A carpet assembly with a load-carrying air duct and a production method for an air duct under the carpet

A production method and air duct technology, applied in the field of automotive parts, to achieve the effects of light weight, good shape fit, and improved rigidity and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Produces a certain model of Dongfeng Infiniti car carpet down duct, the overall dimensions of the duct: length * width * thickness: 732mm*654mm*545mm.

[0034] 1. Raw material preparation: According to the consumption quota requirements of the product, the raw materials are cut into raw material sheets of a predetermined size. The surface weight of PET non-woven fabric layer per unit area is 80g / m 2 , The inner polypropylene layer has a unit area weight of 1000g / m 2 . The total thickness of the material is 1.1mm. Tensile elongation at break is 180%.

[0035] 2. Raw material baking: The raw materials are baked simultaneously by double-sided radiant heating. The PET non-woven fabric layer is radiantly heated by the upper heating plate. The heating temperature: 180℃, the heating time is 40s; the polypropylene layer is radiantly heated by the lower heating plate. , Heating temperature: 220℃, heating time 20s. The polypropylene layer is placed on the Teflon conveyor belt.

[00...

Embodiment 2

[0046] Produces a certain model of Dongfeng passenger car carpet down duct, the overall dimensions of the duct: length * width * thickness: 712mm*422mm*380mm.

[0047] 1. Raw material preparation: According to the consumption quota requirements of the product, the raw materials are cut into raw material sheets of a predetermined size. The surface weight of PET non-woven fabric layer per unit area is 200g / m 2 , The inner polypropylene layer has a unit area weight of 2000g / m 2 , The total thickness of the material is 2.0mm. Tensile elongation at break is 196%.

[0048] 2. Raw material baking: The raw materials are baked simultaneously by double-sided radiant heating. The PET non-woven fabric layer is radiantly heated by the upper heating plate. The heating temperature: 260℃, the heating time is 20s; the polypropylene layer is radiantly heated by the lower heating plate. , Heating temperature: 140℃, heating time 40s.

[0049] 3. Hot pressing and cutting: The heated sheet is placed on ...

Embodiment 3

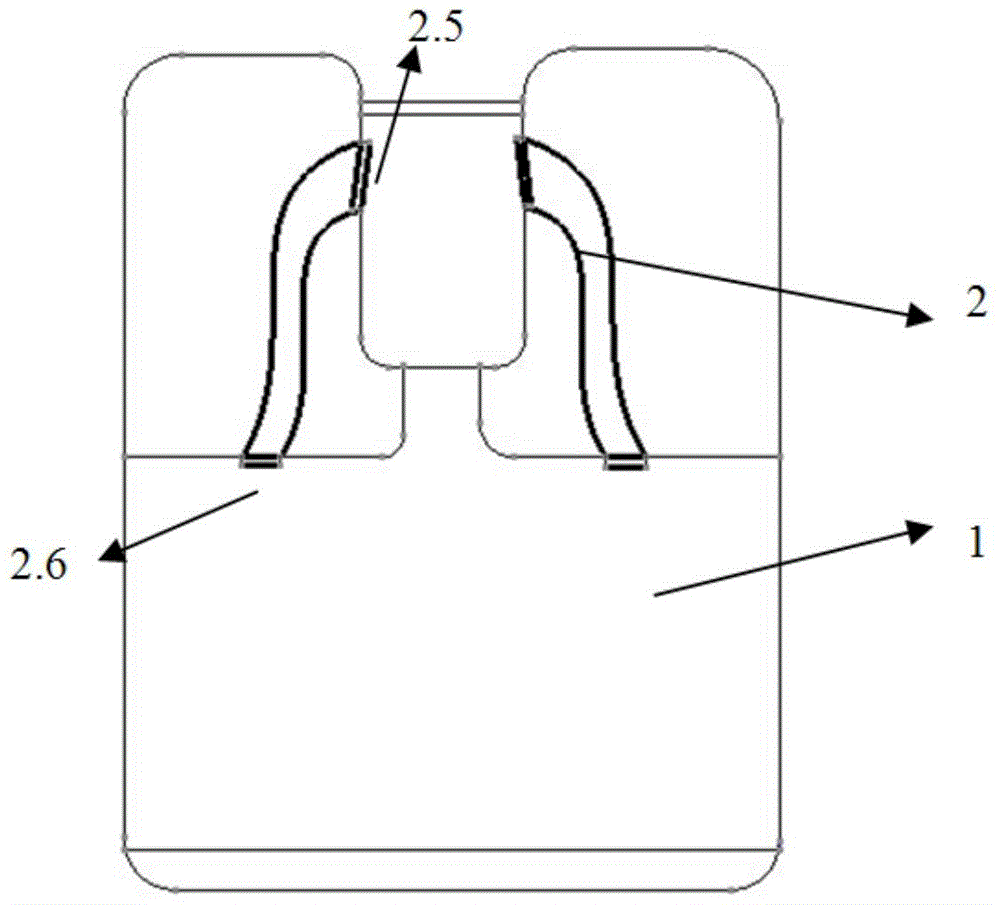

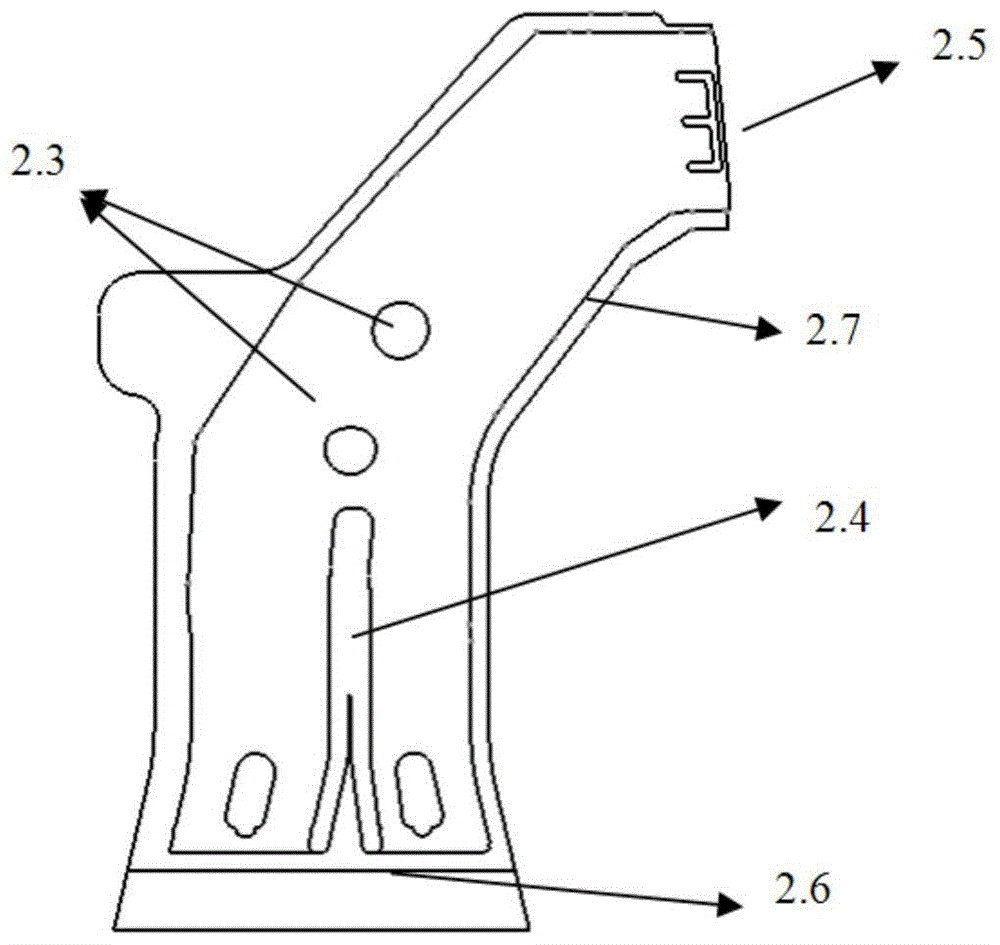

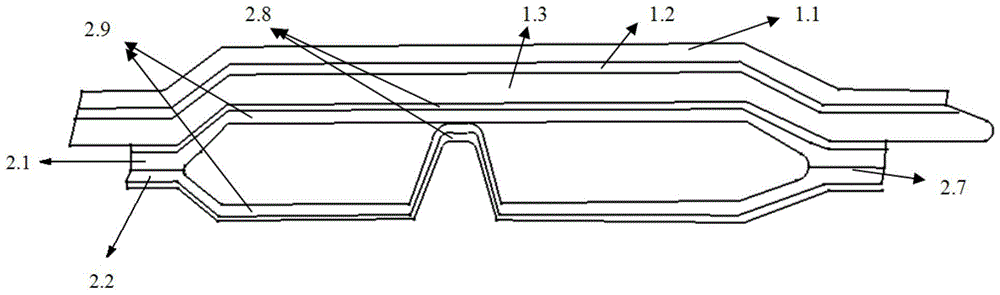

[0059] Such as figure 1 , image 3 As shown, a carpet assembly with a load-bearing duct includes a carpet layer 1 and a duct sub-assembly 2. There are two air duct sub-assemblies 2, which are located in the lower part of carpet layer 1, and are symmetrically distributed on both sides of the center line of carpet layer 1. The carpet layer 1 is composed of three layers of materials. The carpet surface layer 1.1 is a PET needle-punched carpet layer for decoration and wear resistance; the middle layer of the carpet 1.2 is a polyurethane foam layer for shaping and anti-permeability; the carpet bottom layer 1.3 It is a polypropylene layer, which is adhesive after heating. The back of the carpet layer 1 is designed with a groove matching the upper part 2.1 of the air pipe, which is bonded to the surface layer 2.8 of the air pipe material of the upper part 2.1 of the air pipe by hot pressing. The air inlet 2.5 of the air duct sub-assembly 2 is clampedly connected to the air outlet pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com