Composite wave absorber with dual dynamic regulation and control as well as preparation method and application of composite wave absorber

A wave absorber and dynamic technology, applied in the direction of electrical components, antennas, magnetic field/electric field shielding, etc., can solve the problems of fixed absorption frequency, difficulty in adapting, thick and heavy, etc., achieve good absorption performance and improve absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of a composite absorbing body with dual dynamic regulation, the specific method is as follows:

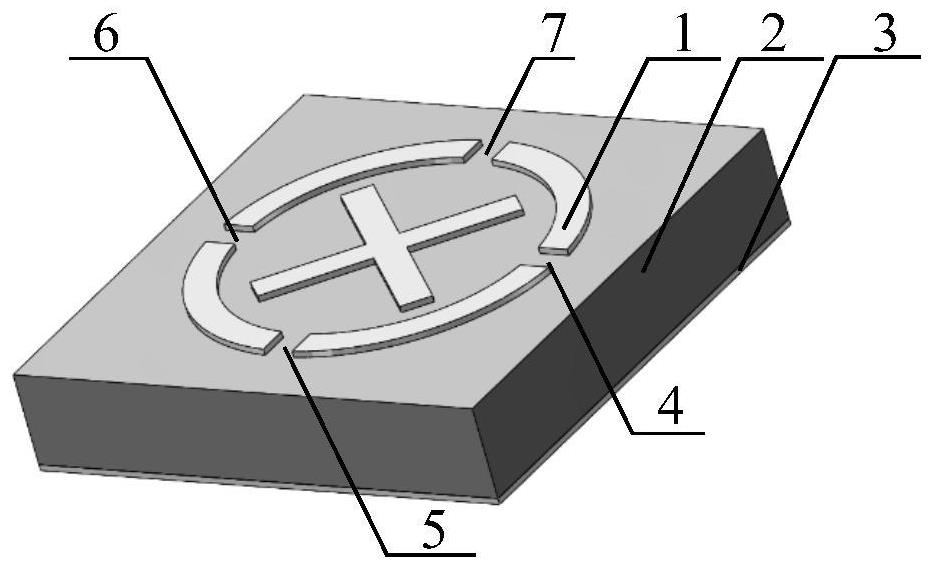

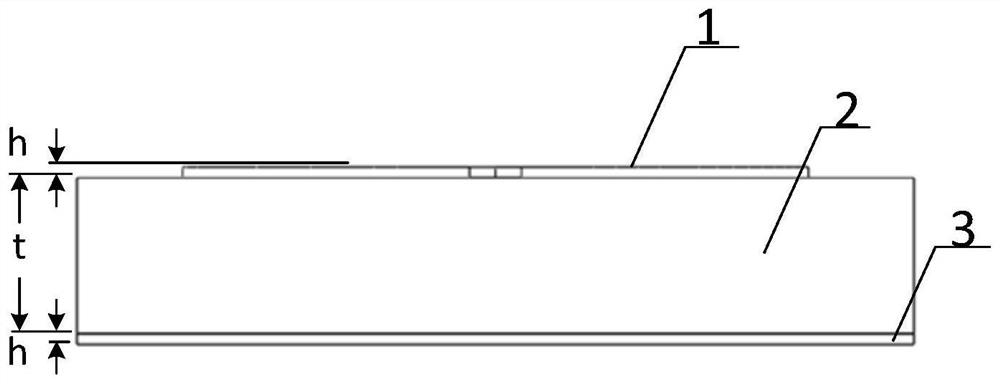

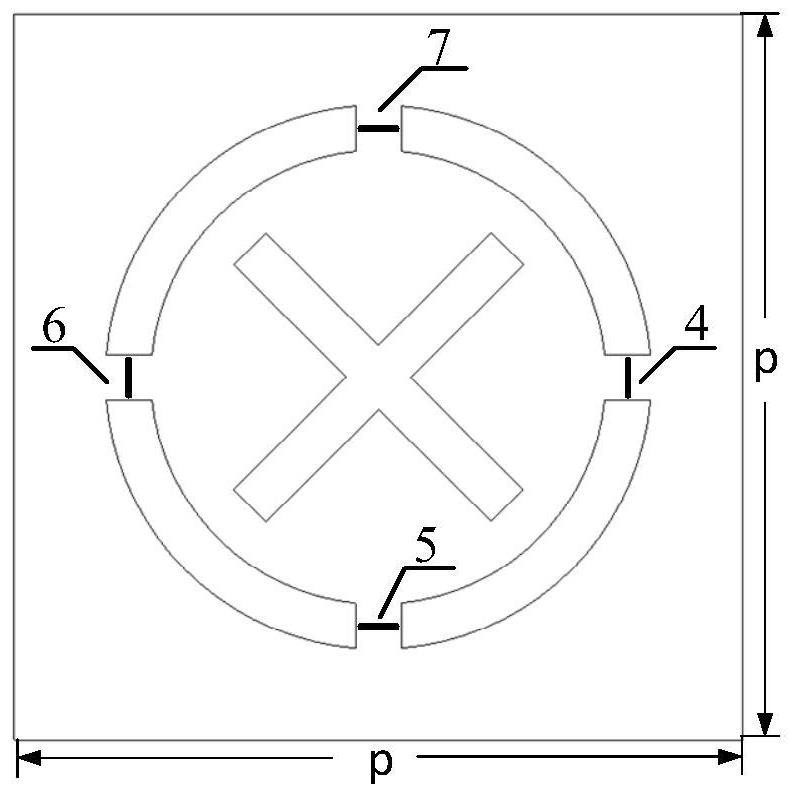

[0035] (1) Turn the four-in-one-in-one open circles to the circle, and set the super-surface material to form a super surface material at four openings, respectively, and the first active device, respectively. The second active device, the third active device, and the fourth active device, these four active devices are set to exactly the same device, and the active device in this implementation is in parallel, wherein the resistance of the resistance is 1000Ω, the capacitance value is 0.5 pF.

[0036] (2) Preparation of a dielectric layer made of magnet adhesive material: first weigh a certain amount of MWCNTs, and add n-hexane to the n-hexane therein, the added amount is capable of complete wetting MWCNTs, stirred and sufficiently Ultrasonic oscillation is dispersed; after the N-HEXANE is evaporated, the A component of MWCNTS and PDMS (Dow Corning 184 silicone rubbe...

Embodiment 2

[0047] First, MRE material, super surface structure, and metal back plate were prepared by the method of the foregoing Example 1.

[0048] Next, four identical active devices are set according to the method in Example 1, respectively, the first active device, the second active device, the third active device, and the fourth active device, wherein the active device is The resistance and capacitance are parallel. By changing the parameters of the active device on the super surface, if the resistance is set to 1000 ohms, the capacitance values of the capacitance are set to 0.5pf, 1pf, 1.5pf, 2pf, 5pf, and five values, to change the composite absorbing material. Absorption performance.

[0049] Figure 7 A reflection curve of a composite absorbing body containing different parameters prepared for Example 2, from Figure 7 It can be seen that when it is determined that the resistance value is 1000 Euros, the capacitance value increases the peak frequency of the composite absorbing mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com