Special-shaped curved-surface aramid fiber paper honeycomb simple pre-shaping die and manufacturing method thereof

A special-shaped curved surface and aramid paper technology, which is applied in the field of molds, can solve the problems of high manufacturing cost and long manufacturing cycle, and achieve the effects of reduced production cost, simple production and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

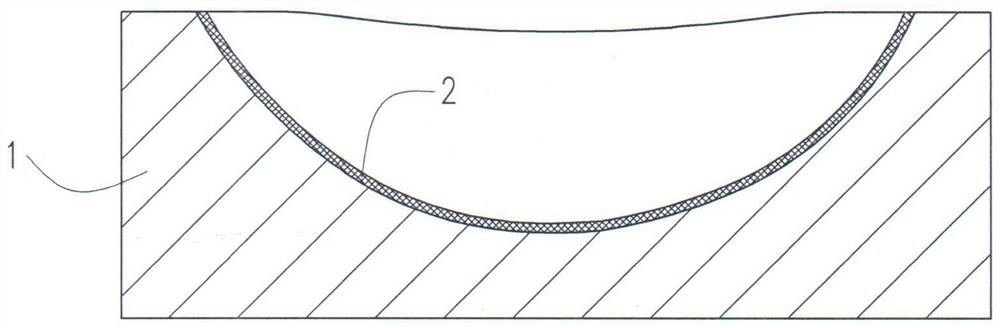

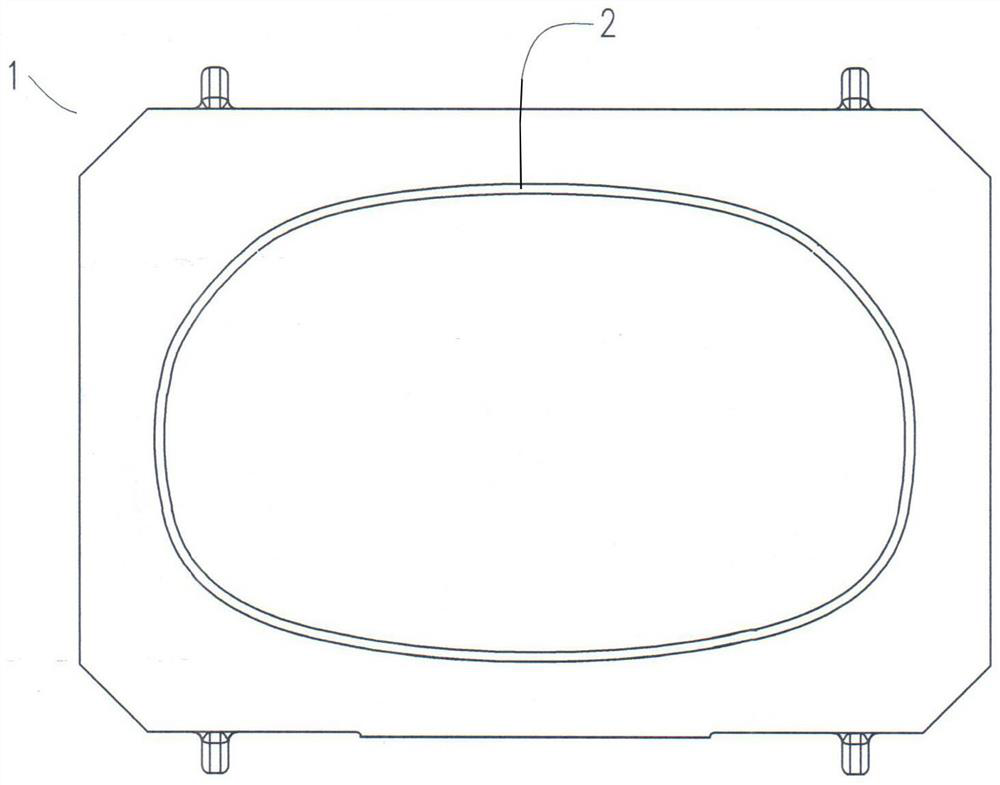

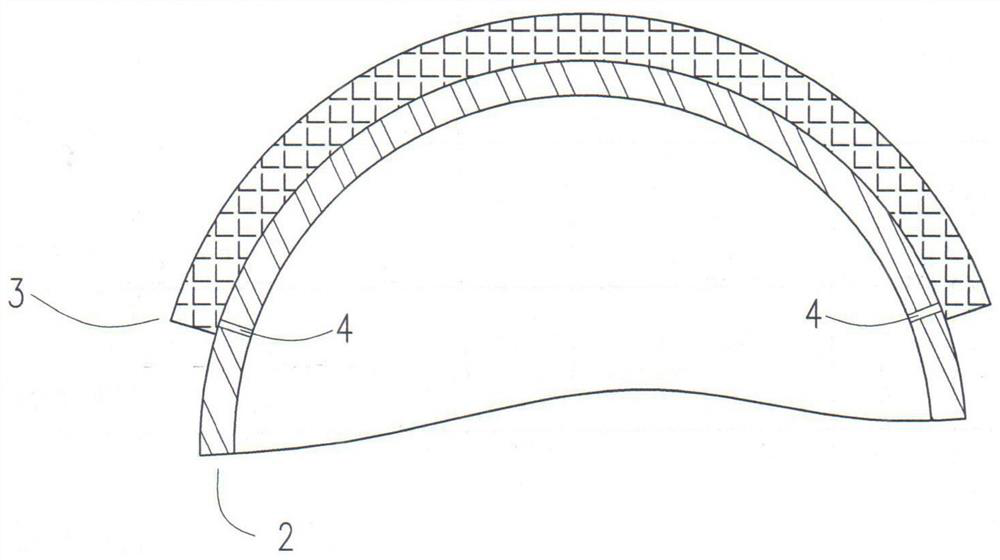

[0020] Such as Figure 1 to Figure 3 As shown, the mold body of an embodiment of the present invention is composed of multiple layers of high-temperature-resistant prepregs. The periphery of the mold body is provided with a plurality of positioning holes 4 for positioning the aramid paper honeycomb.

[0021] The principle is: use the ready-made composite material product forming mold (such as figure 1 In this embodiment shown, the product forming die 1) is used, and multi-layer high-temperature-resistant prepreg is compounded to make a simple pre-setting mold 2 of aramid paper honeycomb with special-shaped curved surface. Positioning holes 4 are provided to cooperate with electrician's clips to locate the aramid paper honeycomb. Using the above-mentioned simple pre-setting mold 2 of aramid paper honeycomb with special-shaped curved surface can replace the traditional steel mold, which is easy to manufacture and low in production cost. After presetting the aramid paper honeyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com