Preparation process of absorbent cotton

A preparation process and technology of water-absorbent cotton, which is applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of unsatisfactory water absorption performance and the use effect of cotton products not reaching the ideal water absorption effect, etc., to achieve improved absorption performance and water absorption Performance improvement, absorption prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

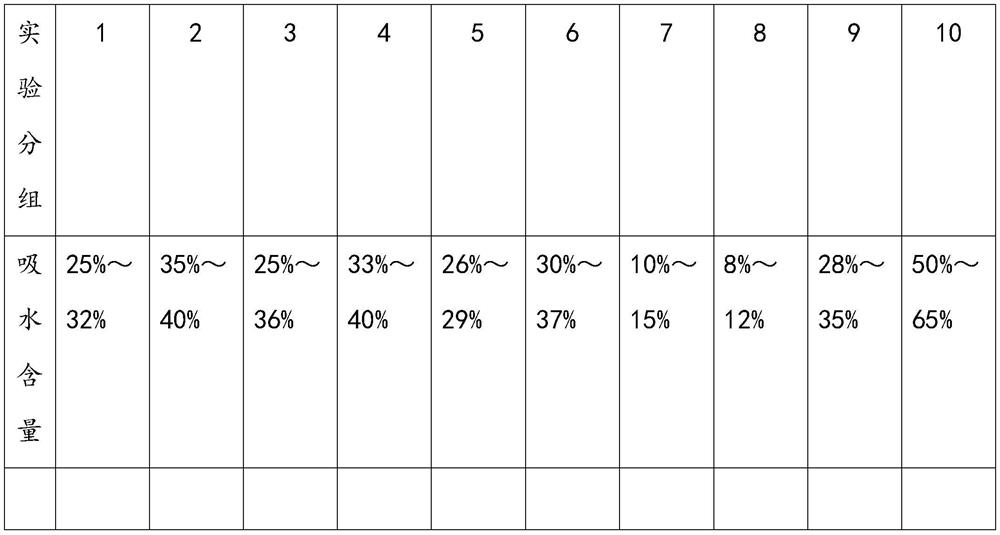

Examples

Embodiment 1

[0026] Prepare a disinfection box, an electronic scale, a foaming mold box, 2 measuring cups, and a mixer, and prepare the above materials for subsequent operations;

[0027] Weigh 80 parts and 20 parts of polyether polyol and hydrophilic polyether polyol respectively through an electronic scale, then weigh 2.8 parts of triethylenediamine and 0.33 parts of dibutyltin dilaurate, and prepare a measuring cup Weigh 41 parts of toluene diisocyanate for subsequent use, and complete the preparation of absorbent cotton

Embodiment 2

[0029] Then pour it into one of the prepared measuring cups, and then use a mixer to stir it evenly. After stirring evenly, use an electronic scale to weigh 1.1 parts of hydrophilic silicone oil and 10 parts of water-absorbing agent, and then mix the hydrophilic silicone oil and water-absorbing agent. Pour it into the measuring cup, the purity of polyether polyol is 96.53%, the purity of toluene diisocyanate is 95.83%, and the purity of hydrophilic polyether polyol is 94.67%, which makes the cotton absorption performance very ideal, and then use The mixer performs uniform stirring, and the stirring temperature is controlled between 40°C and 65°C, which can make the raw materials more fully dissolved;

[0030] Then introduce the prepared 41 parts of toluene diisocyanate into the prepared measuring cup and stir quickly for 3 to 5 seconds, mix the prepared raw materials, and stir evenly, so that the mixed raw materials have water absorption properties.

Embodiment 3

[0032] Put the hollow plant fiber cotton into the foam mold box, the content of cotton fiber in the hollow plant fiber cotton is 55%, and the biological cellulose in the hollow plant fiber cotton in S1 is 45%. Such a ratio makes the hollow plant fiber cotton The absorption performance is better, and then the raw materials in the measuring cup are introduced into the hollow plant fiber cotton, and then the hollow plant fiber cotton is sealed, and then the hollow plant fiber cotton is sealed through the mold and left for a period of time to make absorbent cotton, and then processed into Cotton products are enough, and the uniformly mixed raw materials are prepared, processed, and shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com