Electronic load testing device

A technology for testing devices and electronic loads, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of inability to effectively reduce heat generation and heat dissipation performance of lead wires and radiators, inconvenient expansion of power modules, and unreasonable structural layout, etc. problem, to achieve the effect of reducing the heat generation of the lead wire and the whole machine, eliminating the need for welding, and reducing the volume of the radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

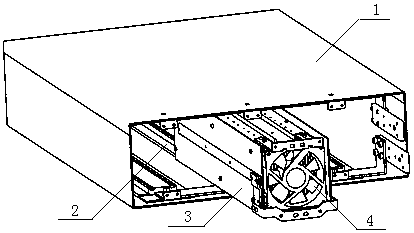

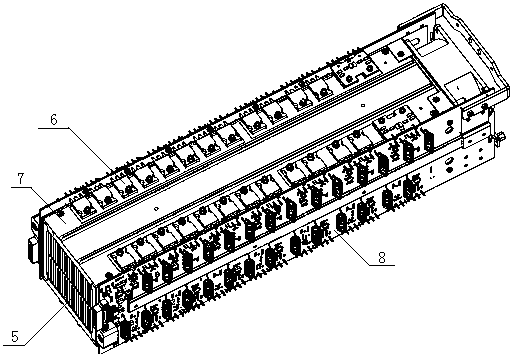

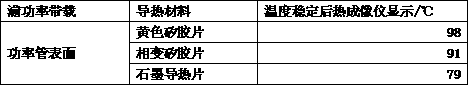

[0015] Example figure 1 with figure 2 As shown, this embodiment provides an electronic load testing device, including a housing 1, a connection board, three electrically insulating guide rails 2, a power module 3 and a main control board, and the main control board controls the power module through the connection board and external testing equipment, a power module 3 is electrically insulated from the housing 1 by means of an electrically insulating guide rail 2 and is installed in the housing 1, and the remaining two electrically insulating guide rails 2 are extended for backup. The power module 3 includes a PCB board 8 , a plurality of power devices 6 and a heat sink 5, the heat dissipation ends of a plurality of power devices 6 are all mounted on the heat sink 5, and the heat dissipation ends on the pins of the power devices 6 are positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com