Composite fiber automobile interior board and production method thereof

A technology for automotive interior panels and composite fibers, which is applied in the field of automotive interior panels, can solve the problems of poor mechanical properties of natural plant fibers, little improvement in the strength of composite materials, and limited improvement in resin-based performance, and achieves strong UV resistance, The effect of good wave transmission performance and high temperature filterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh the raw materials (kg) according to the following weights:

[0027] Polylactic acid fiber 50, jute fiber 30, basalt fiber 20;

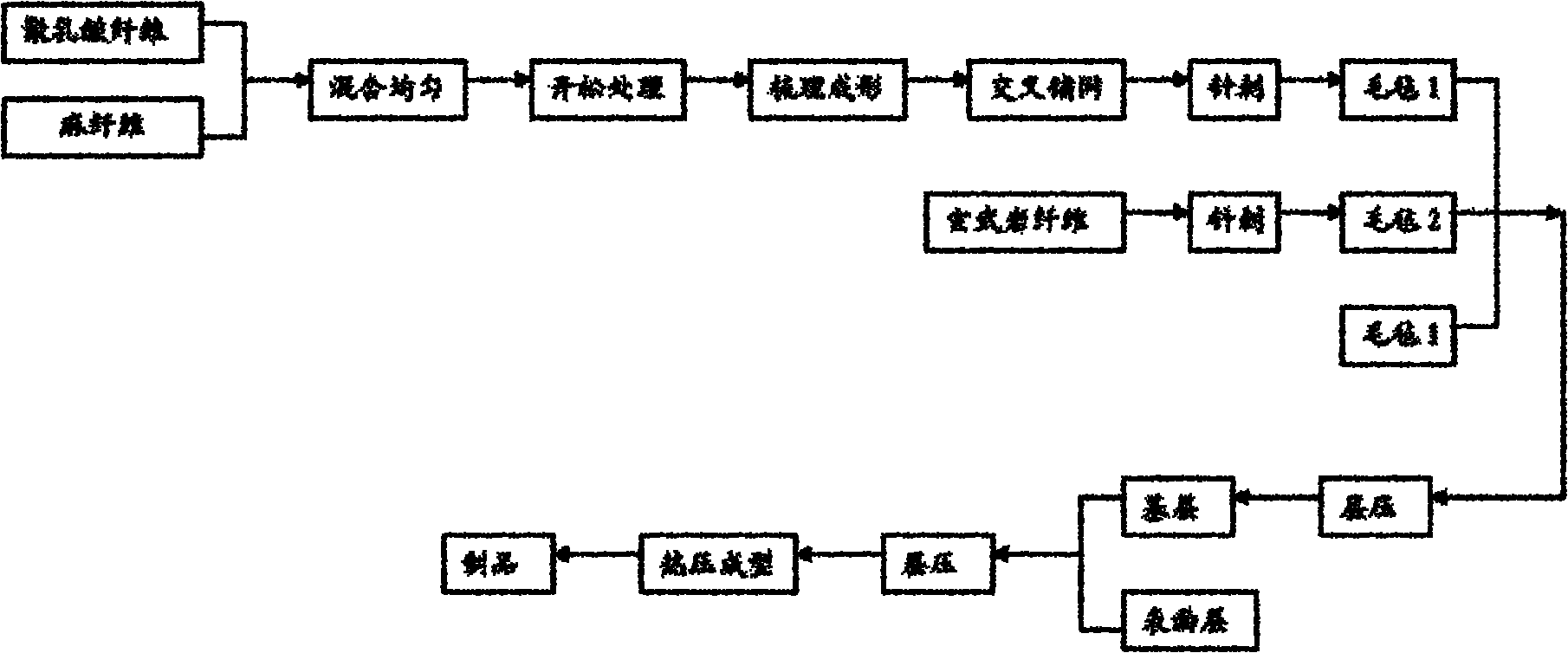

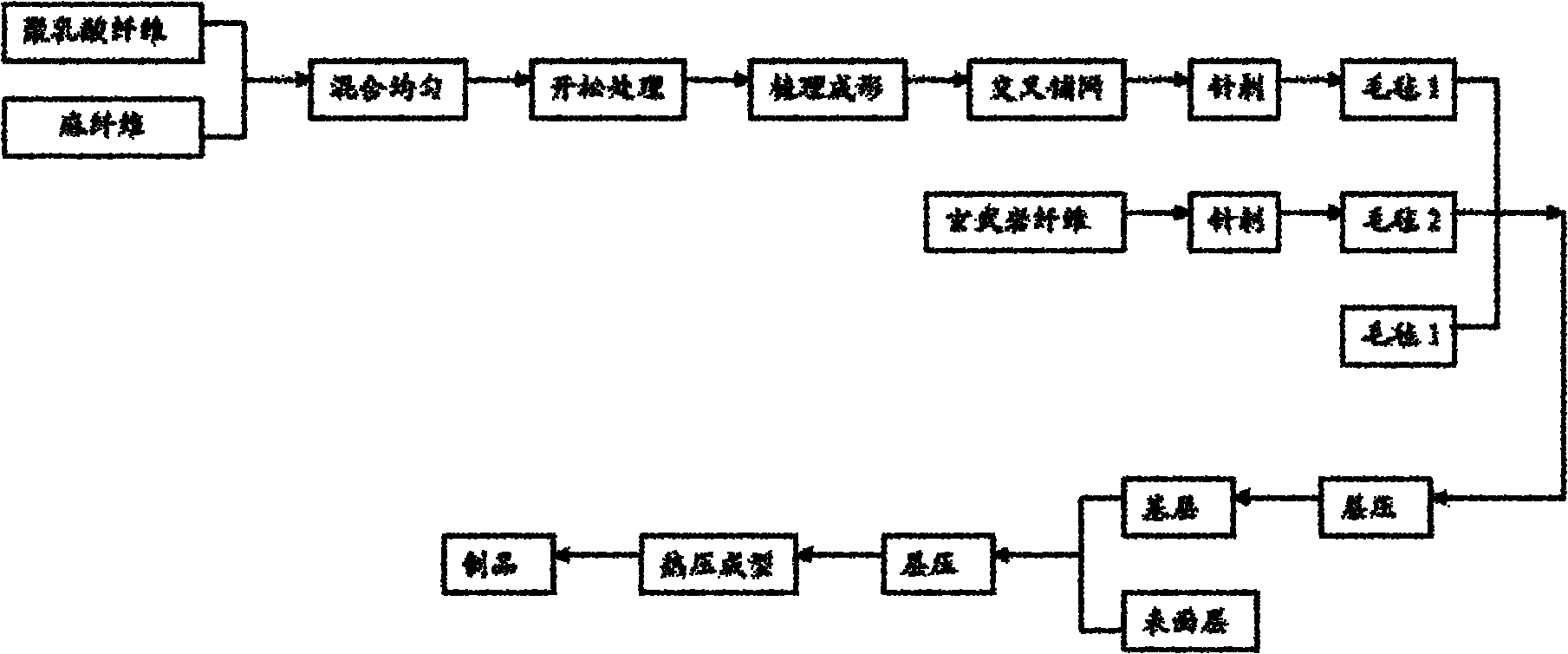

[0028] Method of producing automotive interior panels:

[0029] (1) uniformly mix 50kg of polylactic acid fibers with a length of 5 to 20cm and 30kg of jute fibers with a length of 5 to 20cm;

[0030] (2) Put into the opening machine for opening treatment;

[0031] (3) conveying to the carding machine by air flow for carding and forming;

[0032] (4) Re-feed into the cross-laying machine in the laminating machine;

[0033] (5) The laid net is folded as required and then sent to the pre-needling machine for pre-needling into felt;

[0034] (6) continue to send the pre-needled felt into the main needling machine to carry out main needle punching to form a composite felt 1 of hemp fiber and polylactic acid fiber;

[0035] (7) weaving 20kg basalt fiber into felt 2;

[0036] (8) The felt 1, the felt 2, and the felt 1 are laid out and lam...

Embodiment 2

[0040] Weigh the raw materials (kg) according to the following weights:

[0041] Polylactic acid fiber 50, sisal fiber 25, basalt fiber 25;

[0042] Method of producing automotive interior panels:

[0043] (1) uniformly mix 50kg of polylactic acid fibers with a length of 5 to 20cm and 25kg of sisal fibers with a length of 5 to 20cm;

[0044] (2) Put into the opening machine for opening treatment;

[0045] (3) conveying to the carding machine by air flow for carding and forming;

[0046] (4) Re-feed into the cross-laying machine in the laminating machine;

[0047](5) The laid net is folded as required and then sent to the pre-needling machine for pre-needling into felt;

[0048] (6) continue to send the pre-needled felt into the main needling machine to carry out main needle punching to form a composite felt 1 of hemp fiber and polylactic acid fiber;

[0049] (7) weaving 25kg basalt fiber into felt 2;

[0050] (8) The felt 1, the felt 2, the felt 1, the felt 2, and the fe...

Embodiment 3

[0054] Weigh the raw materials (kg) according to the following weights:

[0055] PLA fiber 40, hemp fiber 20, flax 20, basalt fiber 20;

[0056] Method of producing automotive interior panels:

[0057] (1) 40kg of polylactic acid fibers with a length of 5 to 20 cm, 20 kg of hemp fibers with a length of 5 to 20 cm and 20 kg of hemp fibers with a length of 5 to 20 cm are uniformly mixed;

[0058] (2) Put into the opening machine for opening treatment;

[0059] (3) conveying to the carding machine by air flow for carding and forming;

[0060] (4) Re-feed into the cross-laying machine in the laminating machine;

[0061] (5) The laid net is folded as required and then sent to the pre-needling machine for pre-needling into felt;

[0062] (6) continue to send the pre-needled felt into the main needling machine to carry out main needle punching to form a composite felt 1 of hemp fiber and polylactic acid fiber;

[0063] (7) weaving 20kg basalt fiber into felt 2;

[0064] (8) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com