Preparation method of silver sulfide/silver phosphate/graphene oxide composite photocatalyst

A graphene composite and photocatalyst technology, which is applied in the field of photocatalytic materials, can solve the problems of low degradation rate and poor stability of composite photocatalysts, and achieve the effects of improving separation, improving photocatalytic degradation performance, and reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

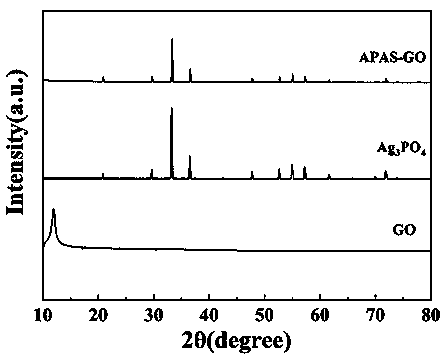

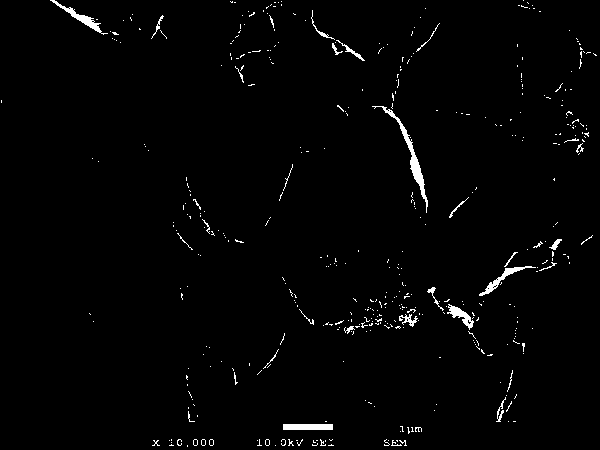

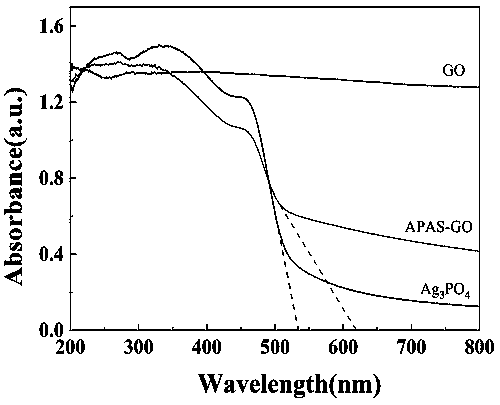

[0022] Graphene oxide (GO) was prepared according to the improved Hummers method. GO was dispersed in deionized water and ultrasonically treated for 3 hours to obtain a GO suspension; 3 mmol of silver nitrate was weighed and dissolved in 8.5 ml of ethanol aqueous solution; and 1 mmol of phosphoric acid diphosphate was weighed Sodium hydrogen, dissolved in 8.5ml ethanol aqueous solution; under the condition of stirring, add the nitric acid solution dropwise to the sodium dihydrogen phosphate solution, and continue to stir for 30 minutes; then add 1ml 0.01 mol / L sodium sulfide solution dropwise, in Stir for 4 hours under dark conditions; add 10ml of graphene oxide suspension to the above solution, continue to stir for 3 hours, centrifuge the obtained reactant, wash with deionized water and ethanol for 5 times, and vacuum dry at 60°C for 12 hours to obtain silver sulfide / silver phosphate / graphene oxide composite photocatalyst.

Embodiment 2

[0024] Graphene oxide (GO) was prepared according to the improved Hummers method. GO was dispersed in deionized water and ultrasonically treated for 3 hours to obtain a GO suspension; weigh 4.2 mmol silver nitrate and dissolve it in 8.5 ml ethanol aqueous solution; then weigh 1.4 mmol Sodium dihydrogen phosphate, dissolved in 8.5ml ethanol aqueous solution; under the condition of stirring, add the nitric acid solution dropwise to the sodium dihydrogen phosphate solution, and continue stirring for 30 minutes; then add 1ml 0.01 mol / L sodium sulfide solution dropwise , stirred for 4h under dark conditions; 10ml of graphene oxide suspension was added to the above solution, and continued to stir for 3h, the obtained reactant was centrifuged, washed with deionized water and ethanol for 5 times, and dried in vacuum at 60°C for 12h to obtain Silver sulfide / silver phosphate / graphene oxide composite photocatalyst.

Embodiment 3

[0026] Graphene oxide (GO) was prepared according to the improved Hummers method. GO was dispersed in deionized water and ultrasonically treated for 3 hours to obtain a GO suspension; 8 mmol of silver nitrate was weighed and dissolved in 8.5 ml of ethanol aqueous solution; and 2.6 mmol of phosphoric acid was weighed Sodium dihydrogen, dissolved in 8.5ml ethanol aqueous solution; under the condition of stirring, add the nitric acid solution dropwise to the sodium dihydrogen phosphate solution, and continue to stir for 30min; then add 1ml 0.01 mol / L sodium sulfide solution dropwise, Stir under dark conditions for 4 hours; add 10ml of graphene oxide suspension to the above solution, continue to stir for 3 hours, centrifuge the obtained reactant, wash with deionized water and ethanol for 5 times, and vacuum dry at 60°C for 12 hours to obtain sulfurized Silver / silver phosphate / graphene oxide composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com