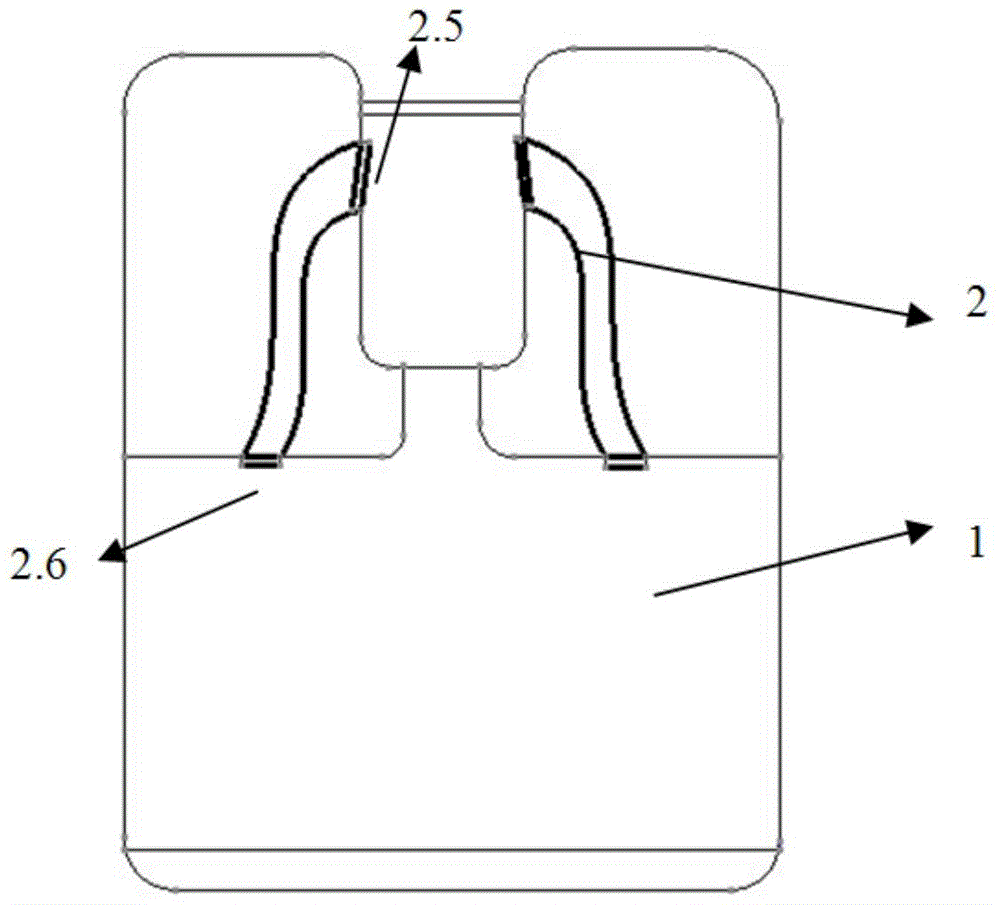

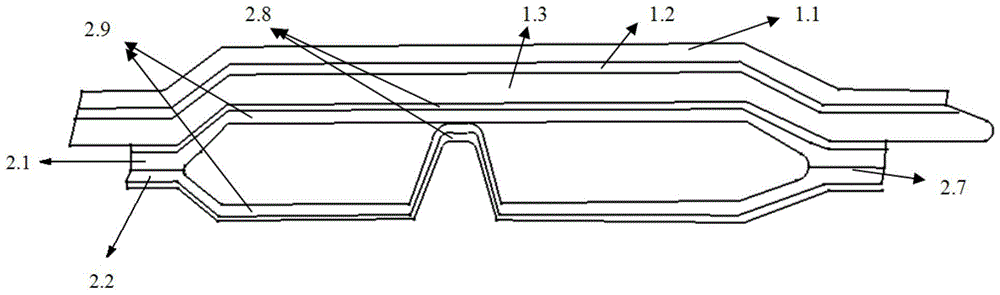

Flexible wall supporting windshield wiper rubber strip with three scraping pieces

InactiveCN104527604AImprove scrapingImprove scraping efficiencyVehicle cleaningStructural engineeringWindshield

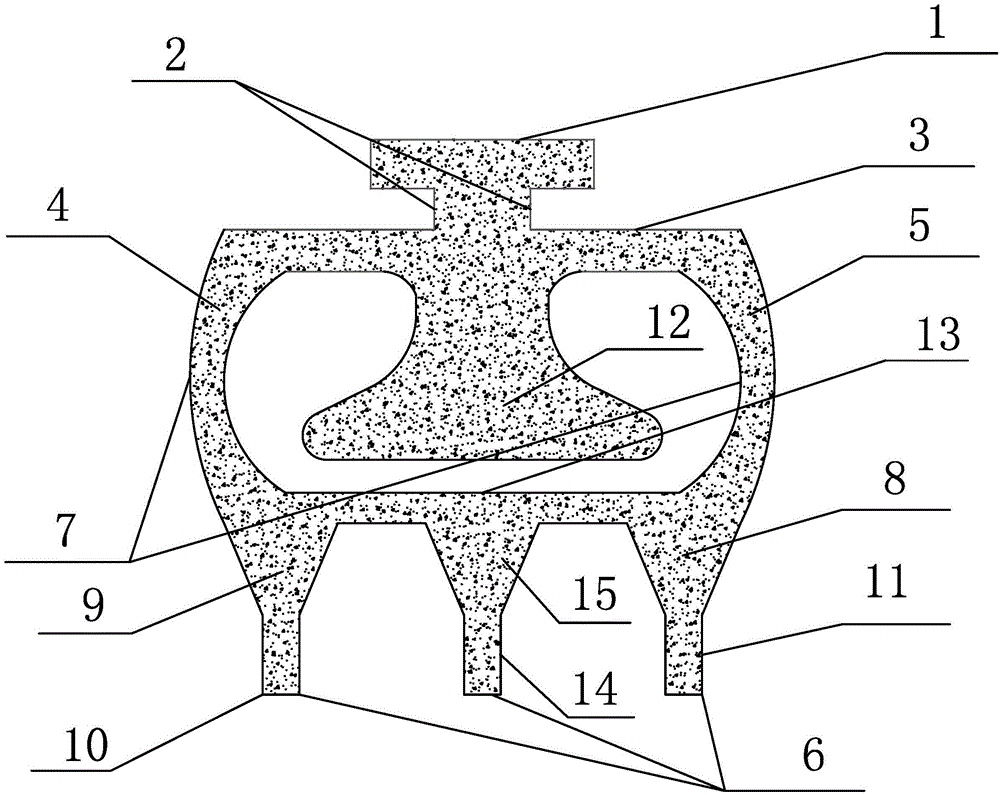

Disclosed is a flexible wall supporting windshield wiper rubber strip with three scraping pieces. A windshield wiper rubber strip fixing clamping groove (2) is formed in the upper portion of the windshield wiper rubber strip (1), and the scraping pieces (6) are arranged on the lower portion. The flexible wall supporting windshield wiper rubber strip with the three scraping pieces is characterized in that the two sides of a bottom plate (3) of the windshield wiper rubber strip fixing clamping groove (2) extend downwards to form a left flexible wall (4) and a right flexible wall (5) respectively, and the left flexible wall, the right flexible wall and the two sides of a flexible wall bottom plate (13) arranged at the upper ends of the scrapping pieces (6) are converged to form a hollow flexible wall supporting structure (7). The left scraping piece (10), the right scraping piece (11) and the middle scraping piece (14) parallel with the axial direction of the flexible wall supporting structure (7) are arranged on the two sides and the middle of the lower portion of the flexible wall bottom plate (13) respectively. The flexible wall supporting windshield wiper rubber strip with the three scraping pieces has the advantages that the scrapping pieces are better attached to the curved surface of windshield glass under the supporting of the flexible wall supporting structure, and therefore the scraping degree of the scraping pieces is improved, and the scraping efficiency of the three-scraping-piece structure is three times that of a common single scraping piece.

Owner:陈学琴

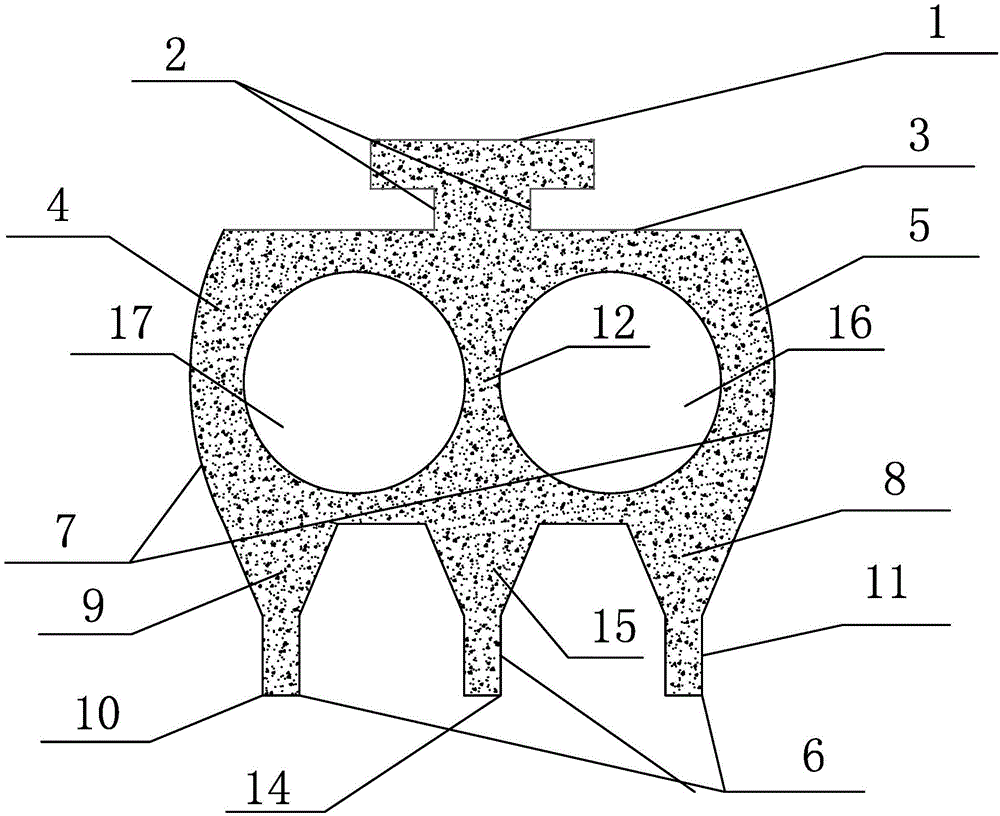

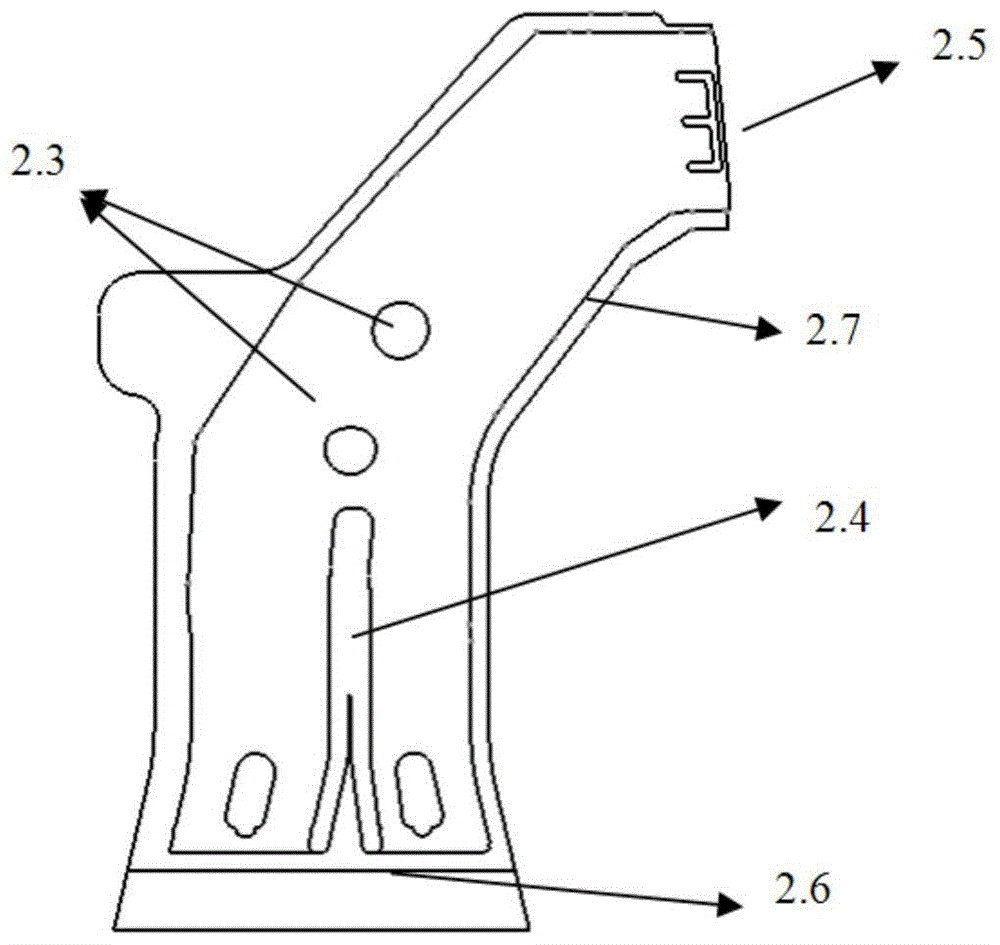

Three-scraper round hole inner support windscreen wiper rubber strip supported by flexible walls

InactiveCN104527603AImprove scrapingGuaranteed flexibilityVehicle cleaningEngineeringBilateral symmetry

The invention relates to a three-scraper round hole inner support windscreen wiper rubber strip supported by flexible walls. Windscreen wiper rubber strip fixing clamping grooves (2) are formed in the upper portion of the windscreen wiper rubber strip (1), and scrapers (6) are arranged on the lower portion of the windscreen wiper rubber strip (1). The windscreen wiper rubber strip is characterized in that two tubular cavities are formed in parallel in bottom plates (3) of the windscreen wiper rubber strip fixing clamping grooves (2) in a bilateral symmetry mode in the axial direction of the windscreen wiper rubber strip (1) and comprise the left cavity (17) and the right cavity (16), the left flexible wall (4) and the right flexible wall (5) and a middle partition wall (12) are formed, and the bottom plates (3), the left cavity (17) and the right cavity (16) form a flexible wall supporting structure (7); the left scraper (10), the right scraper (11) and the middle scraper (14) are arranged in parallel at the lower ends of the two sides of the bottom plates (3) in the axial direction of the flexible wall supporting structure (7) respectively. The three-scraper round hole inner support windscreen wiper rubber strip has the advantages that under the supporting of the flexible supporting structure, the fitting degree of the scrapers is higher, the cleaning degree is higher, and the three-scraper efficiency is higher.

Owner:陈学琴

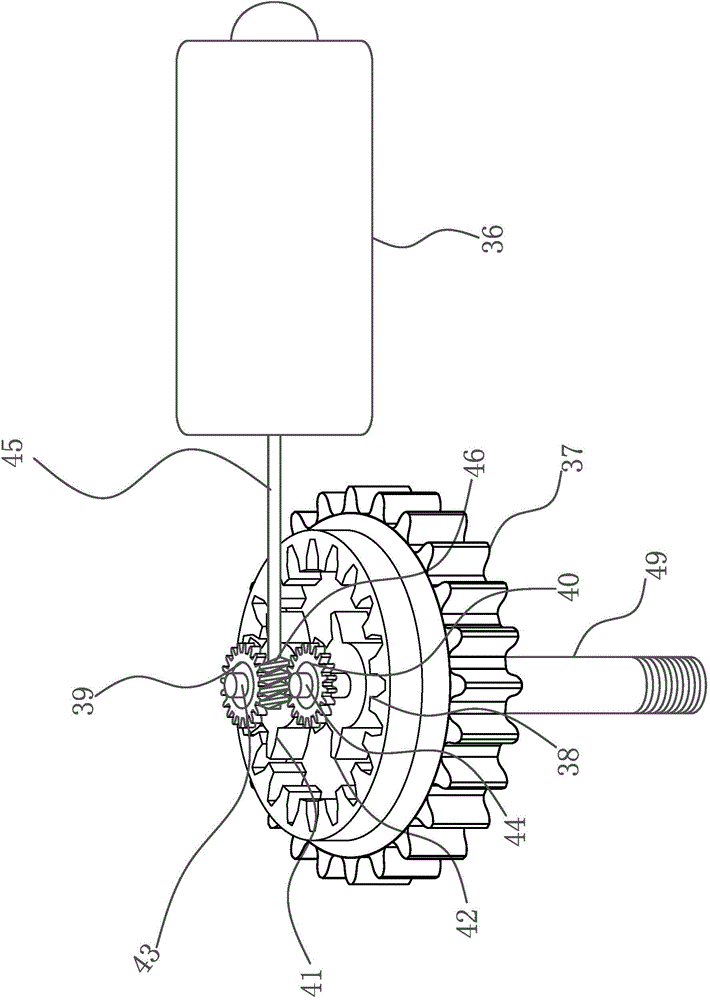

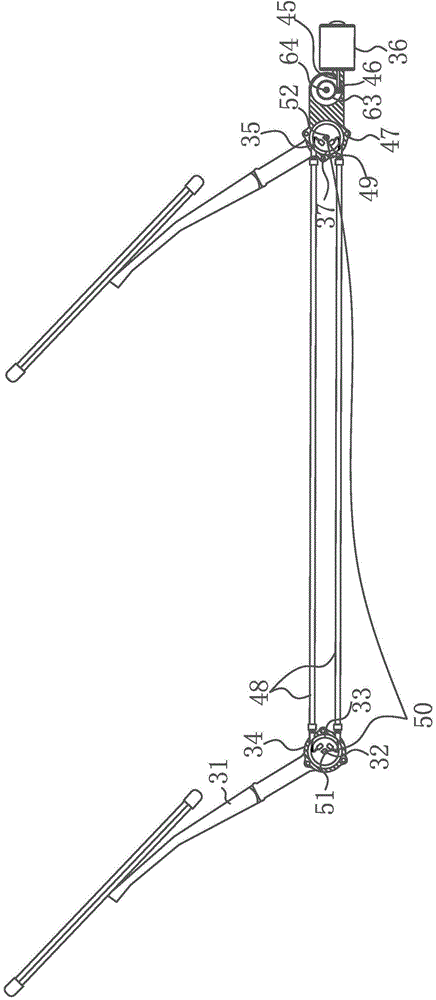

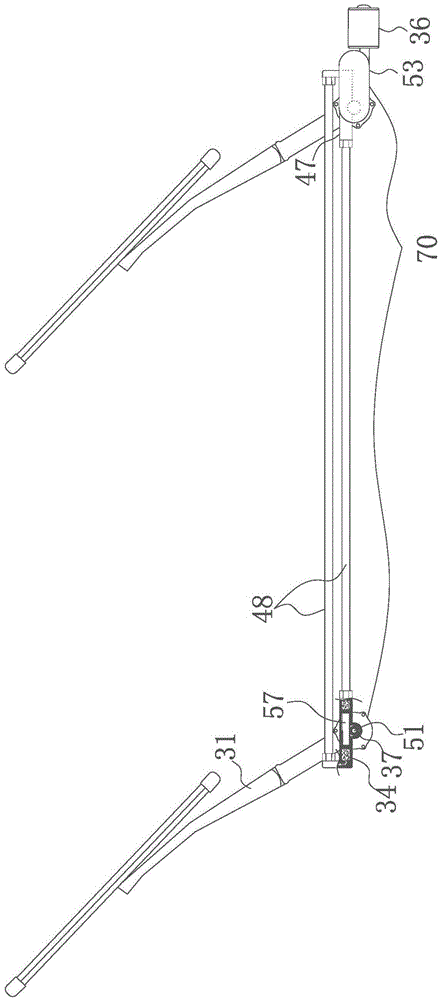

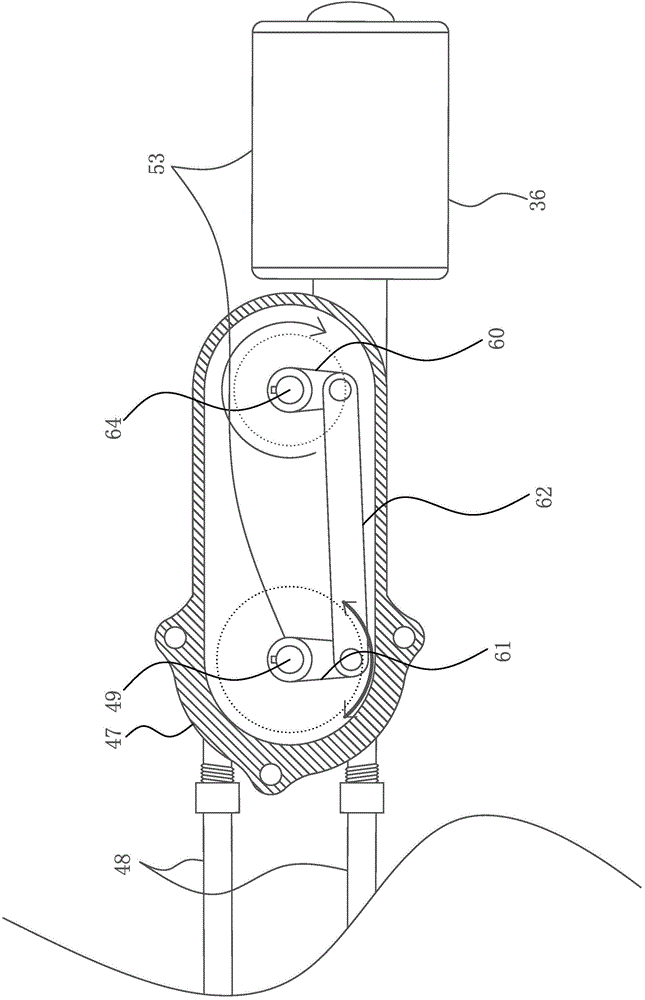

Three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper

A three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. A closed connecting rod rocker arm driving mechanism is arranged on the driving winding wheel. The connecting rod wire wheel type wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:靖江智云信息科技有限公司

Special-shaped curved-surface aramid fiber paper honeycomb simple pre-shaping die and manufacturing method thereof

The invention provides a special-shaped curved-surface aramid fiber paper honeycomb simple pre-shaping die and a manufacturing method. The simple pre-shaping die comprises a die body. The die body isformed by compounding multiple layers of high-temperature-resistant prepreg, and multiple positioning holes for positioning aramid fiber paper honeycombs are formed in the periphery of the die body. The manufacturing method of the simple pre-shaping die includes the steps that the die is formed through an existing composite product, and the multiple layers of high-temperature-resistant prepreg arecompounded. The simple pre-shaping die has the beneficial effects of being simple in structure, easy and convenient to manufacture and light in structure, compared with a steel die, the manufacturingcost is reduced by 80% or above, and the simple pre-shaping die has the technical effects that the pre-shaping treatment is easy to operate, and the attachment effect of the treated aramid fiber paper honeycombs and the curved surface of the composite product is good.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

Structural part of wind power blade and preparation method of wind power blade shell

PendingCN113752590AReduce weightLow costFinal product manufactureMachines/enginesStructural engineeringMechanical engineering

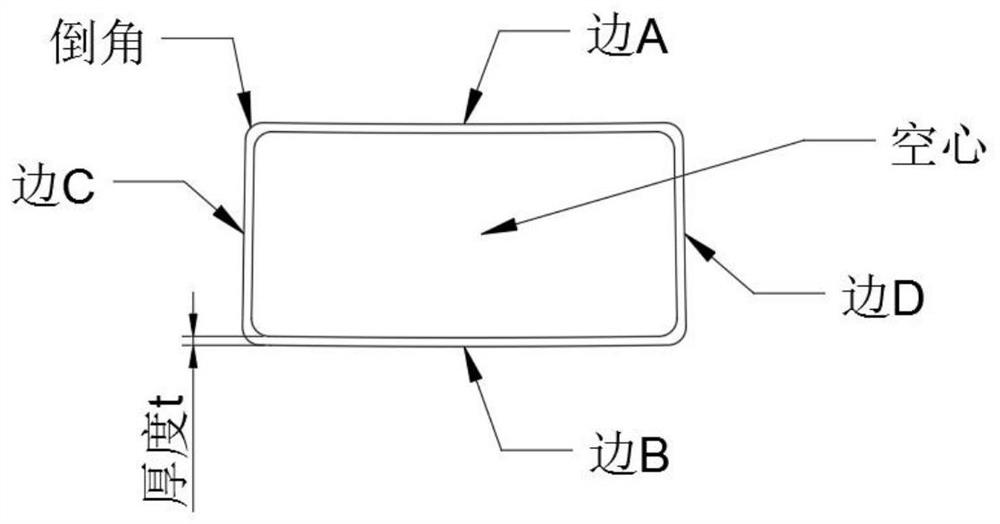

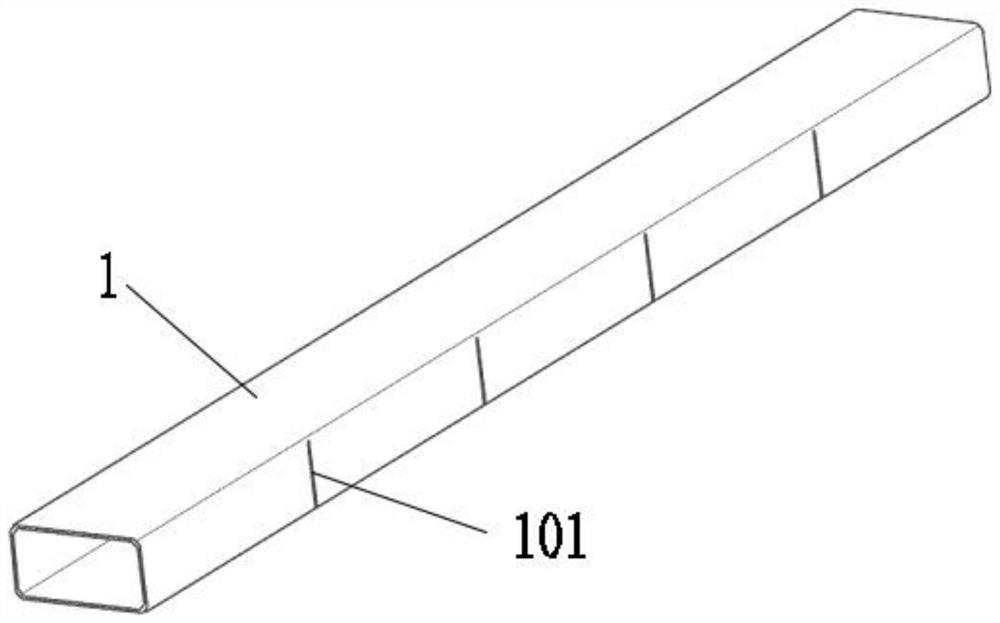

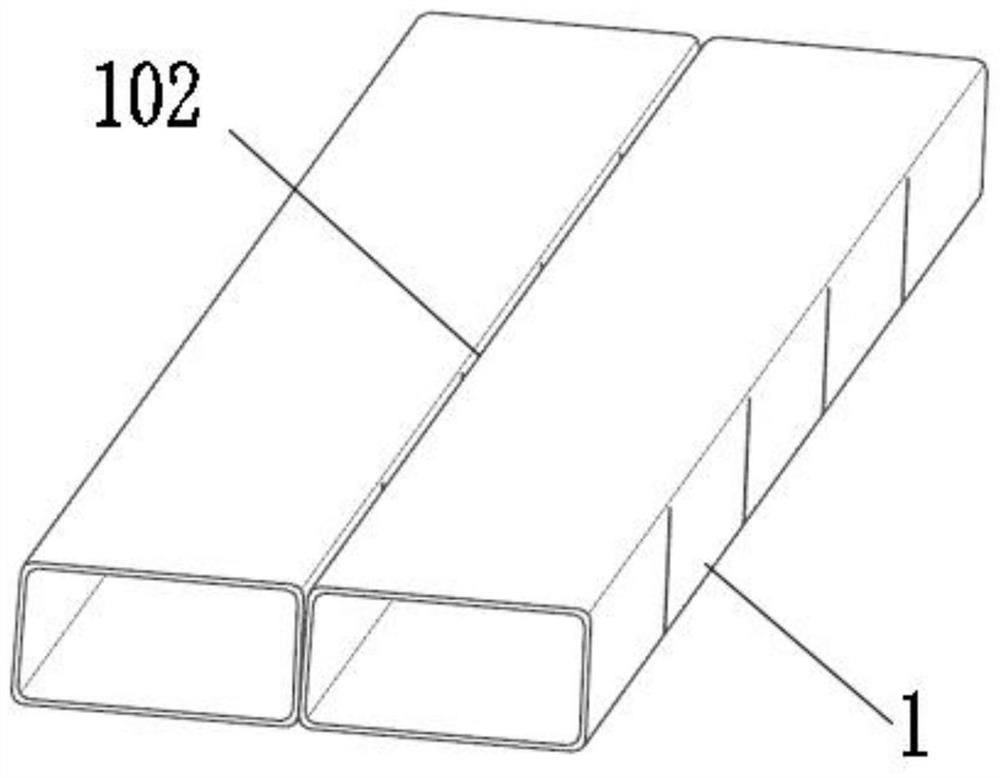

The invention discloses a structural part of a wind power blade and a preparation method of a wind power blade shell. The structural part is laid between main bearing structures of the wind power blade. The structural part comprises a first side wall, a second side wall opposite to the first side wall, a third side wall adjacent to the first side wall and the second side wall and a fourth side wall opposite to the third side wall, the third side wall and the fourth side wall on the cross section of the structural part are both circular arcs, and an included angle is formed between the extension surfaces of the first side wall and the second side wall in the same extension direction. According to the structural part, the weight of the blade core material is greatly reduced; the cost of the blade is effectively reduced, and the buckling resistance of the core material area of the blade is greatly improved; and the cambered surface can ensure that the structural part is well attached to the surface of the blade mold, a blade resin pouring runner is formed, and the manufacturability is good.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

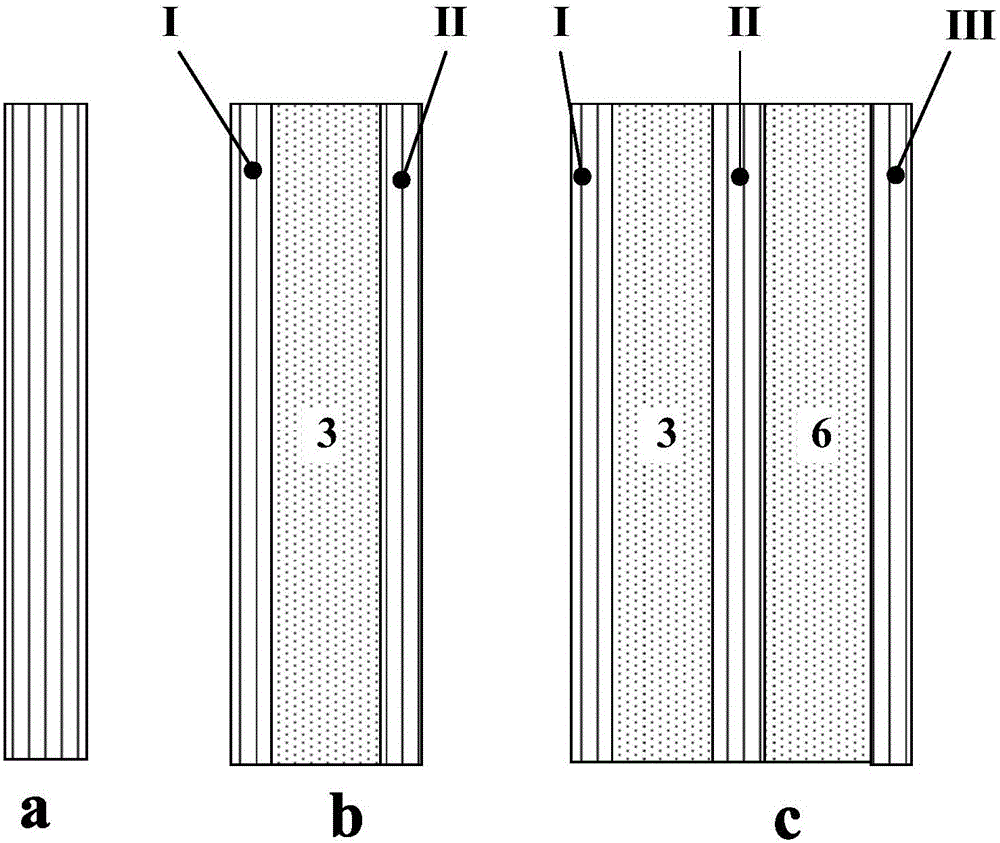

A kind of preparation method of thin-walled foam sandwich structure composite material radome

ActiveCN105922703BGood wave permeabilityAvoid Bonding InsufficiencyLamination ancillary operationsLaminationRadomeThin walled

The invention discloses a preparation method for a composite material antenna cover with a thin-wall foam sandwich structure. The invention aims to solve the problem of difficult processing or incapable processing for a thin-wall foam sandwich layer in the process of preparation of an antenna cover with a sandwich structure. According to a technical scheme of the invention, processing of the entire body of the thin-wall foam sandwich layer comprises two steps: performing primary processing, namely subjecting an initial foam block to single-face mechanical processing; and performing secondary processing after subjecting the single-face mechanically processed foam block to reinforcing and rigidity increasing, i.e., subjecting the rest of faces of the thin-wall sandwich layer to processing on a combination of a rigid mold, a composite material panel and the single-face mechanically processed foam block so as to prepare the thin-wall foam sandwich layer meeting the technical requirements of a target antenna cover. In addition, through resin impregnation with fabrics and a vacuum bag molding technique, preparation of the composite material panel and bonding of the panel with the foam sandwich layer in the target antenna cover are realized. By adopting the preparation method provided by the invention, the difficulty of preparation of the thin-wall foam sandwich layer through processing of the entire body of the initial foam block is overcome; the molding process of the antenna cover is simple; and the prepared antenna cover has the advantages of few defects, light weight and good wave permeability.

Owner:NAT UNIV OF DEFENSE TECH

Three-Blade Flexible Wall Support Wiper Blade Hydraulic Wiper

ActiveCN104527590BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEnvironmental structureWindscreen wiper

A three-scraper wiper blade hydraulic windscreen wiper with flexible wall supporting comprises a windscreen wiper motor, a wiper driving mechanism and a wiper and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe, torque is transmitted between the two blade swing oil cylinders through the hydraulic oil pipe, and a forward and reverse rotation gear intermittent transmission mechanism is arranged on the driving blade swing oil cylinder. The three-scraper wiper blade hydraulic windscreen wiper has the advantages that as flexible pipeline hydraulic transmission is adopted in the wiper driving mechanism of the windscreen wiper, the transmitted torque is large, and structural limit is small when the windscreen wiper is installed; as the windscreen wiper is of a completely closed structure, the windscreen wiper is particularly suitable for the complex external environmental structure and long-distance transmission and not affected by external factors, and the defect that the windscreen wiper motor is burnt due to external obstacles is overcome; windscreen wiper rubber strips are supported by flexible walls and therefore can fit windscreen better, and the scraping efficiency of the three-scraper structure is three times that of a general single scraper.

Owner:泰安泰山科技有限公司

Three-blade flexible wall round hole supports wiper linkage hydraulic swing wiper

ActiveCN104554155BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEngineeringInterior noise

A three-scraping-piece flexible wall round hole internal-supported wiper connecting rod hydraulic swing windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear rack swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a connecting rod rocker arm drive mechanism is arranged on the driving gear rack swing oil cylinder. The three-scraping-piece flexible wall round hole internal-supported wiper connecting rod hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is small in structural limitation during installation, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:齐河智谷产业发展有限公司

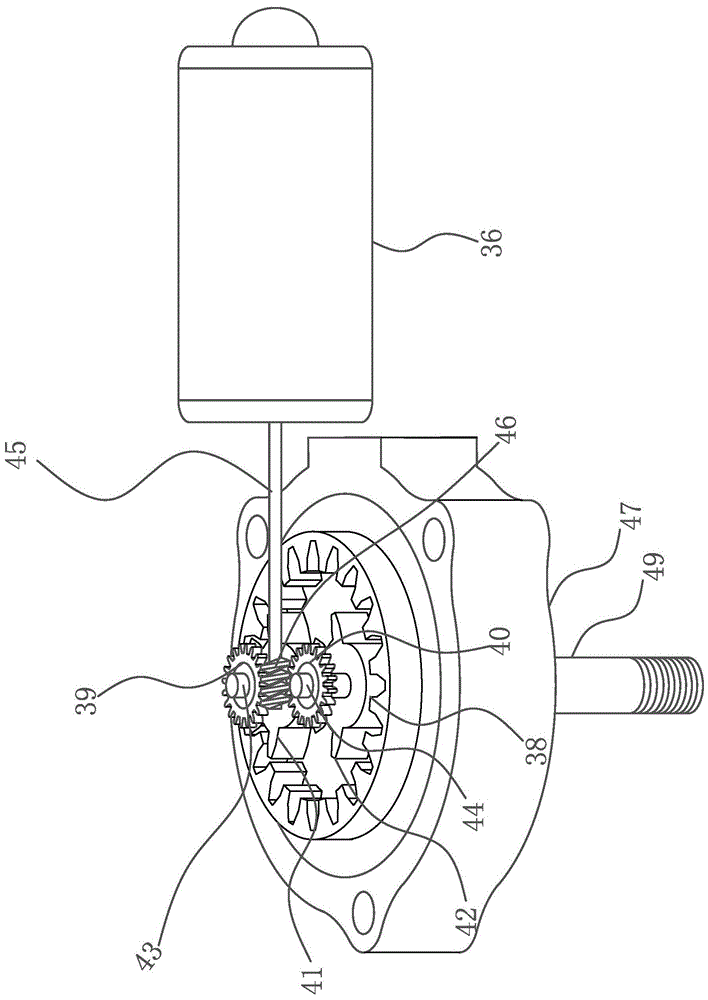

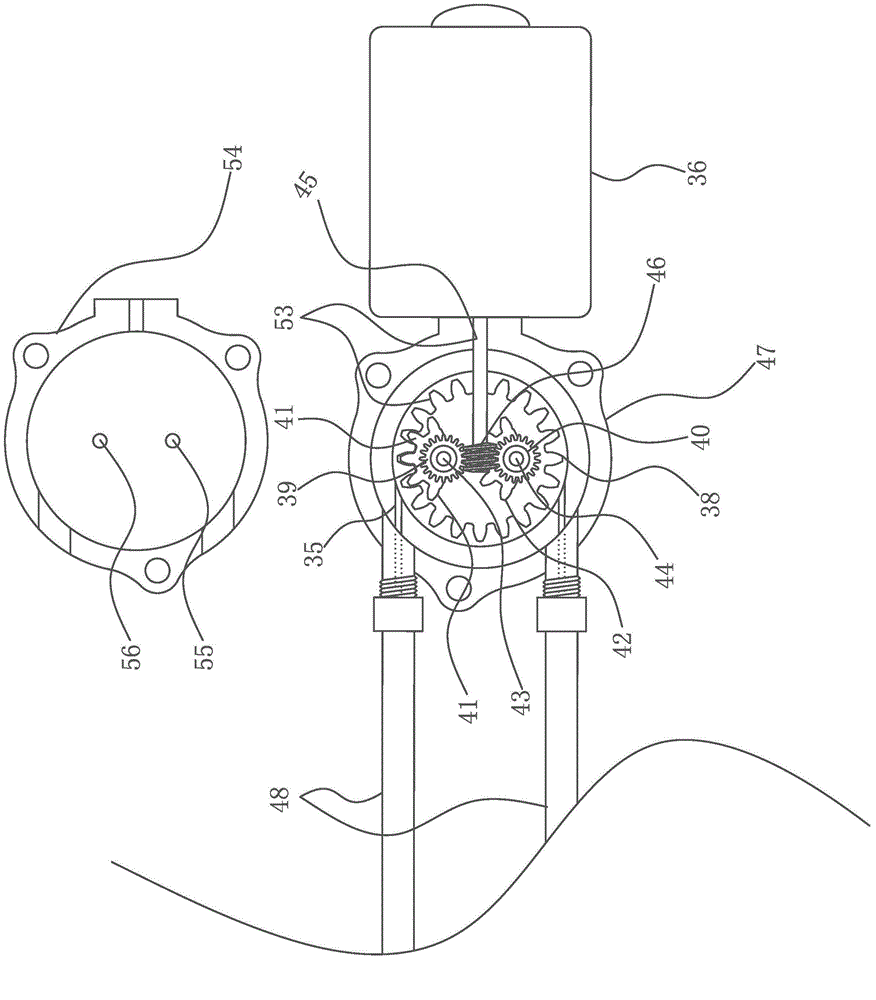

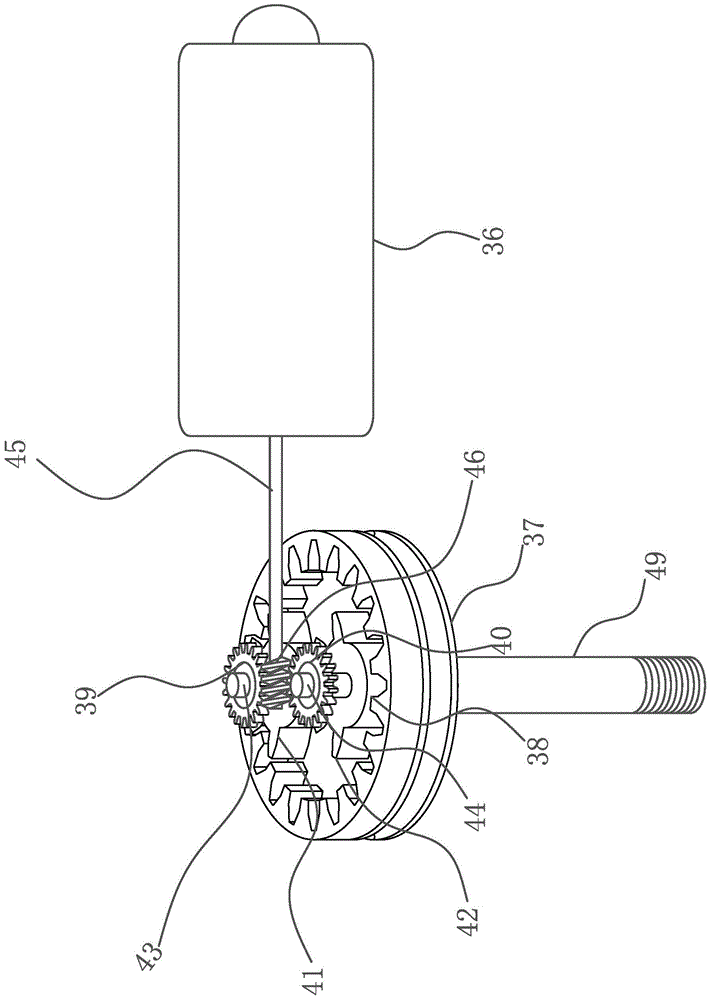

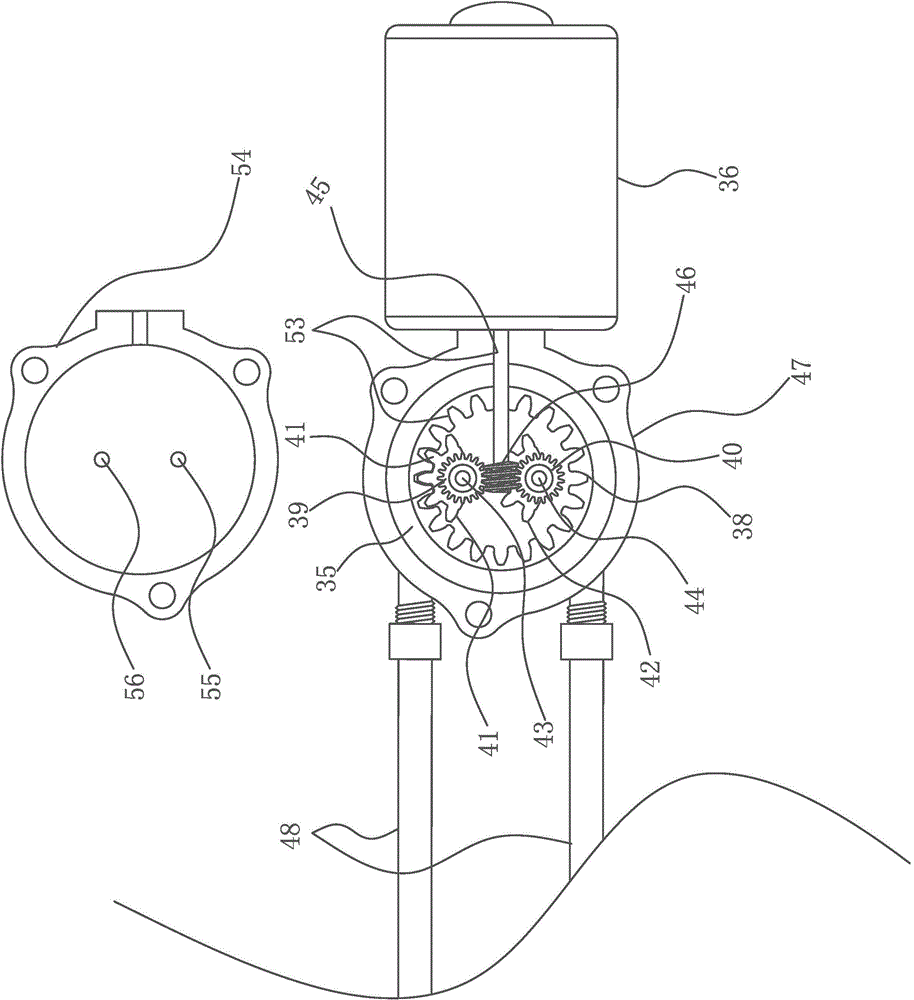

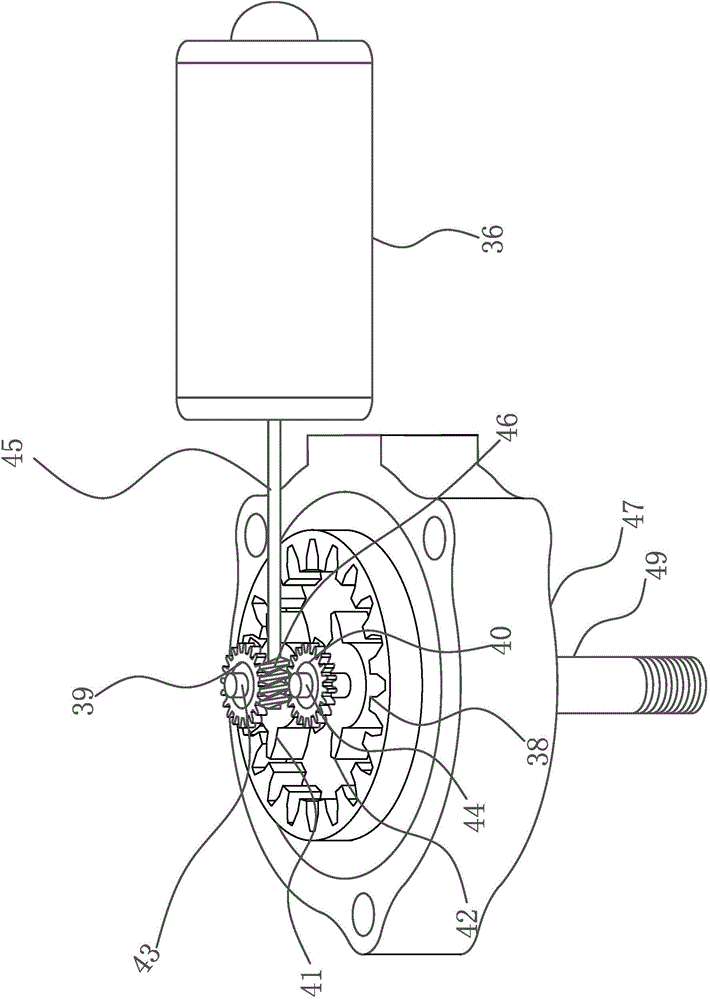

Three-scraping-piece flexible wall supported wiper flexible shaft type windscreen wiper

ActiveCN104554164AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive shaftInterior noise

A three-scraping-piece flexible wall supported wiper flexible shaft type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wiper drive shaft and a driving wiper drive shaft, the driven wiper drive shaft and the driving wiper drive shaft are respectively provided with a driven gear and a driving gear, and the driven gear and the driving gear are connected through a flexible shaft and transfer torque. A forward and reverse rotating gear intermittent drive mechanism is arranged on the driving gear. The wiper driving mechanism of the windscreen wiper is of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicles of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:龙岩市腾兴机械维修有限公司

Three-blade flexible wall circular hole inner support wire wheel drive wiper

InactiveCN104554161BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A three-scraping-piece flexible wall round hole internal-supported wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that the wiper driving mechanism is structurally that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. The wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:盐城华依鑫机械科技有限公司

Flexible wall supported wiper wire pulley driven wiper

ActiveCN104554157BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A flexible wall supported wiper wire wheel driven windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that the wiper driving mechanism is structurally that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft and are connected through a flexible rope and transfer torque. The wiper driving mechanism is of a closed structure and is especially suitable for a complicated external environment structure and remote transmission, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:TONGLING HUIYU IND CO LTD

Three-blade flexible wall round hole inner support connecting rod wire wheel type wiper

ActiveCN104554165BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. A closed connecting rod rocker arm driving mechanism is arranged on the driving winding wheel. The connecting rod wire wheel type wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:靖江智云信息科技有限公司

Flexible Wall Bearing Wiper Link Hydraulic Oscillating Wiper

ActiveCN104494570BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEnvironmental structureInterior noise

A hydraulic swing windscreen wiper with a flexible wall supporting wiper connecting rod comprises a wiper motor, a wiper driving mechanism and a wiper. The hydraulic swing windscreen wiper is characterized in that two gear rack swing cylinders are communicated through a hydraulic oil pipe and transmit torque, and a connecting rod swing arm driving mechanism is arranged on a driving gear rack swing cylinder. The hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper is hydraulically driven by a flexible pipeline, high in transmitted torque, small in size and rapid in response, structural limitation is less in mounting owing to hydraulic driving of the flexible pipeline, the windscreen wiper is of a completely closed structure, low in working noise and particularly suitable for complicated external environmental structures and remote driving, external influence is avoided, the shortcoming of burnout of the wiper motor due to external obstacles is avoided, interior noise is effectively reduced, internal comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be more effectively fitted with a windscreen.

Owner:山东星奥液压机械有限公司

Three-scraper wiper hydraulic swing windscreen wiper with flexible wall supporting

ActiveCN104527588AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningGear wheelEnvironmental structure

A three-scraper wiper hydraulic swing windscreen wiper with flexible wall supporting comprises a windscreen wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear and rack swing oil cylinders are communicated through a hydraulic oil pipe, torque is transmitted between the two gear and rack swing oil cylinders through the hydraulic oil pipe, and a forward and reverse rotation gear intermittent transmission mechanism is arranged on the driving gear and rack swing oil cylinder. The three-scraper wiper hydraulic swing windscreen wiper has the advantages that as flexible pipeline hydraulic transmission is adopted in the wiper driving mechanism of the windscreen wiper, structural limit is small when the windscreen wiper is installed; as the windscreen wiper is of a completely closed structure, noise is low when the windscreen wiper works, the windscreen wiper is particularly suitable for the complex external environmental structure and long-distance transmission and not affected by external factors, the defect that the windscreen wiper motor is burnt due to external obstacles is overcome, the noise in a vehicle is effectively lowered, and the comfort in the vehicle is improved when the vehicle operates; windscreen wiper rubber strips are supported by a flexible wall and therefore can fit windscreen better, and the scraping efficiency of the three-scraper structure is three times that of a general single scraper.

Owner:全椒县全动机械有限公司

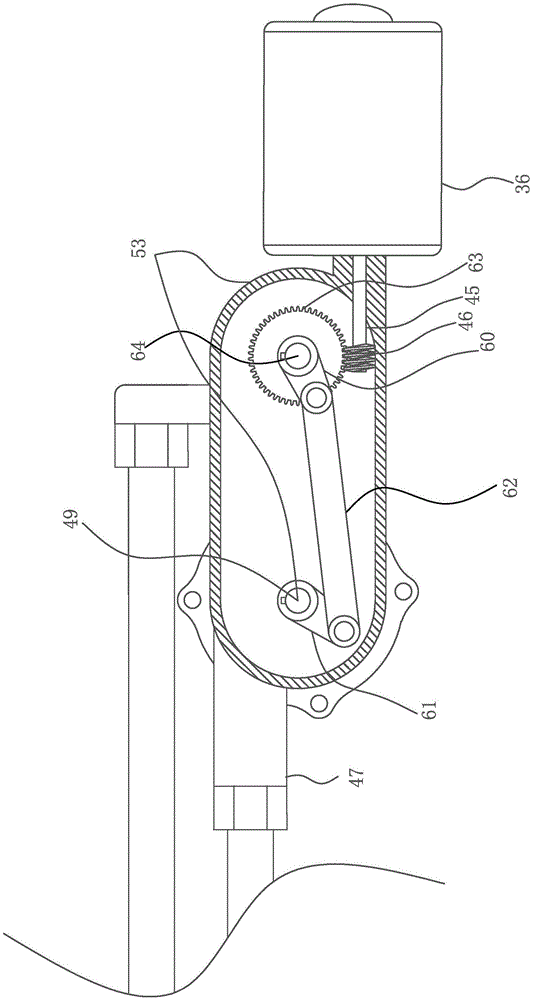

Flexible wall supported wiper connecting rod flexible shaft type windscreen wiper

A flexible wall supported wiper connecting rod flexible shaft type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wiper drive shaft and a driving wiper drive shaft, the driven wiper drive shaft and the driving wiper drive shaft are respectively provided with a driven gear and a driving gear, and the driven gear and the driving gear are connected through a flexible shaft and transfer torque. A closed connecting rod rocker arm driving mechanism is arranged on the driving gear. The wiper driving mechanism of the windscreen wiper is of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicle of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:泰安泰山科技有限公司

Flexible wall supporting windshield wiper connecting rod wire wheel type windshield wiper with three scraping pieces

InactiveCN104527582AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelWire wheel

A flexible wall supporting windshield wiper connecting rod wire wheel type windshield wiper with three scraping pieces comprises a wiper motor, a wiper driving mechanism and a wiper, and is characterized in that a wiper driving shaft comprises a driven wheel wiper driving shaft and a driving wheel wiper driving shaft which are arranged in a driven wheel wiper driving shaft hole of a driven wheel fixing seat and a driving wheel wiper driving shaft hole of a driving wheel fixing seat respectively; the driven wheel wiper driving shaft and the driving wheel wiper driving shaft are provided with a driven winding wheel and a driving winding wheel respectively, the driven winding wheel and the driving winding wheel are connected through a flexible rope and transmit torque, and the driving winding wheel is provided with a closed type connecting rod swing arm driving mechanism. The connecting rod line wheel type wiper driving mechanism of the windshield wiper is of a closed structure, is particularly suitable for complex and long-distance transmission of an external environment, is not affected by the outside and avoids the defect that the wiper motor is burnt out due to an external barrier. A wiper rubber strip is supported by a flexible wall and can be better attached to windshield glass. The scraping efficiency of the three-scraping-piece structure is three times that of a common single scraping piece.

Owner:陈学琴

A carpet assembly with a load-carrying air duct and a production method for an air duct under the carpet

ActiveCN104477066BIncrease stiffnessImprove bearing capacityVehicle arrangementsSynthetic resin layered productsSurface layerPolyethylene terephthalate

Owner:湖北三环汽车工程塑料有限公司

Flexible wall supported wiper blade hydraulic wiper

ActiveCN104554166BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningInterior noiseEngineering

A flexible wall supported wiper blade hydraulic type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a forward and reverse rotating gear intermittent drive mechanism is arranged on the driving blade swing oil cylinder. The flexible wall supported wiper blade hydraulic type windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicle of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:通威精密金属(佛山)有限公司

Double blade flexible wall wiper linkage hydraulic swing wiper

The invention provides a double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper. The double-scraper flexible-wall and hydraulic swinging connecting rod type windscreen wiper comprises a wiper motor, a wiper brush driving motor and a wiper brush. The double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper is characterized in that two gear rack swinging oil cylinders are communicated through a hydraulic oil pipe to transmit torque; a connecting rod rocker arm driving mechanism is arranged on a driving gear rack swinging oil cylinder. The double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper has the beneficial effects that the wiper brush driving mechanism is hydraulically transmitted through a flexible pipeline; the mounting is greatly avoided structural limitation; in addition, the a completely closed structure is provided; the working generates little noise; the complex external environment and long-distance transmission particularly apply, and moreover, outside influence is prevented, so that the shortage that the wiper motor is burnt through an external barrier can be avoided; the noise in a vehicle can be effectively reduced; the internal comfort of the vehicle in running can be improved; rubber strips of the wiper are supported through flexible walls and can be clung to a windscreen; the scraping efficiency of the double-scraper structure is doubled that of the general single-scraper structure.

Owner:烟台鑫运化工有限公司

Three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper

ActiveCN104554170AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive shaftEngineering

A three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper comprises a wiper motor and a wiper drive shaft and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a connecting rod rocker arm drive mechanism is arranged on the driving blade swing oil cylinder. The three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper that a wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:齐河智谷产业发展有限公司

Three-scraping-piece flexible wall round hole internal-supported wire wheel type windscreen wiper

InactiveCN104554161AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A three-scraping-piece flexible wall round hole internal-supported wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that the wiper driving mechanism is structurally that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. The wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:盐城华依鑫机械科技有限公司

Dual Blade Flexible Wall Wiper Hydraulic Oscillating Wiper

InactiveCN104527592BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDouble wallEngineering

A hydraulic swing windscreen wiper with two scraping sheets, flexible walls and a windshield wiper body comprises a windscreen wiper motor, a windscreen wiper driving mechanism and the windshield wiper body, and is characterized in that two gear rack swing oil cylinders are communicated with each other through a hydraulic oil pipe and used for transmitting torque, and the driving gear rack swing oil cylinder is provided with a forward and reverse gear intermittent transmission mechanism. The hydraulic swing windscreen wiper has the advantages that hydraulic transmission is conducted on the windscreen wiper driving mechanism of the windscreen wiper through a flexible pipeline, the windscreen wiper is seldom subjected to structural constraints during installation, is of a completely closed structure, is low in noise during work, is especially suitable for external environments of complex structures and remote transmission, is not influenced by exteriors, overcomes the defect that external obstacles cause burndown of the windshield wiper motor, effectively lowers noise in a vehicle and improves internal comfort when the vehicle runs; windscreen wiper rubber strips are supported by the flexible walls and can be better attached to windshield glass, and scraping efficiency of a double-scraping-sheet structure is twice that of common single-scraping-sheet structures.

Owner:来安县莱英汽车工程有限公司

Flexible wall bearing wiper linkage blade hydraulic wiper

InactiveCN104527585BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive shaftEngineering

A flexible wall supporting windshield wiper connecting rod vane hydraulic windshield wiper comprises a wiper motor and a wiper driving shaft, and is characterized in that two vane swing oil cylinders are communicated through a hydraulic oil pipe and transmit torque; the driving vane swing oil cylinder is provided with a connecting rod swing arm driving mechanism. The flexible wall supporting windshield wiper connecting rod vane hydraulic windshield wiper has the advantages that a wiper driving mechanism of the windshield wiper is driven hydraulically through a flexible pipeline, the transmission torque is large, the size is small, and response is fast; as hydraulic transmission is achieved through the flexible pipeline, the windshield wiper is slightly limited by the structure when installed, is of a fully closed structure, is low in noise when working, is particularly suitable for complex and long-distance transmission of an external environment, is not affected by the outside, avoids the defect that the wiper motor is burnt out due to an external barrier, effectively reduces noise in a car and improves the comfort inside the car in the running process; a wiper rubber strip is supported by a flexible wall and can be better attached to windshield glass.

Owner:重庆市点旭科技有限公司

Three-blade flexible wall mounted wiper linkage hydraulic oscillating wiper

ActiveCN104527589BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEnvironmental structureEngineering

Owner:徐州宇之阳市场营销策划有限公司

Three-scraping-piece flexible wall round hole internal-supported wiper blade hydraulic type windscreen wiper

InactiveCN104554169AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEngineeringWindscreen wiper

A three-scraping-piece flexible wall round hole internal-supported wiper blade hydraulic type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a forward and reverse rotating gear intermittent drive mechanism is arranged on the driving blade swing oil cylinder. The three-scraping-piece flexible wall round hole internal-supported wiper blade hydraulic type windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, is small in structural limitation during installation, is completely of a closed structure, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:徐州宇之阳市场营销策划有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com