Conformal ceramic metamaterial and preparation method thereof

A technology of metamaterials and ceramic powders, applied in the field of conformal ceramic metamaterials and their preparation, can solve problems such as the inability to meet high-strength properties, and achieve the effect of improving strength and good wave-transmitting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

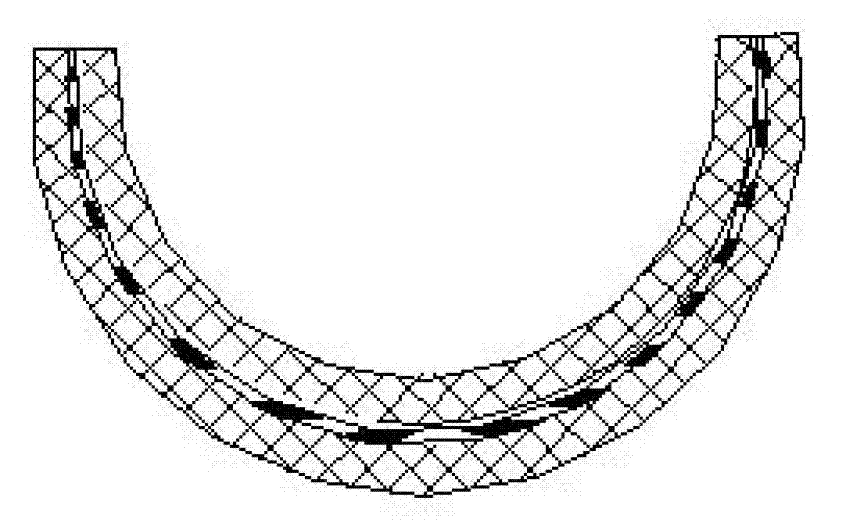

[0023] A preparation method of a conformal ceramic metamaterial, the preparation method comprising the following steps:

[0024] a. Preparation of green body: will contain ceramic powder (such as cordierite, alumina or non-oxide Si 3 N 4 etc.) and the suspension of the organic system are degassed and prepolymerized to obtain a slurry, which is poured into the first mold and inserted into the core of the mold, and after curing, a green body formed by gel injection molding is obtained;

[0025] The specific process is: dissolve the organic monomer and cross-linking agent in water, and add water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com