Flexible wall supporting windshield wiper rubber strip with three scraping pieces

A technology with flexible walls and three blades, which is applied in the field of wiper blades and wiper rubber strips supported by flexible walls with three blades, to achieve the effect of improving scraping cleanliness and scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

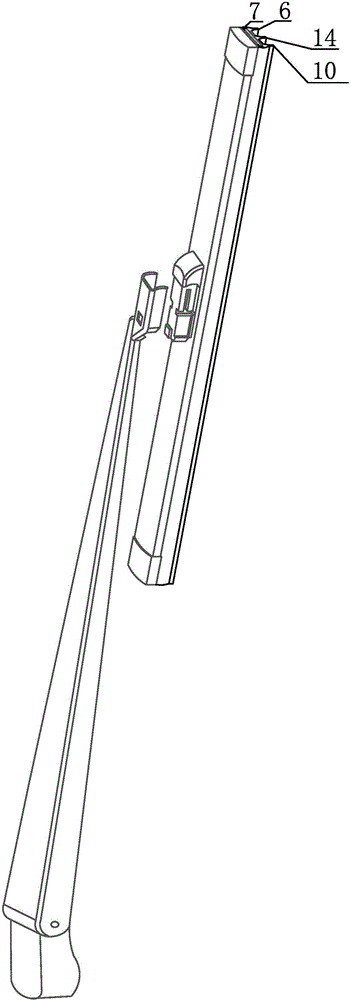

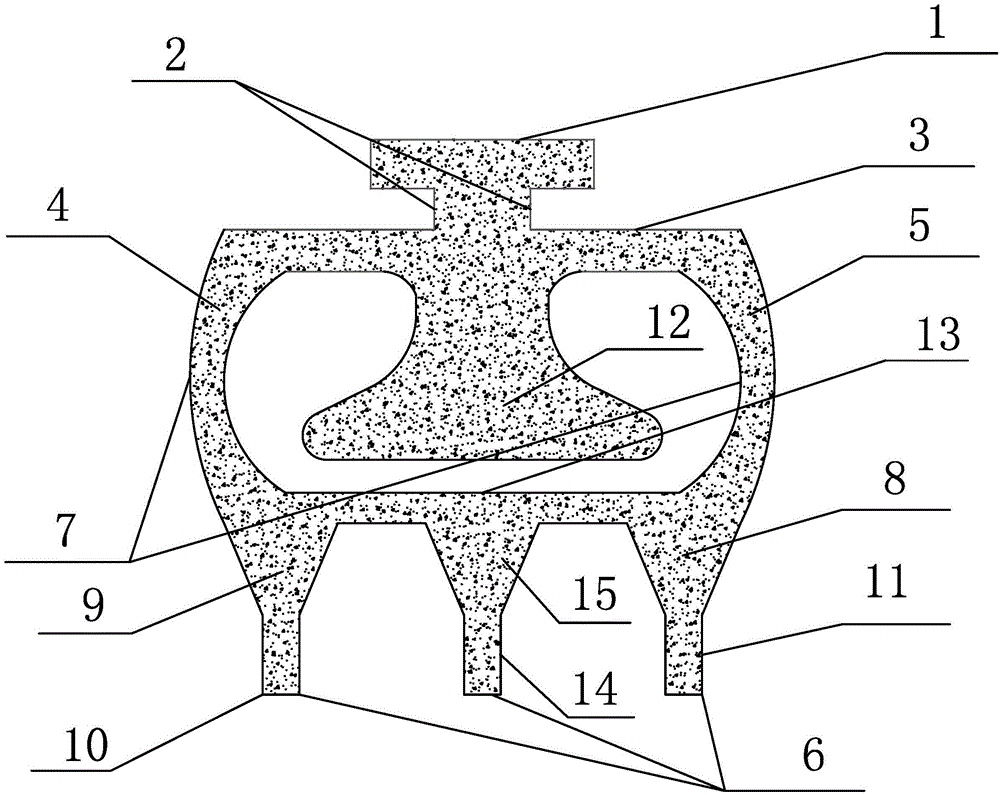

[0013] Figure 1-Figure 2 In the embodiment, the upper part of the wiper rubber strip (1) is provided with a wiper rubber strip fixing slot (2), and the lower part is provided with a wiper blade (6). The two sides of the base plate (3) of (2) extend downwards respectively to form a left flexible wall (4) and a right flexible wall (5). The two sides of the two sides converge to form a hollow flexible wall support structure (7); the left scraper (10) which is arranged in parallel to the axis of the flexible wall support structure (7) is respectively provided at both sides and the middle part of the flexible wall bottom plate (13) ) and the right scraper (11) and middle scraper (14).

[0014] The wall thickness of the left flexible wall (4) and the right flexible wall (5) is gradually changing from thick to thin from the upper and lower ends of the walls to the middle. The middle parts of the left flexible wall (4) and the right flexible wall (5) protrude outward.

[0015] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com