Double-layer allotype surface cement-based absorption material and preparation method thereof

A wave-absorbing material, cement-based technology, applied in the interdisciplinary field of electromagnetics and material science, can solve the problems of high density and high cost of cement-based wave-absorbing materials, achieve excellent wave-absorbing performance and mechanical properties, reduce absorption performance, protect environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

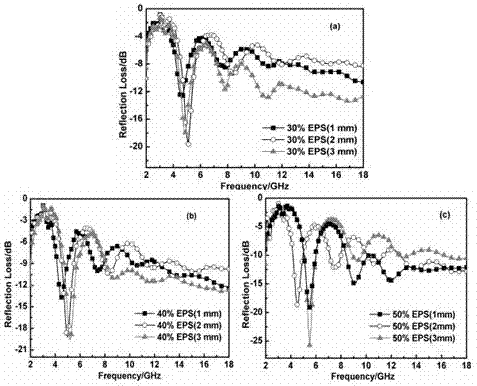

[0036] Example 1: This example is a single-layer cement-based wave-absorbing material, including scheme a, scheme b and scheme c

[0037] Scheme a: This scheme is a single-layer cement-based wave-absorbing material, which is made of the following raw materials in weight percentage: 30% polystyrene foam, 4% fly ash, 4% carbon black, 4% wave-absorbing agent, and 15% cement , the balance is water; wherein, the wave absorbing agent is nickel-zinc ferrite, and the particle diameter of polystyrene foam particles is 1mm;

[0038] The preparation method of the single-layer cement-based wave-absorbing material of this embodiment comprises the following steps:

[0039] S1. Weigh the raw materials in weight percentage, put cement and water into the mortar mixer, and configure it into cement slurry with a water-cement ratio of 0.35, and set it aside. Among them, water is added twice, first pouring in 2 / 3 of the total volume of water After stirring for 3 minutes, pour in the remaining amo...

Embodiment 2

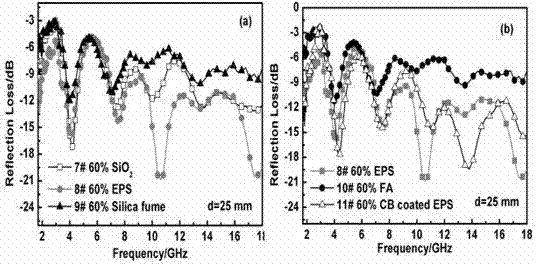

[0053] Example 2#: According to the raw materials and their dosages shown in Table 1, the preparation method of the double-layer special-shaped surface cement-based wave-absorbing material in this example includes the following steps:

[0054] S1. Weigh the raw materials in weight percentage, put cement and water into the mortar mixer, and configure it into a cement slurry with a water-cement ratio of 0.34. Among them, water is added twice, and water accounting for 2 / 3 of the total volume of water is poured first. , after stirring for 3 minutes, pour in the remaining amount of water, and stir for another 5 minutes;

[0055] S2. Add polystyrene foam to the cement slurry prepared in step S1, add at least one of fly ash, expanded perlite, and shale ceramsite or none, stir for 8 minutes, and then add a wave absorbing agent. Stir for 4 minutes to obtain the first mixed slurry, then inject the first mixed slurry into the mold, vibrate for 0.5min, and scrape the surface to obtain the...

Embodiment 3

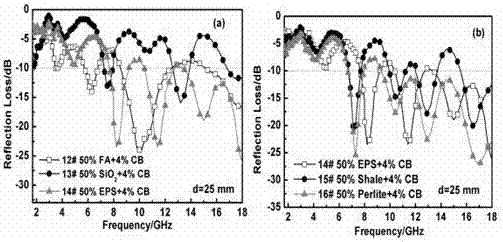

[0058] Example 3#: According to the raw materials and their dosages shown in Table 1, the preparation method of the double-layer special-shaped surface cement-based wave-absorbing material in this example includes the following steps:

[0059] S1. Weigh the raw materials in percentage by weight, put cement and water into the mortar mixer, and configure it into a cement slurry with a water-cement ratio of 0.4, in which, water is added twice, and water accounting for 2 / 3 of the total volume of water is poured first. , after stirring for 3 minutes, pour in the remaining amount of water, and stir for another 5 minutes;

[0060] S2. Add polystyrene foam to the cement slurry prepared in step S1, add at least one of fly ash, expanded perlite, and shale ceramsite or none, stir for 4 minutes, and then add wave absorbing agent, Stir for 8 minutes to obtain the first mixed slurry, then inject the first mixed slurry into the mold, vibrate for 2 minutes, and scrape the surface to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com